b_ if whoa& are in correct alignmenh the straight edge

wi!Jcontactthewheelsatfourpoints,A, B,C and D.

c if: any misdignment e×ists, loosen the set screw (57,

figure 5) in the _ower wheat and, with the straight_

edge contacting points C and D oe the _awet whee!_

adiust it in:or out until the straightedge contacts points

A and B of the _piper whee!_

d. if only one point A or B is contacted, odivstthe se!f_

Iock_ng blade a$igement screw (19) to ti!t the upper

wheel until aS[ four paints are in coetoct,

e_ After proper allgnmeet has been accomplished,

tighten the set screw (571 to secure the iower wheat

on _hearbor shaft (60)_

NOTE: If a _/8-inch w_dth blade is used,

the alignment screw (19) will require 'further

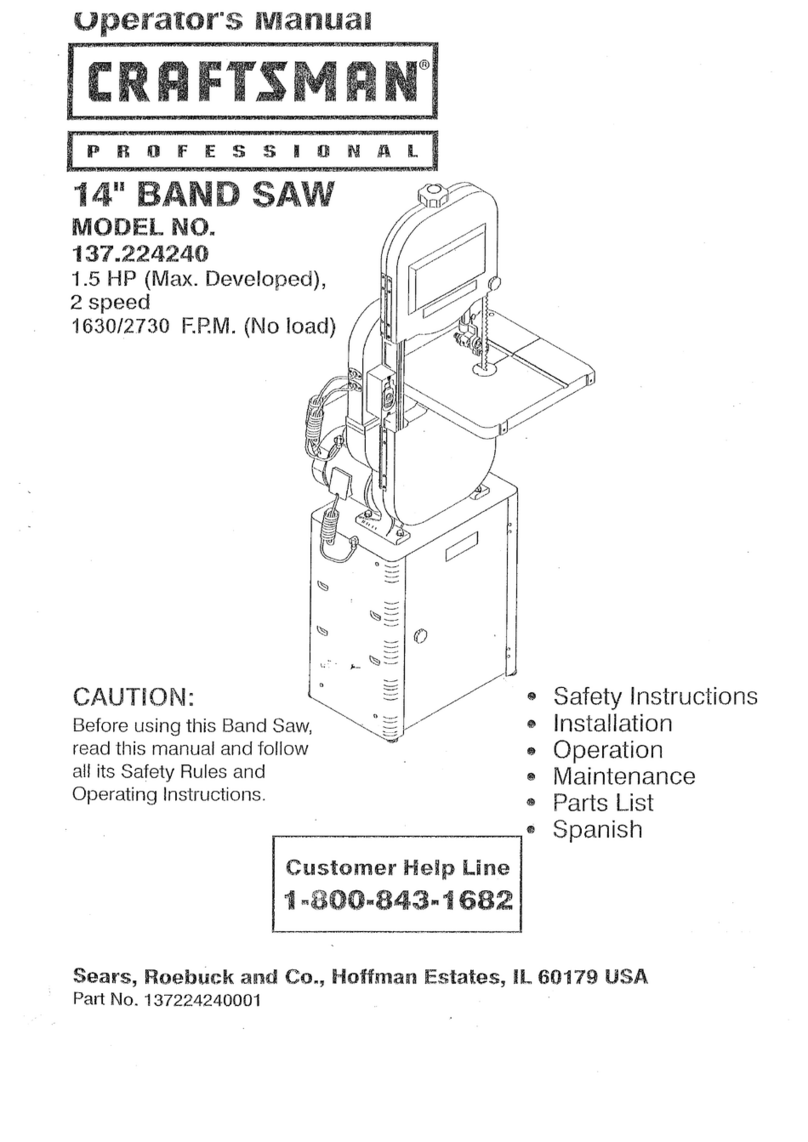

3_ Guldes Sow guide ossembUesare provided both above

and betow the table in order _o support the blade against

[Qtera! thrust end direct thrust_ The _pper saw guide

assembly must operate so the distance from the back

of the saw blade to the thrust roller remains the same

throughout the entire up and down movement of the

b_

C_

d_

if on adjustment is nee:essay, remove the, cover and

turn the upper saw guide bar adiusting _rew_ e_ther

in ar out as required (See flgo_e 4_)When adjus_

meet is completed !ock the adjusting _rew lack nut'

to maintain the adjusiment,

Adjust the sow guide assemblies so the latera! :saw

guides (whoa adjusted) wili coetact the Blade oe the

solid potion only, not on the teeth or valleys behveen

teeth_ (See figure 20 This is accomplished by loosen,.

