Craden DP6 User manual

1

1.0 DP6 & DP7 DOCUMENT PRINTERS - FUNCTIONAL SPECIFICATIONS

1.1 PRINT CHARACTERISTICS

Print Method Impact with automatic thickness compensation

DP6: 9 wire dot matrix DP7: 24 wire dot matrix

Print Line Width 8.0” (203 mm)

Character Spacing 5, 6, 8.5, 10, 12, 17, 20 and 24 characters/inch

Font 96 char. ASCII, international character support

Print Speed

(chars/second)

DP6 DP6 DP7 DP7

Chars/inch 10 12 10 12

Draft 165 200

Normal 125 150 150 180

Correspondence 32 37 75 90

Dot Graphics

(dots/inch)

DP6: 60, 120, 240 horizontal; 72, 144 vertical

DP7: 60,120,180, 360 horizontal; 72, 180 vertical

Feed Speed 50 msec. single line feed at 5 or 6 lines/inch

12 inches/second (305 mm/sec) slew speed

Feed Accuracy +/- 0.6%

1.2 FORMS CHARACTERISTICS

Media Single sheets, passbooks, 6 part multipart forms and

envelopes.

Document Width 2.5” (64 mm) to 9.5” (241 mm)

Document Length 2.5” (64 mm) minimum, no maximum

Document Thickness 0.0035” (0.09 mm) to 0.062” (1.57 mm)

Non-printable Areas DP6 DP7

Top of form 0.25”(6.4mm) 0.16”(4.1mm)

Above horiz. fold 0.25”(6.4mm) 0.38”(9.7mm

Below horiz. fold 0.31”(7.9mm) 0.27”(6.9mm)

Bottom of form 0.40”(10.2mm) 0.45”(11.4mm)

Vertical fold/edge 0.25”(6.4mm) 0.25”(6.4mm)

1.3 RIBBON

Cartridge Endless loop ribbon with internal reinking

DP6: NEC P2200 compatible

DP7: Panasonic KX-P155 compatible

2

1.4 INTERFACE

Standard Serial RS-232, DP6: 1200-9600 baud, 4KB buffer

DP7: 2400-19200 baud, 11KB buffer

Optional RS-232 dual ports or PC parallel port

Command Sets IBM Proprinter/4722, Unisys and Craden

Protocols DTR, Xon/Xoff and Block

Power Input 100-130 or 200-260 VAC, 50-60 Hz, 50 W max.

1.5 PHYSICAL CHARACTERISTICS

Dimensions Width: 14.1” (357mm) Height: 6.3” (160 mm)

Depth: 10.8” (275 mm) operating, 7.8” (197 mm) standby

Weight 18.3 pounds (8.3 kg) + 3.5 pounds (1.6 kg) packing

1.6 ENVIRONMENTAL & STANDARDS

Operating

Storage

10 to 40C, 10 to 90% humidity

-30 to 70C, 5 to 95% humidity

Standards IEC 950, UL 1950, UL File E91899

FCC 20780 Class A certified, Canadian UL Listed

3

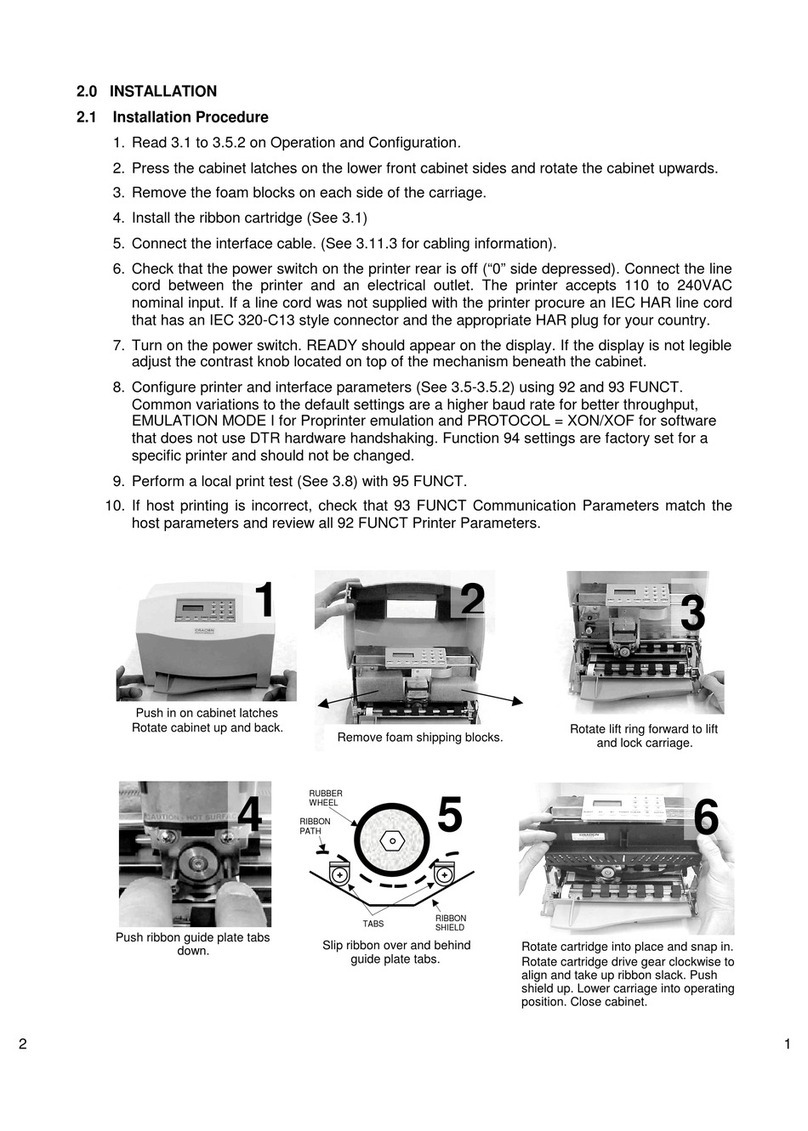

2.0 INSTALLATION

2.1 NORMAL INSTALLATION PROCEDURE

1. Read this section and 3.1 to 3.6 on Operation and Configuration.

2. Remove the cabinet lid and cut the shipping strap that fastens the carriage to the rail on the metal box.

Save the packing material.

3. Install the ribbon cartridge (See 3.3).

4. Check that the label on the printer rear correctly indicates the input supply voltage. (Either 115 VAC for

100-130 VAC input or 230 VAC for 200-260 VAC). If it is incorrect, see Changing Supply Voltage in 2.3.

CAUTION: CONNECTION OF A PRINTER WIRED FOR 115 VAC TO A 230 VAC INPUT CAN

PERMANENTLY DAMAGE THE PRINTER!

5. Check that the power switch on the printer rear is off ("0" side depressed). Connect the line cord to the

printer and then to an electrical outlet. If a suitable line cord was not supplied with the printer, procure an

IEC HAR (harmonized) line cord that has an IEC 320-C13 style connector and the appropriate HAR plug

for your country.

6. Connect and fasten the interface cable to the rear panel connector. (See 3.13.3 for cabling information).

7. Documents longer than 8" will feed out the printer rear. Insure that space is available for the longest

document to be fed.

8. Turn on the power switch located on the rear of the printer. READY should be displayed.

9. Configure the printer by the procedure in 3.6. Default settings are:

LINES/INCH = 6 PROTOCOL = DTR

CHARS/INCH = 10 BAUD RATE = 9600

CHARS = SCRIPT WORD LENGTH = 8

PRINT = NORMAL PARITY = NONE

QUIET MODE = N STOP BITS = 1

DOCUMENT INSERT TOP EDGE INPUT BUFFER MULTIPLE LINE INSERT WITH 1 SEC

PAUSE EMULATION MODE C

BEGIN PRINTING IMMEDIATELY RETURN ON FEED Y

LINE#1 =. 250 IN

In printers with the automatic alignment feature:

SKEW DETECTION CORRECT SKEW

SKEW DETECTION ALLOWED = .050

IF FORM SKEWED ENTER/EJECT KEYS

IF NARROW FORM PROCEED

Common variations are EMULATION MODE I for IBM Proprinter emulation and PROTOCOL = XON/XOF

for software that does not use DTR hardware handshaking. Function 94 settings are factory selected for a

specific printer mechanism and should not usually be changed.

