CPC ARC User manual

2023.05.22 Printed in Taiwan LG-01-W51-EN

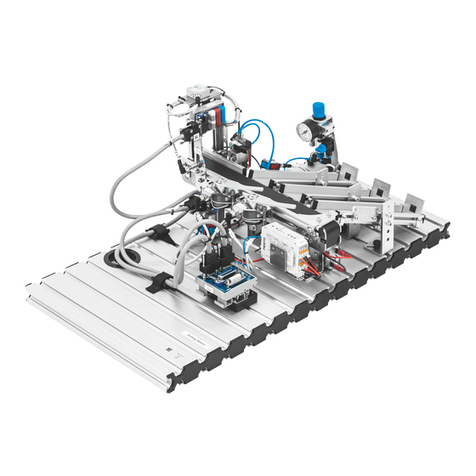

ARC/HRC/ERC Standard 4-Row Ball Bearing Linear Guide

WRC Wide 4-Row Ball Bearing Linear Guide

ARD/HRD/ERD Standard 4-Row Ball Bearing Linear Guide

Equipped with Cover Strip

ARR/HRR/LRR Standard 4-Row Roller-type Linear Guide

PAT.

2280 E. Locust Court.

Ontario, CA 91761, USA

Tel:+1-909-773-1200

Fax:+1-909-773-1202

No.3, Dali 1st Rd., Xinshi Dist., Southern Taiwan

Science Park, Tainan City .741-45, Taiwan (R.O.C)

Contents

ARC/HRC/ERC Product Overview......................................................................................................P01~P02

Product Design (Standard Equipment).............................................................................................P03~P06

Product Design (Optional Accessories).............................................................................................P07~P12

Technical Information..........................................................................................................................P13~P25

Installation Instructions.........................................................................................................................P26~P29

Lubrication.............................................................................................................................................P30

Accuracy...............................................................................................................................................P31

Ordering Information............................................................................................................................P32

Dimensions Specification.....................................................................................................................P33~P40

Product Design....................................................................................................................................P55~P60

Technical Information..........................................................................................................................P61~P62

Accuracy...............................................................................................................................................P63~P64

Ordering Information............................................................................................................................P65~P66

Dimensions Specification.....................................................................................................................P67~P76

Product Features.................................................................................................................................P45

Installation Instructions.........................................................................................................................P46

Ordering Information............................................................................................................................P46

Dimensions Specification.....................................................................................................................P47~P54

Grease Nipple Option.......................................................................................................................P79~P80

Lubrication Kit and Grease Gun.......................................................................................................P81~P82

Ordering Information............................................................................................................................P42

Dimensions Specification.....................................................................................................................P43~P44

ARC/HRC/ERC Standard 4-Row Ball Bearing Linear Guide

ARD Standard 4-Row Ball Bearing Linear Guide Equipped with Cover Strip

WRC Wide 4-Row Ball Bearing Linear Guide

Lubrication Storages Pad Test Report..............................................................................................P83

Linear Guide Service Life Calculation and Model Selection.........................................................P84

LINEAR MOTION TECHNOLOGY

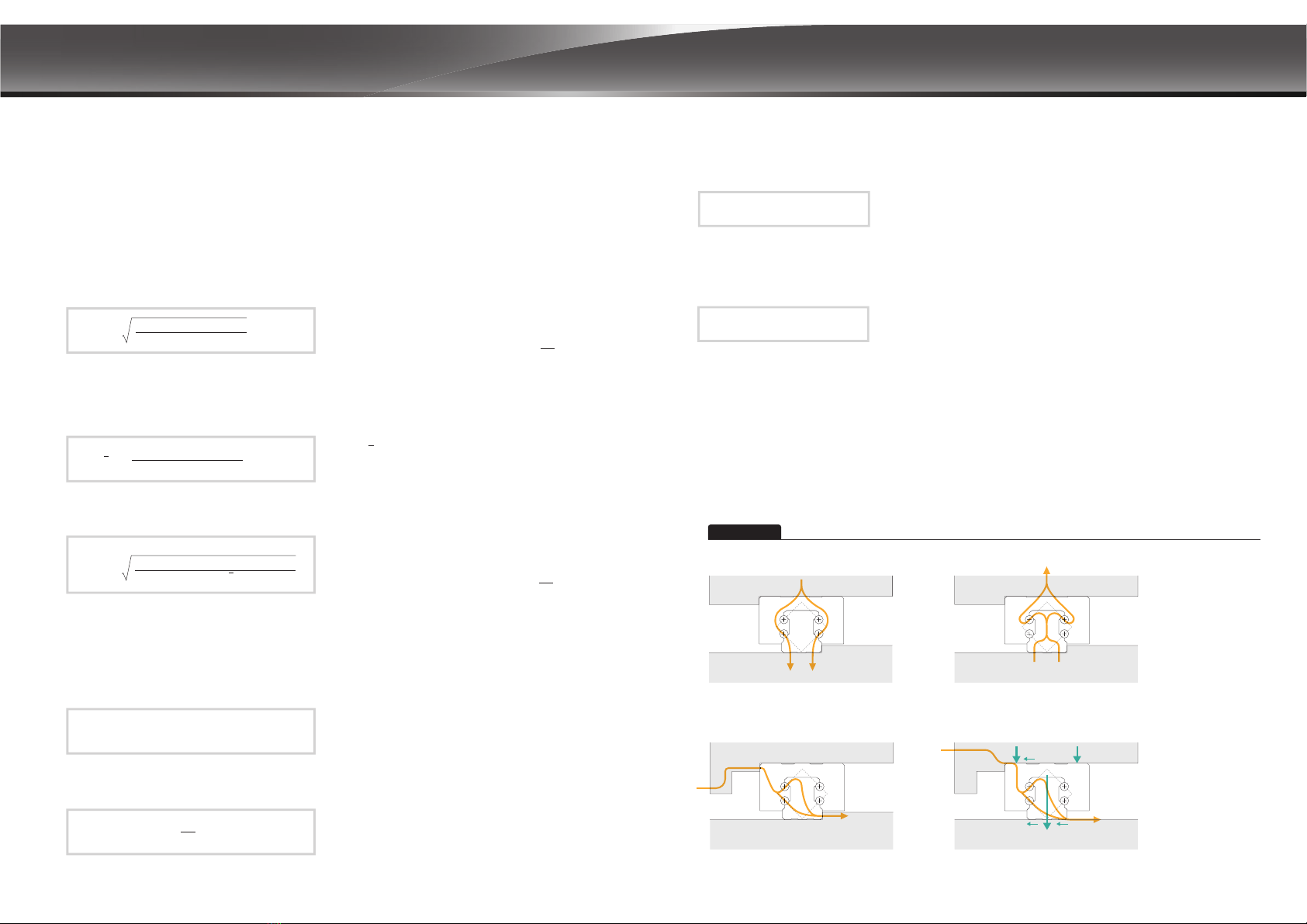

Selection method

ARR/HRR/LRR 4-Row Roller-type Linear Guide

Bellows

Grease Nipple Option

Lubrication Storages Pad Testing Report

Bellows..................................................................................................................................................P77~P78

NO

Calculation by Loading, Lifetime, & Rigidity Analysis Software

of Linear Guide System (LLRAS)

9. Service life and rigidity meet requirement

10. Selection according to the existing

operating conditions

YES

NO

YES

1. Linear guide application requirements (1) Dimension

(2) Service life

(3) Rigidity requirements

(4) Accuracy requirements

(5) Operating environment

(6) Lubrication options

2. Linear guide use condition settings Factors to determine the load of linear guide

(1) Installation position (horizontal, vertical, inclined, hanging, wall mounting)

(2) Load (gravity, size, direction, position), force (size, direction, position) and drive (position)

(3) Stroke

(4) Velocity and acceleration

(5) Frequency

(6) Accuracy level

3. Model selection

Select the specification of linear guide based on operating environment. Determine the desired dimensions

and reference edge corner design according to the bearing capacity of mounting screws (page 23,24)

4. Calculation of equivalent load

Note: Please fill the “Linear guide service life calculation and model selection

inquiry form” (Page 84)

Use the cpc program to calculate the equivalent load of each block based on

selected specification and operating environment.

5.1 Calculate the static

safety factor

Calculate the static safety factor

based on the maximum equivalent load,

basic static load rating, and the bearing

capacity determined by mounting

method of rails and blocks.

5.2 Select pre-load level

- Use pre-load level

- Select the mounting method

- Decide the fix method

5.3 Select the accuracy

level of rail.

- Determine the accuracy level

of installation site.

- Reference table of accuracy

level of different category machine.

6. Determine whether the static safety factor and the

bearing capacity of mounting screws is qualified or not

7. Calculate the average equivalent load

Convert the change of block load in stroke into the average equivalent load

8. Service life prediction and Rigidity

Find out the operating distance, service life and rigidity by life calculating formula.

