CPS-Pumps CST Series Instruction manual

www.cps-pumps.com IOM Manual: IOM-0000-CST

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

Installation, Operation &

Maintenance Manual

For

Series CST

Submersible Turbine Pumps

IOM-0000-CST

IOM-0000-CST

Copyright © 2018 CPS-Pumps

2

www.cps-pumps.com IOM Manual: IOM-0000-CST

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

Table of Contents

4...............INTRODUCTION

4...............SAFETY CONSIDERATIONS

5...............PUMP IDENTIFICATION

5...............MANUFACTURER

5...............TYPE OF PUMP

5...............DATE OF MANUFACTURE

5...............INSTALLATION, OPERATION & MAINTENANCE MANUAL IDENTIFICATION

6...............GENERAL INSTRUCTIONS

6...............HANDLING AND TRANSPORT

6...............METHOD OF TRANSPORT

6...............STORAGE

7...............INSTALLATION & ALIGNMENT

7...............PREPARATION

8...............RECEIVING THE PUMP

8...............ELECTRICAL

CONSIDERATIONS

9...............PROVIDING A PROPER POWER SUPPLY

9...............SELECTING AND INSTALLING A PROPER MOTOR CONTROL SYSTEM

9...............SELECTING THE PROPER DROP CABLE

9...............MAKING THE SPLICE BETWEEN THE MOTOR LEADS AND THE DROP

CABLE

9...............PROPERLY GROUNDING THE UNIT

9...............SELECTING AND INSTALLING AUXILIARY EQUIPMENT

10 ...............PRE-INSTALLATION MOTOR AND DROP CABLE CHECKS AND

PREPARATION

10 ...............MOTOR SERVICING

10 ...............ATTACHING THE MOTOR TO THE PUMP

10 ...............TESTING BEFORE SPLICING DROP CABLE TO MOTOR LEADS

10 ...............MOTOR TESTS

10 ...............DROP CABLE TESTS

10 ...............SPLICING DROP CABLE TO MOTOR LEADS

10 ...............TESTING AFTER SPLICING DROP CABLE TO MOTOR LEADS

11 ............... INSTALLING THE PUMP

13 ...............ROUTINE OPERATION AND MAINTENANCE

13 ...............ROUTINE INSPECTIONS

13 ...............ROUTINE TESTING

14 ...............PERFORMANCE TESTING

18 ...............ELECTRICAL TESTS

18 ...............MEASURING INSULATION RESISTANCE (GROUND TEST)

20 ...............MEASURING RESISTANCE BETWEEN LEADS (MOTOR WINDING RESIS-

TANCE)

22 ...............ASSEMBLY OF PUMP AND

MOTOR

23 ...............UPTHRUST ADJUSTMENT

3

IOM Manual: IOM-0000-CST IOM

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

www.cps-pumps.com

23 ...............PUMPS WITH 4” AND 6” MOTORS

24 ...............PUMPS WITH 8” MOTORS

24 ...............PUMPS WITH 6”, 8”, 10”, 12”, 14” AND 16” MOTORS (OPEN BEARING STYLE)

24 ...............RECOMMENDED SPARE PARTS

26 ...............SUBMERSIBLE TURBINE BOWL ASSEMBLY

4

www.cps-pumps.com IOM Manual: IOM-0000-CST

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

INTRODUCTION

e pumps covered in this manual, when installed correctly, will

last for many years in service. In order to gain the most from

this equipment, this manual should be read thoroughly and fol-

lowed during all stages of installation and operation.

SAFETY CONSIDERATIONS

e CPS-Pumps CST submersible turbine pumps have been

designed and manufactured for safe operation. In order to en-

sure safe operation, it is very important that this manual be read

in its entirety prior to installing or operating the system. CPS-

Pumps shall not be liable for physical injury, damage or delays

caused by a failure to observe the instructions for installation,

operation and maintenance contained in this manual.

Remember that every pump has the potential to be dangerous

because of the following factors:

• Parts are rotating at high speeds

• High pressures may be present

• High temperatures may be present

• Highly corrosive and/or toxic chemicals may be present

Paying constant attention to safety is always extremely impor-

tant. However, there are often situations that require special

attention. ese situations are indicated throughout this book

by the following symbols:

Maximum Lifting Speed: 15 feet/second.

If in a climate where the uid in the system could freeze, never

leave liquid in the pump. Drain the system completely. Dur-

ing winter months and cold weather, the liquid could freeze and

damage the system components. Always remember to drain the

casing assemblies complete.

Do not run the equipment dry or start the pump without the

proper prime (ooded system). Signicant damage can occur to

the unit if even run for a short time period without a fully lled

casing assembly.

Never operate the pump(s) for more than a short interval with

the discharge valve closed. e length of the interval depends

on several factors including the nature of the uid pumped and

it’s temperature. Contact CPS-Pumps Engineering for addi-

tional support if required.

Excessive pump noise or vibration may indicate a dangerous op-

erating condition. e pump(s) must be shutdown immediately.

Do not operate the pump and/or the system for an extended

period of time below the recommended minimum ow.

It is absolutely essential that the rotation of the motor be

checked before starting any pump in the system. Incorrect

rotation of the pump for even a short period of time can cause

severe damage to the pumping assembly.

If the liquid is hazardous, take all necessary precautions to avoid

damage and injury before emptying the pump casing.

Residual liquid may be found in the pump casing, suction and

discharge manifolds. Take the necessary precautions if the liq-

uid is hazardous, ammable, corrosive, poisonous, infected, etc.

Always lockout power to the driver before performing pump

maintenance.

Never operate the pump without the coupling guard (if sup-

plied) and all other safety devices correctly installed.

Do not apply heat to disassemble the pump or to remove the

impeller. Entrapped liquid could cause an explosion.

If any external leaks are found while pumping hazardous prod-

uct, immediately stop operations and repair.

WARNING – Hazards or unsafe practices which COULD result

in severe personal injury or death.

CAUTION – Hazards or unsafe practices which COULD result

in minor personal injury or product or property damage.

DANGER - Immediate hazards which WILL result in severe

personal injury or death.

5

IOM Manual: IOM-0000-CST IOM

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

www.cps-pumps.com

PUMP IDENTIFICATION

MANUFACTURER

CPS-Pumps

125 Morrison Drive

Rossville, TN 38066

United States of America

TYPE OF PUMP

e CPS-Pumps CST submersible turbine pump is a vertical

turbine, multi stage, Francis impeller design centrifugal pump.

DATE OF MANUFACTURE

e date of manufacture is indicated on the pump data plate.

INSTALLATION, OPERATION &

MAINTENANCE MANUAL IDEN-

TIFICATION

Prepared: January 01, 2018 Edition: 01

Revision: Date of Revision:

All pumps are identied by serial number, model number and

size. is information is stamped on a stainless steel identica-

tion plate which is permanently attached to the pump. Do not

remove this plate as it will be impossible to identify the pump

without it. Refer to the pump information in this manual for

specic information.

NAMEPLATE INFORMATION

STAGES : Number of stages within

pump

GPM : Rated capacity of pump

TDH : Rated Total Dynamic

Head of pump

RPM : Speed of pump

HP : HP of pump

IMPELLER : Impeller model of pump

DISCHARGE (IN) : Discharge size of pump in

inches

SUCTION (IN) : Suction size of pump in

inches

WARRANTY

CPS-Pumps guarantees that only high quality materials are

used in the construction of our pumps and that machining and

assembly are carried out to the highest standards.

e pumps are guaranteed against defective materials and/or

faulty craftsmanship for a period of twelve (12) months from

the date of startup or eighteen (18) months from shipment

whichever occurs rst.

Replacement of parts or of the pump itself can only be carried

out after careful examination of the pump by qualied person-

nel.

e warranty is not valid if third parties have tampered with the

pump. If the warranty security seal (which is uniquely bar-

coded) has been removed without PRIOR consent, warranty

consideration may be denied by CPS-Pumps.

is warranty does not cover parts subject to deterioration or

wear and tear (mechanical seals, pressure and vacuum gauges,

rubber or plastic items, bearings, etc.) or damage caused by

misuse or improper handling of the pump by the end user.