10. Perform a local print test using 95 FUNCT. (See 3.9)

11. If the host is unable to print correctly, check that the Communication Parameters selected under 93

FUNCT match the host parameters and review all Printer Parameters selected under 92 FUNCT.

4

2.2 RESHIPMENT

If possible, retain the original packing material for reshipment. In any event the following precautions must

be observed:

1. Fasten the carriage with a cable tie, string or wire passing around the top of the carriage plate and through

the hole in the front of the guide rail. Insure that the carriage can't move horizontally or vertically.

2. If the original packing material is not used, insure that the cabinet lid will not move during shipment and

that the unit has sufficient protective padding on all sides.

2.3 CHANGING SUPPLY VOLTAGE

The printer can be set to operate with either 115 VAC or 230 VAC input. It will operate from 50 or 60 Hz at

either setting. The label on the back indicates the current setting. To change the voltage setting:

CAUTION: THIS CHANGE MUST BE PERFORMED BY TRAINED SERVICE PERSONNEL

1. Disconnect the line cord from the printer.

2. Remove the screw on the right end of the line cord receptacle and the screw to the left of the power switch.

Slide the power input assembly out of the printer rear.

3. Disconnect the internal power cable from the power input assembly.

4. Use a small blade to depress the locking tab on the side of the green/yellow wire contact and slide the

contact out of the connector. Use the blade to pry the plastic key out of the cable connector.

5. Insert the green/yellow wire contact into the connector position where the key had been and insure that it

locks in place. Insert the key into the connector position where the green/yellow wire had been.

6. Reconnect the internal connector to the power input assembly.

7. CHECK THE CONNECTOR TO THIS CHART. THIS IS IMPORTANT!

Position 1 is the pin closest to the power switch.

Position: 1 2 3 4 5 6 7 8

115 VAC: Brown Blue Grn/Yel Wht/Brn Key Wht/Blue

230 VAC: Wht/Blue Grn/Yel Wht/Brn Key Blue Brown

8. Use a meter to insure there is less than 0.1 ohm resistance from the center blade of the line cord

receptacle and the printer baseplate.

9. Slide the power input assembly back into the printer and fasten it.

10. Replace the fuse and fuse holder with the type indicated on the label on the back corresponding to the new

input voltage.

11. Modify the label on the back to indicate the new supply voltage.

5

3.0 OPERATION

3.1 AUTOMATIC DOCUMENT INSERTION

Insertion procedures may be configured to satisfy varied applications. (See Printer

Parameters in 3.6.1). This description first explains a basic insertion sequence and then

describes variations.

1. Place the document under the clear plastic guide and gently push the left edge of the

document against the edge of the document guide.

2. Slide the document forward until it contacts the feed rollers which will automatically

move the document to the first printable line.

3. Printing can now commence. After printing is complete the document may be ejected.

Step 2 may be configured so that the rollers do not activate for a few seconds or until the

A key is pressed. This allows more time to insert cumbersome documents or to train

new operators.

Printers with the auto alignment feature should be configured for no delay. Documents

should be inserted toward the left edge guide and rollers, then quickly released to allow

them to automatically align. Auto alignment may be disabled for an individual document by

pressing the FUNCT key before insertion. See 3.6.5 to configure auto alignment.

Step 2 may be configured to move the document down to the last (bottommost) printable

line.

Step 3 may be configured to delay printing until the ENTER key is pressed. This allows

the operator to insure that the document has inserted correctly. If not, it may be EJECTed

and reinserted.

3.2 SEMI-AUTOMATIC DOCUMENT INSERTION

If delay printing until the ENTER key is pressed has been configured, the document can be positioned to

begin printing at a specific place:

1. Proceed with steps 1 and 2 of the automatic insertion procedure.

2. Use the A and B keys to align the center of the desired print line with the front edge of the metal guide

above the document.

3. Press the ENTER key. The desired print line will be automatically positioned in front of the printhead and

printing can now begin.

4. After printing is complete the document may be ejected.

When Configuration 12 is selected in 94 FUNCT, pressing ENTER before document insertion allows keypad

entry of the number of lines to be fed before printing begins.

3.3 RIBBON CARTRIDGE LOADING/REPLACEMENT

The DP6 cartridge (Part# 99059) is compatible with the NEC P2200 cartridge. Its drive knob is on the right

side of the cartridge. The DP7 cartridge (Part # 99073) is compatible with the Panasonic KX-P155. Its drive

knob is in the center of the cartridge. The useful life of cartridges from various suppliers may vary greatly and

some may be too heavily reinked for document printing applications. The reinker in some DP7 cartridges

must be manually engaged by removing a clip or pressing a spring when printing becomes light. Do not

engage the reinker until printing becomes light or else printing will become too dark.