Selection completed

- Lubrication Design

- Dustproof Design

- Surface Treatment

- Lubrication method / cycle

LINEAR MOTION TECHNOLOGY

15 12.4

16.4

19.5

24.0

30.4

38.2

43.1

9.35

12.5

14.5

17

19.5

24

28.5

LOHC

20

25

30

35

45

55

F = Mr/Lo

)

Lx

*

Unit:mm

O-Type Arrangement X-Type Arrangement

Mode Code

01 02

Product Overview

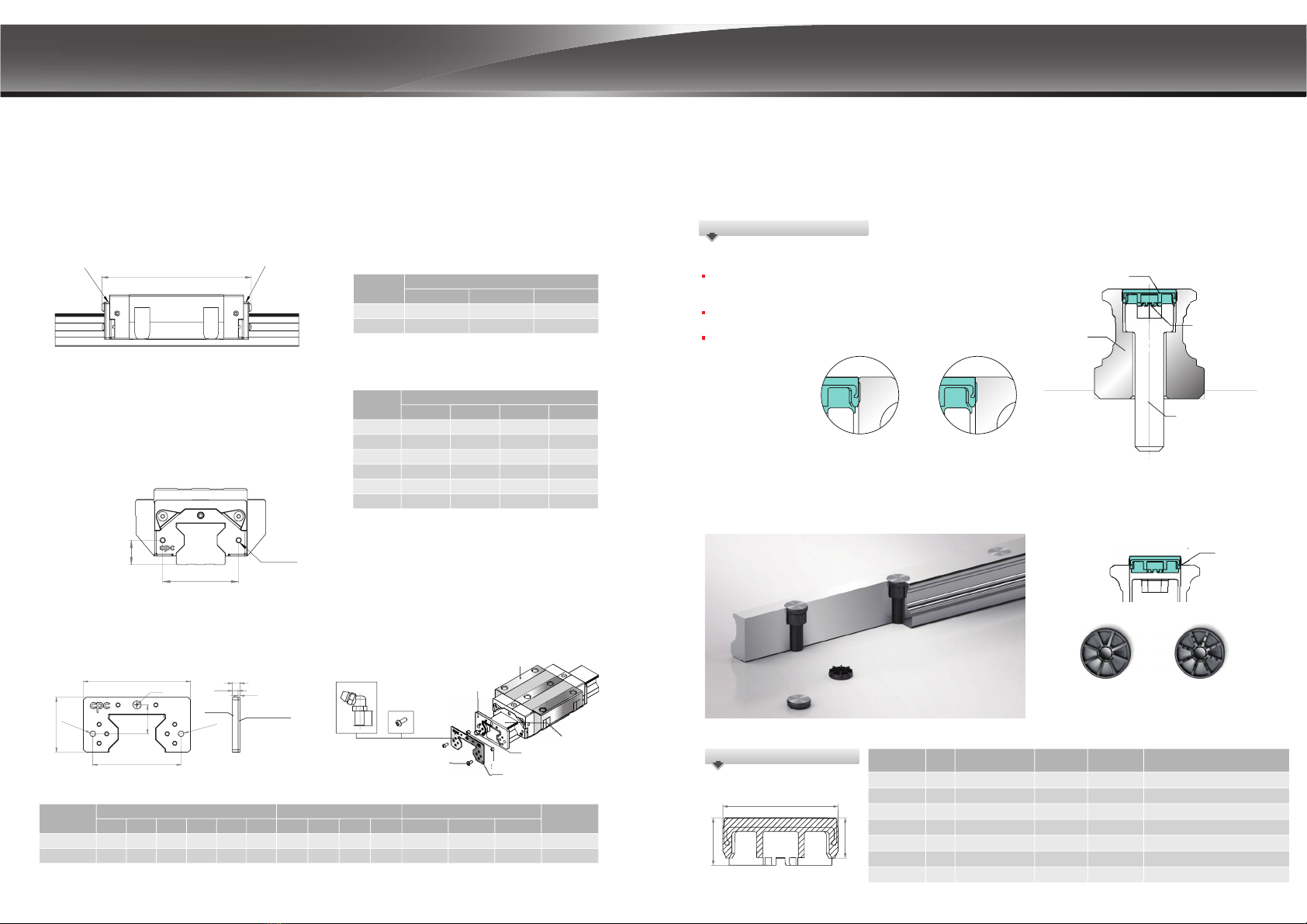

ARC/HRC/ERC Product Characteristics

Inner Lubrication storage Pad (Upper)

No need to increase the length of the runner block

Full lubrication contact with balls, particularly suitable

for short stroke movement.

End Cap

All-around lubrication

holes system

Inner Lubrication storage

Pad (Bottom)

High abrasion resistant

material end seal

Standard contactless, low friction,

high dust proof seal

Ball chain

Patented design to enable reverse operations.

Muted and prolonged service life

Stainless steel

reinforcement plate

Total scraping of external objects above 0.3mm

Increased X-axis axial force capacity

High Load and torque capabilities

Excellent dynamic performance: Reach Vmax 10 m/s Reach Ĵmax 450 m/s2

Can provide counterbored holes from the top and tapped mounting holes from

the bottom rail

Can provide specialized steel surface treatment

Our standard cpc ARC/HRC/ERC Linear Guide Series uses the O-type arrangement for its four-row ball

circulation design. The 45-degree contact angle between the rails and balls allows our product to realize

a four-directional equivalent load effect. cpc has placed special emphasis on strengthening the arm

length (Lo) of our product so that when sustaining external force (F), this can have an even higher Mr value,

which increases its rigidity and torsion-resistant capabilities. The larger and more numberous balls in our

products allows it to have a 10-30% greater load capacity than similarily sized competitor products.

These and other characteristics are the source of our product's high load capacity, moment, and stiffness

features.

HC

F

F

LINEAR MOTION TECHNOLOGY

B

S

Average Friction of Block

UnitȈN

UnitȈN

UnitȈN

ᢳ/ARC25MN SZ V1N

Block friction!>!1.6+2.5+3 = 7.1N

ᢴ/HRC30FL BZ V0P

Block friction>!1.4+3+2 = 6.4N Block friction

Friction caused from ball bearing

Bottom Seals + Inner Seals

+) End Seals (2 sides)

Applied example

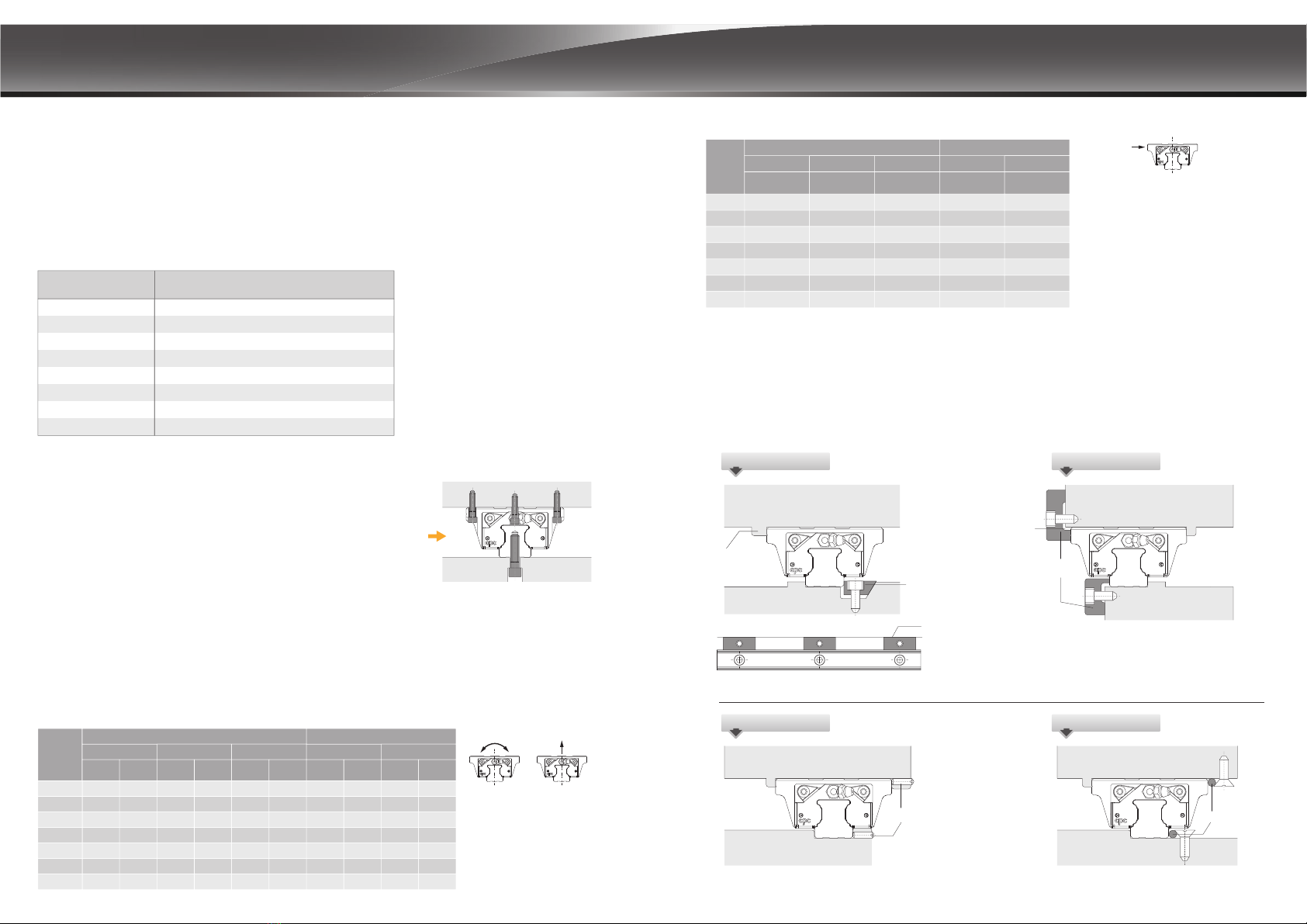

Low Friction Seals (B)

Our low-friction seals have slight contact with the rail

and are suitable for most environments, with both low

friction and a scraper function.

Standard Seals (S)

Our standard seals are in direct contact with the rail

surface, giving them increased dustproof and lubrication

retention capabilities. cpc recommends this class of seal

for blocks that operate in environments high in foreign

particles, such as sawdust, for long periods of time. S-type

seals will have comparatively higher friction than B-Type

seals.