ing the sew guide assembly adiusfieg screws and

moving the saw guide assemblies, forward or' back-

ward as required. Whoa the adjustment is correct,

Jack the saw guide assemblies in position

Set the lateral saw guides us close as possible to

the blade without binding the blade ot any point

or deflecting it sidewise. Lock the set screws securing

the lateral saw guides when the adjustment is correct

The blade thrust ro,!!ers shouid be set the thkkness

of a piece of newspaper from the back edge of the

e_

blade,(See figure 4.) Using ascrewdriver, turn the

the bearing hoJder in or' o_t until @e roller is ie

correct position, The blade should to_ch these rollers

oe!y when cu_ing, not whee saw is ru_ning ffee_

The above odjustme_:ts should result i_ afree running

saw b!_de when no c_#ing operofioes are being

g_

h_

The table should be square with the blade and, at

the some time, the po#tter should indicate :zero on

the scaJe_ if a correctloe is necessary, it may be made

by piecing an accurate _uare an the table surface

and against the s_w blade_ (See figure 2_) Adjust

the 90 a stop screw untl] the adjustment is correct,

The te:bJe tilt poieter may now be reodiusted to the

zero mark on thescale by loosening the screw which

hoids the pointer to the sow. (See figure 1_)

After comp!eting a!! adiustme_ts on the s_w, check:

tar'el:oily by turning the mechanism by hand several

revolutions before operating the sow with power

NOT_: After a few hours of operation,

tlghte_ aH pulley set screws.