6

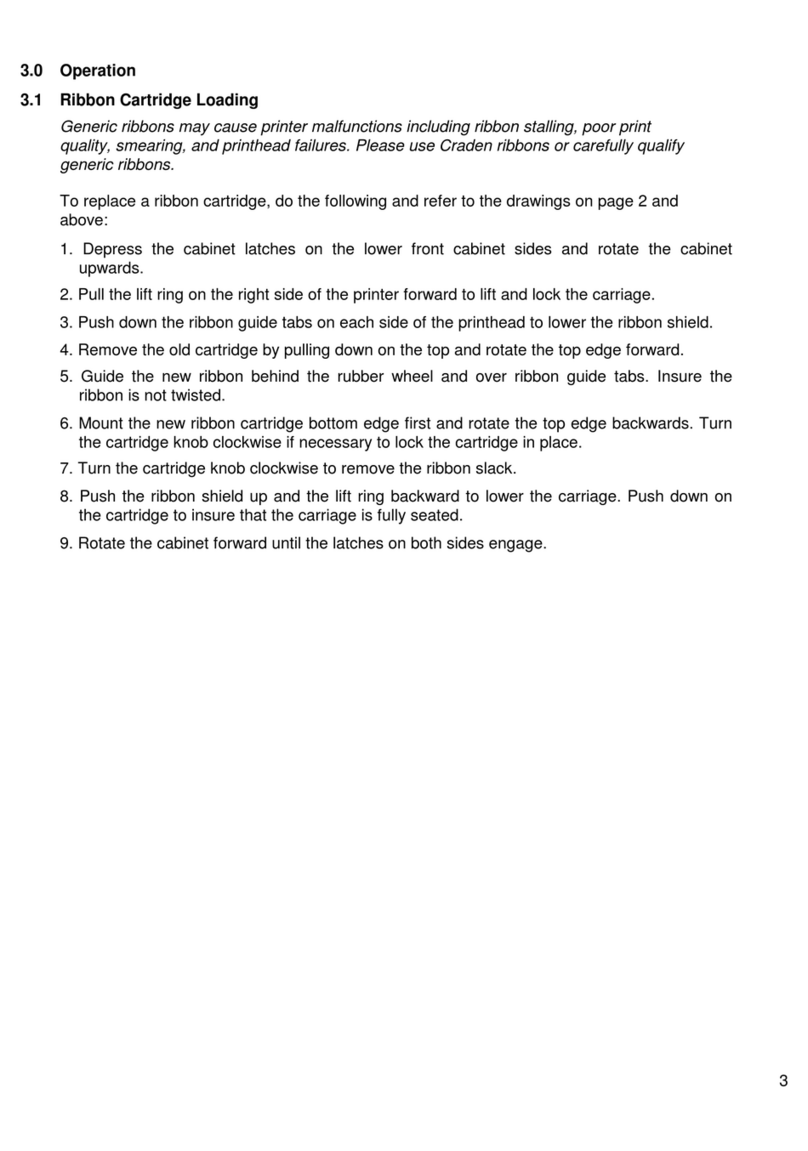

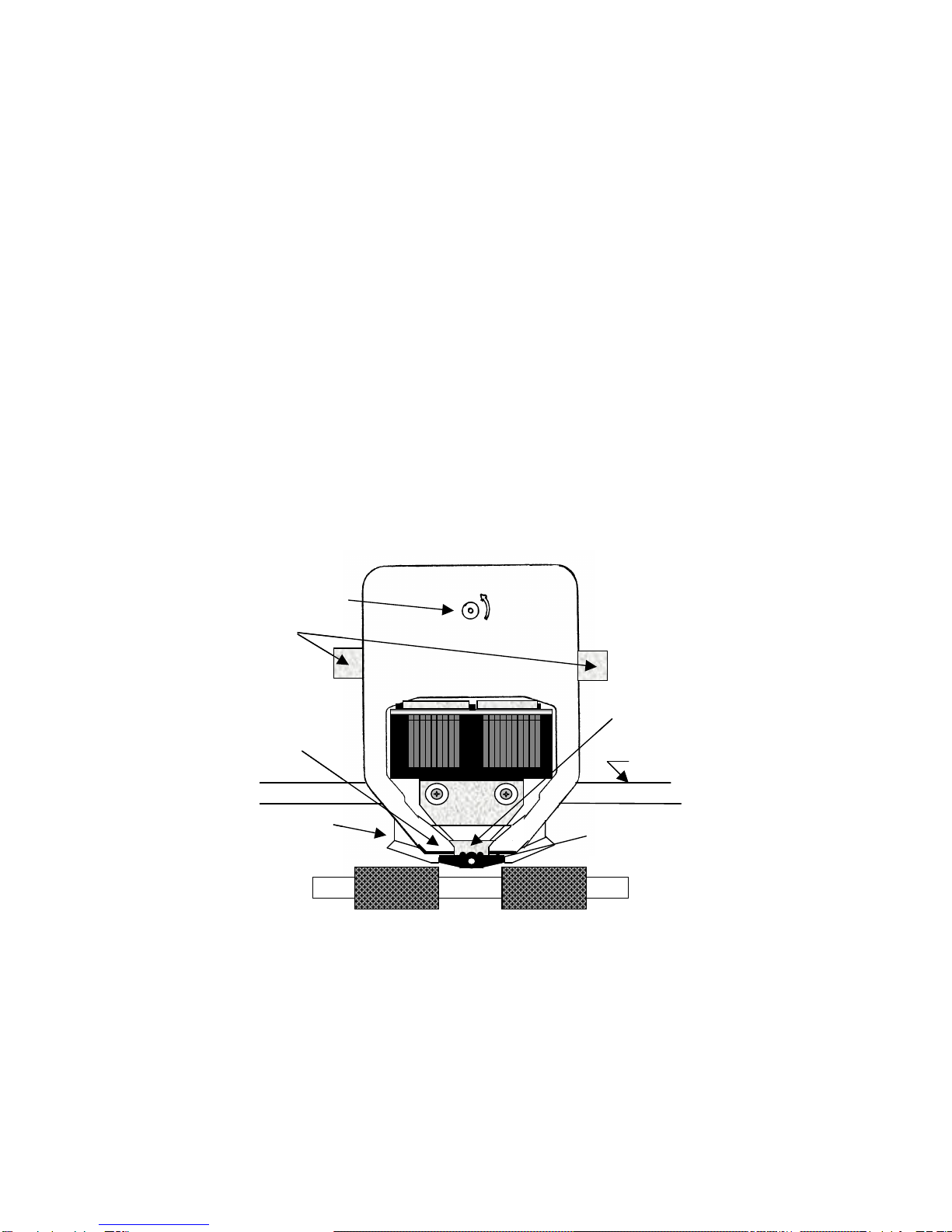

3.3.1 DP6 Ribbon Cartridge Loading/Replacement

To replace a DP6 ribbon cartridge:

1. Remove the lid. If the printer has just finished more than 3 minutes of continuous printing, the printhead

fins may be hot to the touch. Avoid contact with the fins.

2. Press the A and B keys simultaneously to position the printhead nose just to the right of the leftmost

rubber roller segment.

3. Release the old cartridge from the carriage by pulling the release bar on top of the cartridge forward. Lift

the carriage shaft and remove the old cartridge.

4. Rotate the ribbon drive knob until the slot on its bottom side lines up with the ribbon drive tab on the

carriage. Pull a small loop of ribbon from the nose of the cartridge.

5. Lift the carriage shaft with a little finger. Insert the ribbon loop between the bottom of the printhead nose

and slotted plastic ribbon shield and then push the cartridge against the carriage until it snaps into place.

6. Insure that the ribbon is located between the printhead nose and the ribbon shield and the shield is seated

with the notched side toward the rear of the printer. If the ribbon is caught on the front of the printhead

nose use a pen point to push it into place. Rotate the knob on the cartridge clockwise and check that the

ribbon moves correctly.