Dust

Lubrication oil

B type S type

End Seals

End Seals

The end deals work in conjunction with the bottom and

inner seals to block foreign particles out and prevent

lubrication leakage. Our engineering plastic has a strong

friction resistance and is less prone to cracking than typical

NBR plastics.

Force of Friction

Time

Seal type friction comparison

Friction levels will be the highest on new linear rails. But,

after short periods of operation, such friction will be

reduced to a constant level.

Product Design (Standard)

Stainless Steel Reinforcement Plate

Dustproof design

Inner Seals

The newly designed inner seals both protect the rails

from foreign particles and keep the lubrication inside

the runner block while maintaining a low friction profile.

Bottom Seals

The bottom seals work in conjunction with the inner seals

to keep foreign particles out and lubrication from leaking

out. Our comprehensive sealing design significantly

reduces re-lubrication needs and prolongs the service life

of the runner block.

Inner seals

Bottom Seals

03 04

The reinforcement plate also functions as a scraper for

larger particulates like iron fillings, and has no more than

0.3mm clearance between the plate and the rail. ARC/HRC/ERC

VC

0.30 4

5

8

10

12

20

0.40

0.60

0.55

0.65

0.85

1.6 4.1 5.5

0.65

0.75

0.95

1.10

1.25

2.10

0.85

1.40

1.60

2.00

2.50

2.80

1.10

1.60

1.95

3.10

3.25

7.95

4.00

1.5

2.0

2.0

2.5

3.0

3.0

4.0

2.0

2.5

3.0

5.0

8.0

11.0

13.0

0.5

1.0

1.5

2.0

3.0

4.0

-

--

-

15MN/FN

20MN/FN

25MN/FN

30MN/FN

35MN/FN

45MN/FN

55MN/FN

V0 V1 V2

ARC/HRC/ERC

VC

0.30

0.40

0.50

0.50

0.60

0.70

0.90

1.00

0.80

1.10

1.20

1.80

1.00

1.40

1.80

2.30

1.5

2.0

2.5

3.0

2.0

2.5

3.0

5.0

0.5

1.0

1.5

2.0

15MS/FS

20MS/FS

25MS/FS

30MS/FS

V0 V1 V2

ARC/HRC/ERC

VC

0.40

0.50

0.70

0.80

0.90

1.00

1.9

0.70

0.80

1.20

1.40

1.60

2.30

4.3

0.90

1.60

1.80

2.20

2.70

3.50

6.6 8.6

1.40

1.80

2.00

2.80

3.50

4.55

1.5

2.0

2.0

2.5

3.0

3.0

4.0

2.0

2.5

3.0

5.0

8.0

11.0

13.0

0.5

1.0

1.5

2.0

3.0

4.0

15ML/FL

20ML/FL

25ML/FL

30ML/FL

35ML/FL

45ML/FL

V0 V1 V2

55ML/FL

4

5

8

10

4

5

8

10

12

20

Block Type

Block Type

Friction caused from ball bearing

Preload Class

Block Type

Friction caused from ball bearing

Preload Class

Bottom Seals +

Inner Seals S-Type

Standard

B-Type

Low friction

End Seals ( 2 sides )

External NBR seal with

metal scraper

Bottom Seals +

Inner Seals S-Type

Standard

B-Type

Low friction

End Seals ( 2 sides )

External NBR seal with

metal scraper

Friction caused from ball bearing

Preload Class Bottom Seals +

Inner Seals S-Type

Standard

B-Type

Low friction

End Seals ( 2 sides )

External NBR seal with

metal scraper

< 0.3mm

The following table shows the resistance value of the running block mounted with different seal types under the condition

when the running block lubricated with ISO VG32 lubricant.

Note: The end seal is made of elastic plastic material, not NBR, with low friction resistance and constant dynamic and static friction.

<pic.1>

Side Lubrication Port

(both sides of block have

lubrication holes)

LINEAR MOTION TECHNOLOGY

Product Design (Standard)

This test uses a total of 4 groups of products (2 rails matched with 2

lubrication methods) which are put on a saw wood dust surface on

which a back and forth motion test is performed.

Rail

Runner Block

Testing conditions

Installation Steps

1. Stroke = 600mm

2. Total testing stroke = 30m

Test items

1. If saw wood dust enters the inner surface of the runner block

2. If saw wood dust enters the ball bearing runner area

Test results

Tapped from bottom (oil) Tapped from bottom (grease)

Checked Item

Installation status

ARU Rail SZ Type Runner

Block (oil lubrication)

If saw wood dust

enters inner

block surface

If saw wood dust

enters ball bearing

runner area

ARU Rail S Type Runner

Block (grease lubrication)

AR Rail SZ Type Runner

Block (oil lubrication)

AR Rail S Type Runner

Block (grease lubrication)

No No

No No

No

No

Yes (belly area)

Yes (belly area)

Test result

ɓ!The standard rail has hole plugs, leading to rail unevenness, allowing some saw wood dust to enter the runner block belly

area. The 2 sides of the runner block belly area are completely protected by stainless steel reinforcement plates and end seals,

meaning that the ball bearing runner area is fully shielded from saw wood dust.

ɓ!The rail tapped from the bottom has an even rail surface so that the ball bearing runner area is fully protected from saw wood dust.

Saw wood dust

Runner block

Rail

Saw wood dust Test

Test content

Multi-Directional Lubrication Nozzles (All-direction Lubrication Nozzles)

Our product features lubrication ports on the top, bottom, and sides, allowing the installation of optional grease nipples for

relubrication. The top port comes with an O-ring seal to allow easy relubrication from the top, and our diverse comprehensive

lubrication injection design allows for lubrication from all directions.

Vmax >10 m/s Ĵmax >450m/s2

Using 2 stainless steel reinforcement plates, the L form

design allows for screws to be fastened onto the top

and bottom of the runner block, reinforcing the rigidity

and cladding of its caps.

The clearance between the rail profile with the seal

design is below 0.3mm, reinforcing the steel plates

while enabling scraper functions.

Our ARC/HRC/ERC, ARD/HRD/ERD type features stainless steel

reinforcement plates and additional bottom latches, increasing

its axial force and tolerance capacity to achieve a faster

operating speed.

F

Fx

Fy

Stainless Steel

Reinforcement

Plate

End Cap

Stainless steel reinforcement plate (Patent)

Scraping function on both sides

Function of high speed operation

05 06

1. Standard rail plus hole plugs (AR)

2. Rail tapped from the bottom (ARU)

1. Installation of standard contact type seals (S), using grease.

2. Installation of lubrication storage Pad and standard contact type

seals (SZ), using grease.

Fx

Fx

Fx

Instruction for side lubricant-nozzle-installation port of

Linear Guide

The side lubrication injection port (see pic.1) on cpc’s linear guide blocks is sealed

on delivery to prevent leakage of lubricants.

Before installing lubricant injection nozzle or piping, the seal must be broken to allow

lubricant to enter the runner block.

1. Tool

7RSLHUFHWKHVHDOVHOHFWDQDZOZLWKDGLDPHWHUOHVVWKDQǗPPVHHSLF

<pic.2>

2. Side lubrication port

The seal is in a deeper small hole in the middle of

the side lubrication injection hole on the block

(see Detail View A from pic.3). The seal is only 0.2

~0.3mm thick.

A

<pic.3>

<Detail View A>

Side lubrication

hole’s “seal”

3. Piercing method

Use the awl to stab into the seal showed in above picture. Press the awl against the seal (see pic.4A) and move gently forward by

about 1mm. Please do not use power tools or pierce too deep, to prevent damage to guide block end cap, which may impact its

functionality and interfere with lubricant passage.

<pic.4A> <pic.4B>

Sealed lubricant passage Cleared lubricant passage

LINEAR MOTION TECHNOLOGY

Product Design (Option)

2332km

10000 2000 3000 4000 5000 6000

-20 12 44 76 108 140 172 204 236 268 300

0

1.5

3

4.5

6

7.5

9

10.5

12

13.5

Condition

Model:ARC25MN SZC V1H Dynamic load rating C100Ȉ33.6kN

Velocity:1m/sec Stroke:960mm

Load capacities:7.44kN(0.3C) PreloadȈ0.05C

Rating Life()3 x 100km=()3 x 100km=2332km

-

P

C

-

0.05C+0.3C

C

With traditional ball type linear guides, the spinning of balls in different directions leads to a two-times faster contact speed.

Such high friction greatly reduces the service life of such products. Additionally, the contact point between such balls also

produces high pressure and noise levels while increasing the danger of oil film cladding damage.

Low noise ball chain

The contact point between the balls

and ball chain leads to a low

surface pressure level.

Traditional Ball type linear guide

Because the contact point of ball

type linear guides is only between

balls, the surface pressure is

significantly higher.

The

cpc

ball chain provides a greater contact area between the balls and the ball chain. Because the film cladding will not

be damaged easily and due to the lower noise volume, balls can move at a higher speed while product service life can also

be extended significantly.

*

*

The block with the ball chain design has the same dimensions as that without ball chains, allowing for the use of the same rails.

Heavy load test

Nominal life:

Travel distance (continuing):5877 km

Travel distance(km)

Smoothness test

Model code:ARC25MNSV1N

Velocity:10 mm/sec

Dynamic frictional (N)

Stroke(mm)

Ball chain

None ball

chain

After testing, grease remains

without anomalies.

Raceway surface

pitting

Low noise, superior quality high speed ball chain (Patent)

The table on the right shows the Ccage and

CISO values via different machine type testing.

