PalmgrenOperatingManual&Parts List

INSTALLATION {CONTINUED}

• Grounding plug should be plugged directly into a properly

installed and grounded :_ prong grounding_type receptacle

(See Figure 2).

•Donotremoveoraltergroundingpronginanymanner._nthe

event of a malfunction or breakdown, groun_ng provides a

path of least resistance for electrical shock.

WARNING: Do not permit fingers to touch the terminals of plug

when installing or removing from outlet.

•Plug must be plugged into matching oudet that is propedy

installed and grounded in accordance with all local codes and

ordin antes. Do not modify plug provided.If it will not fit in out-

let, have proper outlet installed by aqualified electrician.

Inspect tool cords periodically, and, ff damaged, have repaired

by an authorized service facility.

°Green (or green and yellow) conductor in cord is the grounding

wire. If repair or replacement of the electric cord or plug is nec-

essary" do not connect the green Ior green and yellow) wire to

a I_ve terminal.

° Where a 2-prong wall receptacle is encountered, it must be

replaced with a propedy grounded B-prong receptacle installed

in accordance with National Electric Code and Ic_:al codes and

ordinances.

WARNING;This work should be performed by a qualified

electrician.

•Atemporary 3-prong to 2-prong grounding adapter (See

Figure 3) isavailable for connecting plugs to a two pole outlet

if it is properly grounded.

Grounding Lug Make sure this is

Adapte:___._ Conn_ to aknown

3_ro Grounded Receptare

2Prong Recepfacle

Figure 3 - 2-Prong Receptacle

Do not use a 3-prong to 2 prong grounding adapter unless

permitted by local a_d national codes and ordinances.

(A 3 prong to 2-prong grounding adapter is not permitted in

Canada{ Where permitted, the rigid green tab or terminal on

the side of the adapter must be securely _onnectod to ape_

manent electrical ground such as aproperly grounded water

pipe, apropedy grounded oudet box ar a propedy grounded

wire system.

• Many cover plate screws, water pipes and outlet boxes are not

properly grounded.To ensure proper ground, grounding means

must be tested by a qualified etectTician.

EXTENSION CORDS

The use of any extension card will cause some drop in voltage

and loss of power.

Wires of the extension cord must be of suffident size to carry

the current and maintain adequate voltage,

Running the unit on voltages which are not within _1 G% of the

specified voltage may cause overheating and motor burn-out.

Use the table to determine the minimum wire size (A.W.G.)

extension cord.

Use only 3 wire extension cords having 3-pT'ong grounding

type plugs and 3-pole receptades which accept the tool plug.

If the extension cord is worn. cut or damaged in any way,

replace it immediately.

82064

EXTENSION CORD LENGTH

Wire Size ............................................... _,.W.G.

Up to 25 It ................................................... 16

NOTE: Using extension cords over 25 ft. long is not recommended.

ELECTRICAL CONNECTIONS

WARNING: All electrical €onnecfions must be pe_ormed by a

qualified elect dc_an. Make sum tool is off and d(sconnected from

power source while motor is mounted, connected, reconnected or

anytime wiring is inspected.

• Motor is assembled with approved, 3-conductor cord to be

used at 12G vdit s.Motor is prewlred at the factory for t ZO volts.

Refer to Figure 4,

WARNING_ Alwayswear safetyglassescomplying with United

States ANSi Z_7.1 (shown on package) before commencing power

tool operation.