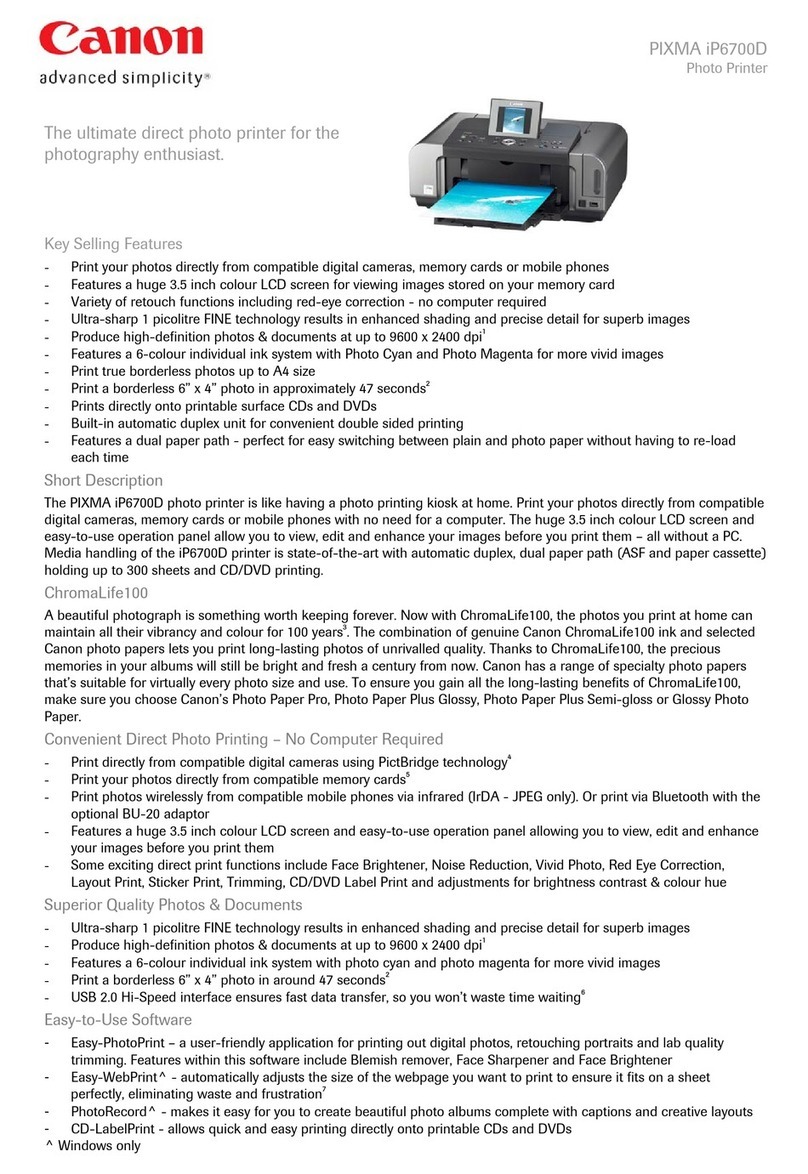

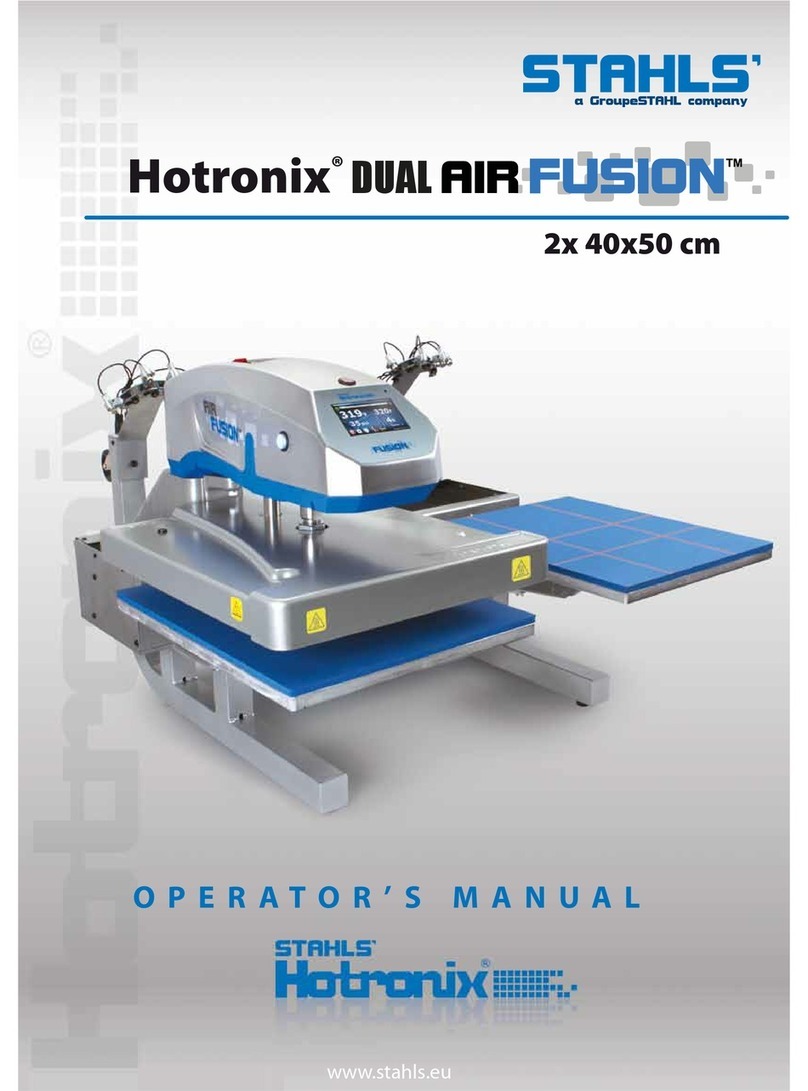

Ribbon Shield

Ribbon Drive Knob

Release Bar

Carriage Shaft

Printhead Fins

Gap Adjust Screws (2)Printhead Attach Screws (2)

Printhead Nose

Leftmost Roller

DP6 RIBBON CARTRIDGE LOADING

7

3.3.2 DP7 Ribbon Cartridge Loading/Replacement

To replace a DP7 ribbon cartridge:

1. If the new cartridge has a plastic ribbon shield attached, remove it.

2. Pull about a 1/2" loop of ribbon from the new cartridge.

3. Remove the lid. If several minutes of continuous printing have just been finished, the printhead and

carriage may be hot to the touch. Avoid contact with those parts.

4. Press the A and B keys simultaneously to position the printhead nose between two drive roller

segments.

5. Lift the carriage shaft with a little finger. Remove the old cartridge by pressing the side clips while pulling

the old cartridge forward.

6. Push the metal ribbon shield downward. Guide the new cartridge's ribbon loop around the pivoting slider

and under the printhead nose.

7. Locate the cartridge tips behind the pivoting slider.

8. Move the cartridge toward the carriage and rotate the cartridge knob counter-clockwise until the cartridge

seats on the carriage plate.

9. Insure that the ribbon lies flat against the printhead nose and that both metal side clips lock onto the

cartridge tabs.

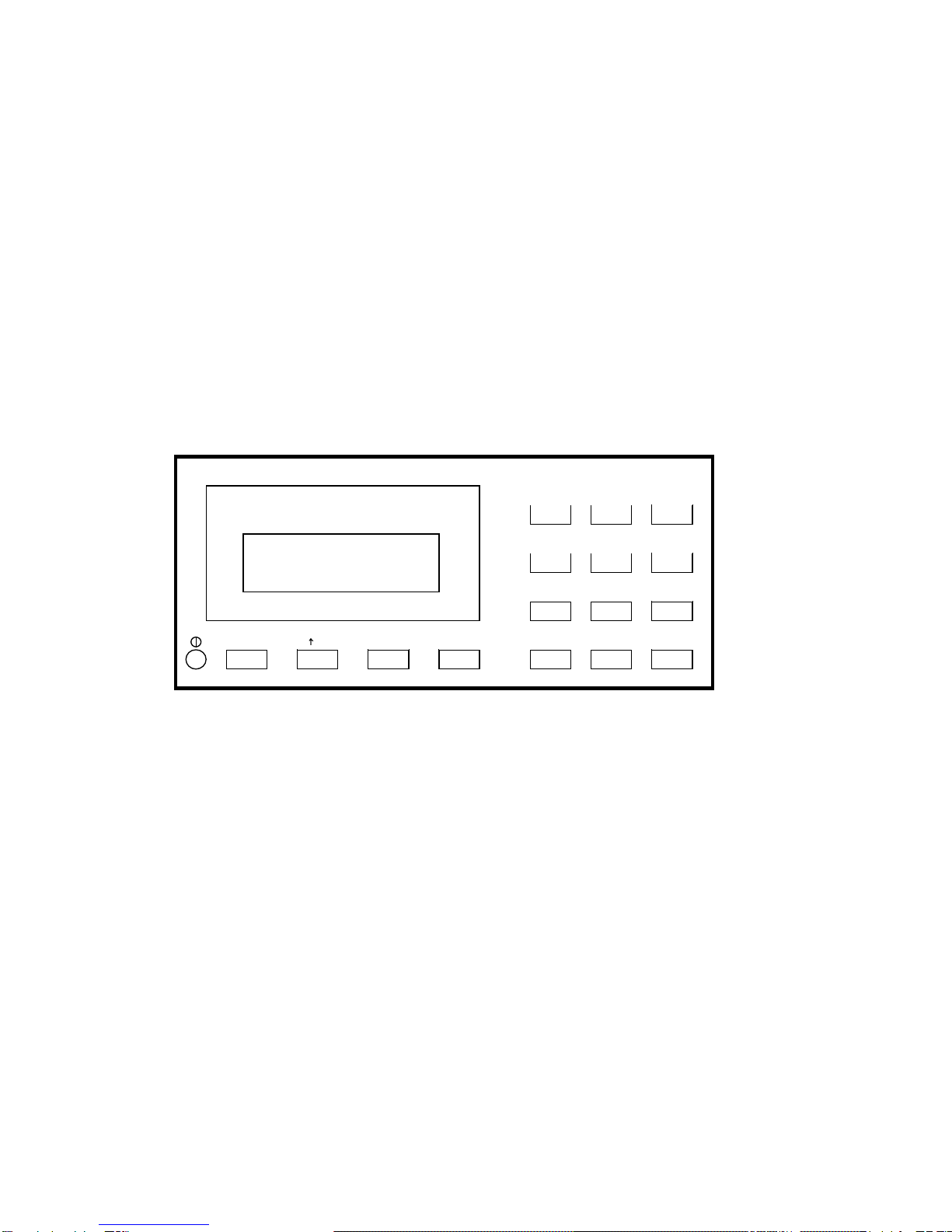

3.4 KEYPAD OPERATION

EJECT: ejects an inserted document if the print buffer is empty.