(According to ISO-14728 regulations)

Mp/Mp0

My/My0

15

20

25

30

35

45

16.2

25.7

36.4

49.6

70.2

102.8

15

20

25

30

35

45

15

20

25

30

24.3

34.3

51.6

66.1

94.7

159.7

10.8

17.1

24.3

28.9

130

275

465

780

1575

2955

195

370

655

1040

1940

4185

85

185

310

455

95

200

340

530

1010

1775

215

350

640

900

1575

3280

45

85

145

205

95

200

340

530

1010

1775

215

350

640

900

1575

3280

45

85

145

205

Static rating load(kN) Static torque(Nm)

C

0

M

r0

M

p0

M

y0

1. The space block in the ball chain can prevent the oil film from rupturing by ball to ball contact and decrease friction induced wear.

2. The retainer block of the ball chain can maintain a reliable oil film layer by continuously applying grease on the moving part.

3. The ball chain provides the important function of leading steel ball motion. For traditional blocks without ball chains, its steel balls are

pushed by the rotating back steel balls on the raceway, meaning that the contact angle between the balls and rail is less precise,

causing vibration and an increased stress level between balls. In comparison, the balls in our ball chain product are led by the ball

chain to ensure a correct fit and accurate contact angles. In this way, our product's ball chain design ensures that it can fit

correctly when entering the raceway and that the contact angle will be accurate. This means that our Ball chain design provides

for a smooth performance, lower vibration levels and less additional stress levels. Subsequently increase the dynamic load rating,

Ccage value.

15

20

25

30

35

45

9.4

15.4

22.4

31.0

43.7

67.6

15

20

25

30

35

45

15

20

25

30

12.5

18.9

28.5

38.0

50.6

86.2

7.1

11.6

16.8

21.3

11.8

22.3

33.6

46.5

65.6

101.4

15.6

27.4

42.8

57.0

75.9

129.3

8.9

16.8

25.2

32.0

CISO (kN) Ccage(kN)

Ordering code: C

Load capacity of ball chain

There are three advantages of ARC/HRC/ERC/, ARD/HRD/ERD ball chain series as compared with traditional, non-ball chain blocks:

Model Code

Model Code

Dynamic rating load

Static rating load & Static torque

The C type block of ARC/HRC/ERC, ARD/HRD/ERD

will increase the pitch between balls on the

operating profile. Therefore, the static rating

load C0and the static rating torque Mr0, Mp0

and My0values will be decreased.

07 08

Ccage/C0Ccage/C0

Ccage/C0Ccage/C0

Mr/Mr0

ARC/ARD-MN C

ARC/ARD-FN C

HRC/HRD-MN C

HRC/HRD-FN C

ERC/ERD-MN C

ARC/ARD-ML C

HRC/HRD-ML C

HRC/HRD-FL C

ERC/ERD-ML C

ARC/ARD-MS C

ARC/ARD-FS C

ERC/ERD-MS C

ARC/ARD-MN C

ARC/ARD-FN C

HRC/HRD-MN C

HRC/HRD-FN C

ERC/ERD-MN C

ARC/ARD-ML C

HRC/HRD-ML C

HRC/HRD-FL C

ERC/ERD-ML C

ARC/ARD-MS C

ARC/ARD-FS C

ERC/ERD-MS C

LINEAR MOTION TECHNOLOGY

or

N2

N1

Ln

Product Design (option)

Upper Lubrication Storage Pad

Bottom Lubrication Storage Pad

Lubrication Design

Inner oil storage and oil supply system design

Our Inner PU Lubrication Storage Pad design does not increase the length of the runner block and

can effectively lubricate all balls. Customers can inject lubrication oil directly through its lubrication

holes to ensure sufficient storage in the PU Lubrication storage pad. This not only enables long-term

lubrication effects but also a higher degree of ease at conforming to environment protection needs

and lowering maintenance costs. For short-stroke movements, this product allows for highly effective

lubrication.

(Ordering Code: Z)

External NBR Seal with Metal Scraper (Ordering Code: SN / HN)

(ARC/HRC/ERC, WRC, ARD/HRD/ERD, ARR/HRR/LRR)

Available for applications in harsh environments such as in grinding, glass processing, graphite processing and wood-working machinery,

providing a highly effective dust and iron scrap proofing solution.

Stainless Steel

Rubber

Exterior Dimension Bore Specification Screw Specification

Model Code

Model Code

Model Code

Unit: mm

Unit: mm

Unit: mm

Nozzle Screw

External NBR Seal

External NBR Seal

(NBR/HNBR)

Block

Screw

Metal Scraper

Metal Scraper

Sleeve

Nozzle Sleeve

Guide Rail

Grease nipple

or

N2

N1

Ln

Nozzle Screw

External NBR Seal

Block

Screw

Metal Scraper

Sleeve

Nozzle Sleeve

Guide Rail

Grease nipple

Installation Manual

1. When installing the external NBR seal, please ensure that the block is

on the rail.

2. Ensure that the rubber part is fitted in the sleeve. If the rubber part has

fallen off, set the sleeve to the corresponding bore.

3. Overlap the rubber part and metal scrapper with the corresponding

salient point and bore. The

cpc

logo must be facing outward.

4. Slide the external NBR seal into the rail from two sides and closely

connect with the block.

5. Fasten the screw into the correspondence bore and align the seal

with the center of the rail and properly fastened. Do not allow the

metal scraper to make contact with the guide rail.

(ARC/HRC/ERC, ARD/HRD/ERD)

09 10

SN: (made by BRB) For application in harsh environment.

HN: (made by HNBR) For application of resisting acidic / basic coolant.

ARC/HRC/ERC ball type external NBR seal dimensions and specifications

P4S5N5g3

La

15

20

25

30

35

45

55

27/20

27/20

27/20

54.2

62.2

75.8

88

-

-

-

--

68.5

82

83

99.6

115.5

131.2

157.5

188.5

98.2

100.2

123.4

138

156.6

193.5

222

MS/FS MN/FN ML/FL

15

20

25

30

35

45

55

25

29

36.5

42.5

50

50

65

73

9.4

12.5

14.5

17

11

19.5

24

28.5

Dimensions of the block mounted with

external NBR seals

P

4

S

5

N

5

x g

3

15

T

4

6

6

6

6

4

5.2

1

1.5

1.5

1.5

1.5

1

1.2

3

4.5

4.5

4.5

4.5

3

413

4

33

58

68

84

98

61

41

47

10.2

17.5

20.5

24.9

28

11.5

11.5

13.5

3.5

4.5

4.5

4.5

5.5

3.5

3.5

3.5

3.5 M3x0.35 M3x0.5 A/B-M3-L

A/B-M3-L

A/B-M3-L

A/B-M6-L

A/B-M6-L

A/B-M6-L

A/B-M6-L

B-PT1/8-L

M3x0.5

M3x0.5

9

9

9

12

12

M3x0.35

M3x0.35

M3x0.35

M6x0.75

M6x0.75

M6x0.75

M6x0.75

PT1/8

M4x0.5

M4x0.5

M4x0.5

M5x0.5

M3x0.35

M3x0.35

M3x0.35

M3x0.35

M4x0.5

M4x0.5

M4x0.5

M5x0.5

2.3

2.1

2.5

2.8

3.2

3.1

5.8

5.6

6.5

6.5

6.5

10

3.5

3.5

6.5

20.3

34.2

39.3

49.6

57

22.5

23.2

26.5

t1t2P5

WH

3S6ØD1ØD2N1N2

20

25

30

35

45

55

12

12

15

Ln

Dimensions of external NBR seals

P

5

ØD

1

H

3

W

S

6

ØD

1

T

t

2

t

1

ØD

2

25

29

36.5

42.5

50

50

65

73

External NBR Seal with

Metal Scraper

External NBR Seal with

Metal Scraper

Exterior Dimension La

Exterior Dimension

Nipple

Extending the relubrication interval and reducing the amount of lubricant has always been the main issues for the manufacturers of linear guides.

The rolling elements and the raceway surface must be completely lubricated. This is the condition that the linear guide must have to operate.

However, the application environment of linear guides is quite different. A critical environment due to acid, iron filings, wood chips, coolant, working

speed, stroke length, load, installation, etc. will affect lubrication. The cpc lubrication storage can keep oil/grease for a long time. cpc block with the

lubrication unit can be used in the same way as the block without an oil tank. The grease nipple can be mounted on the block and the lubricant

can be supplied directly and achieves the effect of permanent lubrication!

The size and position of the screw hole on

the stainless steel reinforcement plate

Functions of the screw hole on the stainless steel reinforcement plate:

1. using for external NBR seal

2. using for the bellow

3. using for MSS reader

ARC/HRC/ERC

ARC/HRC/ERC

ARC/HRC/ERC

WRC

WRC

WRC

LINEAR MOTION TECHNOLOGY

ARR/HRR/LEE roller type external NBR seal dimensions and specifications

11

La

P

4

S

5

N

5

x g

3

P

5

!

ØD

1

H

3

W

S

6

ØD

1

T

t

2

t

1

ØD

2

12

C

H

ØD

(Ordering Code: MPC)

Cap can be Smoothly Installed on Bolt-Hole

The Most Convenient Metal Cap Used in Industry

Bolt-hole cap of conventional linear guides, due to the difficulty of controlling hammering strength, often result in caps being

hammered too deep or surface unevenness which leads to the accumulation of dirt or scrap iron. Our

cpc

cap is especially

designed with a supporting block to prop up the cap and to fix the screw stably, thus preventing such unnecessary sinking.

The upper part of the cap is made of stainless steel which can prevent

sharp foreign objects from piling up on the bolt-hole and affect the end

seal function.

The lower part of the cap is made of plastic, and can be installed directly

on a standard rail without the need for additional bolt-hole slot milling.

