iLC CME Series User manual

USER MANUAL

ILC Srl

CME

CME series electric gear pump for oil and soft grease

Use in single-line and air+ oil centralised lubrication systems

Translationoforiginalinstructions

All ILC products must only be used for their intended purposes, as specified in this brochure and in all instructions. If the product is supplied together with user instructions, the user is required to read

them and comply with them. Not all lubricants are suitable for centralised lubrication systems. ILC lubrication systems or relative components cannot be used together with gas, liquid gas, pressurised

gasinsolution and liquids with vapour pressure exceeding normal atmospheric pressure (1013bar) by more than 0.5 bar, maximum temperature permitted. Any type of dangerous materials, inparticular

those classified as such by European Community Directive (EC) 67/548/EEC, Article 2 (2), can only be used in ILC centralised lubrication systems or relative components upon consultation with ILC and

after having received written approval from the company.

Copyright©2018 by I.L.C. Srl

All rights reserved.

I.L.C. srl - Via Garibaldi, 149 - 20155 Gorla Minore - Italy

TABLE OF CONTENTS

1.

Introduction 3

2.

Application 3

3.

Operating principle 3

4.

Technical specifications 3

5.

Installation 4

6.

Commissioning 4

7.

Hydraulic diagram 5

8.

Version without electronic board 6

Electrical connections 6

9.

Version with electronic board 7

10.

Operating mode 10

10.1

Operating Mode 10

10.2

Programming Mode 10

11.

Menu type selection 10

11.1

Setting Reduced Menu 10

11.2

Setting Complete Menu 10

12.

Pause and operating Mode setting 11

12.1

Program Pause time in h/m/s (FU-PL) 11

12.2

Program Pause time in pulses (FU-IL)

13.

Advanced programming (complete menu) 11

13.1

Set warm-up cycles operating Seconds* 11

13.2

Set warm-up cycles pause seconds* 11

13.3

Set warmupcycles number* 12

13.5 Pre-lubrication enabling 12

13.7 Pressure switch alarm enabling 12

13.4 Warm-up enabling* 12

13.6 Level alarm enabling 12

13.8 Air pressure switch alarm enabling** 12

14.

Maintenance 13

14.1

Maintenance table 13

15.

Transport 14

15.1

Delivery 14

15.2

Storage 14

16.

Operation 15

16.1

General information 15

16.2

Commissioning 15

17.

Decommissioning 16

17.1

Temporary decommissioning 16

17.2

Definitive decommissioning 16

17.3

Disposal 16

18.

Precautions for use 17

18.1

It is recommended to 17

18.2

Flammability 17

18.3

Pressure 17

18.4

Noise 17

19.

User instructions 18

19.1

Lists used 18

19.2

Inadmissible fluids 18

20.

Dimensions CME 2L 19

21.

Dimensions CME 3L 20

22.

CME order code configurator 21

23.

Fittings order codes 21

24.

Spare parts 22

25.

Warranty 23

26.

Machine identification 23

2

CME

Introduction

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

3

1.

Introduction

This use and maintenance manual refers to the CME pump.

Using this pump makes it possible to distribute oil or soft

grease in lubrication systems.

The latest version can be obtained by contacting the Sales

Technical Office.

The pump that this manual refers to must be used by qualified

personnel with basic hydraulic and electrical knowledge.

This use and maintenance manual contains important

information to protect the health and safety of personnel

who intend to use this equipment. This manual must be read

carefully and kept in good conditions so that it is always

available tooperatorswho intend to refertoit.

2.

Application

At this point the pressurised lubricant will activate a release

valve, which will discharge the pressure inside the tank and

enablethevolumetricvalvestobefilled.

The process repeats each time the motor is switchedon and

off.

When the system is at rest, a check valve maintains the main

line at a pressure of 0.5/0.6 bar, thus preventing air from

entering.

Thestatuschangeofthepressureswitchduringoperatingtime

allows us to ensure there are no oil leaks in the main line.

The lack of lubricant inside the tank is signalled by a minimum

level sensor.

4. Technical specifications

The CME gear pump has been designed for use in single-line

or air + oil centralised lubrication systems. These systems use

the principle ofpressure and release pulses andthe lubricant is

sent to the volumetric valves or to the mixers positioned near

thepoints of the machine to be lubricated.

Any use other than described above shall not be in agreement

with the specifications of I.L.C. srl (pump manufacturer), who

Measured capacities (A)

Electrical connections

100 cc/1' 50 Hz AC

120 cc/1' 60 Hz AC

200 cc/1' 24 V DC

1 cable gland for power supply

1 cable gland for signals

shall not be held responsible for any damage resulting from a

different use.

3. Operating principle

The pump sends pressurised lubricant through two side

outlets. This way the customer can connect the main pipe to

bothoutletsorto oneonly,pluggingtheunusedone.

When the motor is powered on, by an internal timer or an

externalPLC,thegearpumpisactivated, whichsends lubricant

from the reservoir to the distribution network through the two

outlets or through the selected one.

Pressurisation of the distribution network forces the volumetric

valves, whose metering chamber has been filled since the last

lubricationcycle,tosendthevolumeoflubricantinsidethemto

the points. Onceall thevalves have beenactuated, the pressure

will increase until a pressure switch is triggered and, after a

short time, it will be possible to interrupt motor operation.

Pressuregauge 0 - 60 bar

Oils from 20 to 1000 mm²/s

Soft greases NLGI 000 and 00

Protection rating

IP-65

Manual button amperage

1 A 250 V AC - 3 A 120 V AC

Noiselevel

<70db(A)

Operating mode S3, 20%

Max Operating Time

20% min×0.2 = 4 min. Pump cycle

with subsequent down time of 16

min.

Operating humidity

90% max

Storage temperature

10°C ÷ +40°C

Weight (empty tank)

3.5 Kg (2l)

4.3 Kg (3l)

Operating temperature

0°C - 50°C

Operating pressure

from 22 to 30 Bar

Tank capacity

2L - 3L

Outlet connections

2BSP1/4”seats (standardsupplied

with 1 left-hand lock cap)

Filling

Cap with 200 µ load filter

Lubricants

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

4

CME

Installation

5.

Installation

Onlyinstallthepumpinahorizontalposition,fasteningitto the

wall by two M6 bolts.