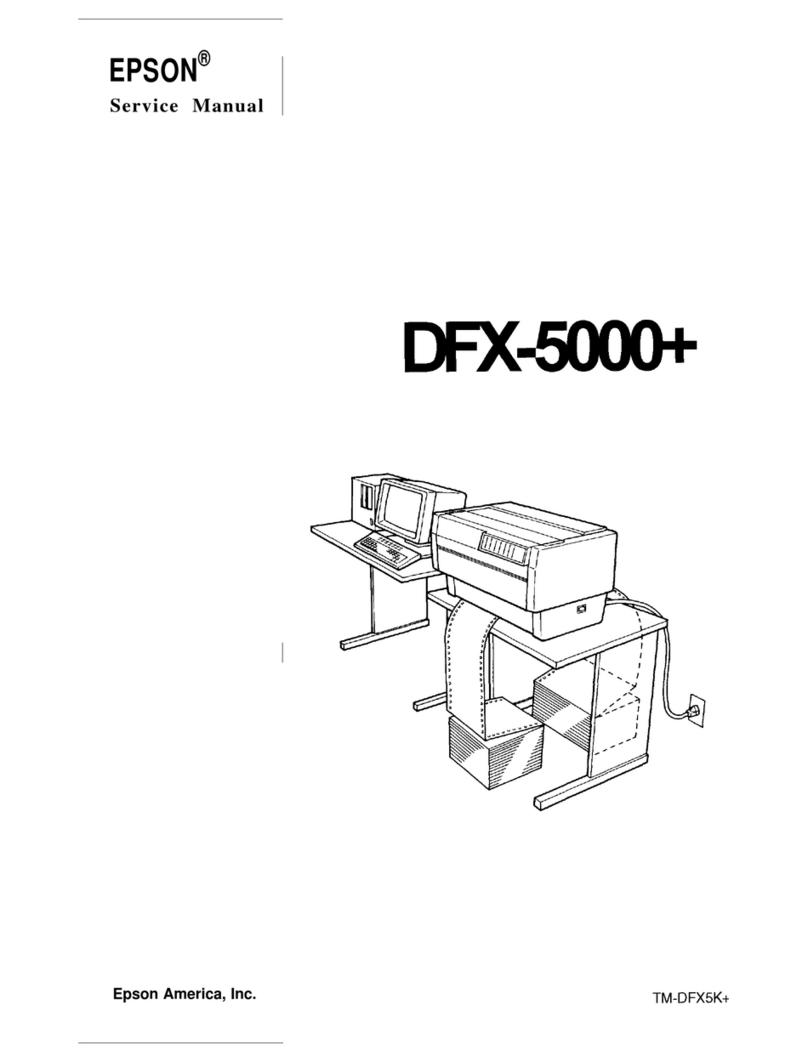

Drive Knob

Side Clips

Cartridge Tip

Ribbon Shield

Printhead Nose

Carriage Shaft

Pivoting Slider

DP7 RIBBON CARTRIDGE LOADING

8

A: moves a document up 1/60" with each depression. If held depressed, the document will slowly

move into the printer. Also initiates document insertion if the printer is configured for key rather

than automatic insertion. (See 3.6.1)

B: moves a document down 1/60" with each depression. If held depressed, the document will slowly

move out of the printer .

FUNCT: enters previously keyed digits as a function code. All function codes beginning with 9 are reserved

for internal printer operations. All other function codes are transmitted to the host system and

their usage is defined by the host. On printers with the auto alignment feature, pressing FUNCT

before document insertion will disable auto alignment for an individual document. See 3.6.5 to

configure auto alignment.

CLEAR: erases any previously keyed digits before they are transmitted to the host by the FUNCT or

ENTER keys.

ENTER: transmits previously keyed digits to the host system. All responses are defined by the host. This

key also initiates document printing if the printer is configured to delay printing until the ENTER

key is pressed (See 3.6.1).

0 to 9: enter digits to be transmitted to the host by the FUNCT or ENTER keys. Key depressions appear

on the lower display line.

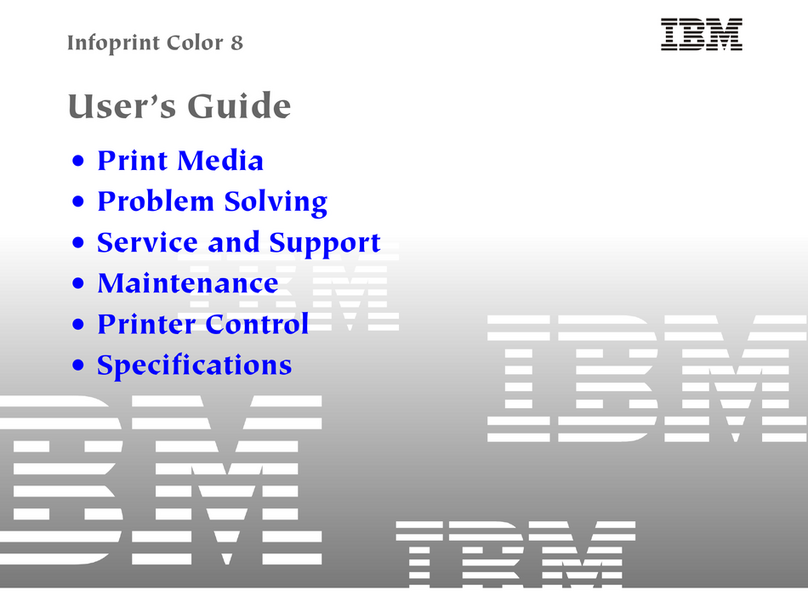

KEYPAD & DISPLAY

PANEL

3.5 DISPLAY

OPERATION

The display

consists of 2 lines

of 16 characters

each and is used

to display messages both from the printer and the host system. There is a contrast knob to the left of the

EJECT key that should be adjusted for maximum legibility depending on the display viewing angle. When the

printer is turned on, "READY" will be displayed.

READY

1

2

FUNCT CLEAR ENTEREJECT

3

4

5

6

7

8

9

0

B

A

9

3.6 CONFIGURATION

The printer may be completely configured from the keypad with all parameters saved in a non-volatile

memory. There are 4 configuration function codes:

Configuration Category Press

Printer Parameters 9 2 then FUNCT

Communication Parameters 9 3 then FUNCT

Service Parameters 9 4 then FUNCT

Override Parameters 9 9 then FUNCT

After accessing a category, each parameter will be displayed. Press A to display the next choice for the

parameter or press ENTER to display the next parameter. If the display does not change when A is

pressed, the keypad is locked. See 3.6.4 to unlock the keypad.

3.6.1 Printer Parameters

Press 9 2 then FUNCT to display the following parameters or press 9 0 0 then FUNCT to print them on a

previously inserted document. Changes may be made as described above. Before proceeding, see 3.1-3.2

and select the insertion sequence which best fits your application.

DISPLAY REMARKS

LINES/INCH = 5 or 6 Select 5 or 6 lines per inch vertical spacing

CHARS/INCH = 10, 12 or 17 Select 10, 12 or 17 characters per inch horizontal spacing.

CHARS = BLOCK or SCRIPT Select BLOCK or SCRIPT lower case characters in NORMAL mode

(DP6 only).

PRINT = NORMAL, CQ or

DRAFT Select NORMAL, correspondence quality CQ or high speed DRAFT

(DP6 only) print. Do not use DRAFT on thick forms or passbooks.

QUIET MODE = Y or N Select Y for reduced noise on thin documents. Select N for darker print

on thick documents.

DOCUMENT INSERT = TOP

or BOTTOM EDGE Select insertion to the TOP EDGE or the BOTTOM EDGE of the

document.

DOCUMENT INSERT WITH

X SEC PAUSE or WITH A

KEY

Select automatic insertion 0, 1 or 2 seconds after a placing a

document in the input tray or delay insertion until A is pressed to allow

more time for aligning documents.

BEGIN PRINTING

IMMEDIATELY or

AFTER ENTER KEY

Select to begin printing IMMEDIATELY after the document insertion or

delay printing until ENTER is pressed to verify proper alignment.

LINE # 1 = .XXX Select the distance, between -0.80” and 0.80”, from the document top

edge to the center of the first print line. Select 0.25” unless needing

software compatibility with another printer.

See 3.6.5 for automatic alignment parameters that appear on the Printer Parameter menu.

NOTE: Most Printer Parameters may be configured by the host system via the HT or other commands. This

allows for dynamic reconfiguration on a document by document or line by line basis.

10

3.6.2 Communication Parameters

Press 9 3 then FUNCT to display the following Communication Parameters or press 9 0 0 then FUNCT to

print them on a previously inserted document. Changes may be made as described in 3.6.