The bolt-hole chamfer for standard rails is C0.2mm. For further dustproof

requests, the non-bolt-hole chamfer rail is optional upon ordering. (order code: TR)

Metal Cap Features Introduction

Dimensions and Specifications

Metal-Plastic-Cap

Metal-Plastic-Cap

Rail

Supporting Block

Screw

Bolt-Hole with Chamfer

(standard)

Bolt-Hole without Chamfer

(optional: /TR)

Temporary

Support

Cap before

Hammering

(Plastic Support)

Plastic Support after

Hammering

(The form of the 8 supporting

blocks will become altered to

fit with the screw)

Block Height

C

A4

A5

A6

A8

A12

A8-R

M4

M5

M6

M8

M12

1.7 2.07.7

9.7

11.3

14.3

20.4

4.0

3.5

4.5

5.6

3.4

2.9

3.9

5.0

AR15 , WRC21/15, WRC27/20, ARR15

AR20 , ARR20

AR25 , ARR25

AR30 , AR35

M8 14.3 9.58.0 ARR35

AR45 , ARR45

Model Code Screw External Diameter

D

Cup Height

HRail

Metal-Plastic-Cap Patent Design for Standard Rail-Bolt-Hole

(With patent)

A14 M14 24.4 6.56.0 AR55 , ARR55

Stainless Steel

Rubber

or

N2

N1Screw

Ln

Nozzle Screw

External NBR Seal

Block

Metal Scraper

Sleeve

Nozzle Sleeve

Guide Rail

Grease nipple

T

6

6

1.5

1.5

4.5

4.5

69

84.9

60

70 22.9

20 4.5

4.5

M6x0.75 A/B-M6-XL

A/B-M6-XLM6x0.75

M4x0.5

M4x0.5

6.5

6.5

37.6

43.5

t1P5

t2WH

3S1S2ØD1ØD2N1N2

35

45

16

16

Ln

60

70

Exterior Dimension Bore Specification Screw Specification

Model

Code

Unit: mm

Nipple

External NBR Seal with

Metal Scraper

External NBR Seal with

Metal Scraper

Dimensions of the block mounted with

external NBR seals

The size and position of the screw hole on

the stainless steel reinforcement plate

Functions of the screw hole on the stainless steel reinforcement plate:

1. using for external NBR seal

2. using for the bellow

3. using for MSS reader

Dimensions of external NBR seals

35

45

142

176

167.5

211

197.5

246

MN/FN ML/FL MXL/FXL

Unit: mm

Unit: mm

Model

Code

Exterior Dimension La

P4S5N5g3

35

15

20

25

45

55

60

70

18

22.5

M4x0.5

M4x0.5

4.7

26 9.6 M3x0.35 1.4

29 12.5 M3x0.35 1.4

36.5 14 M3x0.35 1.7

3.3

3.576 27 M4x0.5

Exterior Dimension

Model

Code

LINEAR MOTION TECHNOLOGY

Basic static load capacity C0

The static load along the direction of the force; under this static load, the maximum calculated stress at the

center point of the contact surface between the ball and the track:

The value is 4200 MPa when radius of curvature ratio = 0.52

The value is 4600MPa when the radius of curvature = 0.6

Roller and rail contact surface produces the maximum calculated stress:

The value is 4000MPa

cpc's design of the roller guide series products has optimized the contact surface

between the roller and the raceway of the rail. The line contact stress is evenly

distributed. There is no edge stress effect, so they can withstand greater stress, as

shown in the right picture.

Note: At this point of maximum stress contact will yield a permanent deformation, which corresponds to 0.0001

diameter of the rolling element. (Above according to ISO 14728-2)

Static load safety factor calculation

(1) S0= C0/ P0

(2) S0= M0/ M

(3) P0= Fmax

(4) M0= Mmax

Equivalent static load P0and basic

static torque M0

Static load safety factor S0

The application of the static load capacity of the linear guide

series must be considered:

- Static load of linear guide

- Allowable load of screw fixation

- Permissible load of connected bodies

- The required static load safety factor for the application

The equivalent static load and static torque are the maximum

load and torque values, refer to equations (3) and (4).

In order to be able to withstand the permanent

deformation of the linear bearing and ensure that it

will not affect the accuracy and smooth operation of

the linear slide system. The static load safety factor S0

is calculated as equations (1) and (2).

S0 Static load safety factor

C0 Basic static load N in direction of load

P0 Equivalent static load N in direction of load

M0 Basic static torque Nm in direction of load

M Equivalent static torque Nm in direction of load

Operating situation S0

General operation

Shock or impact

High precision and smooth operation

1~2

2~3

≧ 3

13 14

Technical Information

Load capacity and service life

Definition: C100 is a radial load with constant magnitude and direction; when the linear bearing is

subjected to this load, its rated life can theoretically reach a walking distance of 100 kilometers,

and C50 is a walking distance of 50 kilometers. (Above according to ISO 14728-1)

According to ISO 14728-1 for the bearing steel used in the current technology, the calculated life

span of 90% survival rate for a single or batch of sufficient and identical linear bearings under normal

manufacturing quality and normal operating conditions is as follows:

C100

P

Ĵ

3

10

L >!rated life

C100 /C50!>!Dynamic Load Rating!)N*

P!!>!equivalent load!)N*

When using a ball type linear guide!!Ĵ= 3

When using roller linear guide !Ĵ=

(5) L = •105

C50

P

Ĵ

L = •5 x 104

Please refer to equations (6) and (7) for a comparison of the basic rated load capacity defined by the

two types of basic load capacity conversion when the standard rated load capacity C50 is taken as the

standard when the 50 km distance is taken as the rated life. (according to ISO14728-1)

(6) C50 = 1.26•C100

(7) C100 = 0.79•C50

Ball

(8) Lh= =

2•s•n•60 vm•60

LL

According to the operating velocity and frequency, the service distance can be converted to service life, assuming

the equivalent load and average velocity are constant.

Lh!>!Rated life!)h*

L >!Rated life for walking 100 km!)m*

s!!>!Single stroke )m*

n!!>!Frequency of reciprocating stroke!)min-1*

Vm!!>!Average velocity!)m/min*

If the block alone experiences the torque from Mp and My direction, the maximum allowable torque

for the block to run smoothly is 0.2 to 0.3 times static torque. And the block with larger preload would

have larger maximum allowable torque and vice versa. When static torque Mp and My is larger than

maximum allowable torque, the jumping of the block will be caused when the ball is rolling through the

loaded / unloaded region in the block. If you have above mentioned design problem, please contact

our technical department.

When the block alone experiences the torque

Ccage is a basic dynamic load capacity value of block with ball chain, which is 120 to 130% of the CISO value according

to the practical test (see Page 8). Formulas (5), (6), and (7) also apply to C100/cage and C50 / cage

Basic dynamic load capacity CISO (general design) /

Ccage (ball chain design )

CISO:C100 /C50

Pcpc

PCylindrical roller

Pmax

Raceway surface

Stress

LINEAR MOTION TECHNOLOGY

15 16

v =

q1•v1 + q2•v2 +...+qn•vn

100

(10)

When the velocity changes, the equivalent velocity is calculated according to formula (10).

v!!>!equivalent velocity!)m/min*

q!>!portion of working distance per segment (%)

When the load and velocity all change, the equivalent load is calculated according to formula (11).

P = Ĵ

ĴĴ Ĵ

q1•v1•F1 + q2•v2•F2 +...+qn•vn•Fn

100

(11) v

3

10

P >!!equivalent load!)N*

When using ball-type linear guide!!Ĵ= 3

When using roller-type linear guide!!Ĵ=

q!>!percentage of walking distance per segment!)%*

v!!>!velocity of each segment!)m/min*

F1!>!load per segment!)N*

When the linear guide is subjected to any angular load and the direction of the force other than the horizontal

or vertical direction, the approximated value of equivalent load is calculated as (12).

3 ɕ)Xɕɕ)Yɕ

(12)

P >!equivalent load!!)N*

FX!!>!force at horizontal component!)N*

FY!!>!force at vertical component!)N*

When the linear guide experience both load and torque at the time, the approximated value of equivalent

load is be calculated by formula (13)

3 ɕ)ɕɕ0ɕ•

(13) 00

C0

P >!equivalent load!)N*

F!!>!ORDGDSSOLHGWRWKH/0JXLGH!)N*

0!!>!static torque!!)Nm*

C0!!>!basic static load direction!)N*

00!!>!basic static torque in direction of force )Nm*

In general, the loads on the linear guide exert on the four major planes. However it can be the load from any angle.

In this case, the life of the linear guide is reduced. This can be interpreted by the flow of forces inside the system.

Line chart

As can be seen from the three diagrams in Figure A to Figure D, when subjected to upward, downward and lateral

loads, the force flow will be distributed to the two ball transfer.

Figure A

Lateral force 1 Lateral force 2

Figure B

Figure C Figure D

Under pressure Pull up

Ff1

Ff2

FS2

FS1

FS1、FS2:screw fixation

Ff1、Ff2:frictional

resistance

Ff= FS•Ǎ0

Equivalent load and Velocity

When the load and velocity are not constant, all actual loads and velocities must be considered, and it will impact the service life.

For each segment of each block, when the load changes, the equivalent load is calculated according to formula (9).

P = Ĵ

ĴĴ Ĵ

q1•F1 + q2•F2 +...+qn•Fn

100

(9)

3

10

P >!equivalent load!)N*

When using ball-type linear guide!!Ĵ= 3

When using roller-type linear guide!!Ĵ=

q!>!portion of working distance per segment (%)

F1!>!load per segment!)N*

Load capacity and life

Technical Information Operating temperature range

Friction

The linear guides have stable and constant running friction and slight start-up friction, which brings out the properties of the

product's low frictional resistance to the full.