Parts replaced under warranty become the property of CPS-

Pumps.

Contact the CPS-Pumps’ factory:

CPS-Pumps

125 Morrison Drive

Rossville, TN 38066

United States Of America

Phone: (901) 850-5115

Fax: (901) 850-5119

www.cps-pumps.com

FIGURE 1 – Pump Data Plate (Discharge Head & Bell Tag)

MODEL : Model designation of

pump (8CKC-4)

SERIAL NUMBER : Serial Number of pump

unit (issued by Production

Control)

SERIAL NOMODEL

STAGES GPM TDH

RPM HP IMPELLER

DISCHARGE (IN) SUCTION (IN)

SERIAL #

MODEL #

6

www.cps-pumps.com IOM Manual: IOM-0000-CST

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

GENERAL INSTRUCTIONS

e pump and motor unit must be examined upon arrival to

ascertain any damage caused during shipment. If damaged

immediately notify the carrier and/or the sender. Check that

the goods correspond exactly to the description on the shipping

documents and report any dierences as soon as possible to the

sender. Always quote the pump type and serial number stamped

on the data plate.

e pumps must be used only for applications for which the

manufacturers have specied:

• e construction materials

• e operating conditions (ow, pressure, tempera-

ture, etc.)

• e eld of application

In case of doubt, contact CPS-Pumps.

Upon receipt of the pump, a visual check should be made to

determine if any damage has been incurred during transit or

shipment. e main areas to diligently inspect are:

• Broken or cracked bowl assembly, including the

motor bracket, motor, discharge head and discharge

anges

• Bent or damaged shafts

• Broken motor end bells, bent lifting eye bolts or

damaged conduit boxes on the driver

• Missing parts

Parts and/or accessories are sometimes wrapped individually

or fastened to the equipment. Coupling hubs are shipped in

separate boxes (sometimes housed under the coupling guard). If

any damage or loss has been incurred, promptly contact CPS-

Pumps and the freight company that delivered the equipment.

HANDLING AND TRANSPORT

METHOD OF TRANSPORT

e pump must be transported in the horizontal position

INSTALLATION

During installation and maintenance, all components must

be handled and transported securely by using suitable slings.

Handling must be carried out by specialized personnel to avoid

damage to the pump and persons. e lifting rings attached to

various components should be used exclusively to lift the com-

ponents for which they have been supplied.

Maximum lifting speed: 15 feet/second

It is important to exercise extreme care in handling and install-

ing all parts. Certain items are precision machined for proper

alignment and, if dropped, banged, sprung or mistreated in any

way, misalignment and malfunction will result. Other compo-

nents, such as the electrical cable, may be vulnerable to goug-

ing or scung. Parts which are too heavy to be lifted from the

transporting car or truck should be skidded slowly and carefully

to the ground to prevent damage. Never unload by dropping

parts directly from the carrier to the ground and never use ship-

ping crates for skids.

If the bowl assembly is strapped to an I-beam for support, do

not remove the bowl assembly from the I-beam support until

the bowl assembly is in the vertical orientation.

If job site conditions permit, you may be able to install directly

from the truck that delivered the pump. If not, move the com-

ponents to the installation area and lay them out in a clean and

protected space convenient to the work location. Column pipe

sections should be placed on suitable timbers to keep them out

of the dirt, arranged so that the coupling ends point toward the

wellhead. e bowl/motor assembly should be left on the skids

until lifted for installation. e power cable and motor leads

must receive special protection to avoid damage to the jacket or

insulation.

If installation cannot begin within a few days after delivery,

segregate and identify all components of the shipment so they

won’t be confused with other equipment arriving to the job site.

READ and FOLLOW the storage instructions carefully

because care of the pump during this period before installation

can be as important as maintenance after operation has begun.

Check all parts against the packing list to make sure nothing

is missing. It is much better to nd out now than during the

installation. Report any discrepancies immediately to CPS-

Pumps.

STORAGE

SHORT-TERM STORAGE

Normal packaging is designed to protect the pump during ship-

ment and for dry, indoor storage for up to two months or less.

If the pump is not to be installed or operated soon after deliv-

7

IOM Manual: IOM-0000-CST IOM

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

www.cps-pumps.com

ery, store the unit in a clean, dry place, having slow changes in

environmental conditions. Steps should be taken to protect the

pump against moisture, dirt and foreign particulate intrusion.

e procedure followed for this short-term storage is summa-

rized below:

Standard Protection for Shipment :

a. Loose unmounted items, including, but not limited

to, oilers, packing, coupling spacers, stilts and mechan-

ical seals are packaged in a water proof plastic bag and

placed under the coupling guard.

b. Inner surfaces of the bearing housing, shaft (area

through bearing housing) and bearings are coated with

Cortec VCI-329 rust inhibitor or equal.

c. Regreasable bearings are packed with grease (Exxon

Mobile Polyrex EM).

d. After a performance test, if required, the pump is

checked for drainage (some residual water may re-

main in the bowl assembly). en, internal surfaces of

ferrous casings, covers, ange faces and the impeller

surface are sprayed with Calgon Vestal Labs RP-743m,

or equal. Exposed shafts are taped with Polywrap.

e. Flange faces are protected with plastic covers se-

cured with plastic drive bolts. 3/16 in (7.8 mm) steel or

1/4 in (6.3 mm) wood covers with rubber gaskets, steel

bolts and nuts are available at extra cost.

f. All assemblies are bolted to a wood skid which con-

nes the assembly within the perimeter of the skid.

g. Assemblies with special paint are protected with a

plastic wrap.

h. All assemblies having external piping (seal ush and

cooling water plans), etc. are packaged and braced to

withstand normal handling during shipment. In some

cases components may be disassembled for shipment.

e pump must be stored in a covered, dry location.

It is recommended that the following procedure is taken:

1. Ensure that the suction and discharge anges are

covered and secured with cardboard, plastic or wood to

prevent foreign objects from entering the pump.

2. If the pump is to be stored outdoors with no

overhead covering, cover the unit with a tarp or other

suitable covering.

LONG-TERM STORAGE

Long-term storage is dened as more than two months, but less

than 12 months. e procedure CPS-Pumps follows for long-

term storage of pumps is given below. ese procedures are in

addition to the short-term procedure above.

Solid wood skids are utilized. Holes are drilled in the skid to

accommodate the anchor bolt holes in the base plate, or the cas-

ing and bearing housing feet holes on assemblies less base plate.

Tackwrap sheeting is then placed on top of the skid and the

pump assembly is placed on top of the Tackwrap. Metal bolts

with washers and rubber bushings are inserted through the skid,

the Tackwrap and the assembly from the bottom of the skid and

are then secured with hex nuts. When the nuts are “snugged”

down to the top of the base plate or casing and bearing hous-

ing feet, the rubber bushing is expanded, sealing the hole from

the atmosphere. Desiccant bags are placed on the Tackwrap.

e Tackwrap is drawn up around the assembly and hermeti-

cally (heat) sealed across the top. e assembly is completely

sealed from the atmosphere and the desiccant will absorb any

entrapped moisture. A solid wood box is then used to cover the

assembly to provide protection from the elements and handling.

is packaging will provide protection up to twelve months

without damage to mechanical seals, bearings, lip seals, etc. due

to humidity, salt laden air, dust, etc. After unpacking, protec-

tion will be the responsibility of the user. Addition of oil to the

bearing housing will remove the inhibitor. If units are to be idle

for extended periods after addition of lubricants, inhibitor oils

and greases should be used.

Every three months, the shaft should be rotated approximately

10 revolutions.

INSTALLATION & ALIGNMENT

PREPARATION

Before installing the pump, clean the discharge ange thor-

oughly. Remove any protective coatings that may be on the

shaft.