Anareaofferinga view ofthefrontpanel,easyaccessincase

of maintenance, easy access to the filling system and easy

connection to the distribution network is recommended.

Arrange space below the unit for any tank disassembly.

The unit allows connection to the distribution network from two

outlet ports and is supplied with a ¼” Gas cap installed on the

left side. In caseof supply from the left side, the cap must be

movedtotherightside.Ifthedistributionnetworkispresenton

both sides, the cap must be removed. The two outlets are both

¼" Gas and the 6 mm pipe fitting must be ordered separately

(codes below).

03-257-2 03-257-4

network, without creating pipe sections that go up and down.

This is in case air enters the distribution lines. Air bubbles

tend to rise towards the end of the distribution line and are not

removed along the way. The presence of air bubbles along the

distribution line prevents the correct operation of the metering

valves and mixers.

Use the pressure switch to check for leaks in the main line

during the lubrication cycles. For systems with a main line

exceeding 8 m, we recommend installing a pressure switch at

the end ofthe main line and not connecting the one onthe unit.

Caution!

All electrical connections must be set up by

qualified personnel and all requirements of

local regulations must be followed. Refer to

the electrical connection diagram for correct

wiring.

Caution!

The unit must be protected by a differential

magnetothermal switch with a breaking

threshold of 0.03 A and a max time of 1

second (breaking power = 10 KV

–

rated

current = 4A).

6.

Commissioning

The tank is filled with clean lubricant, without exceeding the

MAX level, by means ofthe load cap complete with filter (incase

of oil). It must be recommended by the machine manufacturer

and must comply with the following viscosities

ZZZ106-105-L ZZZ106-005-L

The unit is supplied with two cable glands, one for voltage and

the other for the controls.

All rigid pipes, flexible hoses and fittings must be compatible

with the lubricant, the operating pressure and the surrounding

environment. In general, try to install the unit in the lowest

position (vertically) in relation to the rest of the distribution

Loosen the cap in the distribution network furthest from the

unit. Supply the pump until lubricant leaks, air-free, from the

loose cap. Tighten the cap, run lubrication cycles until the

lubricant comes out ofthe volumetric valves. Fill the secondary

pipes with additional cycles. The system is now ready to

lubricate all points.

Oils from 20 to 1500 cSt

Soft greases

NLGI 000 or 00

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

5

CME

Hydraulicdiagram

7.

Hydraulic diagram

1 gear pump 6

pressure switch for controlling the main line

2 pressure relief valve 7

pressure gauge

3 release valve 8

intake valve

4 minimum level of lubricant check 9

electric motor

5

lubricant loading filter

P

7 6

MA DS

E

3

M

4

WS

ST

5

1

DBV

2

R

8

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

6

CME

Version withoutboard

8.