Frn = μ· F Frn!>!Friction!)N*

F >!Load!)N*

Friction Factors

- Sealing system

- Collision between rolling elements and rolling

elements during operation

- Collision of the rolling elements with the return path

- Resistance caused by the rolling and sliding phenomenon at

the contact point of the rolling element and the raceway of

the rail

- Resistance caused by the squeezing of lubricant when the rolling

elements running

- Resistance caused by contaminations

Ý&aÝ&

7KH5OOHU*XLGH6HULHVIULFWLRQIDFWRULVDSSUR[ a

The Linear Guide Series have a permissible operating temperature between -40 °C

DQG&DQGWKHPD[LPXPWHPSHUDWXUHIRUVKRUWWHUPRSHUDWLRQFDQUHDFK&

Friction

LINEAR MOTION TECHNOLOGY

17 18

As shown in the two diagrams in Figures E and F, the load acting on the 45-degree angle has the greatest effect on the system's

life because the transfer of force is limited to a single row of balls.

When the load is applied horizontally or vertically (0 Ý, 90 Ý, 180 Ý

, 270 Ý), the equivalent load of the slide is equal to the actual

load. When the load angle is 45 , its equivalent load is approximately

1.414 times that of the main direction. (as shown in formula (12))

Ý Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Actual equivalence

load

Equation (12) (Page 15) calculates the

approximate value of the equivalent load

0

0.5

1.5

1.0

Therefore, in order to increase the service life of the linear system,

it should be installed in the appropriate direction to bear the load.

Otherwise, the service life will be greatly reduced, as shown in the

figure below. Since the relationship between life and load is as the

power of formula (5), when the acceptance angle is 45Ý, the service

life will be significantly reduced.

Ý Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

Ý

10%

0%

20%

30%

40%

50%

60%

70%

80%

90%

100%

Ball Roller

The following is the life L comparison chart (in %) for different angles

under the same load.

When the same load is at different angles, the comparison of

equation (12) and the actual equivalence load is as shown in the

following figure.

Ý Ý

Load calculation

1. The load exert on the linear guide would varies due to the position of object’s center of gravity, thrust position and acceleration /

deceleration induced inertia.

2. Because of the uneven distribution of force on linear guide, when a certain part of rail, or when a force exertion point is damaged,

the linear guide system would start to malfunction.

3. The point with largest force exertion must be identified, and be used reference to calculate the equivalent load, to ensure the

reliability of service life calculation.

Q ןF ( Dw2 ȂDž2ȂCDž

2 ) Q ן)DžןȂleff

ǃ)

Ball Roller

Q = !load

Dž !amount of rolling element

deformation

Dw = ball diameter

CDž= geometric constant

Q = load

Dž= amount of rolling element

deformation

leff = contact length

Q = load

Dž amount of rolling

element deformation

As shown by the formula, the relationship between the amount of

deformation of the rolling element and load is not linear. A larger

deformation will cause the non-linear increase of load.

Therefore by using the cpc self-developed program, the “Loading, Lifetime, & Rigidity Analysis Software of Linear Guide System

(LLRAS)”, a precise service life estimation can be derived. This is done by optimum calculation of deformation and rotation when

a linear guide experience load, in this case the accurate equivalent load can be calculated.

1 3 3

-

The following is a comparison diagram of the equivalent load approximate value and the actual equivalent load calculated by

Equation (13). The example uses the ARC25MN linear guide to withstand a fixed down pressure and the torque gradually increases.

The above figure shows the torque in the Mr direction. The figure below shows the torque in the Mp/y direction.

0

5

10

15

20

25

30

35

40

0 50 100 150 200 250 300 350

(kN)

(Nm)

Actual equivalence load Actual equivalence load

0

5

10

15

20

25

30

35

40

45

50

0 100 200 300 400 500 600

(kN)

(Nm)

˖!!˖•C0

Mr

Mr0 ˖!!!!˖•C0

Mp/y

Mp0/y0

Load capacity and life

Line chart

Figure E Figure F

(Equivalent load)

(Equivalent load)

(Mrdirection torque) (Torque in Mp/y direction)

Equation (13) (Page 15) Calculate the approximate

value of the equivalent load

Equation (13) (Page 15) calculates the approximate value of

the equivalent load

Q

Dž

Technical Information

LINEAR MOTION TECHNOLOGY

19 20

2. Set the carriage size model

Variables can be set:

- Block span

- Block type

- Block preload

1. Set the slide rail position, the number of slides on the slide

Variables can be set:

- Linear guide span

- Linear guide height

- Linear guide placement angle

- Platform inclination

- Number of block

3. Set the exercise state

4. Set external force and torque position, size, direction

Variables can be set:

- Working status

- Drive position

- Actuation frequency

Variables can be set:

- External force (torque) intensity

- External force (torque) position

- External force (torque) working

zone

Loading, Lifetime, & Rigidity Analysis Software of Linear Guide System (LLRAS)

Data input guidance

Technical Information

LINEAR MOTION TECHNOLOGY

6. Check if the settings are correct from the 3D chart

The calculation results are shown in the figure, and the information such as force and equivalent load, safety factor, and life span of

each section can be obtained, and the deformation of any measured point can also be obtained.*

This program can be used to calculate the installation and dimension design of various linear slide rails under different load and

movement conditions. The obtained information such as deformation amount, force distribution, and life span can help to provide

appropriate and correct design recommendations.

* For the calculation of amount of deformation, only the rolling object is considered. For actual deformation the steel body of block

must be considered as well. When the load > 20% C0, the actual deformation is 1.5 times larger than calculated deformation.

When Load = C0, the actual deformation is 2~2.5 times of calculated deformation.

5. Set the quality position size

Variables can be set:

- Center of gravity position

- Center of gravity

dimension

- Load range

21 22

Using the ARC 25 MN VC block, the schematic diagram of the mechanism is as follows:

Motion status is as follows

Traditional calculated results obtained by geometric distribution.

cpc

Results calculated by program

Application Example

Centroid position 100kg Centroid position 100kg

2 m/s2-2 m/s2

0.5

250mm 500mm 250mm

1.0 1.5

1

V (m/s)

T (sec)

At acceleration

At constant velocity

At deceleration

Average load

Block 1

348.6

384.0

419.4

385.9

348.6

384.0

419.4

385.9

914.5

949.9

985.3

951.0

914.5

949.9

985.3

951.0

Block 2 Block 3 Block 4 Block 1

220

245

270

220

245

270

711

736

761

711

736

761

736

Block 2 Block 3 Block 4

In this case, the calculated result of equivalent load is 30% higher than result obtained by traditional geometric distribution method,

and the service life is about 2 times different.

If there is a demand for life and rigidity calculation, please fill in form of 【Linear guide service life calculation and model selection】

and contact cpc technical department.

Block 1 & Block 2

Block 1 & Block 3 Block 2 & Block 4

Block 3 & Block 4

400

200 300

200

50

50

The maximum value

of average load

Drive position Drive position

Loading, Lifetime, & Rigidity Analysis Software of Linear Guide System (LLRAS)

At acceleration

At constant velocity

At deceleration

Unit:N Unit:N

Technical Information

LINEAR MOTION TECHNOLOGY

23 24

Lateral bearing surfaces and lateral fixing elements

When the lateral load is greater than the lateral load capacity, the lateral bearing surface is required to bear the lateral force. If the

lateral force is bidirectional, Lateral fixing elements can be used to provide a bidirectional lateral load capability of the linear guide

on the other side of the side bearing surface, and help close to the lateral bearing surface, the lateral straightness and side load

capacity after installation will be greatly improved, and its allowable value will vary according to the type of fixed component.

The following diagram shows several common elements.

Wedge block

Wedge block

Open slot

Binder plate

Mandrel

The linear guide rail is tightened by locking the

bolts on the wedge block.

The open slot must be machined to prevent

interference between the linear guide and carriage

on the corners during installation.

When the installation space is limited, the size of lateral

mounting element must be considered.

Use the slope of the nut to advance the roller

to achieve the effect of tightening the linear

LM guide.

Socket set screws

Linear guide often experience lateral load when used; in the case of mounting screw

only, the lateral bearing capacity is suggested to be determined by the static friction

force resulted from the screw tightening torque. If the maximum lateral load is exceeded,

the support from the edge, lateral mounting and plugs are possible options to enhance

the load capacity.

The lateral bearing capacity (without support from edge and

lateral mounting)

Screw tightening torque (Nm)

Strength grade 12.9

Alloy steel screws s teel cast iron Non-ferrous metals

M3 2.0 1.3 1.0

4.1 2.7 2.1

8.8 5.9 4.4

13.7 9.2 6.9

30 20 15

118 78 59

157 105 78

M4

M5

M6

M8

M12

68 45 33M10

M14

Lateral bearing

surfaces

The maximum bearing capacity of linear guide is not only related to the static load capacity C0, but also the screw mounting of

coupling parts. Factors such as length of block, distance between rails, size of screws, and contact width of rail would impact

the maximum bearing capacity of screw mounting.

Socket set screws Mandrel fixing

Binder plate

Wedge block

Fmax

FZ,max

N

FZ,max

N

FZ,max

N

FZ,max

N

FZ,max

N

Mt,max

Nm

Mt,max

Nm

Mt,max

Nm

Mt,max

Nm

Mt,max

Nm

15 3200

5500

8100

15900

-

-

-

22

51

87

210

-

-

-

26

60

100

240

300

970

1600

30

68

120

280

340

1100

1800

50

115

190

470

590

1900

3200

60

134

240

560

680

2200

3600

3700

6400

9400

18500

18500

45900

63700

4200

7300

10800

21100

21100

52400

72800

7200

12500

18700

36900

36900

91700

127400

8000

14500

21000

42200

42200

104800

145600

20

25

30

35

45

55

Screw maximum tensile strength and torque

According to DIN637, DIN SIO 12090-1 and DIN EN ISO 898-1 regulation, when the tensile strength, torque and lateral force exert on

class 8.8 alloy steel screw is larger than the values in table below, the screw mounting and design of edge support must be revised

to avoid loose.

