The pump can be properly grounded by checking that the electrical connections and clamps

are tight. The pump is able to support a voltage variation equal to ± 10% with respect to the

nameplate data: failure to comply with this condition will result in a reduction in the useful life

of the pump. Check the presence and correct positioning of the gasket in the wiring terminal

box in order to avoid the accidental entry of water into the motor and into the live electrical

parts.

START

Before starting the pump for the first time, check the calibration of the electrical protection

devices of the motor and that the protective devices against electrical and mechanical contacts are

correctly positioned and fixed. Do not use the pool at the time of the first check of the pump

installation.

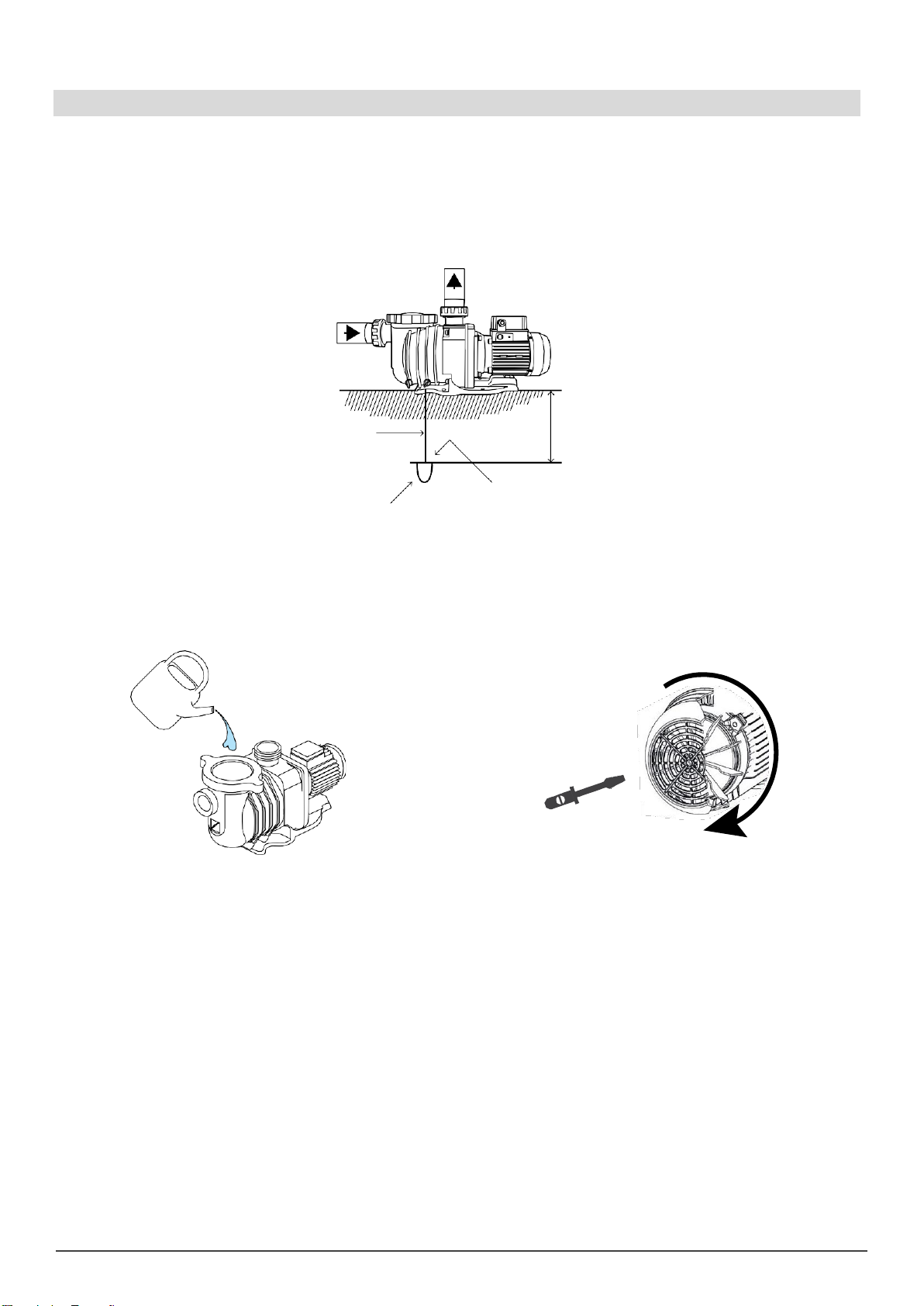

Perform the following procedure to properly prime the pump before starting the pump

:

1.

Open the prefilter cover;

2.

Fill the pump with clean water through the prefilter until the water comes out through

the intake duct;

3.

If the basket moves during these operations, do not forget to place it again inside the

prefilter to prevent coarse-grained particles from infiltrating the pump which could

damage it;

4.

Close the prefilter checking the correct coupling of the cover gasket with the pump

body.

WARNING

Dry running causes irreparable damage to the mechanical seal: in the event of an accidental dry

start, immediately disconnect the power supply, then wait for the engine to cool and then fill it with

clean water. Start the pump and check, in the three-phase version, that the direction of rotation is

correct: this should be done clockwise when looking at the pump from the fan side. If this is not

the case, invert the phases in the connection terminal after disconnecting the power supply to the

pump (fig. C). Avoid contact, even accidental, with the moving parts of the machine during its

operation or before its complete stop.

RACOMMENDATIONS

The pump should not be started more than twenty times in an hour so that the motor is not

subjected to excessive thermal stress. Before proceeding with any maintenance operation, check

that the machine is disconnected from the power supply and that the start-up devices are blocked

.

MAINTENANCE AND CLEANING

Under normal use conditions the pump does not require maintenance operations, however it could

be useful to clean the hydraulic parts if you notice a loss of pump efficiency. The pump must not be

disassembled by unqualified personnel or by unauthorized technicians.

In any case, all operations must be carried out only after having disconnected the pump from the

electricity mains and after having turned off the ignition devices.

.

PERIODIC CHECKS

Check periodically:

-The correct fastening of the mechanical components and the condition of the machine support screws

-The correct position, fastening and condition of the power conductors and insulating components

-

The temperature of the machine and the electric motor. In the event of an anomaly, stop the machine

immediately