DISPLAY REMARKS

INTERFACE PROTOCOL =

BLOCK, DTR, XON/XOF or

PARALLEL INTERFACE

Select the protocol which matches your system configuration (See

3.13). Select PARALLEL if the parallel interface option is installed

& skip the next 4 items.

BAUD RATE = XXXX Select 1200 (DP6 only), 2400, 4800, 9600 or 19200 (DP7 only)

baud.

WORD LENGTH = 7 or 8 Select 7 or 8 bits/word.

PARITY = XXXX Select parity bit as EVEN, ODD or NONE.

STOP BITS = 1 or 2 Select 1 or 2 stop bits.

INPUT BUFFER SINGLE LINE or

MULTIPLE LINE Select a SINGLE LINE or a MULTIPLE LINE buffer of 3K (DP6)

or 11K (DP7).

EMULATION MODE =

C, I, EF4565 or

EF4600/EFP95

Select C to enable commands used with previous versions of this

printer. Other selections enable commands compatible with

popular PC based financial printers.

AUTO CARRIAGE RETURN ON

FEED = Y or N or

N

Select Y unless compatibility with software written for another

printer is needed.

DUAL PORT = Y or N Select Y if the dual port option is installed to allow printer sharing

between two hosts. Either DTR or XON/XOF protocol must be

selected.

PAPER OUT = NO DOC or

NEVER Select NO DOC if the parallel interface is to indicate paper empty

whenever no document is in the printer or NEVER if it is never to

indicate paper empty.

SELECT = DOC PRES or

ALWAYS Select DOC PRES if the parallel interface is to indicate off-line

whenever no document is in the printer or ALWAYS to always

indicate on-line.

11

3.6.3 Service Parameters

Press 9 4 then FUNCT to display the following Service Parameters. These parameters are factory selected

specifically for each printer mechanism and recorded on the label next to the display inside the printer. They

do not usually need to be modified by the user.

CAUTION: CHANGE OF THESE PARAMETERS BY UNTRAINED PERSONNEL MAY RESULT IN

INCORRECT PRINTER OPERATION.

DISPLAY REMARKS

TOP OFFSET = XX Adjusts the uppermost print line location. Smaller values print

closer to the top document edge.

INDEX OFFSET = XX Adjusts the distance moved when semi-automatic positioning is

used. Larger values move the print line up the document.

LEFT OFFSET = XX Adjusts the carriage home location during document insertion.

Larger values move the carriage to the left.

LEFT MARGIN = XX Adjusts the first column print position. Larger values move printing

to the right.

CAR. ALIGN = XX Positions lines printed right to left so they align with lines printed left

to right. Larger values move those lines to the left.

FORWARD COMPENSATION

= XX Adjusts distances moved down the document. Larger values

increase the distance moved between the topmost and bottommost

line.

REVERSE COMPENSATION

= XX Adjusts distances moved up the document. Larger values increase

the distance moved between the bottommost and topmost line.

EJECT HOLD OFFSET = XX Adjusts how much of the document is held in the feed rollers after it

is ejected. Lower values hold less of the document.

CONFIGURATION = XX Selects custom interface options. Select 00 unless indicated

otherwise on the Parameter label or incorrect operation may occur.

GATE OFFSET = XX Adjusts gate height. Larger values raise gate. (DP7 with Automatic

Alignment feature only)

NORMAL DARKNESS = 0 to

10 Adjusts darkness at normal print speed. Lower values reduce

darkness and increase ribbon life. Select the lowest value that

provides suitable legibility on thick forms (DP7 only).

CQ DARKNESS = 0 to 10 Adjusts CQ print darkness (DP7 only).

12

3.6.4 Override Parameters

Press 9 9 then FUNCT to display the following Override Parameters. Changes should be made only by

trained personnel.

DISPLAY REMARKS

LOCKED or UNLOCKED LOCKED allows parameters to be displayed but not changed.

UNLOCKED allows parameters to be changed by the A key.

COVER OVERRIDE OFF or

ON OFF requires the cabinet lid to be closed for printing to occur. ON

allows trained personnel to print with the lid removed. Replacing the lid

automatically sets the override OFF.

3.6.5 Automatic Alignment Parameters

The following printer parameters may be selected at the end of the Printer Parameter (9 2 FUNCT)

menu on printers with the automatic alignment feature:

DISPLAY REMARKS

SKEW DETECTION =

CORRECT SKEW, DETECT

SKEW, or IGNORE

select CORRECT SKEW to automatically align skewed documents,

DETECT SKEW to detect but not align skewed documents, or

IGNORE to disable both skew detection and correction.

SKEW DETECTION ALLOWED

= .030, .050, .080, .110 or .130 Select the maximum skew per 4 inches of document width. Treatment

of documents with excess skew is set by the next parameter.

IF FORM SKEWED =

ENTER/EJECT KEYS or

AUTOMATIC EJECT

If a document has excess skew, ENTER/ EJECT KEYS will continue

printing if ENTER is pressed or eject the document if EJECT is

pressed. AUTOMATIC EJECT will always eject a document with

excess skew

IF NARROW FORM =

PROCEED or ENTER/EJECT

KEYS

Documents less than 4.5 inches wide will be detected as skewed.

PROCEED will always accept the document, ENTER/EJECT KEYS will

continue printing if ENTER is pressed or eject the document if EJECT

is pressed.

3.7 DIAGNOSTICS

3.7.1 Power Up Diagnostics

Diagnostic routines are automatically executed during power-up. If a fault is detected, ROM TEST BAD

or RAM TEST BAD may be displayed. If a fault occurs, press A to advance to the next test. However,

the printer should not then be operated. If the problem is not a POWER FAILURE (see 3.10.1), contact

your Service Personnel or see 5.6 of the Technical Manual for troubleshooting.

3.7.2 Enhanced Diagnostics

Diagnostics may be executed by pressing 9 0 then FUNCT. If no faults exist, PROM REVISION XX,

ROM TEST OK and RAM TEST OK will be displayed. If a fault exists, "BAD" will be displayed instead of

"OK" until A is pressed to advance to the next test.

After RAM TEST XXX is displayed, SENSORS LFBC will be displayed. L is the left home carriage sensor; F

and B are the front and back document sensors and C is the cover open sensor. Any sensor that is covered

will have its corresponding indicator erased. Each sensor may be activated to check for proper operation.

Press A to conclude this test.

13

3.8 SELF TEST

A document may be test printed by pressing 9 1 FUNCT. SELF TEST is displayed until a document is

inserted. Then CHAR LENGTH = 30 is displayed. Press A to select CHAR LENGTH = 80. (30 characters

requires a document at least 3 1/2" wide, 80 characters requires 8 1/2".) Do not print across a vertical fold or

document edge. Press ENTER to print the top and bottom lines of the document and then eject it.

3.9 LOCAL PRINTING

In addition to Self Test function 91, it is possible to print several variable length lines without host commands.

Proceed as follows:

1. Insert a form manually or automatically and then press 9 5 FUNCT.

2. In response to CHAR LENGTH = 30, key in a two digit number of characters per line and then press

ENTER. Insure that printing will not occur across a fold or document edge.

3. In response to LINE COUNT = 01, key in a 2 digit number of lines.

4. Each time ENTER is pressed, that number of lines will be printed.

5. Press EJECT to eject the document and CLEAR to clear the display.

3.10 ERROR CONDITIONS

3.10.1 Power Failure

All Configuration Parameters are stored in a non-volatile memory. Power up diagnostics display POWER

FAILURE if an error is detected in that memory. It is now necessary to re-enter the parameters. Press

FUNCT to begin the prompting sequence. The factory set values for the Service Parameters are listed on

the label next to the display inside the printer.

3.10.2 Document Jam

In the unlikely event that a document becomes jammed in the printer, printing will stop and "DOCUMENT

JAM" will be displayed. The operator must clear the jam condition by moving the printhead left as far as

possible and removing the document from the printer.

3.10.3 Cover Open

If the printer lid is removed to replace a ribbon cartridge or clear a document jam, COVER OPEN is displayed

and printing is disabled. Printing will resume 3 seconds after the lid is replaced.

3.10.4 Page Overflow

If the printer is commanded to move past the last printable line on a document it will eject the document and

display PAGE OVERFLOW INSERT NEXT PAGE. Printing will resume when another document is inserted.