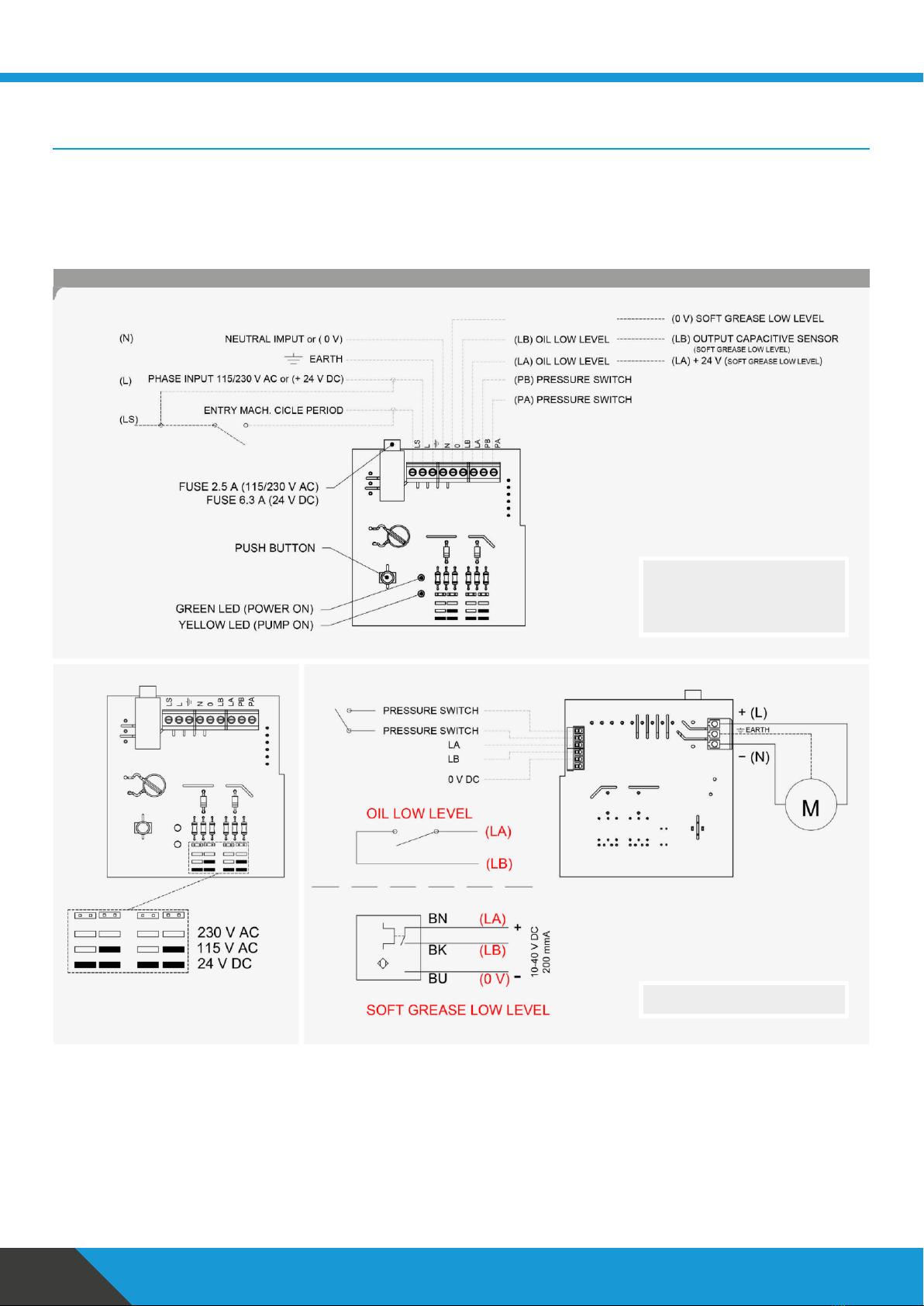

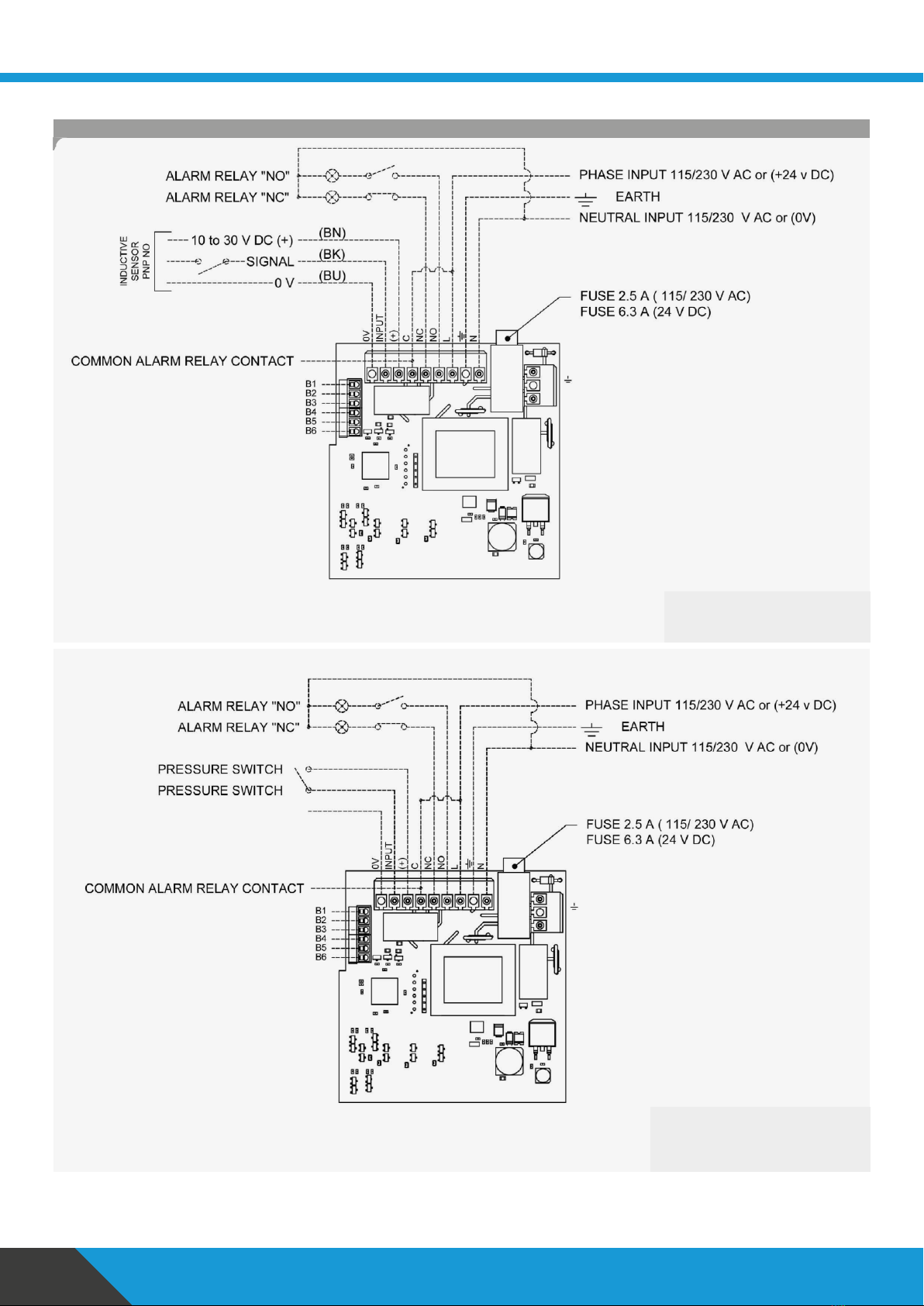

Version without electronic board

The lubrication cycles are programmed by an external PLC. The pump is equipped with a board in which all electrical connections

merge and isequipped with a manual button for extra-cycles. Furthermore it will be possible to connect the contact ofthe minimum

lubricant level and the pressure switch to the PLC to generate any alarms.

Electrical connections

pause = the stop period of the pump / operation = the running time of the pump

For volumetric or air + oil systems with

pause and operation adjustable in

hours, minutes orseconds or pulse-

adjustable pause.

Connections set up by ILC.

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

7

CME

Version withboard

9.

Version with electronic board

Anelectronicboardisinstalledinsidethepumpwhichcontrolsandchecksthe operation oftheentiresystem.Theboardisequipped

with a display with 4 digits and 4 programming buttons, including the extra-cycle button. In this version, the pump isdelivered with

level alarm activated (AL-1), oil pressure switch alarm activated (AO-1) and prelube on (the pump starts when it is switched on and

operates for the set operating time) PL-1.

The pump can be programmed to:

•

immediately run a lubrication cycle when the motor is switched on (which we will call PRELUBE) or not.

•

Set a pause time (the pump stops) and an operating time (the pump operates)

•

Alternatively the pause (pump stopped) can be established innumber of pulses insteadof inhours/minutes/seconds. Once

the set number ofpulses is reached, the pump starts running for the selected operating time.

•

Settheminimumelectricallevelcontrolfunctionofthelubricant.

•

Set the oil pressure switch control function to check system operation.

•

Set the air pressure switch control function in the air + oil systems to check that air is always present in the system.

•

Adjustthewarm-updepending oncustomerneeds.

pause = the stop period of the pump / operation = the running time of the pump

Electrical connections

Forvolumetricorair + oil systems

with pause and operation adjustable

inhours,minutes orseconds.

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

8

CME

Version withboard

pause = the stop period of the pump / operation = the running time of the pump

For volumetric or air + oil systems.

for pulse pause time counted by a switch.