If the pump is coming from Short-Term or Long-Term storage

and has been prepared for storage in the manner above, remove

all grease and/or oil from the bearings. e bearings should be

ushed with an appropriate uid to remove any contamination

prior to placing the pump into service.

8

www.cps-pumps.com IOM Manual: IOM-0000-CST

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

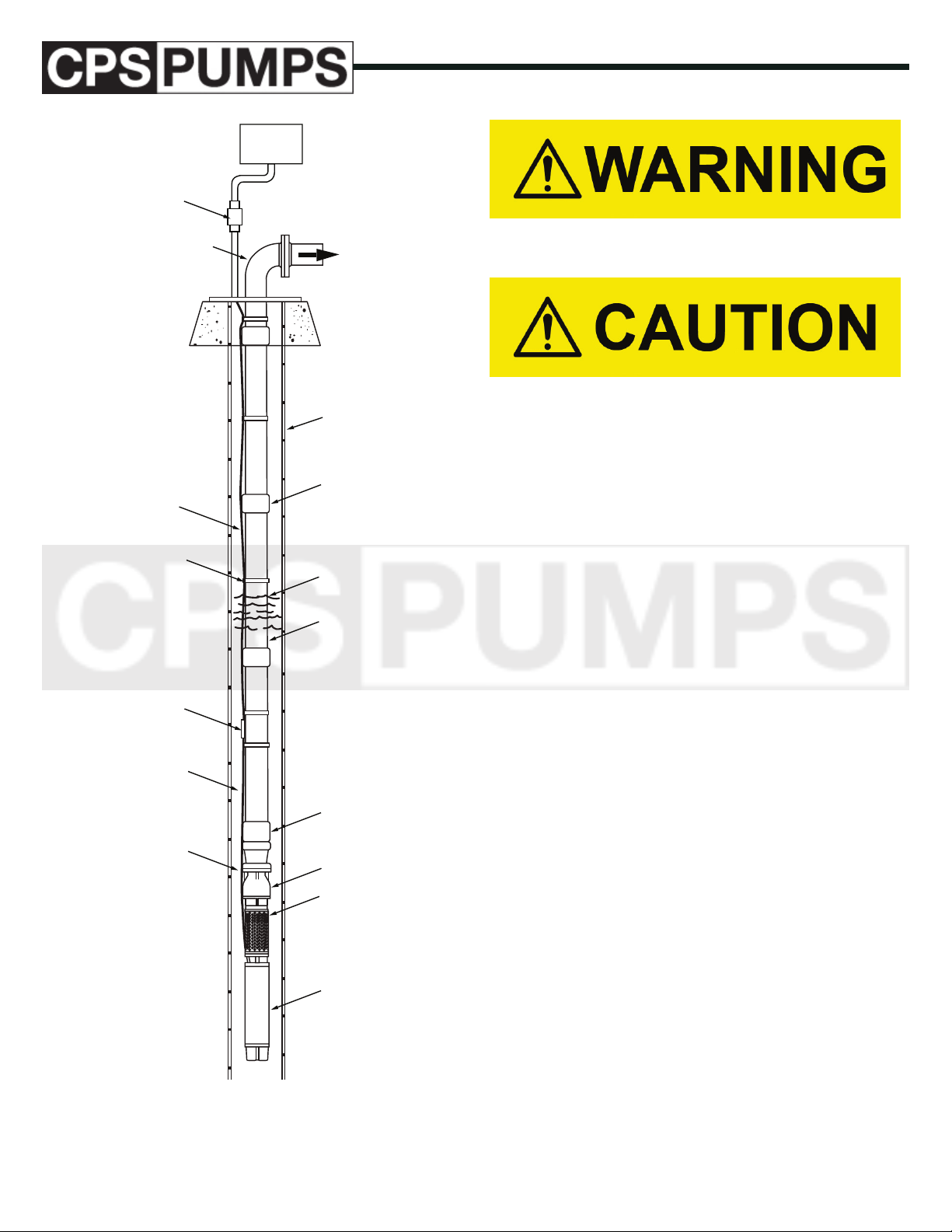

e height of the equipment must be sucient to accommodate the

longest component to be installed.

ELECTRICAL

PANEL

TERMINAL BOX

DISCHARGE ELBOW

DROP CABLE

CABLE CLAMP

WATER LEVEL

COLUMN PIPE

COUPLING

WELL CASING

DISCHARGE TO

ABOVE GROUND

PIPING SYSTEM

COLUMN PIPE

CHECK VALVE

PUMP

PUMP SUCTION

SUBMERSIBLE MOTOR

CABLE SPLICE

MOTOR LEADS

MOTOR LEADS

SHIELD

FIGURE 2 – Submersible Turbine Installation

Equipment for removal of the pump after it has been in operation

must be capable of lifting the above weight plus the weight of the

water in the column pipe (if applicable).

RECEIVING THE PUMP

Immediately upon receipt, check that the number of boxes and

pieces received is the same as shown on the freight bills. Check

for shipping damage. Note any shortages or damages on the

carrier’s copy of the freight bill prior to signing. Report these

damages or shortages to CPS-Pumps or your local factory rep-

resentative immediately.

If facilities are not available for lifting the materials o the car-

rier’s vehicle, use skids for unloading rather than allowing the

parts to drop to the ground. Even though a pump is made up

of heavy steel parts, it is a piece of machinery and it is essential

that its parts be handled with care. It is extremely easy to dam-

age shafting, threaded parts, and mating surfaces of parts which

must t together. Even a minor bend in one piece of shafting

can cause a pump to vibrate excessively; thus shortening the life

of the pump drastically.

ELECTRICAL

CONSIDERATIONS

A major portion of the work associated with a submersible

pump is the electrical consideration. It is not the intent of this

manual to provide detailed instructions for the electrical work.

e services of a competent power electrician or electrical con-

tractor will be required. All work must be done in accordance

with applicable codes, the pump motor manual, instructions

for other equipment that is part of the installation and sound

electrical practices. e electrical work performed will include

but not be limited to the following:

9

IOM Manual: IOM-0000-CST IOM

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

www.cps-pumps.com

PROVIDING A PROPER POWER

SUPPLY

e power supply must have an adequate capacity (KVA) and

must be of the proper voltage, phase and frequency to match

the motor requirements. ree phase systems should have a full

three phase supply utilizing three individual transformers or one

three phase transformer. Open delta or wye systems using only

two transformers must be de-rated. Such installations are also

more likely to suer from phase unbalance problems. Unbal-

anced voltage on three phase power sources will cause unbal-

anced motor currents. Motor current unbalances in excess of

5% can be expected to cause excessive heating in the motor, re-

sulting in poor motor performance, nuisance overload tripping,

and premature failure of the motor. If the power company can-

not guarantee less than 5 percent unbalance, the use of the next

larger size motor and the next larger size cable is recommended.

Contact CPS-Pumps for further information. e warranty can

be voided by the use of an improper power supply.

SELECTING AND INSTALLING A

PROPER MOTOR CONTROL SYS-

TEM

e motor control system must be sized to accommodate the

pump motor. e control system should protect the motor

from damage from abnormal conditions such as low voltage,

high voltage, overload, excessive current unbalance, phase loss,

overheating, lightening, etc. Single phase 3-wire motors require

a special submersible motor control box. A standard magnetic

starter with special extra-quick overload relays can be used

for three phase motors; however, a control which is designed

specially for submersible pumps is recommended. Overload

protection and fuse requirements are given in the pump motor

manual. e warranty can be voided by the use of an improper

control system.

SELECTING THE PROPER DROP

CABLE

Submersible pump drop cable is a special waterproof, heavily in-

sulated cable made especially for this use. e cable size is based

on the motor horsepower and voltage, and the distance from the

motor to the control panel. Cable size selection charts are given

in the motor manual. Failure to use the proper size and type

cable can void the warranty.

