CPG 351EF300 User manual

USER MANUAL

Countertop Fryers

FRYER MODELS:

351EF300, 351EF302

REVISED 11/2019

2 www.CookingPerformanceGroup.com

USER MANUAL

IMPORTANT FOR FUTURE REFERENCE:

Please complete this information and retain this manual for the life of the equipment. For Warranty Service and/

or other parts, this information is required.

Model Number Serial Number Date Purchased

WARNING: For your safety, do not store or use gasoline or other ammable vapors or liquids in the vicinity of

this or any appliances. Keep the area free and clear of combustible materials. (See ANSI Z83. 14B, 1991).

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury, or death. Read the installation, operating, and maintenance instructions thoroughly before installing, or

servicing this equipment.

CAUTION: These models are designed, built, and sold for commercial use only. If these models are positioned

so the general public can use the equipment, make sure that cautions, warnings, and operating instructions are

clearly posted near each unit so that anyone using the equipment will use it correctly and not injure themselves

or harm the equipment.

WARNING: A factory authorized agent should handle all maintenance and repair. Before doing any

maintenance or repair, contact your authorized service representative

WARNING: An earthing cable must connect the appliance to all other units in the complete installation and

from there to an independent earth connection.

NOTICE: The unit when installed, must be electrically grounded and comply with local codes, or in the absence

of local codes, with the national electrical code ANSI/NFPA70- latest edition. Canadian installation must comply

with CSA-STANDARD C.22.2 Number 0 M1 982 General Requirements-Canadian Electrical Code Part ll, 109-M1981-

Commercia Cooking Appliances.

WARNING: SHOCK HAZARD - De-energize all power to equipment before cleaning the equipment.

www.CookingPerformanceGroup.com 3

USER MANUAL

LOCATION OF DATA PLATE

The data plate is located on the side panel.

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All equipment should be examined for damage before and during unloading. The freight carrier has assumed

responsibility for its safe transit and delivery. If equipment is received damaged, either apparent or concealed, a

claim must be made with the delivering carrier.

A) Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be signed by

the carrier representative (Driver). If this is not done, the carrier may refuse the claim. The carrier can supply the

necessary forms.

B) If concealed damage is not apparent until after equipment is uncrated, a request for inspection must be

made to the carrier within 15 days. The carrier should arrange an inspection. Be certain to hold all contents and

packaging material.

CONTENTS

Safety Precautions: ..............................4

Installation Instructions: ........................5

Operating Instructions:..........................5

Cleaning: ...........................................4

Explosion View Drawing and Spare Parts: ...6

Specications and Dimensions: ...............7

Parts Diagram & List: ..........................8-9

Troubleshooting: ................................10

Limited Warranty: ...............................11

Congratulations on your purchase of Cooking Performance Group commercial cooking equipment. Cooking

Performance Group takes pride in the design and quality of our products. When used as intended and

with proper care and maintenance, you will experience years of reliable operation from this equipment. To

ensure best results, it is important that you read and follow the instructions in this manual carefully.

4 www.CookingPerformanceGroup.com

USER MANUAL

Installation and service should be performed by a qualied installer who thoroughly reads, understands and

follows these instructions.

If you have questions concerning the installation, operation, maintenance or service of this product, visit Cooking

Performance Group’s website at www.CookingPerformanceGroup.com.

SAFETY PRECAUTIONS

DANGER: This symbol warns of imminent hazard which will result in serious injury or death

WARNING: This symbol refers to a potential hazard or unsafe practice, which could result in serious injury or

death.

CAUTION: This symbol refers to a potential hazard or unsafe practice, which could result in minor or moderate

injury or product or property damage.

NOTICE: This symbol refers to information that needs special attention or must be fully understood even

though not dangerous.

NOTICE: This product is intended for commercial use only. Not for household use.

NOTICE: Local codes regarding installation vary greatly from one area to another. The National Fire Protection

Association, Inc., states in its NFPA96 latest edition that local codes are “Authority Having Jurisdiction” when it

comes to requirements for installation of equipment. Therefore, installation should comply with all local codes.

www.CookingPerformanceGroup.com 5

USER MANUAL

INSTALLATION INSTRUCTIONS

1. Always clean equipment thoroughly before rst use

2. Check rating label for your model designation & electrical rating. Consult with your electrician before using

any electrical equipment. Hardwired units MUST be installed by a qualied Electrician. Failure to do so will void

the warranty.