Electrical connections (continued)

Connections set up by ILC.

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

9

CME

Version withboard

pause = the stop period of the pump / operation = the running time of the pump

for air oil systems with air control through

a pressure switch. By checking the air

pressure switch, the pause cannot be

adjusted in pulses.

AIR

Electrical connections (continued)

For volumetric or air + oil systems.

For pulse pause time counted by a

proximity sensor.

CME

Modes andprogramming

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

10

10.

Operating mode

10.1 Operating Mode

In operating mode, the board controls the pump by

alternating work cycles with pause cycles. The duration

of the work stage can be configured as time while

the duration of the pause can be counted in time (PL

mode) or in number of pulses, which the board reads

via the dedicated input (IL mode).

Circularly scrolls the menus downwards

Enters programming mode if pressed for 3+ seconds

10.2 Programming Mode

Programming mode is accessed by holding the ENT

key for 3s. This mode allows the user to access and

change all the setting parameters of the board and

alarms.

Caution! In order to memorise the programming of

all entered changes, hold the Enter key for at least 5

seconds

after the changes have been made.

Then, the pump will automatically start for one cycle.

Circularly scrolls the parameters downwards

Increases the value of a parameter

If held for 5+ seconds, saves changes and switches to Operating mode

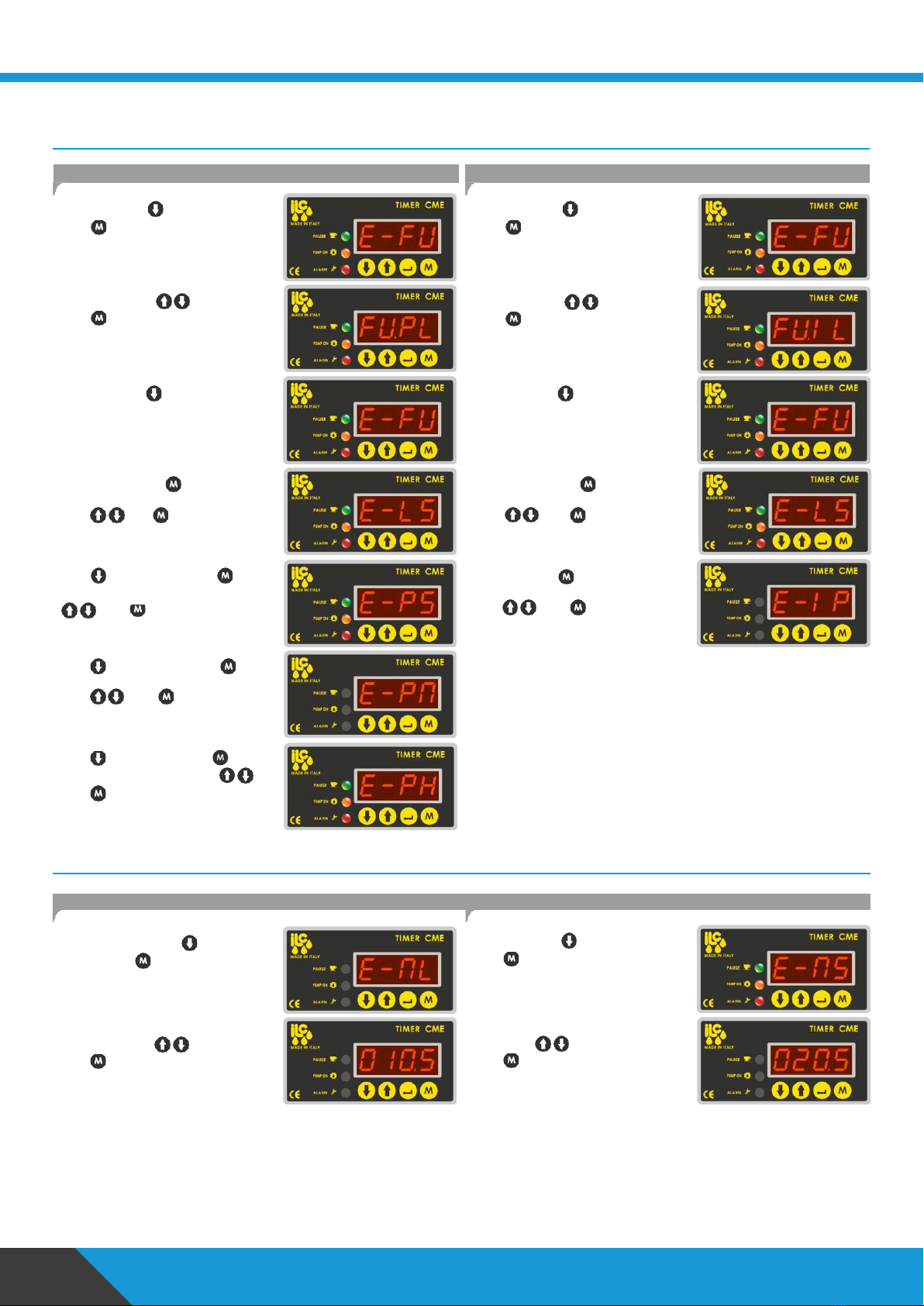

11.

Menu typeselection

Hold the

key down for 3 seconds to start

programming

ThewordE-CMappearswiththe3LEDs

flashing on the left.

Press the button

Select CM-b using

Press

E-CMappears.E-CM isnow in Reduced

Menu mode.

Hold the

key down for 3 seconds to

start programming

ThewordE-CMappearswiththe3LEDs

flashing on the left.

Press the button

Select CM-F using

Press

.

E-CMappears. E--CMisnowinComplete

Menu mode.

Circularly scrolls the parameters upwards

Decreases the value of a parameter

Circularly scrolls the menus upwards

11.1 Setting Reduced Menu

11.2 Setting Complete Menu

Key

Function

Accesses the parameter edit / validates a setparameter and goes back

to the overall parameter list.