MAKING THE SPLICE BETWEEN

THE MOTOR LEADS AND THE

DROP CABLE

A water-tight splice must be made to connect the drop cable to

the motor leads. See PRE-INSTALLATION MOTOR AND

DROP CABLE CHECKS AND PREPARATION on page

10.

PROPERLY GROUNDING THE

UNIT

All units must be grounded in accordance with applicable codes.

Failure to ground the unit properly can result in serious or fatal

shock.

MAKING AND EVALUATING ELECTRICAL TESTS.

Installation, troubleshooting, and maintenance of a submers-

ible pump will require performing and evaluating electrical tests

such as resistance, continuity, voltage, current, current unbal-

ance, etc. Some of these tests are described in ELECTRICAL

TESTS on page 18. e use of electrical testing as a trouble-

shooting tool can very often quickly identify the problem and

prevent the unnecessary time and expense of pulling the pump.

SELECTING AND INSTALLING

AUXILIARY EQUIPMENT

A low water level switch is recommended and can be supplied

as an option from CPS-Pumps. e installation will also most

likely require auxiliary equipment such as ow switches, pres-

sure switches, level switches, time switches, etc. e need for

this equipment must be evaluated based on the requirements

of each installation and the proper equipment must be selected

and installed.

Since most submersible pump service problems are electri-

cal, it is imperative that the electrical work be done properly

using high quality materials if the pump is to provide the long,

trouble-free life for which it is designed.

10

www.cps-pumps.com IOM Manual: IOM-0000-CST

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

PRE-INSTALLATION MOTOR AND

DROP CABLE CHECKS AND

PREPARATION

prox. 1 minute) running test in a tank of water. If a

tank is not available, “bump” the motor (do not exceed

2 seconds) to check that it will run.

Do not use motor leads to lift or handle the motor. e motor leads

are easily damaged. ey should be protected and handled with care

at all times.

e following tests can usually be done in the shop provided the

motor leads and drop cable are protected and handled carefully

during transportation to the installation site.

MOTOR SERVICING

Consult the motor manual and perform any pre-installation

servicing that is required. Some motors may require lling with

oil or water.

ATTACHING THE MOTOR TO

THE PUMP

If the pump motor has not already been attached to the pump,

attach it per the instructions given in INSTALLING THE

PUMP on page 11. For longer units, it may be more practical to

assemble the pump to the motor in the vertical position at the

installation site.

TESTING BEFORE SPLICING

DROP CABLE TO MOTOR LEADS

Perform the following tests before making the splice between

the motor leads and the drop cable. Instructions for performing

resistance tests and evaluating the results are given in ELEC-

TRICAL TESTS on page 18.

MOTOR TESTS

Measure the resistance between each motor lead and ground

with the motor submerged in water. See ELECTRICAL

TESTS on page 18.

• Measure the resistance of the motor windings. See

Section ELECTRICAL TESTS on page 18.

• Record the values for future reference.

• If possible, give the motor/pump unit a short (ap-

Ground the unit when testing. Failure to ground the unit properly

can result in serious or fatal shock. Also, the high starting torque

of the motor will cause it to “kick” when power is applied. e unit

should be restrained suciently to prevent damage to the equipment

or personal injury.

DROP CABLE TESTS

• Measure the resistance between the cable conductors

and ground with the cable submerged in water. See

ELECTRICAL TESTS on page 18.

SPLICING DROP CABLE TO MO-

TOR LEADS

A waterproof splice must be made to connect the drop cable to

the motor leads. A properly made splice will last the life of the

pump. An improperly made splice will become a service prob-

lem. Make the splice per instructions supplied with the drop

cable or per instructions in the pump motor manual. e splice

should be located above the pump bowl. See FIGURE 3. It

should be as compact as possible. A compact splice is less likely

to be damaged as the pump is being lowered into the well.

TESTING AFTER SPLICING DROP

CABLE TO MOTOR LEADS

Perform the following tests after making the splice, but before

lowering the pump into the well.

• Check that the splice is waterproof by immersing it

in a container of water for approximately one hour and

then taking resistance readings between each cable

conductor and the water. See ELECTRICAL TESTS

on page 18.

• Measure the total resistance of the complete drop

cable and motor circuit to insure that a good splice

was made. Record the values for future reference. See

ELECTRICAL TESTS on page 18.

11

IOM Manual: IOM-0000-CST IOM

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

www.cps-pumps.com

INSTALLING THE PUMP should remain attached during uprighting of very long units.

Check that all of the steps below have been completed:

• Assemble pump and motor. See page 10.

• Install the bottom piece of column in the pump dis-

charge. Do not lower the unit into the well at this time.

• Complete PRE-INSTALLATION MOTOR AND

DROP CABLE CHECKS AND PREPARATION

on page 10. (testing before splicing cable).

• Complete PRE-INSTALLATION MOTOR AND

DROP CABLE CHECKS AND PREPARATION

on page 10. (cable splicing).

• Complete PRE-INSTALLATION MOTOR AND

DROP CABLE CHECKS AND PREPARATION

on page 10. (testing after splicing cable).

Temporarily connect the drop cable to the electric panel and

start the pump for not more than 2 seconds to check that it will

run.

e pump motor will exert a torque that will tend to unscrew

threaded column pipe connections. For this reason, threaded column

joints must be tightened to a torque of at least 10 ft.-lbs. per rated

HP of the motor (example, 500 ft.-lbs. for a 50 HP motor). If the

pump installation rig cannot produce this amount of torque, it will

be necessary to weld each joint or use some other method to keep the

joints from unscrewing.

If a check valve is to be used and it is not already installed,

install the check valve on the pump. See FIGURE 3. Clean the

threads and apply thread sealant. Check that the arrow on the

check valve is pointed in the direction of ow. Check that the

valve disc or pop- pet is not stuck in the open or closed position.

Tighten the valve securely. See Caution above.

e method of installing the pump, motor, and bottom piece

of column will vary depending on the size and length of these

components:

• For smaller units, the bottom section of column can

be screwed into the pump and the entire pump/ motor/

column assembly handled as one piece.

• For larger units, it may be more practical to install

the pump/motor assembly and the bottom piece of col-

umn pipe separately. A special elevator or clamp may

be required to hold the pump/motor assembly in place

while the rst piece of column is being screwed into the

pump discharge.

• For very large units or extremely long units where

the pump and motor have not been assembled, it may

be desirable to lift the pump and motor separately and

assemble the motor to the pump in the vertical posi-

tion. See ASSEMBLY OF PUMP AND MOTOR

on page 10. is method requires a special elevator

or clamp to hold the motor in place while the pump is

being connected and a special elevator or clamp to hold

the pump/motor assembly in place while the rst piece

of column is being installed. Eyebolts or some other

means of lifting the motor will also be required.

Rig the rst piece of equipment for lifting, hoist it into the

vertical position, and position it over the well. Do not allow the

equipment to drag along the ground as it is lifted. Special care

must be taken when lifting long pumps or pump/motor assem-

blies, since they may sag excessively in the middle when raised

at one end and permanently deform the unit. e shipping skid

Ground the unit when testing. Failure to ground the unit properly

can result in serious or fatal shock. Also the high starting torque of

the motor will cause it to “kick” when power is applied. e unit

should be restrained suciently to prevent equipment damage or

personal injury.

On 3-phase units, check for proper rotation during this test. If

the unit kicks clockwise (when viewed from above), the rota-

tion is correct and the wires should be tagged so that they can

be reconnected to the same terminals in the panel. If the unit

kicks counter-clockwise, interchange any two of the three wires

before tagging them. DISCONNECT THE CABLE FROM

THE PANEL.

Install a cable clamp on each side of the cable splice. See FIG-

URE 3. Be careful not to damage the cable. If an air line is to

be installed, route it beside the cable, making sure that it is not

pinched by the clamps. If there is any danger that the splice will

rub against the well casing during installation, it should be pro-

tected by thick rubber chang pads or by a steel shield. Check

that the grounding system is in place.

12

www.cps-pumps.com IOM Manual: IOM-0000-CST

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

Failure to ground the unit can result in serious or fatal shock. Refer

to electrical code requirements.