Mt,max

FZ,max

Screw lateral bearing capacity

Fy,max

When class 10.9 class alloy steel screw is used, the value is about 1.4 times larger than the value in table above.

When 12.9 class alloy steel screw is used, the value is about 1.68 times larger.

Fy,max

N

Fy,max

N

Fy,max

N

Fy,max

N

Fy,max

N

15 240

410

610

1200

-

-

-

280

480

710

1400

1400

3400

4800

320

550

810

1600

1600

3900

5500

550

950

1400

2800

2800

6900

9600

630

1050

1600

3200

3200

7900

11000

20

25

30

35

45

55

size

ball type

short standard long standard long

roller type

ball type

short standard long standard long

size

roller type

Technical Information

LINEAR MOTION TECHNOLOGY

25 26

ARC/ARD/WRC

VC 0

0.02CV0

V1

V2

Preload and clerance

The ARC/HRC/ERC, ARD/HRD/ERD linear guides provide 4 different preload classes VC, V0, V1, V2.

Class Description

ǍP

Clearance

Application

Clearance

Light

Preload

0HGLXP

Preload

Heavy

Preload

Preload

Value 15

WRC21/15 WRC27/20

+5~+0 +5~+0 +5~+0 +5~+0 +5~+0 +5~+0 +5~+0

+5~+0 +5~+0 +5~+0 +5~+0 +5~+0 +5~+0 +5~+0

20

25 30 35 45 55

6PRRWKPRWLRQ

low friction

For precision situations,

VPRRWKPRWLRQ

High stiffness, precision,

high load situations

Super high stiffness,

precision and load

capacity

HRC/ERC/HRD/ERD

VC

V0

V1

V2

Class Description

ǍP

Clearance Application

Clearance

Light

Preload

0HGLXP

Preload

Heavy

Preload

Preload

Value 15 20 25 30 35 45 55

6PRRWKPRWLRQ

low friction

For precision situations,

VPRRWKPRWLRQ

High stiffness, precision,

high load situations

Super high stiffness,

precision and load

capacity

0

0.02C

0.05C

0.08C

0.08C

0.13C

+0~-4 +0~-5 +0~-6 +0~-7 +0~-8 +0~-10 +0~-12

-4~-10 -5~-12 -6~-15 -7~-18 -8~-20 -10~-24 -12~-28

-10~-16 -12~-18 -15~-23 -20~-31 -24~-36 -28~-45-18~-27

+0~-4 +0~-5 +0~-6 +0~-7 +0~-8 +0~-10 +0~-12

-4~-12 -5~-14 -6~-16 -7~-19 -8~-22 -10~-25 -12~-29

-12~-19 -14~-23 -16~-26 -22~-35 -25~-40 -29~-46-19~-31

1B 1B1A 1A

P/2 P/2

P/2 P/2

Figure B

Figure A

Installation Notice

'LPHQVLRQRIUHIHUHQFHHGJH

Rail Joint

7RHQVXUHWKDWWKHOLQHDUJXLGHLVSUHFLVHO\DVVHPEOHGZLWKWKHPDFKLQHWDEOHcpc devices have a recess installed in the

UHIHUHQFHHGJHFRUQHU7KHFRUQHURIWKHPDFKLQHWDEOHPXVWEHVPDOOHUWKDQWKHFKDPIHURIWKHOLQHDUJXLGHWRDYRLG

LQWHUIHUHQFH7RFRQVXOWRQFKDPIHUVL]HVDQGVKRXOGHUKHLJKWVSOHDVHUHIHUWRWKHWDEOHEHORZ

7KHVWDQGDUGOHQJWKRIRXUODUJHUDLOVLVPHWHUV,IORQJHUUDLOVDUHUHTXLUHGcpc can provide a joint rail solution for which the joint

QXPEHUZLOOEHPDUNHGRQWKHUDLO

$VVKRZQLQILJXUH$SOHDVHIROORZWKHMRLQWQXPEHUWRDVVHPEOH

2. )RUPRUHWKDQWZRXQLWVLQHDFKD[LVWRDYRLGDFFXUDF\HIIHFWVIURPPXOWLSOHEORFNVSDVVLQJWKURXJKWKHVDPHFRQQHFWLRQSRLQW

we advise to use the connection points separately as shown on figure B.

3. 3OHDVHXVHWKHVOLGHDVDFRQQHFWLRQSRLQWWRWLJKWHQWKHVOLGHEHIRUHWLJKWHQLQJWKHWRUTXHVWRIDVWHQWKHVFUHZVIURPLQVLGHWRRXWVLGH

section

separation of guideway connection points

section

h2

E

r2PD[

h1

r1PD[

2SHUDWLQJ7HPSHUDWXUH

7KH/LQHDU*XLGH6HULHVRIVWDQGDUGEDOOJXLGHZLGHEDOOJXLGHDQGUROOHUJXLGHVKDYHDSHUPLVVLEOHRSHUDWLQJWHPSHUDWXUH

EHWZHHQ&DQG&DQGWKHPD[LPXPWHPSHUDWXUHIRUVKRUWWHUPRSHUDWLRQFDQUHDFK&

7HFKQLFDO,QIRUPDWLRQ

Unit:PP

15 0.5

0.5

1.0

1.0

1.0

1.0

1.5

0.5

0.5

1.0

1.0

1.0

1.0

1.5 10.0 10.0 12.0

3.3

5.0

6.0

6.6

7.6

9.3

2.5

4.0

5.0

5.5

6.5

8.0

r1PD[ r2PD[ h1h2E

20

25

30

35

45

55

4.0

5.0

5.0

6.0

6.0

8.0

ARC/HRC/ERC, ARD/HRD/ERD

21/15

27/20

0.4

0.4

0.4 2.7

3.5

2.0

3.0

r1PD[ r2PD[ h1h2E

5.0

0.4 5.0

WRC

35

15

20

25

0.5

0.5

1

0.5

0.5

1

4

5

5

2

3.4

4

2.9

4.4

5

45

1

1

16

8

5

7

r1PD[ r2PD[ h1h2E

8

0.5 10

1.5 1081.5 10

55

ARR/HRR/LRR

Type

Type

Type

LINEAR MOTION TECHNOLOGY

Installation surface geometry position

accuracy

27 28

d

e2

The rough finishing or milling on installation site will impact

the working accuracy of linear guide, and reduce the service

life of both standard, wide ball type linear guide and roller type

linear guide. The accuracy of installation site and linear guides

are critical factors to determine the accuracy of work bench.

When the error of installation site is larger than the value

calculated by following formula, the working resistance and

service life will be impacted.

Installation datum plane

Rail: Both edges of rail can be reference edge, it shouldn’t

be marked separately.

Block: The side steel body of the block with

1. milled surface

2. Without groove mark can be the reference side.

Applicable to 15-55 all models

Installation instructions

e3

//

b

e1

VC

5.2

43.1 29.7 18.3 8.9

4.8

3.1

10.5

7.3

17.5

12.3

26.0

18.4

4.5

4.2

3.5

3.1

2.8

2.2

1.8

1.7

1.1

0.8

0.7

1.3 1.1 1.0 0.8

1.2 1.1 0.9 0.7

1.2 1.0 0.9 0.7

V0 V1 V2

MS / FS

MN / FN

ML / FL

ARC/HRC/ERC (f1)

VC V0 V1 V2

MN / FN

ML / FL

MXL / FXL

ARR/HRR/LRR (f1)

VC V0 V1 V2

MS / FS

MN / FN

ML / FL

ARC/HRC/ERC (f2)

VC V0 V1 V2

7.1 6.2 5.2 4.3

5.3 4.7 3.9 3.2

4.2 3.6 3.0 2.5

MN / FN

ML / FL

MXL / FXL

ARR/HRR/LRR (f2)

VC

20 14

14

13

12

9

8

7

5

4

3

12

15

14

13

8

6

18

17

23

21

30

28

15

7

8

8

11

10

10

15

13

8

16

10

9

6

5

4

18

22

22

20

28

27

25

35

32

46

44

24

16

18

16

25

23

21

31

27

38

37

35

49

45

65

62

33

31

V0 V1 V2

ARC (f3)

VC V0 V1 V2

15 MN / FN / FN-R

15 ML / ML-R / FL / FL-R

20 MN / FN / FN-R

20 ML / ML-R / FL / FL-R

25 MS

25 MN / FN / FN-R

25 ML / ML-R / FL / FL-R

30 MN / FN / FN-R

30 ML / ML-R / FL / FL-R

35 MN / FN / FN-R

35 ML / ML-R / FL / FL-R

45 MN / FN / FN-R

45 ML / ML-R / FL / FL-R

55 MN / FN / FN-R

55 ML / ML-R / FL

15 MS / FS

15 MN / FN

15 ML

20 MS / FS

20 MN / FN

20 ML

25 MS / FS

25 MN / FN

30 MS / FS

30 MN / FN

35 MN / FN

45 MN

30 ML

35 ML

45 ML

55 MN

55 ML

HRC / ERC (f3)

18

16

13

12

8

7

4

3

16

14

10

9

5

4

23

21

31

27

25

22

20

18

15

13

11

8

6

5

33

31

24

22

15

14

8

7

8

8

37

35

27

25

17

16

49

45

65

62

35

32

23

21

46

44

30

28

11

10

15

13

V0 V1 V2

11 7 4

10 7 3

10 6 3

13 9 4

12 9 4

11 8 3

45 MN / FN

45 ML / FL

45 MXL / FXL

55 MN / FN

55 ML / FL

55 MXL / FXL

ARR/HRR/LRR (f3)

ྤ৴לԒ

V0 V1 V2

96 3

54 2

53 2

75 2

75 2

75 2

65 2

64 2

85 2

85 2

35 MN / FN

35 ML / FL

35 MXL / FXL

25 MN / FN

25 ML / FL

25 MXL / FXL

15 MN / FN

20 MN / FN

15 ML / FL

20 ML / FL

ARR/HRR/LRR (f3)

Block length

Block length

Block length

Block length

Block length

Block length

Block length

Block length

LINEAR MOTION TECHNOLOGY

29 30

Lubrication

unit :cm3unit :cm3

unit :cm3

unit :cm3

unit :cm3unit :cm3

Function

Rail installation

Recommended precision measurement method

Diagram FeatureDescription

ȆNo Straightening

ȆNot allowed

•Straightening by pin

•Not suggested

•Straightening based on

straight edge, calibrated

by meter

•With support edge and

lateral mounting screw

No precision

Low lateral bearing capacity

Low precision

Low lateral bearing capacity

Low to mid precision

Low lateral bearing capacity

High precision

One side with high lateral

bearing capacity

Very high precision

High lateral bearing capacity

on both sides.