Key

Function

Immediately starts an extra work cycle for the set time

Resets all alarms

CME

Pause/Operatingprogramming

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

11

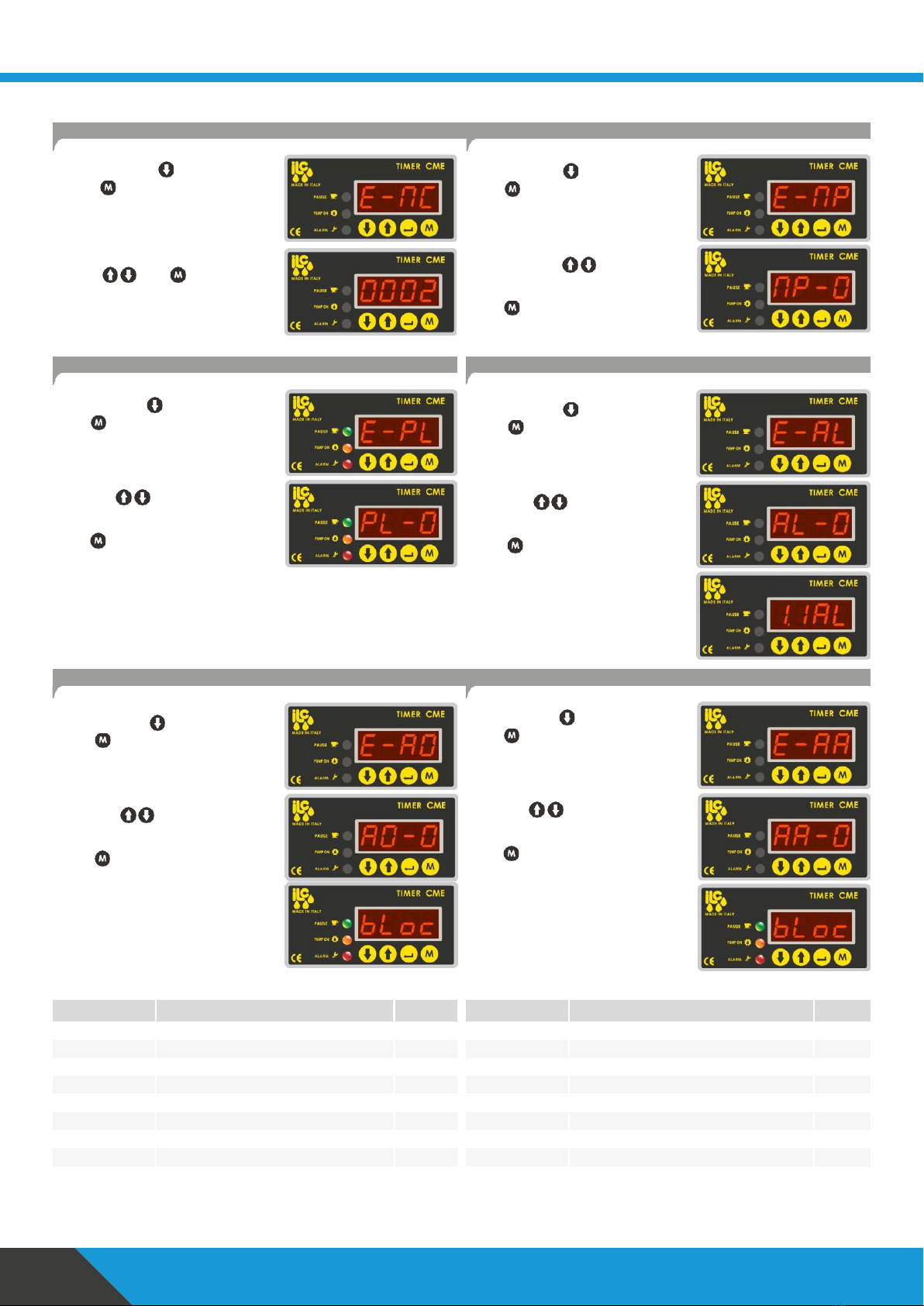

12.

Pause and operating Mode setting** (complete and reduced menu)

From E-CM Press .E-FUappears

Press

.

Select FU.PL using .

Press

to confirm and return to E-FU.

From EC-M Press

E-FU appears.

Press

.

Select FU.IL using .

Press

to confirm and return to E-FU.

From E-FU, press

From E-FU, press

E-LS appears. Press . Adjust the

operating time in seconds from 1 to a 60

using

Press

to confirm.

E-LS appears. Press . Adjust the

operating time in seconds from 1 to a 60

using

Press

to confirm.

Press

. E-PS appears. Press . Set a

pause time from 150 to 999

¹

seconds using

.Press

to confirm.

Press

. E-PM appears. Press .

Set a pause time from 0 to 999 minutes

using .Press

to confirm.

Press

. E-PH appears. Press . Set

atimefrom0to999hoursusing

.

Press

to confirm.

Select E-IP. Press .

Set the pause in pulses from 1 to 9999

using .Press

to confirm.