Slowly lower the unit into the well (or sump) adding joints of

column pipe as the unit is lowered. Tighten each joint securely.

See note above. Remove slack from the drop cable and attach

a cable clamp approximately every 10 feet. For units with large

heavy drop cable, additional cable support can be obtained by

installing a clamp immediately above each pipe coupling. Line

up the cable on one side of the pump and maintain as much

clearance as possible on that side when lowering the pump in

the well.

Be extremely careful not to scrape or damage the drop cable,

drop cable splice or grounding system when lowering the pump.

Hold the drop cable up away from the well casing as the pump is

being lowered. Never force the pump into the casing.

After the last piece of column pipe has been installed, install the

discharge elbow. Install a cable clamp between the last column

pipe coupling and the discharge elbow surface plate. Route the

drop cable and grounding system thru the large threaded hole

in the surface plate. Route the air line (if used) thru one of the

smaller threaded holes in the surface plate. e remaining small

threaded hole is for connection of a well vent or other acces-

sories. All of these holes are threaded with standard NPT pipe

threads. If a gasket is required between the discharge elbow and

its mounting surface, the gasket should be placed on the foun-

dation prior to installing the discharge elbow.

After the discharge elbow has been properly tightened, carefully

rotate the entire unit in the well until the discharge ange is

facing in the desired direction. Push the unit to one side of the

well, providing the maximum clearance for the drop cable when

rotating the unit.

Slowly lower the discharge elbow onto its mounting surface.

BE CAREFUL NOT TO DAMAGE THE GROUNDING

SYSTEM OR PINCH THE DROP CABLE BETWEEN

THE SURFACE PLATE AND THE WELL CASING. If a

gasket or other sealing device is used, be sure that it is aligned

properly and that it is not damaged. Install the discharge elbow

mounting bolts.

Before connecting the drop cable to the control panel:

• Take a resistance reading between the drop cable

conductors and ground to assure that the insulation on

the cable or splice was not damaged during installation.

See ELECTRICAL TESTS on page 18.

• Measure the resistance of the drop cable and motor

circuit. See ELECTRICAL TESTS on page 22. Com-

pare these readings with those taken in PRE-INSTAL-

LATION MOTOR AND DROP CABLE CHECKS

AND PREPARATION on page 10 to assure that the

splice is still intact.

Make the electrical connection between the drop cable and

the control panel. It may be desirable to use a terminal box at

the discharge to simplify the electrical work required when

the pump is pulled. See FIGURE 3. Be sure that the unit is

grounded properly.

Be sure to connect the leads as they were marked previously in

the procedure.

STARTING THE PUMP

Initial start-up and testing may require starting and stopping

the pump several times. BE SURE TO ALLOW ADEQUATE

COOLING OFF PERIOD BETWEEN STARTS. Consult the

motor manual. If no information is given, a good rule-of-thumb is

to allow a minimum of 15 minutes between starts.

For initial start-up allow the water to be pumped out onto the

ground. A throttle valve in the discharge line is recommended.

Position the throttle valve approximately one-fourth open for

start-up of the pump. is will prevent surging the well or the

pump during start-up.

If the pump has been in the well for several days before the

start-up, check the resistance between the cable conductor and

ground to assure that water has not penetrated the splice or the

cable insulation. See ELECTRICAL TESTS on page 18.

Clamp the tongs of a clamp-on type ammeter around one power

lead to the pump. Set the ammeter on the maximum scale.

After the motor starts, it can be reset to a lower scale as desired.

Refer to the motor manual and determine the normal operating

amps for the installed motor.

Start the pump and observe and record the current readings on

each conductor of the power lead. If the current exceeds the

normal value determined in the motor manual, stop the pump

immediately. A high current reading indicates that something

is wrong. Among the potential problems are:

13

IOM Manual: IOM-0000-CST IOM

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

www.cps-pumps.com

• Incorrect pump rotation (3 phase only)

• Improper voltage

• Sand locked pump

• Improper cable size or leak in cable

• Mechanical damage

In any case, the problem must be corrected before the pump can

be operated.

On three phase units if water does not appear within one min-

ute (deeper settings may require approximately one half minute

per 100 ft. setting) the motor may be running backwards. Stop

the pump and interchange any two of the three cable connec-

tions. If there is any doubt about the proper rotation, run the

motor in one direction and then the other. e rotation that

gives the highest pressure and ow is always the correct one.

Check the voltage. e voltage when the pump is running

should be within 5% of the pump motor nameplate voltage.

Open the throttle valve. If a ow meter is available, open the

throttle valve to rated ow of the pump. If sand appears in the

water, throttle the pump at approximately 80% of full ow until

the sand clears. If excessive noise develops, pressure uctuates,

or water appears foamy white, the pump is probably cavitating

and the ow should be throttled until the noise diminishes, the

pressure remains steady, and the water is clear.

On three phase units check for current unbalance. Details of

the current unbalance test are given in ELECTRICAL TESTS

on page 18. THE MAXIMUM ALLOWABLE CURRENT

UNBALANCE IS 5%. If the current unbalance exceeds 5% af-

ter rolling the leads and connecting them for the lowest unbal-

ance, the pump should be stopped and corrective action taken.

Current unbalance in excess of 5% can be expected to cause ex-

cessive heating in the motor and premature failure. Operation

with a current unbalance in excess of 5% will void the warranty.

After the unit is operating properly, a performance test should

be considered. See ROUTINE OPERATION AND MAIN-

TENANCE on page 15. If a performance test is conducted

when the pump is new, subsequent tests can be used to deter-

mine the degree of wear or deterioration of the pump without

removing it from the well.

After the unit has been in operation for approximately one

week, perform the routine tests listed in ROUTINE OPERA-

TION AND MAINTENANCE on page 13.

ROUTINE OPERATION AND

MAINTENANCE

A submersible pump, properly installed in a clean well, will run

for a long period of time with a minimum of attention. How-

ever, conditions are not always ideal and can change for the

worse in the course of time. Submersible pumps usually run

unattended and automatic control devices are used to stop and

start the unit and to protect it from abnormal conditions such as

overloads, line faults, etc. It is important that these automatic

devices be adjusted properly and maintained in good working

condition. Failure of an automatic control can easily cause the

failure of a pump that is in excellent condition. Unfortunately

these protective devices may not protect the installation against

all of the hazards that may be encountered.

In order to assure that potential problems are identied and

corrected as soon as possible, a program for regular inspection

and testing of the unit should be established. e frequency of

inspection and testing will vary depending on the complexity of

the controls, the consequences of a failure, the cost of making

the inspections and tests, the age and condition of the unit,

the results of previous inspections and tests, and the operating

philosophy of the owner.

ROUTINE INSPECTIONS

On a periodic basis, the unit should be given a quick inspection.

e inspection should include the following:

• Check for any obviously abnormal conditions such as

gross leakage or gross damage.

• Check that the unit is not making excessive noise.

Check the electric panel for alarms, blown fuses, etc.

• Check the electrical system for signs of overheating

or other abnormal conditions.

Any problems noted should be carefully investigated and cor-

rected immediately.

ROUTINE TESTING

e following tests should be performed on a periodic basis and

at any time the pump is started up after a prolonged shutdown.

All test readings should be recorded so that they can be used for

comparison. Gradual changes can indicate a gradual deterio-

ration. Large changes can indicate rapid deterioration with a

potential for sudden failure in the near future.

• Check the resistance between the drop cable conduc-

tor and ground. See FIGURE 5.

• Measure the resistance of the drop cable and motor

windings. See ELECTRICAL TESTS on page 18.

• Measure the voltage and the current. Compare the

readings with previous readings. If either the voltage

or the current has changed substantially, check the cur-

rent unbalance. See ELECTRICAL TESTS on page

18. Excessive current is an indication of a problem

somewhere in the system which should be corrected

immediately.