3.10.5 Carriage Fault

This message will be displayed if the carriage could not move to the left margin and is probably caused by a

jammed carriage, bad motor driver fuse or a bad left home sensor.

14

3.11 DP6 & DP7 PROGRAMMING

CAUTION: DURING PROGRAM DEVELOPMENT ALL PRINTING SHOULD BE DONE ON SINGLE

SHEET PAPER UNTIL PRINT FIELDS ARE CORRECTLY FORMATTED. PRINTING DIRECTLY ACROSS

THICK FOLDS AND DOCUMENT EDGES CAN DAMAGE THE PRINTHEAD.

The printer accepts two separate command sets, C and I, that are selectable either from the keypad using 9

3 FUNCT (see 3.6.2) or the interface. Mode C is compatible with previous versions of this printer while Mode

I is compatible with popular PC based printers. If Mode I is selected, the DP6 can use a IBM Proprinter driver

and the DP7 can use a IBM Proprinter X24 driver. Unique Mode C commands to communicate with the

keypad/display and request status can still be accessed in Mode I by preceding the Mode C command with a

ESC character.

3.11.1 Mode C Command Summary

Mode C recognizes the following ASCII control sequences:

ASCII Hex Command

STX 02 Start envelope data

ENQ 05 Status request

BEL 07 Load upper display immediate

* BS 08 Reverse line feed

HT 09 Configuration download

* LF 0A Line feed

* VT 0B Vertical tab feed

* FF 0C Eject document

* CR 0D Print buffer

SO 0E Begin expanded characters

SI 0F End expanded characters

DC1/DLE 11/10 Key buffer request

DC2 12 Line count request

DC3/ETB 13/17 Load upper display delayed

DC4 14 Master reset

EM 19 Document length request

SUB 1A Status request delayed

ESC SO 1B 0E Begin double height characters

ESC SI 1B 0F End double height characters

* ESC n 1B 3# Feed document up #/120 inches

ESC A 1B 41 Begin 60 dot/inch graphics

ESC B 1B 42 Begin 120 dot/inch graphics

ESC E 1B 45 Begin bold print

ESC F 1B 46 End bold print

* ESC J n 1B 4A Feed document up n/216 inches

ESC ] 1B 5D Reverse line feed

ESC ~ I 1B 7E 49 Select Mode I

FS 1C Load lower display immediate

GS 1D Load lower display delayed

RS n 1E n Skip n blank spaces in print line

US 1F Begin/End underscore

Commands prefixed with a * will not be executed until after an ENQ is received if the BLOCK protocol is

used. ENQs are not required if DTR or XON/XOF protocols are used.

15

3.11.2 Mode C Document Movement Commands

BS or ESC ] moves the document down one line, with line spacing keypad selected (see

3.6.1) or set by an HT command.

LF moves the document up one line, with line spacing keypad selected (see 3.6.1) or set by

an HT command.

VT n moves the document a variable number of lines or steps with n being a single byte, bit

coded as 01ULCCCC where:

U = 1 = Up feed U = 0 = Down feed

L = 1 = Line feed (1/6” or 1/5”) L = 0 = Step feed (1/60”)

CCCC = Line count or step count

ESC n moves the document up (CCCC)/120 inches where n is a single byte bit coded as

0011CCCC.

ESC J n moves the document up n/216 inches where n is a single binary coded byte.

FF ejects the document.

If any document movement command (BS, LF, VT, ESC n, ESC ], ESC J n or FF) has been preceded by any

printable ASCII characters, they will be printed before the movement command is executed.

3.11.3 Mode C Print Commands

CR prints all preceding printable ASCII characters. There is no document movement due to the

CR.

SO starts double width printing. All characters received after an SO and before an SI, CR or

feed command will be printed double width.

SI stops double width character printing.

ESC SO starts double height printing. All characters received after an ESC SO and before an ESC SI,

CR or feed command will be printed double height. Single height characters will be printed in

line with the top of double height characters if they are mixed in a print line.

ESC SI stops double height printing.

ESC E starts bold, double strike printing in 10 and 12 character/inch NORMAL print speed and

reduces print speed by 33% (DP6) or 50% (DP7).

ESC F stops bold printing.

RS n inserts n blank spaces into the print line and can be used to reduce the number of

characters transmitted when large blank spaces are to be printed. n is of the form

01NNNNNN where NNNNNN is the number of blanks to be inserted. RS A is 1 blank, RS z

is 58.

US enables or disables underscoring of printable characters. All characters received after a US

and before another US, CR or feed command will be printed with the character underscored.

STX

prints envelopes. It must be immediately followed by two bytes, X and Y, each bit coded as

01NNNNNN. NNNNNN/10 inches is the distance from the top edge of the envelope to the first

line of text for X and from the left edge of the envelope to the first column of text for Y.

Following X and Y are normal lines of text separated by

LF's and finally terminated by a FF

which causes printing and ejection.

DC4 clears all previously received data out of the buffer.

16

3.11.4 Mode C Display Commands

BEL immediately displays the following 16 characters on the upper line of the alphanumeric

display. The characters must not be control characters and there must be exactly 16

displayable characters.

FS loads the lower display line just like BEL loads the upper line.

DC3 or ETB operate identically to a BEL command but all previously received print and

document movement commands are executed before the upper line of the display is

loaded.

GS loads the lower display line just like DC3 loads the upper line.

3.11.5 Mode C Configuration Commands

HT changes the machine configuration and must be followed by 2 characters of the form

01PVHFCS and 01LEIBDQ where:

P = 1: Permanent configuration change.

0: Change just for one document

V = 1: 5 lines/inch vertical spacing

0: 6 lines/inch vertical spacing

H = 1: 12 characters/inch horizontal spacingif S=0

0: 10 characters/inch horizontal spacing if S=0

F = 1: Script lower case

0: Block lower case

C = 1: Correspondence quality print if S=0

0: Normal print if D = 0

S = 1: 17 characters/inch horizontal spacing

0: Horizontal spacing determined by H bit

L = 1: Lock keypad from modifying set up parameters

0: Unlock keypad for modifying set up parameters

E = 1: Document present set by ENTER key after insertion

0: Document present set automatically after insertion

I = 1: Insertion initiated by DOWN key

0: Start insert _ seconds after document sensed in chute

B = 1: Insertion to bottom edge

0: Insertion to top edge

D = 1: Draft print (do not use on thick documents) if C=0

0: Print mode determined by C bit

Q = 1: Quieter print on thin documents

0: Darker print on thick documents

All parameters configurable by an HT are also programmable from the keypad. See 3.6.1.

ESC ~ I clears all previously received data out of the buffer and switches the interface to Mode I.

17

3.11.6 Mode C Status and Keypad Commands

Status, key buffer contents, line count or document length data are transmitted when requested by the host.

ENQ requests printer status and is executed when it is received.

SUB also requests printer status but it is executed identically to an ENQ only after all previously

received commands have been executed. SUB may be used to interrupt the host and notify it

that the printer is now idle.

Printer status is a single byte that is bit significant as follows:

0 1 DP XE DJ KB BZ BA

DP = Document present. Set whenever a document is in the feed path.

XE = Transmission error. If BLOCK protocol is used, all characters received since the last ENQ will be

ignored and should be retransmitted. If DTR or XON/XOF protocols are used the character

associated with the error will be printed as a “@”.

DJ = Document jam. The printhead has not returned to the document edge correctly and operator attention

is required.

KB = Key buffer. The key buffer contains key stroke information that will be transmitted upon receipt of a

DC1.

BZ = Busy. Either printing or document movement is now occurring.

BA = Input buffer available. At least 1000 characters of space are available in the input buffer or the buffer

is empty. Buffer operation is detailed in 3.13.1.

DC1 or DLE request keypad data. Upon receipt of either, all keypad input that has been pressed since the

previous DC1 or DLE will be transmitted. A maximum of 16 strokes can be buffered. Transmitted

characters will be one of the following:

ASCII Meaning

0-9 Numeric keys 0-9

: FUNCTion key

; ENTER key

< Either A or B key

= EJECT key

? End of buffer

The last character transmitted is always a ?. If a DC1 or DLE is received and no keys have been

pressed only a ? will be transmitted.