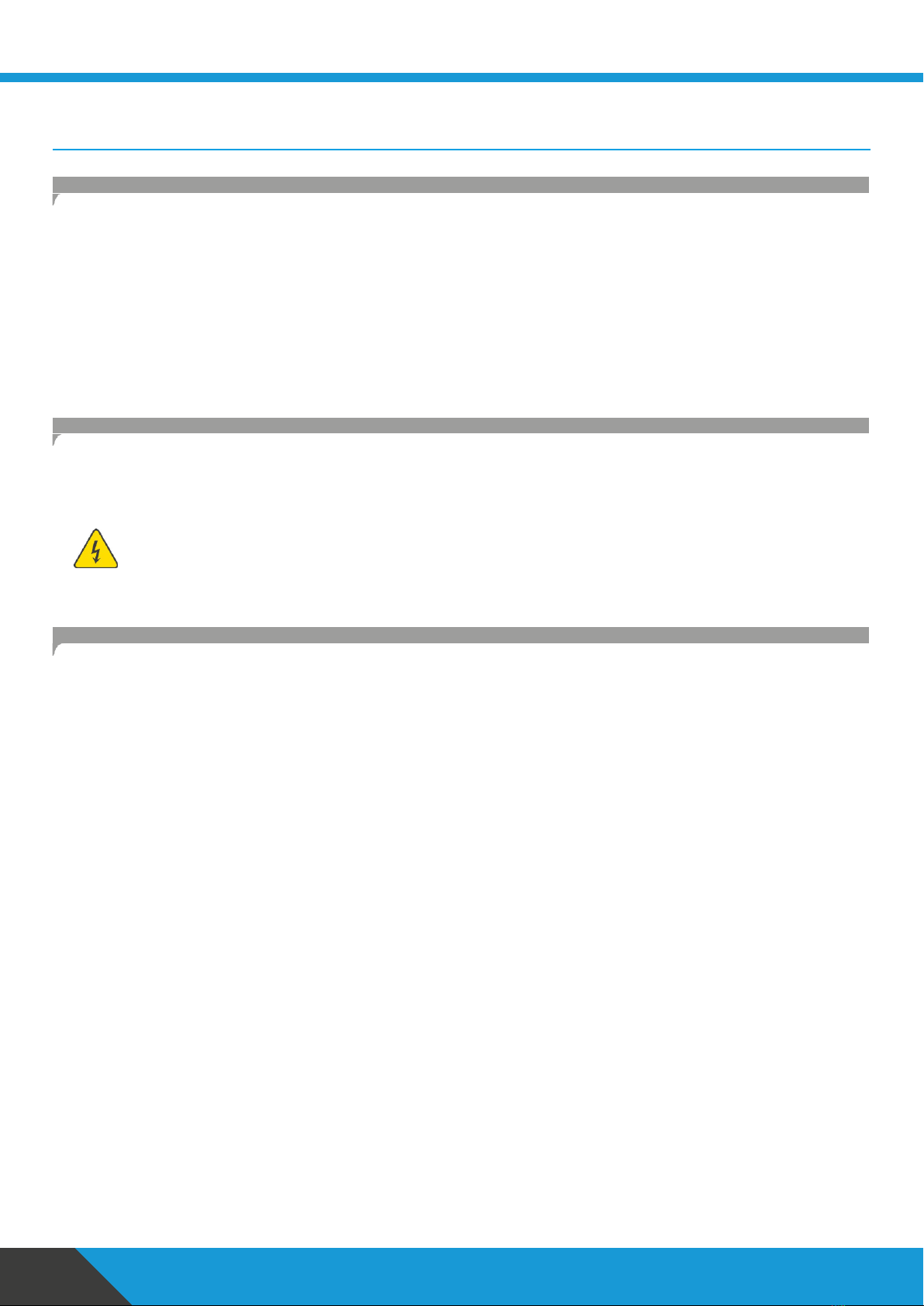

13.

Advanced programming (complete menu)

13.1 Set warm-up cycles operating Seconds* 13.2 Set warm-up cycles pause seconds*

From E-PH or E-IL, press . E-ML

appears. Press

From E-ML, press

.E-MSappears.

Press

Set the operating seconds for warm-up

cycles(1-60) using .

Press

to confirm.

Set the pause seconds for warm-up cycles

(1-60)using .

Press

to confirm.

¹ With E-PM=0 and E-PH=0 E-PS can only be adjusted from 150 to 999.

With E-PM or E-PH are different from 0 E-PS can only be adjusted from 0 to 999.

*functions only for air+oil systems exclusively for use by ILC

** pause = the stop period of the pump / operation = the running time of the pump

12.1 Program Pause time in h/m/s (FU-PL)

12.2 Program Pause time in pulses (FU-IL)

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

12

CME

Advanced programming

13.3 Set warmup cycles number* 13.4 Warm-up enabling*

From E-MS, press . E-MC appears.

Press

.

Set the warm-up cycles number (1-99)

using .Press

to confirm.

From E-MC, press

.E-MPappears.

Press

.

Select mode with

MP-0 indicates Warm-up not enabled.

MP-1 indicates Warm-up enabled.

Press

to confirm.

13.5 Pre-lubrication enabling

From E-MP, press

.E-PLappears.

Press

.

13.6 Level alarm enabling

From E-PL, press . E-AL appears.

Press

.

Select with

PL-0 prelube not enabled

PL-1 prelube enabled

Press

to confirm.

Select with

AL-0 alarm not enabled

AL-1 alarm enabled

Press

to confirm.

Inthe event ofanalarm, the display will

show 1.1AL. This alarm does not block the

pump if triggered.