• Measure the water level in the well. A drop in the

14

www.cps-pumps.com IOM Manual: IOM-0000-CST

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

water level may indicate over pumping of the well or

clogging of the well screen which can result in dam-

age to the well, pump, and the motor. Be sure that the

pump is always under the water. Lowering the pump

by installing additional column pipe should be con-

sidered if the pump suction is submerged 5 feet or less

when pumping.

PERFORMANCE TESTING

Performance testing of the pump consists of measuring and

recording the following:

• Discharge pressure (feet) (feet = psi x 2.31 for water)

• Pumping level (feet) (distance from the center of the

discharge pressure gage to the water level when pump-

ing)

• Flow (gallons per minute)

• Input power (kilowatts)

• Line voltage on all phases (volts)

• Current in all three phases (amps)

e above information should be taken at four operating points:

shuto, slightly less than rated ow, rated ow and slightly

greater than rated ow.

Do not operate the pump at shuto for more than 30 seconds as

this can cause the motor to overheat and burnout.

Record the above information and retain it for comparison with

previous or subsequent performance tests.

e following formulas will be helpful in evaluating the read-

ings taken.

Pump Output HP

(Water Horsepower) = Q x W x SG

3960

Where:

Q = ow in gallons/minute

H = total head in feet

SG = Specic Gravity

Power Input HP = KW input x 1.34

Wire-to-Water = Pump Output HP

Eciency Pump Input HP

e pump output horsepower is a measure of pump perfor-

mance. Over the lifetime of the pump the output horsepower

will decrease due to wear. By comparing output horsepower

readings taken over a period of time the rate and degree of wear

of the pump can be deter- mined. Note that both head (pres-

sure) and ow are included in the pump output horsepower

formula. Be careful not to try to draw conclusions about the

pump’s performance by considering pressure alone or ow

alone. For example, consider what happens if the pumping level

in the well changes. e pump output horsepower will remain

essentially the same and the ow will change. is change in

ow could be misinterpreted as a change in pump performance.

e wire-to-water eciency is a measure of how well the pump

and motor unit are utilizing the power consumed.

TROUBLESHOOTING

When properly installed and operating in non-abrasive, non-

corrosive water a pump is a relatively long lived piece of machin-

ery, requiring a minimum of attention. However, machinery is

subject to wear. e most common causes of improper opera-

tion are given below.

ese include problems created by wear and other adverse con-

ditions. Note that most of these problems require removal of

the pump from the well in order to correct the problem. Con-

tact CPS-Pumps or your representative for this type of service.

15

IOM Manual: IOM-0000-CST IOM

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

www.cps-pumps.com

POSSIBLE EFFECT

No liquid delivered

Not enough liquid delivered

Not enough discharge pressure

Loss of liquid after starting

Pump operating for a short time, then stops

Pump is pulling high horsepower

Driver running hot

Excessive vibration

Cavitation noise from pump

Pump bearings running hot

PROBLEM

Suction lift too high

Discharge head too high

Rotational speed too low

Incorrect direction of rotation

Impeller plugged/impeller partially blocked by debris

Air leak in discharge line

Insucient Net Positive Suction Pressure Available (NPSHA)

Damaged impeller

Defective packing

Inlet pipe not submerged enough

Impeller diameter too small

Obstruction in water passageways

Entrained air or gas in liquid

Discharge head lower than previously thought

Specic gravity of liquid higher than previously thought

Viscosity of liquid higher than previously thought

Bent or damaged shaft

Bearings worn

Misalignment of pump and driver

Defect in driver

Voltage and/or frequency lower than previously thought

Rotor assembly binding

Rotational speed too high

16

www.cps-pumps.com IOM Manual: IOM-0000-CST

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

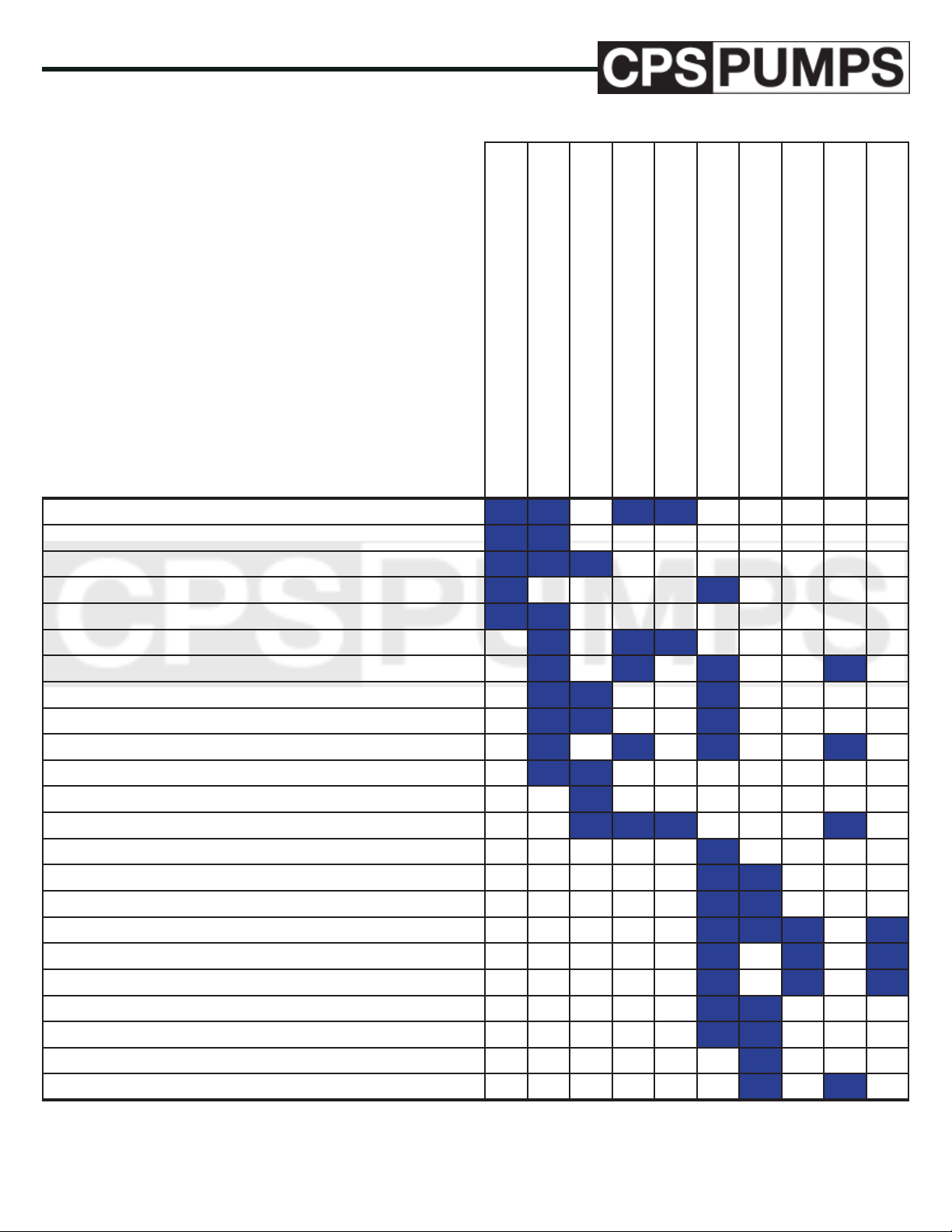

PROBLEM POSSIBLE CAUSE RECOMMENDED REMEDY

Problem #1

Pump not reaching design ow rate.

1.1

Insucient NPSHA. (Noise may not be

present)

Recalculate NPSH available. It must

be greater than the NPSH required by

pump at desired ow. If not, redesign

suction piping, holding number of

elbows and number of planes to a mini-

mum to avoid adverse ow rotation as it

approaches the impeller.

1.2

System head greater than anticipated.

Reduce system head by increasing pipe

size and/ than or reducing number of

ttings. Increase impeller diameter.

NOTE: Increasing impeller diameter

may require use of a larger motor.