3. For best results, use stainless steel countertops that are even and free of debris/liquids.

4. Attach the four legs to the bottom of the unit and place the fryer on the countertop. Use a level to ensure the

adjustable feet are all even.

GENERAL OPERATING INSTRUCTIONS

1. All food service equipment should be operated by trained personnel. Serious injury or death can result in

improper use of fryers since temperatures reach in excess of 350F.

2. Do not allow your customers to come in contact with any part of the fryer.

3. Before operating, check to ensure your power supply is correct to match the data plate.

4. Once the fryer is installed on a level surface and connected to a power source, add oil to the oil pan. DO NOT

ll above the max ll line. It is recommended to start at the MIN line and then add more if needed to prevent any

chances of overll.

5. With the oil in the pan, turn the fryer on and move temperature knob to desired temperature.

6. Allow the Fryer 15-30 min to reach desired temp.

7. Do not overload the basket with product.

8. Drop the basket in slowly and fry for desired time.

9. If using tongs to separate product, you must also wear high heat gloves to prevent burns.

10. Once product is done, lift the basket and use the side mounted hanger to drain the additional grease o the

product.

6 www.CookingPerformanceGroup.com

USER MANUAL

CLEANING

1. Always turn unit o and allow it to cool completely before cleaning.

2. Never clean unit by immersing it in water

3. Tilt the fryer head back which lifts the element. Remove the oil pan and safely drain the oil using the side

handles on the pan. Oil should be drained nightly at a minimum and more depending on frequency of use.

4. Replace the pan and move the heating head/element back into operating position.

5. Add water to the “MAX” Line

6. Add the Noble Fryclone cleaner or other food grade cleaner and follow cleaner instructions.

7. Turn the thermostat to 250°F. Let the heating unit bring the solution to a boil.

8. Boil long enough to loosen or dissolve all varnish or carbon deposits. This should take approximately 30

minutes.

9. Turn the unit o.

10. Rinse with clean water to remove all cleaning mixture.

11. Rinse the inside of the tank with 2 cups of vinegar.

12. Rinse with clean water until the vinegar odor is gone. The fry tank must be thoroughly rinsed since even a

trace of cleaner left inside the tank will contaminate the fry compound.

13. Dry thoroughly.

14. Cover the tank if compound will not be added until a future date.

15. Clean all exterior surfaces of unit on a regular basis with a damp cloth.

16. To remove discolorations or oil lm, a non-abrasive cleaner may be used such as Noble’s 147QUIKSAN.

Tough on grease. Tough on carbon. Tempest deep fat

fryer cleaner offers thorough elimination of encrusted

grease and grime.

www.CookingPerformanceGroup.com 7

USER MANUAL

TECHNICAL SPECIFICATIONS

Name 15LB Deep Fryer 30LB Deep Fryer

Model EF300 EF302

Voltage 208/240V 208/240V

Power 5200/5500W 8,400/11,000W

Plug Nema 6-30P Hardwired

Number of Oil Tanks 1 2

Size of Oil Tanks 14 ” x 12 ” x 9” 14 ” x 12 ” x 9”

Number of Frying Baskets 1 2

Size of Frying Baskets 11.25” x 9.75” x 5.5” 11.25” x 9.75” x 5.5”

Cooking Temperature Range 120°F - 375°F 120°F - 375°F

Temperature Safety Cut-O 446°F 446°F

Overall Dimensions 21.5” x 14” x 21.5” 43” x 14” x 21.5”