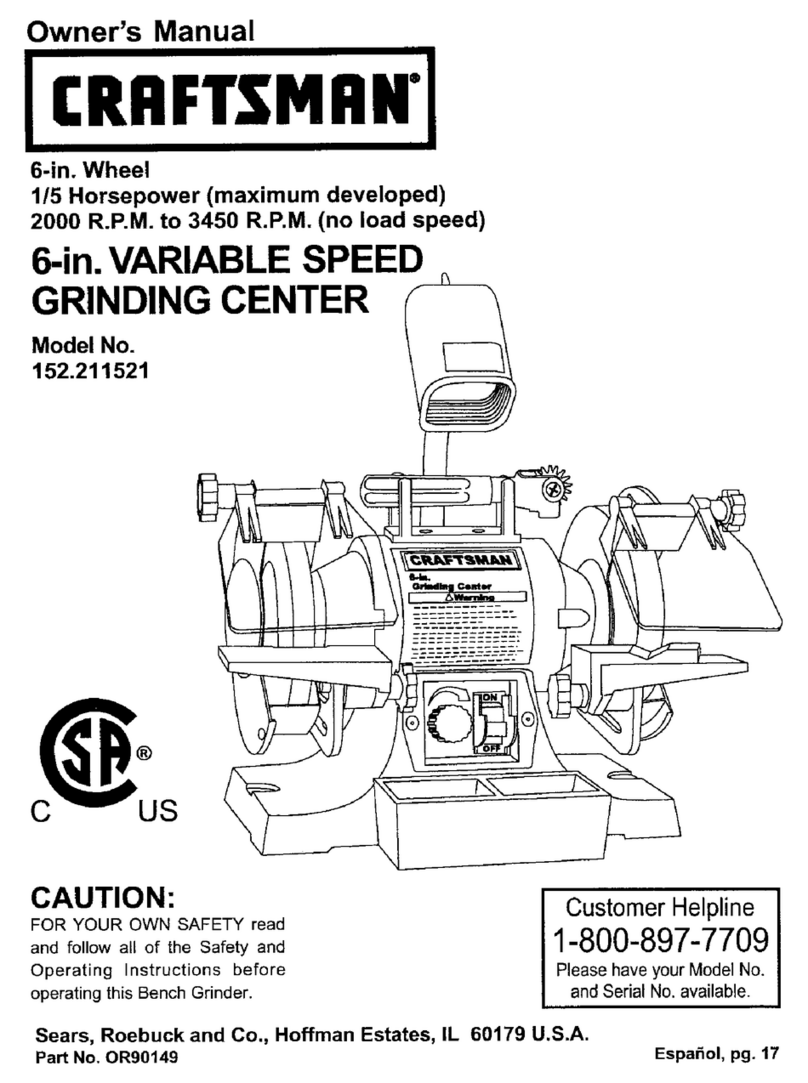

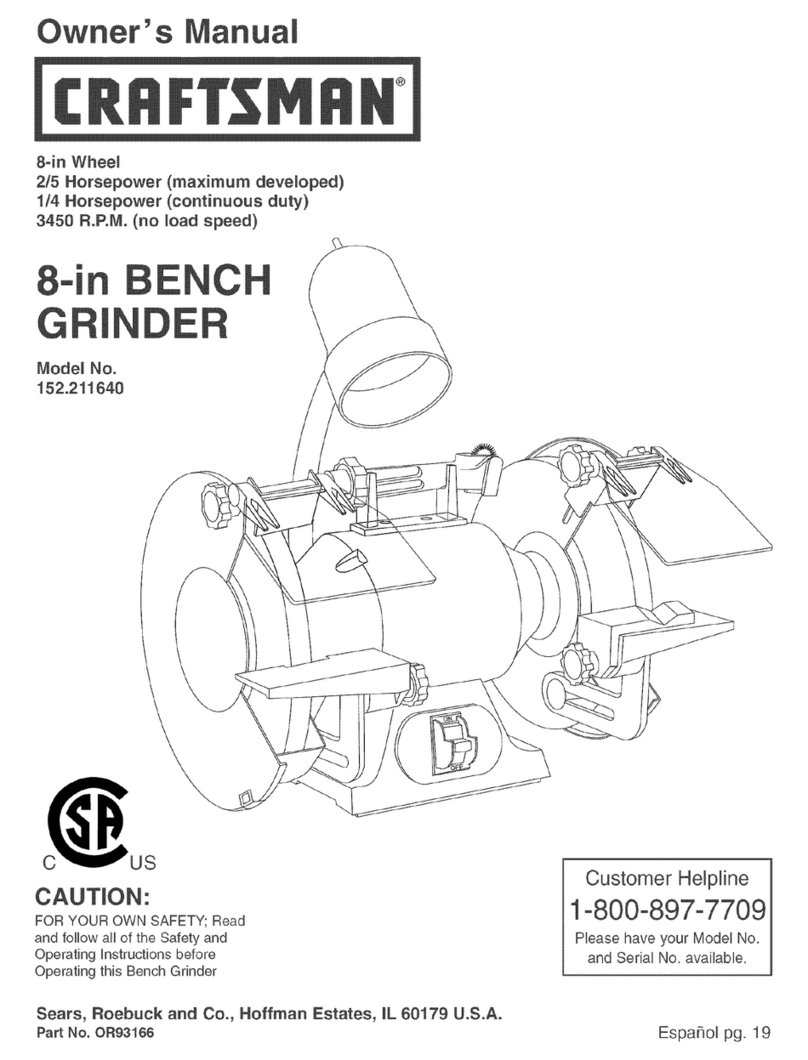

• TOtom gdnder "ON_flickswitch upward (Ref.No. 3gl. NOTE:

switch has a key which canbe removed to prevent unautho-

rized use.

•Toope_te grinder at foil speed (34S0 RPMI,turn knob (ReL No.

5g) completely counte_dockwise.

To ope_aLegdnder at aslower speed tom knob clockwise.The

speed is infinitely variable from 2000 to _,300rpm.

•Keepa steady, moderate pressureon the work and keep it

moving at an even pace for smooth grinding.

•Pressingtoo hard overheats the motor and prematurely wears

down the grinding wheels.

Note the origina) bevel angle o_ the item to be sharpened and

try to maintain that angle. Sharpening a cutting edge requires

removing burrsfrom edge.

•Debuning edge isdone best by using the gdnder to pull burr

fi'om edge acrossthe bevel angle.

• The grinding wheel should rotate into object being shaqoened,

•Usedower wheel speed when sharpening tempered tools.

Overheating will dest]oy the tofnper.

•When grinding at high speed, dip work into a coolant regulady

to prevent ovei'heat_ng,Overheedng can weaken metals.

As wheels wear, tool zests should be positioned closer to the

face of the wheels.

The gap bebveen the wheel and the Cool rest should not be

greater than _/_When the wheels are worn to the extent that

the _/_ maximum gap cannot be maintained, the wheels

should be replaced.

Replacement wheels should have a minimum rated speed of at

least 3600 RPM.

Maximum wheel diameter is 6."

To }oosen nuts holding the wheels, disconnect powe_" and push

a wood wedge between the tool rest and the wheel to keep

the shaft horn turning.The threads on the right side of the

gffnder (facing unit} are right hand; threads on the left side are

left hand._ghten nuts securely before operatfag the gdnder.

For gdnding effidenc, y, wheels should be dressed periodically,

espe_ally if they become clogged _rom gdndiag soft n_ta/s.

4