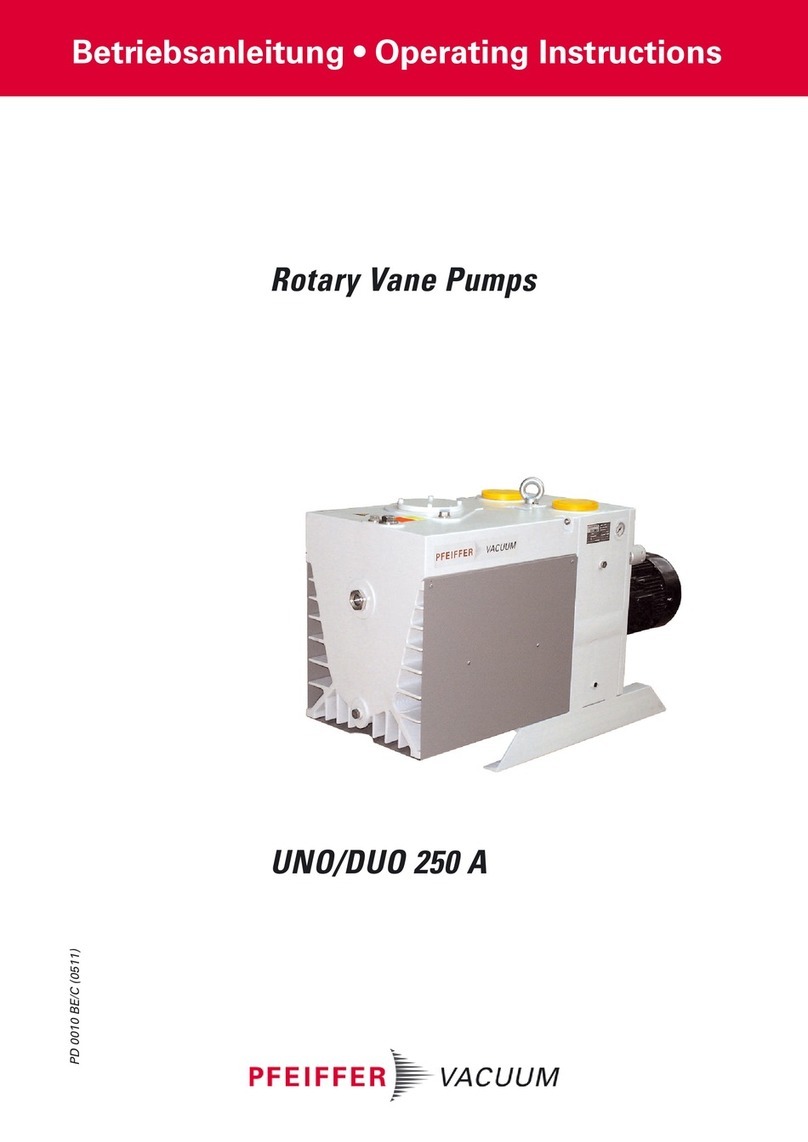

13.7 Pressure switch alarm enabling 13.8 Air pressure switch alarm enabling**

From E-AL, press . E-AO appears.

Press

.

From E-AO, press . E-AA appears.

Press

.

Select with

AO-0 alarm disabled

AO-1 alarm enabled

Press

to confirm.

Select with

AA-0 alarm not enabled

AA-1 alarm enabled

Press

to confirm.

In the event of an alarm, the display will

show bloc.

This alarm blocksthepump iftriggered.

In the event of an alarm, the display will

showbloc.

This alarm blocks the pump if triggered.

Parameter

Description

Default

Parameter

Description

Default

E-CM

Menu type

b

MS

Warmup pause seconds

20

FU

Operating Mode

PL

MC

Warmup cycles

2

LS

Operating seconds

5

MP

Warm-up enabling

0

PS

Pause seconds

150

PL

Prelube enabling

0

PM

Pause minutes

0

AL

Level alarm enabling

1

PH

Pause hours

0

AO

Oil alarm enabling

1

IP

Pause pulses

2

AA

Air alarm enabling

0

ML

Warmup operating seconds

10

*functions only for air+oil systems exclusively for use by ILC

**to be enabled only if a pressure switch to control the air is required

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

13

CME

Maintenance

14.

Maintenance

Premature wear of pump gears and other moving parts is caused by contaminated and dirty lubricants.

Failure of the volumetric valves which, as a consequence, do not send lubricant to the points, is caused by the presence of air in the

distribution network or by contaminated lubricant. The unit does not require special maintenance if you avoid using contaminated

lubricant and injecting air into the hydraulic circuit. Before performing any operation, make sure you have disconnected the power

supply.

The maintenance table shows the main faults, causes and solutions. If the problem cannot be solved after consulting it, contact

the technical office at ILC.

14.1 Maintenance table

Symptoms

Potential causes

Potential solutions

1. The pump does not dispense

lubricant

1.1

Internal fittings loose or damaged

1.2

Gear pumpworn

1.3

Release or intake valve dirty or dam-

aged

1.1

Tighten the fittings

1.2

Replace the pump

1.3

Clean the valves

2. The pump does not dispense

lubricant at the operating

temperature

2.1

Pump worn

2.2

The pressure relief valve is not

calibrated correctly or is dirty and the

lubricant returns to the tank

2.3

Release valve dirty ordamaged

2.1

Replace pump

2.2

Replace the pressure relief valve

2.3

Replace the releasevalve

3. The release valve does not

open at the end of the

operating cycle and themain

line remainspressurised

3.1 Release valve dirtyor damaged 3.1 Replace the releasevalve

4. The main line is emptied during

the pause time

4.1

Loose fittings at pump outlet or along

the distribution line

4.2

check valve dirty ordamaged

4.3

Release valve dirty ordamaged

4.1

Tighten the loose fittings

4.2

Replace the check valve

4.3

Replace the releasevalve

5. The lubrication cycle is not

performed

5.1

Main line damaged or loose fittings

5.2

Uncalibrated pressureswitch

5.3

The pump does not dispense oil

5.4

The pump does notdispense lubricant

at the operating temperature

5.1

Repair the main line or tightenthe

fittings

5.2

Replace the pressure switch

5.3

See point 1.

5.4

See point 2.

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

14

CME

Transport

15.

Transport

TheproductsofI.L.C. Srlarepackagedto marketstandardaccordingtotheregulationsinforce inthecountryofdestination.Proceed

with caution during transport. The product must be protected against impact. There are no restrictions for transportation by land,

air or sea.

Caution!

Do not spill or throw away the product

15.1 Delivery

After receiving the shipment it is necessary to check the integrity of the products based on the accompanying documents. Packaging

materials must be kept until any discrepancies have been clarified.

15.2 Storage

The following storage conditions apply for I.L.C. Srl products:

Storageoflubricationunits

•

Environmental conditions: dry and dust-free environment, storage in a well-ventilated and dry location

•

Storage period: max. 24months

•

Admissible air humidity:<65%

•

Storage temperature: from 10° C to 40°C

•

Light: avoid direct exposure to sunlight or UV rays, isolate heat sources located in the vicinity

Storage of electronic and electrical equipment

•

Environmental conditions: dry and dust-free environment, storage in a well-ventilated and dry location

•

Storage period: max. 24months

•

Admissible air humidity:<65%

•

Storage temperature: from 10° C to 40°C

•

Light: avoid direct exposure to sunlight or UV rays, isolate heat sources located in the vicinity

General notes forstorage

•

Dust-protected storage by covering the devices with plastic film is recommended

•

Protection against floor humidity, by storing on shelves or on wooden structures

•

Before storage, it is recommended to protect the polished metal surfaces, specifically the friction components and the

assembly surfaces, by treating them with a long-term anticorrosion product

•

Approx. every 6 months: check for corrosion. If signs of corrosion are visible, it is recommended to eliminate them

immediately and treat again with the anticorrosive agent

•

The drives must be protected against mechanical damage

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

15

CME

Operation

16.

Operation

16.1 General information

The pump operates automatically. However, the flow of the lubricant inside the piping must be checked periodically.

The filling level of lubricant in the reservoir, being installed, must be visually checked periodically. If an excessively low lubricant level

isdetected, itmustbe toppedupto the maximum marking asdescribedinthe"Commissioning"chapter.

The information provided by the manufacturer of the machinery and of the lubricants must be strictly complied with.