8 www.CookingPerformanceGroup.com

USER MANUAL

PARTS DIAGRAM

www.CookingPerformanceGroup.com 9

USER MANUAL

PARTS LIST

ITEM # PART PART #

351PEF1 Power Cord 208/240V 1

351PEF2 Power Cord Connector 2

351PEF3 Terminal Block 3

351PEF6 Microswitch 6

351PEF7 Thermostat 7

351PEF10 Temp Limiter 10

351PEF12 Knob Control Metal 12

351PEF13 Element 13

351PEF14 Element Cover 14

351EFBASK Basket Fryer 11”x 9.75”x 5.5” 15

351PEF16 Oil Tank Fryer 16

351PEF18 Adjustable Leg 18

10 www.CookingPerformanceGroup.com

USER MANUAL

TROUBLE SHOOTING GUIDE

PROBLEM

PROBLEM CAUSE

Excessive & Premature Foaming

Greasy Food / Excessive Frying Com-

pound Absorption

Objectionable Odor or Flavor of Frying

Compound

Objectional Flavor of Fried Food

Excessive Smoking of Frying Compound

Excessive Darkening of Frying Compound

Frying Compound Won’t Hold Heat

Food Crust Color Not Brown

Rapid Breakdown of Frying Compound

Contamination of Fryer Compound

(Due to salt or other foreign material)

Improper Preparation of Food

Inadequate Frying Compound Turnover

High Moisture Content in Food Being Fried

Improper Draining of Food After Frying

Overloading Fryer

Frying Temperature Too Low/Underheating

(Check Thermostat)

Frying Temperature Too High/Overheating

(Check Thermostat)

www.CookingPerformanceGroup.com 11

USER MANUAL

LIMITED WARRANTY

Cooking Performance Group warrants its equipment free from manufacturer defect and workmanship for a

period of 1 Year from the original date of purchase. CPG equipment installed in/on a food truck or trailer will be

limited to a period of 30 Days from the original date of purchase. The CPG equipment umbrella covers:

• CPG Charbroilers • CPG Stock Pot & Work Ranges

• CPG Griddles • CPG Fryers

• CPG Flat Top Grilles • CPG Convection Ovens

• CPG Rangers • CPG Cook & Hold

CPG warrants all cast iron equipment parts fora period of 90 days from the equipment’s original date of purchase.

CPG does not warrant parts or accessories purchased independently from equipment. This CPG Limited Warranty

is non-transferable and valid to the original commercial purchaser only.

CPG shall bear the standard labor charge for each approved repair or replacement, to the extent that such repair

of replacement is performed within 50 miles of an authorized service agency, during regular (i.e. straight time)

hours of operation. CPG does not assume responsibility for travel exceeding 50 miles, or any work performed

outside of regular hours of operation (i.e. overtime). CPG reserves the right to approve or deny the repair or

replacement of any part or repair request.

CPG Limited Warranty Does NOT Cover:

• CPG equipment not purchased directly from an authorized dealer.

• Installation of CPG equipment in a non-commercial or residential setting.

• Failure to install or use CPG equipment under proper operating conditions.

• CPG equipment purchased, installed, or used outside of the Continental United States.

• CPG equipment damage or failure due to improper installation, improper utility connection or supply, and

issues resulting from improper ventilation or airow.

• CPG equipment where the serial number plate has been removed or altered.

• CPG equipment that has not been used appropriately, or subject to misuse, neglect, abuse, accident,

alteration, negligence, damage during transit, delivery, or installation, re, ood, or an act of God.

• CPG equipment that has been altered, modied, or repaired by anyone other than an authorized service

agency. Cooking Performance Group shall not be held liable for any damages to any person or property

which may result thereafter.

• Parts deemed by Cooking Performance Group to be categorized as normal wear and tear parts, such as light

bulbs, gaskets, porcelain, and other glass components.