1.3

Entrained air.

Air leak from atmosphere on suction

side.

1. Check suction line gaskets and

threads for tightness.

2. If vortex formation is observed in suc-

tion tank, install vortex breaker.

3. Check for minimum submergence.

1.4

Entrained gas from process.

Process generated gases may require

larger pumps.

1.5

Speed too low.

Check motor speed against design

speed.

1.6

Direction of rotation wrong.

After conrming wrong rotation,

reverse any two of three leads on a three

phase motor. e pump should be

disassembled and inspected before it is

restarted.

1.7

Impeller too small.

Replace with proper diameter impeller.

NOTE: Increasing impeller diameter

may require use of a larger motor.

1.8

Impeller clearance too large.

Replace impeller and/or case wear rings.

1.9

Plugged impeller, suction line or casing

which may be due to large solids.

1. Reduce length of suction when pos-

sible.

2. Reduce solids in the process uid

when possible.

3. Consider larger pump.

1.10

Wet end parts (bowl, impeller) worn,

corroded or missing.

Replace part or parts.

Problem #2.0

Pump not reaching design head

(TDH).

2.1

Refer to possible causes under Problem

#1.0.

Refer to remedies listed under Problem

#1.0 and #3.0.

Problem #3.0

No discharge or ow

3.1

Not properly primed.

Repeat priming operation, recheck

instructions. If pump has run dry, disas-

semble and inspect the pump before

operation.

17

IOM Manual: IOM-0000-CST IOM

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

www.cps-pumps.com

PROBLEM POSSIBLE CAUSE RECOMMENDED REMEDY

Cont. Problem #3.0

No discharge or ow

3.2

Direction of rotation wrong.

After conrming wrong rotation,

reverse any two of three leads on a three

phase motor. e pump should be disas-

sembled and inspected before operation.

3.3

Plugged impeller, suction line or casing

which may be due to a brous product

or large solids.

Refer to recommended remedy under

Problem #1.0, Item #1.9.

3.4

Damaged pump shaft, impeller.

Replace damaged parts.

Problem #4.0

Pump operates for short period, then

loses prime.

4.1

Insucient NPSHA.

Refer to recommended remedy under

Problem #1.0, Item #1.1.

4.2

Entrained air.

Air leak from atmosphere on suction

side. Refer to recommended remedy

under Problem #1.0, Item #1.1.

Problem #5.0

Excessive noise from wet end.

5.1

Cavitation - insucient NPSH avail-

able.

Refer to recommended remedy under

Problem #1.0, Item #1.1.

5.2

Abnormal uid rotation due to complex

suction piping.

Redesign suction piping, holder number

of elbows and number of planes to a

minimum to avoid adverse uid rotation

as it approaches the impeller.

5.3

Impeller rubbing.

1. Replace impeller and/or case wear

rings.

2. Check outboard bearing assembly for

axial end play.

Problem #6.0

Pump will not run.

6.1

No power to control box.

Refer to ELECTRICAL TESTS

6.2

Motor protection device tripped.

Refer to ELECTRICAL TESTS

6.3

Blown fuse.

Refer to ELECTRICAL TESTS

6.4

Open circuit in cable, splice or motor

winding.

Refer to ELECTRICAL TESTS

6.5

Control box malfunction.

Refer to ELECTRICAL TESTS

18

www.cps-pumps.com IOM Manual: IOM-0000-CST

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

PROBLEM POSSIBLE CAUSE RECOMMENDED REMEDY

Problem #7.0

Overload Protector Trips

7.1

Incorrect control box.

Replace with correct control box.

7.2

Incorrect, loose or corroded electrical

connections.

Replace defective item. Refer to ELEC-

TRICAL TESTS.

7.3

Incorrect voltage.

Correct line voltage.

7.4

Current overload.

Check for:

1. Tight motor or pump bearing.

2. Pump clogged with sand.

3. Unbalanced voltage.

4. Grounded cable, splice or motor

winding. Refer to ELECTRICAL

TESTS.

5. Low Voltage.

6. Insucient cooling of motor.

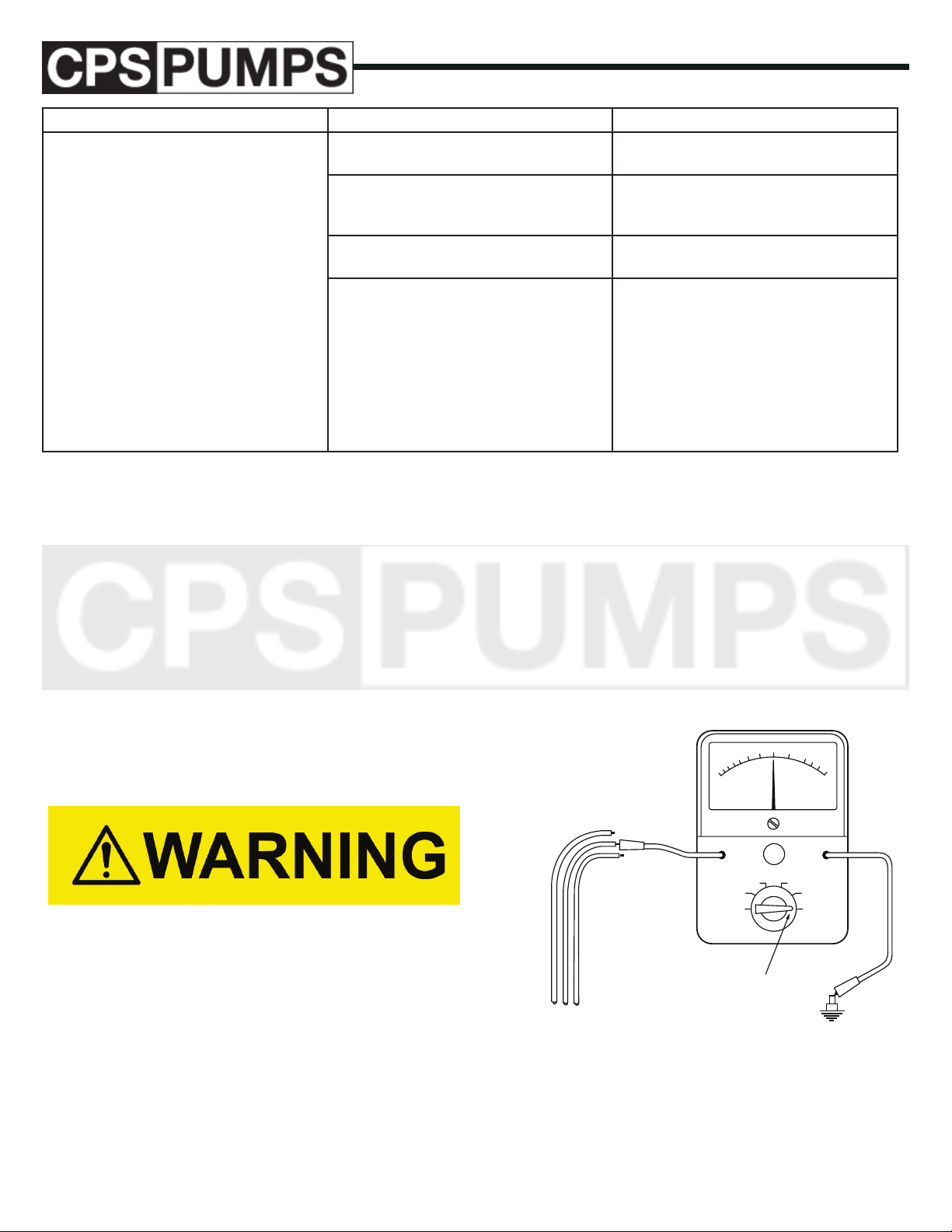

ELECTRICAL TESTS

MEASURING INSULATION RESIS-

TANCE (GROUND TEST)

e condition of the insulation around a conductor can be

determined by measuring the electrical resistance between the

conductor and ground. is measurement can be made with

a meggar or an ohm-meter. e value is stated in ohms or

megohms (ohms x 1,000,000). High ohm values indicate good

insulation.

e basic procedure for measuring insulation resistance is given

below:

Turn o all power and disconnect the leads to be tested from the

electrical panel.