Caution!

Only fill clean lubricant using a suitable device. The use of contaminated lubricants may cause very severe system

malfunctions. The lubricant reservoir must be filled avoiding the formation of bubbles.

Caution!

Do not mix different types of lubricants, as damage may occur, resulting in expensive cleaning operations of the product/

central lubrication system. To avoid confusion, it is recommended to apply a note on the reservoir identifying what lubricant

was used.

16.2 Commissioning

Before commissioning the product, it is recommended to check all electrical and hydraulic connections and, if applicable, the

pneumatic connections.

Thelubricantmustbe supplied without bubbles. Forthis purpose,fill the reservoirwith cleanlubricant. Then, runthepumpuntil the

lubricant comes out of all lubrication points without bubbles.

The purge cycle of the central lubrication system is carried out by opening the ends of the main pipe, so that lubricant comes out

from this point without bubbles.

The inclusion of air in the lubricant greatly affects system operation, with potential damage due to the lack of lubrication of moving

parts.

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

16

CME

Decommissioning

17.

Decommissioning

17.1 Temporary decommissioning

Temporary decommissioning of the product described occurs by disconnecting the electrical, pneumatic and/or hydraulic power

supply connections.

For prolonged product decommissioning, please refer to the information in the "Transport and storage" chapter in these assembly

instructions.

For product recommissioning, please refer to the information in the "General information" and “Commissioning” chapter in these

assembly instructions.

17.2 Definitive decommissioning

For definitive product decommissioning, the regional legal regulations and the laws on the disposal of contaminated operating

equipment must be strictly complied with.

Caution!

Lubricants may pollute the soil and groundwater. Therefore, it is recommended to properly use and dispose of the

lubricants. Regional regulations and laws regarding disposal of lubricants must be complied with.

17.3 Disposal

During maintenance ordemolitionofthe machine, do not release polluting partsinto the environment. Refer tolocalregulations for

correctwastedisposal.Whendismantlingthepump,theidentificationplateandeveryotherdocumentmustbedestroyed.

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

17

CME

Precautions

18.

Precautions for use

Itis necessary to carefully read the warningsontherisks related to using a lubricant pump. The operator must know how itfunctions

and clearly understand the hazards of pumping pressurised lubricants.

18.1 It is recommended to

•

Check the chemical compatibility of the materials that the pump is built with, with the fluid to be pumped. A wrong choice may

cause, in addition to damage to the pumps and pipes, serious risks for people (leakage of irritating and harmful products to

health) and for theenvironment.

•

Never exceed the maximum operating pressure value allowed by the pump and by the components connected to it. In case of

doubt, refer to the dataonthe machine plate.

•

Only use original spare parts.

•

Should it be necessary to replace components with others, make sure that they are suitable for operating at the maximum

operating pressure of thepump.

•

Never attempt to stop or divert any leaks with your hands or other parts of your body.

•

Note: Personnel must use protective devices, clothing and tools that comply with the regulations inforcein relation to the

location andto the use ofthe pump both during operation and maintenance operations.

18.2 Flammability

Thelubricantusedinlubrication circuits is nota normally flammable liquid. However,itiscrucial to adopt allprecautions possible to

prevent it from coming into contact with very hot parts or open flames.

18.3 Pressure

Before every operation, make sure there is no residual pressure in any branch of the lubricant circuit, which could cause oil to spray

when disassembling fittings or components.

After long periods of inactivity, check the tightness of all the parts subject to pressure. Do not subject the fittings, pipes and pressurised

parts to violent impact. Damaged flexible hoses or fittings are DANGEROUS, replace them. We recommend only using original spare

parts.

18.4 Noise

Under normal operating conditions, the noise emission does not exceed a value of 70 dB "A"at a distance of1 metre (39.3 inch) from

the pump.

Use of the pump with NLGI00 consistency greases must be evaluated on a case by case basis, due to the extreme difference in the

pour properties of the compound, depending both onthe viscosity ofthe base oil but also onthe soaps and additives used.

For further information about the technical features and the necessary safety measures, refer to the Product Safety sheet (Directive

93/112/EEC) regarding the type of lubricant chosen and supplied by the manufacturer.

I.L.C. srl

- Via Garibaldi, 149 - 20155 Gorla Minore - Italy

Phone +39 0331 601697 - Fax +39 0331 602001 - www.ilclube.com -

info@ilclube.it

18

CME

User instructions

19.

Userinstructions

Conformity to essential safety requirements and to the provisions in the machinery directive has been checked by filling out the

prepared checklists contained in the technical file.

19.1 Lists used

•

Risk assessment (UNIENISO 14121-1).

•

Conformity to essential safety requirements (Machinery Directive –EC 06/42).

Risks not fully eliminated, but considered acceptable

:

•

Electrocution: this can only occur in the event of serious user carelessness.

•

Use of unsuitable lubricant: the types of fluids that are not compatible with correct pump operation are listed below.*

•

Contact with harmful fluids.

19.2 Inadmissible fluids

Liquids

Hazards

1. Lubricants with abrasive additives Wear of the internal pump components

3. Petrol - solvents - inflammable liquids Fire - explosion - damaged gaskets

5. Water Pump oxidation

* For more detailed information on product compatibility with particular fluids, contact the I.L.C. Technical Office

4. Corrosive products

Pump corrosion - injury to persons

2. Lubricants with silicone additives

Pump seizing

6. Food products

Contamination of said products

Popular Water Pump manuals by other brands

Graco

Graco Husky 2150 instruction manual

Giant

Giant GXR Series Operating instructions/ repair and service manual

Xylem

Xylem FLYGT Compit 901 Series Installation, operation and maintenance manual

KSB

KSB EtaLine Pro Series Installation and operating manual

Pfeiffer Vacuum

Pfeiffer Vacuum UNO Operating instruction

Munsch

Munsch NPC Series operating manual

WITA

WITA Delta HE 35 series Original installation and operating instructions

Tri-Clover

Tri-Clover Tri-Flo CL Series Service & installation manual

Homa

Homa C 80 W Original instruction manual

Flotec

Flotec FPCI3350 owner's manual

Danfoss

Danfoss ASV-P instructions

Oase

Oase AquaMax Eco Expert 6800 operating instructions