As numeric keys are pressed, their values are displayed on the lower display line. Pressing ENTER or

FUNCT transfers the key strokes to the key buffer. Pressing CLEAR deletes numeric key strokes

before they are transferred to the key buffer.

Function values beginning with 9 are reserved for internal printer operation and are not transferred to

the key buffer. See 3.6 to 3.9 for details of the internal printer functions.

DC2 requests line count information. Upon receipt, 2 bytes are transmitted. The first byte indicates the

number of lines and the second indicates the number of additional 1/60” steps moved since the

document was initially registered at top edge or bottom edge.

EM requests document length information. Upon receipt, 2 bytes representing the document length (if the

document was automatically inserted to the bottom edge) are transmitted. The first byte indicates the

number of lines and the second byte indicates the number of additional 1/60 inch steps.

18

3.11.7 Mode C Graphics Commands

Dot addressable graphics may be printed at 60 or 120 dots/inch (dpi) horizontally by 72 or 144 dpi vertically.

ESC A must precede each line of 60 dpi data with a maximum of 480 data bytes. ESC B must precede each

line of 120 dpi data with a maximum of 960 bytes. Each line of data must be terminated by a feed command,

usually a VT e, ESC 1 or ESC 9.

Each data byte is of the form 1ABCDEF where A is the lowest and F is the highest of 6 vertical dots printed in

a single dot column. Each bit must be set to a 1 for the corresponding dot to be printed.

VT e moves a document up 5/60 inch and positions it for printing contiguous rows of graphics since 5/60 is

the same height as 6/72. The RS command is useful for filling multiple blank dot columns. For example, the

following sequence will print a diagonal line starting in the upper left corner of column 1 and slanting down to

the right:

ASCII Hex

ESC A A B D H P ` VT e 1B 41 41 42 44 48 50 60 0B 65

ESC A RS F A B D H P ` VT e 1B 41 1E 46 41 42 44 48 50 60 0B 65

ESC A RS L A B D H P ` VT e 1B 41 1E 4C 41 42 44 48 50 60 0B 65

ESC 1 feeds a document up 1/120 inch or about one half dot height. Graphics can be printed at a vertical

density of 144 dpi by using ESC 1 but the host must interleave the data. Each line of data must contain dot

data for every other row of dots to be printed. After an ESC 1 and the next line of dot data, an ESC 9 moves

the document 9/120 inch and positions it for printing the next contiguous row of dots.

Assuming full width lines, graphics throughput is 18 seconds/inch for 60 by 72 dpi and 22 seconds/inch for

120 by 72 dpi. Speed is halved when printing 144 dpi vertically

19

3.12.1 Mode I Command Summary

Mode I recognizes the following ASCII control sequences:

ASCII Hex Command

* BS 08 Print the buffer and backspace one character

HT 09 Move the print pointer to the next horizontal tab

* LF 0A Line feed

* VT 0B Move the document to the next vertical tab

* FF 0C Eject the document

* CR 0D Print the buffer

SO 0E Begin expanded characters

SI 0F Begin 17.1 character/inch printing

DC2 12 Begin 10 character/inch printing

DC4 14 End expanded characters

CAN 18 Clear the print buffer

ESC - n 1B 2D n Begin (n=1) or end (n=0) underscore

ESC 0 1B 30 Set 1/8 inch line spacing

ESC 1 1B 31 Set 7/72 inch line spacing

ESC 2 1B 32 Set line spacing stored by prior ESC A

ESC 3 n 1B 33 n Set n/216 inch line spacing

ESC 4 1B 34 Eject the document

ESC 5 n 1B 35 n Begin (n=1) or end (n=0) automatic LF after CR

ESC : 1B 3A Begin 12 character/inch printing

ESC A n 1B 41 n Store n/72 inch line spacing

ESC B 1B 42 Set vertical tab stops

ESC D 1B 44 Set horizontal tab stops

ESC E 1B 45 Begin bold print

ESC F 1B 46 End bold print

ESC G 1B 47 Begin correspondence quality (CQ) print

ESC H 1B 48 End correspondence quality print

ESC I n 1B 49 n Begin CQ (n=2) or normal (n=0) print

* ESC J n 1B 4A n Feed document up n/216 inches

ESC K 1B 4B Begin 60 dot/inch graphics

ESC L 1B 4C Begin 120 dot/inch graphics

ESC R 1B 52 Set all tabs to default values

ESC W n 1B 57 n Begin (n=1) or end (n=0) expanded chars

ESC X mn 1B 58 Set left and right margins at columns m and n

ESC Y 1B 59 Begin 120 dot/inch full speed graphics

ESC Z 1B 5A Begin 240 dot/inch graphics

ESC [ @ 1B 5B 40 Begin or end double high or wide

ESC [ I 1B 5B 49 Set character pitch

ESC [ J 1B 5B 4A Set 1/5 inch line spacing

ESC [ d 1B 5B 64 Set print quality

ESC [ g 1B 5B 67 Set graphics mode (DP7 only)

* ESC ] 1B 5D Reverse line feed

ESC d 1B 64 Move print position

ESC ~ C 1B 7E 43 Select Mode C

ESC XXX 1B XXX Execute Mode C command XXX

20

Commands prefixed with a * will not be executed until after an ESC ENQ is received if the BLOCK protocol is

used. ESC ENQ's are not required if DTR or XON/XOF protocols are used.

3.12.2 Mode I Document Movement Commands

LF moves the document up one line, with line spacing keypad selected (see 3.6.1) or set by an ESC

0,1,2 or 3 command.

ESC 0 sets line spacing to 1/8 inch.

ESC 1 sets line spacing to 7/72 inch.

ESC 2 sets line spacing stored by a prior ESC A n.

ESC 3 n sets line spacing to n/216inch with n being a single binary coded byte.

ESC 5 n sets auto LF if n=1 and resets it if n=0. A line feed is automatically performed when a CR is

received if auto LF is set.

ESC A n stores lines spacing of n/72 inch with n being a single binary coded byte but the stored line

spacing will not begin until it is set by an ESC 2.

ESC [ J followed by the 4 byte hexadecimal sequence 02 00 20 01 sets line spacing to 1/5 inch.

VT moves the document up to the next vertical tab stop or does a LF if no tab stops are set.

ESC B nnnnn0 sets up to 64 vertical tab stops at each line n with each n being a single binary coded

byte and terminating with a 0 byte. ESC B 0 clears all vertical tab stops.

ESC R clears all vertical tabs and sets horizontal tabs to default values of column 9 and every eighth

column to the right.

ESC J n moves the document up n/216 inches with n being a single binary coded byte.

ESC ] moves the document down one line, with line spacing keypad selected (see 3.6.1) or set by an

ESC 0,1,2 or 3 command.

FF or ESC 4 ejects the document.

If any document movement command (LF, VT, FF, ESC 4, ESC J # or ESC ]) has been preceded by any

printable ASCII characters, they will be printed before the movement command is executed.

3.12.3 Mode I Print Commands

CR prints all preceding printable ASCII characters. There is no document movement due to the CR

unless auto LF has been set by a ESC 5 01 command and then a LF will be performed.

BS prints all preceding printable ASCII characters and positions the print pointer so the next

character will be printed over the last character.

HT moves the print pointer to the next horizontal tab to the right if one is set.

ESC D nnnnn0 sets up to 28 horizontal tab stops at each column n with each n being a single binary

coded byte and terminating with a 0 byte. ESC D 0 clears all horizontal tab stops.

ESC R sets all horizontal tabs to default values of column 9 and every eighth column to the right and

clears all vertical tabs.

ESC d mn moves the next print position right by (256 X n + m)/120".

ESC X mn sets the left and right margins at columns m and n. Printing will then begin at column m and

can not extend past column n.

SO starts double width printing. All characters received after an SO and before a CR, DC4, CAN,

ESC W or feed command will be printed double width.

DC4 stops double width character printing.

ESC W n starts double width printing if n=1 and stops it if n=0.

This manual suits for next models

1

Table of contents

Other Craden Printer manuals