Do not touch any bare wires or allow bare wires to come in con-

tact with the ground or metal. False readings will result.

If the meter needle is at either extreme end of the scale, a more

accurate reading can be obtained by switching the selector

switch to another scale. Re-zero the meter each time the selec-

tor switch is moved.

e readings obtained from drop cables and motor leads should

be within the range specied in FIGURE 5. Low readings

indicate that the motor windings are grounded or that the cable

or splice insulation is damaged. If low or marginal readings are

obtained on a new installation the problem should be corrected

before proceeding with the installation.

Failure to turn o the power will damage the meter and can cause

serious or fatal shock.

Failure to disconnect the leads can result in false readings.

Set the meter selector knob to RX 100K or RX 100,000. (Some

meters may not have RX 100K in which case RX 10K or RX

10,000 scale can be used.) Clip the meter leads together and

adjust the meter to zero.

Unclip the leads and attach them. See FIGURE 4.

OHMS

ZERO

OHMS

OHMS

ZERO

OHMS

DROP CABLE

OR

MOTOR LEADS

DROP CABLE

OR

MOTOR LEADS

SINGLE PHASE, 2 WIRE - MEASURE BETWEEN TWO WIRES

SINGLE PHASE, 3 WIRE - MEASURE BETWEEN BLACK AND

THREE PHASE - MEASURE BETWEEN EACH PAIR, AB, AC

YELLOW AND THE MEASURE

BETWEEN RED AND YELLOW

GROUND

SET SELECTOR

KNOB AT

R x 100K

SET SELECTOR

KNOB AT R x 1

R x 100K

R x 1

R x 10

R x 100 R x 1000

R x 10K

10

20

25

5

2

0

R x 100K

R x 1

R x 10

R x 100 R x 1000

R x 10K

FIGURE 4 – Measuring Insulation Resistance

19

IOM Manual: IOM-0000-CST IOM

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

www.cps-pumps.com

Insulation resistance does not vary with rating. All motors of all

HP, voltage and phase rating have the same insulation resis-

tance ranges.

CONDITION OF MOTORS AND LEADS OHMS MEGOHMS

METER READING

R x 100K

or

R x 100,000

scale

R x 10K

orR x 10,000

scale

BENCH TESTS

• A new motor (without drop cable)

• A used motor which can be reinstalled in the

well

• Cable splice after immersion for one hour in

water

20,000,000+

10,000,000+

2,000,000+

20+

10+

2+

200+

100+

20+

2000 + or 2K +

1000 + or 1K +

200+

WELL TESTS (ohm readings are for drop cable

plus motor)

• A new motor or used motor in good condition.

• A motor in reasonably good condition.

• A motor which may have been damaged by

lightning or with damaged leads. Do not pull the

pump for this reason.

• A motor which denitely has been damaged

or with damaged cable. e pump should be

pulled and repairs made to the cable or the motor

replaced. e motor will not fail for this reason

alone, but will probably not operate for long.

• A motor which has failed or with completely

destroyed cable insulation. e pump must

be pulled and the cable repaired or the motor

replaced.

2,000,000 +

500,000-2,000,000

20,000-500,000

10,000-20,000

less than 10,000

2+

0.5-2.0

0.02-0.5

0.01-0.02

0-0.01

20+

5-20

0.2-5

0.1-0.2

0-0.1

200+

50-200

2-50

1-2

0-1

+ Indicates that the reading should be the value shown or

greater. Higher readings indicate better insulation.

FIGURE 5 – Nominal Insulation Resistance Values Between

All Legs & Ground

20

www.cps-pumps.com IOM Manual: IOM-0000-CST

Series CST: Submersible Turbine

01/01/2018 - Edition 1A

MEASURING RESISTANCE BE-

TWEEN LEADS (MOTOR WIND-

ING RESISTANCE)

e general condition of motor windings can be deter- mined

by measuring the resistance of the motor windings (i.e. the re-

sistance between the motor leads) and comparing the measured

resistance with values given in the motor manual. e resistance

is measured with an ohm-meter and the value is stated in ohms.

e basic procedure for measuring motor winding resistance is

given below.

Turn o the power and disconnect the leads to be tested from the

panel.

Failure to turn o the power will damage the meter and can

cause serious or fatal shock.

Failure to disconnect the leads can result in false readings.

Set the meter selector knob to “Ax 1 “. Clip the meter leads

together and ad-just the meter to zero.

Unclip the leads and attach them. See FIGURE 6.

Resistance measured between the motor leads prior to splicing

the drop cable to the motor leads should be within the mo-

tor winding resistance limits specied in the motor manual.

Resistance measured between the drop cable leads after splicing

the drop cable to the motor leads will indicate the resistance of

the drop cable plus the motor windings. e motor winding re-

sistance is obtained by the formula below. e calculated value

should be within the limits specied in the motor manual.

Motor winding resistance reading measured at drop cable from

FIGURE 6.

A higher winding resistance than shown in the motor manual

indicates a possible burned (open) winding, an open cable, a

loose connection or the wrong motor (dierent HP or voltage

than readings being referenced).

A considerably lower winding resistance than shown in the

motor manual indicates a possible shorted (burned together)

winding or the wrong motor.

Unequal resistance between the windings on a three phase mo-

tor indicates a burned winding or a faulty connection.

OHMS

ZERO

OHMS

OHMS

ZERO

OHMS

DROP CABLE

OR

MOTOR LEADS

DROP CABLE

OR

MOTOR LEADS

SINGLE PHASE, 2 WIRE - MEASURE BETWEEN TWO WIRES

SINGLE PHASE, 3 WIRE - MEASURE BETWEEN BLACK AND

THREE PHASE - MEASURE BETWEEN EACH PAIR, AB, AC

YELLOW AND THE MEASURE

BETWEEN RED AND YELLOW

GROUND

SET SELECTOR

KNOB AT

R x 100K

SET SELECTOR

KNOB AT R x 1

R x 100K

R x 1

R x 10

R x 100 R x 1000

R x 10K

10

20

25

5

2

0

R x 100K

R x 1

R x 10

R x 100 R x 1000

R x 10K

e values below are for copper conductors. If aluminum con-

ductor drop cable is used, the resistance will be higher for each

foot of cable of the same size. To determine the actual resis-

tance of aluminum drop cable, divide the ohm readings from

this chart by 0.61. is chart shows total resistance of cable

from control box to motor and back.

FIGURE 6 – Measuring Winding Resistance

C. CURRENT UNBALANCE TEST

For three phase units,THE CURRENT UNBALANCE

BETWEEN LEGS OF THE POWER SUPPLY SHOULD

NOT EXCEED 5%. Current unbalance is determined by mea-

suring the amperage in each of the three legs and then calculat-

ing the percent current unbalance using the formula below. is

calculation must be performed using each of the three hookups

shown.

THE HOOKUP THAT RESULTS IN THE LOWEST PER-

CENT CURRENT UNBALANCE SHOULD BE USED

FOR THE FINAL CONNECTION OF THE POWER

LEADS. is procedure is commonly known as “rolling the

leads”. To prevent changing the motor rotation, be careful to

follow the hookups shown below very carefully. A worksheet

and sample calculation are given. See FIGURE 7.

Table of contents

Popular Water Pump manuals by other brands

Grundfos

Grundfos Unilift CC 5 Installation and operating instructions

Grundfos

Grundfos SMART Digital S-DDE Safety instructions and other important information

Watson Marlow Pumps

Watson Marlow Pumps 720DuN user manual

Ulvac

Ulvac DOP-181S Series instruction manual

Gardena

Gardena Comfort 5000/5 Operator's manual

MULTIQUIP

MULTIQUIP st41230 Operation and parts manual