LL

h1h2

The working accuracy of linear guide is defined by the parallelism between block and rail(height, side). In practical application

the linear accuracy is required, the measuring method is diverse, so we would suggest following measure to acquire the linear

accuracy of linear guide.

H The horizontal working accuracy +

base plane flatness ɕK

1

-h

2

ɕ

total length

( above mentioned method can be used to exclude the skew error

of rail on roll direction)

AB

W

2

The horizontal working accuracy +

the straightness of rail installation

(Please refer to table of working precision page 31 ) (Please refer to table of working precision page 31 )

* When the error of flatness of base plane is 0, the value is the

linear working accuracy of rail at the certain height

A

B

Installation instructions

straightedge

straightedge

straightedge

*When the error of the straightness of the rail is 0, the

value is the horizontal working accuracy on the side.

•Place the rail on a

supporting edge

(Precision vise applied) Precautions when lubrication with oil

1. If indicate "oil lubrication" on the order, the carriage provided will not be pre-filled with grease.

2. If the block already has grease inside and the grease is different from the grease set by the customer or has exceeded the 12-month

shelf life, you must clean the block before assembling. Test the lubricants to avoid grease incompatibility. Ensure that the channel

is free, and the lubricant can flow to the rolling elements and be lubricated.

3. If using the grease nipple combined with the tubing kit or the set screws for the lubricating oil inlet channel, must wrap it with a tapseal

to achieve a leakproof effect.

ARC/HRC/ERC, ARD/HRD/ERD

15 1.4 2

4

7

10

16

32 37

19.5

12.5

9

5

2.5

2.3

3.9

5.9

-

-

-

1.2

2.3

3.9

5.4

-

-

-53

3.2

5.5

9.5

14

21

40

66.5

1.5

3.5

7

9

15

30

--

20

25

30

35

45

55

15

20

25

30

35

45

55

Size

21/15

27/20

2.2

4.8

WRC

21/15

27/20

2.7

5.3

ARR/HRR/LRR

15

20

15

20

-

25

30

-

35

45

16.2

22

18.0

3.7 4.5

6.1 7.2

9.5 10.8

26.4

21.3

11.9

12.4 13.7 15.1

55

30.8

31.2 38.5 46.8

-

-

25

35

30

45

14.7

20.8

16.5

3.1 3.9

5.0 6.3

24.3

19.8

8.5 9.7 10.8

11.2 12.5 13.9

27.7

55 30.6 37.8 46

ARC/HRC/ERC, ARD/HRD/ERD (ball chain type)

Size short (S) standard (N) long (L) Size short (S) standard (N) long (L)

WRC (ball chain type)

standard (N)Size standard (N)

Size extra long (XL)standard (N) long (L) Size extra long (XL)standard (N) long (L)

ARR/HRR/LRR (roller chain type)

Lubrication methods and note on lubrication

1. The block already contains lubricants that can be directly installed on the machine without additional cleaning.

2. If cleaning of the block is required which the oil storage is equipped, please wait until the cleanser and clean naphtha in the oil

storage are dry, and then put the block in lubricating oil, so that the oil storage can absorb enough lubricating oil before it will be

installed in Machine.

3. Before the first start-up, the carriage and the rail must be protected by adding lubricating grease and contact with liquid or solid

contaminants must be avoided.

4. The cpc block is provided with lubrication holes at the front and rear ends, as well as left and right and on the top. The grease can

be injected into the block through the holes. The amount of grease required for a single block is given in the table below.

5. The block must run back and forth while lubricating.

6. Must consistently provide an oil film on the surface of the rail, which is easily noticeable optically.

7. If dry and discolored, relubrication should be carried out immediately, and the relubrication interval should be determined according

to the environment and conditions of use.

8. The user must inform in advance if it is used in a cleanroom environment or requires acid and alkali resistance.

9. If the use of a guide deviates from the horizontal installation, the use of oil lubrication must be carefully checked.

10. The re-lubrication interval must be shortened if the travel stroke is < 2 or > 15 times the length of the steel body of the runner block.

11. If the stroke is less than two times the steel body of the block, the grease must be injected through the lubrication hole from the left

and right of the block and then run on a rail that is at least three times the length of the block to distribute the grease evenly in the

block. Repeat this step twice.

12. For the central lubrication system, cpc recommends the use of liquid grease NLGI 00 or NLGI 000.

When operating the linear guides under sufficient lubrication, a one-micron layer of the oil film at the contact zone separating the

loaded rolling elements and the raceway.

Sufficient lubrication will:

- Reduce the friction - Minimize wear - Prevent oxidation - Dissipate heat and increase operating life.

Space for grease in the block inside

LINEAR MOTION TECHNOLOGY

31 32

Tolerance of dimension width W2

Variation of height for different

runner blocks on the same

position of Rail

Accuracy

Application

Technical information Ordering information

Customization code(The meaning of suffix characters)

:slide rail connection

:customer designated lubricant

:with Inspection report

J

:special straightness requirements for rail

S

G

I

:special processing for block

B

:with plastic caps for counter holes

on the rail

PC

:with Metal-Plastic Caps for rail

mounting holes.

MPC

:with extension and contraction support

layer.

BL

:external NBR seal with metal scraper

SN :external HNBR seal with metal scraper

HN

:black chrome coating treatment

on the rail

BR

:black chrome coating treatment

on the block

BB

:with stainless steel ball bearings

SB

:reference edges of block and rail on

opposite sides

DE

:customized designated preload

pressure value

VD

:clear chrome coating treatment on

the rail

CR

:clear chrome coating treatment on

the block

CB

:nickel coating treatment on the rail

NR

:raydent coating treatment on

the rail

RR

:raydent coating treatment on

the block

RB

:nickel coating treatment on the

block

NB

:raydent coating treatment on

the block and rail

RRB

:clear chrome coating treatment on

the block and rail

CRB

:block install with grease nipple by cpc

OA

:installation of side grease holes

and set screws

SG:special process for rail

:bolt-Hole without chamfer

TR

R

:black chrome coating treatment

on the block and rail

BRB

:nickel coating treatment on the

block and rail

NRB

Note: For special process or customized requirement, please contact cpc for more information.

( Please contact cpc for direction of grease nipple

installation)

(Available for size 15,20,25,30,35 and 45)

ARC 15 N -RMB2ZCV1P /JII-20-20-1480LU

R: six mounting holes

Customization code

End hole pitch (mm)*

Starting hole pitch (mm)*

Rail length (mm)

Accuracy grade : UP, SP, P, H, N

Preload class : VC, V0, V1, V2

C: with ball chain

Z: with lubrication storage pad

Block quantity

Seal type : B: Low friction S: Standard

Block length : L: long N: standard S: short

Block width : M: standard F: flanged

Block type : 15, 20, 25, 30, 35, 45, 55

U: rail ( tapped from the bottom)

Number of rails on the same

moving axis

Product type : ARC: automation series HRC/ERC: heavy load series

Unlabeled: Standards

* The end pitch of the rail should not exceed the 1/2 of original pitch, this is to avoid the misfit of the rail to

the workbench.

N

H

P

SP

UP

The ARC/HRC/ERC, ARD/HRD/ERD, WRC linear guides provide 5

different grades of precision : N, H, P, SP, and UP, Engineers can

choose different grades depending on the machine applications.

Accuracy

Size

15 ~ 20

25 ~35

45 ~ 55

UP SP P H N

Ʀ+

H

W2

Ʀ:2

± 5

± 5

3

3

± 10

± 7

5

5

± 15

± 10

6

7

± 30

± 20

10

15

± 70

± 40

20

30

± 5

± 5

3

3

± 10

± 7

5

5

± 20

± 10

7

7

± 40

± 20

15

15

± 80

± 40

20

30

± 5

± 5

3

3

± 10

± 7

5

5

± 20

± 10

7

7

± 40

± 20

15

15

± 80

± 40

25

30

Ʀ+

H

W2

Ʀ:2

Ʀ+

H

W2

Ʀ:2

$FFXUDF\JUDGHVǍP

Tolerance of dimension height H

Variation of width for different

runner blocks on the same

position of Rail

Tolerance of dimension width W2

Variation of height for different

runner blocks on the same

position of Rail

Tolerance of dimension height H

Variation of width for different

runner blocks on the same

position of Rail

Tolerance of dimension width W2

Variation of height for different

runner blocks on the same

position of Rail

Tolerance of dimension height H

Variation of width for different

runner blocks on the same

position of Rail

Runner block relative to linear guide, datum plane parallel motion precision

running parallelism