To register your CPG equipment, visit: www.CookingPerformanceGroup.com/Warranty

This manual suits for next models

1

Table of contents

Other CPG Fryer manuals

Popular Fryer manuals by other brands

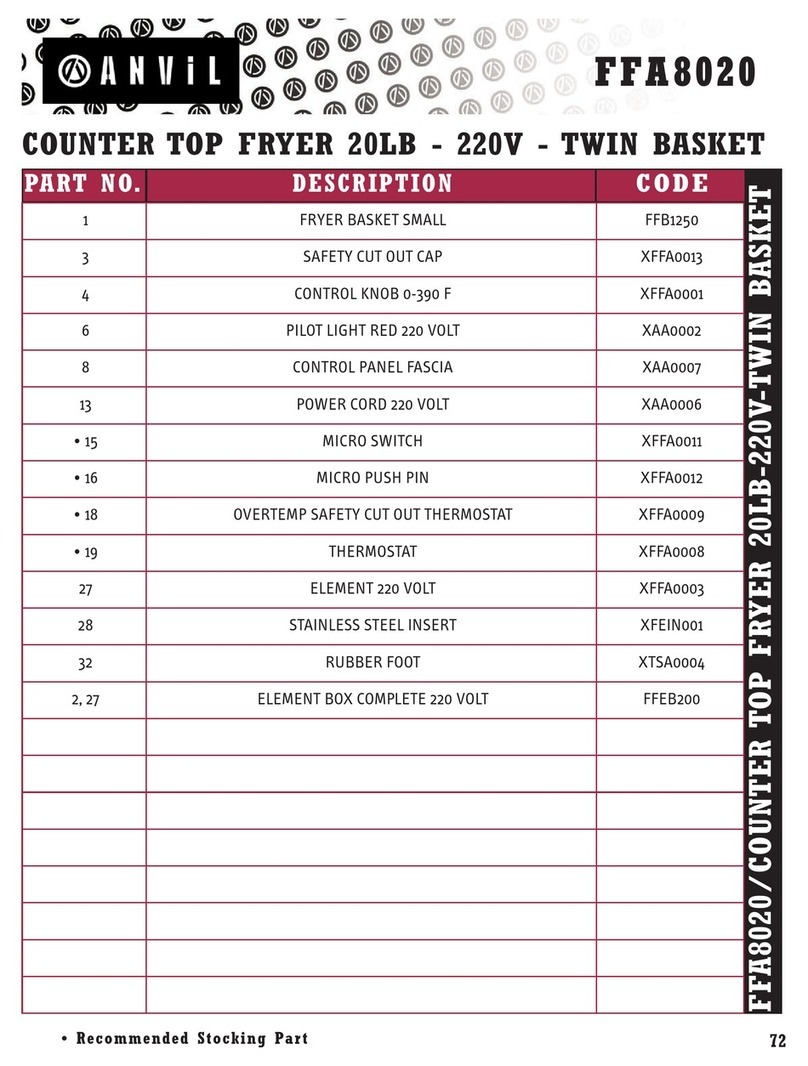

Anvil

Anvil FFA8020 parts list

Lotus cooker

Lotus cooker BR-50-78G Instructions for installation and use

DeLonghi

DeLonghi Electric Deep Fryer Instructions for use

George Foreman

George Foreman GHFD6810B use and care manual

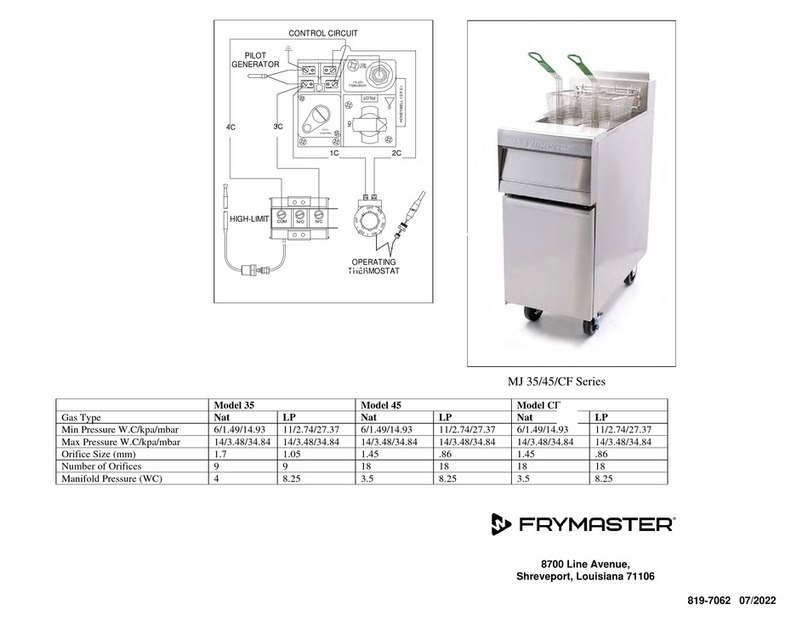

Frymaster

Frymaster Enodis RE14-2TC Specifications

Beper

Beper P101FRI200 use instructions