OPERATION

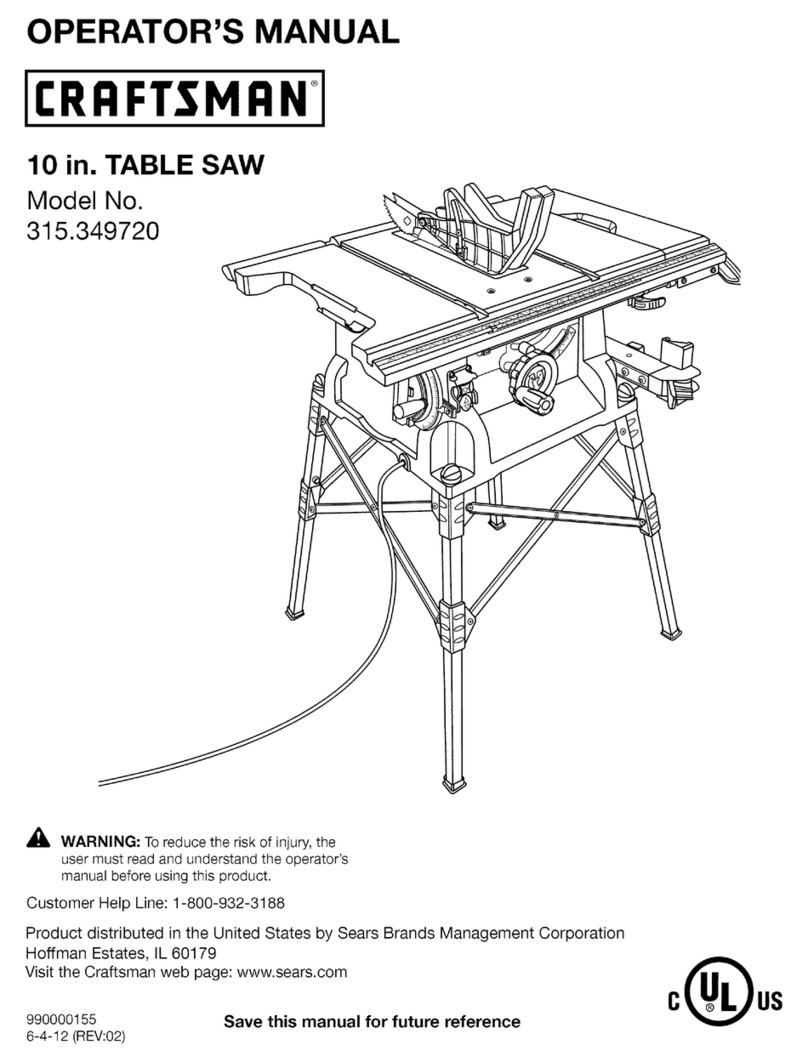

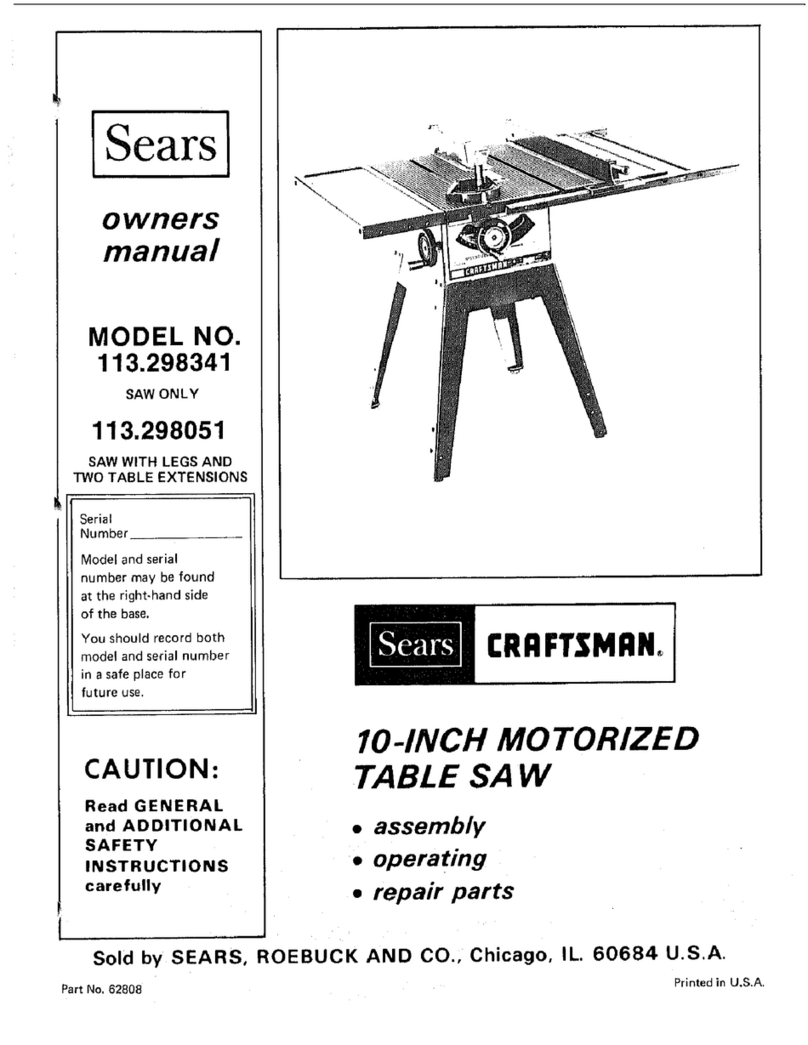

, Co_tre_so The operator should become familiar w_th aH

cont_o!s before operating the: saw_ A _i_!e time spent i:n

this effort wilt protect the saw and insure operational

sofe_ (See figures 2 and 4_)

a. The t_b|e 'Jilt |ock he,die _ lacks the tobie in any

position with the saw blade from 90 ° to 45°,

b_ The t_bie tilt p_inter _ indicates the table angle on

@e caiibrated trunnion _ale

c, The blade g_ides _ back up the blade far both

[otera! and direct thrust,

d_ The b,l_e g_ide eieveti_ |ock k:_eb _ controls

the upper assembly in relation to tobie surface for

various work piece thicknesses,

e. The blade _[ig_e_ s_ew _ provides _ means af

tihing the upper wheel for correct saw blade tracking

5

The blede tensie_ cam - (35, figure 5) provides a

quick and easy meaes _or changing saw b4ades, Pull

the cam handle down to re!ease the upper wheel and

loosen the saw biode_ Push the cam handte up to

repo@ion the wheel and tighten the saw blade.

2_ Open,flag Pr'e_ed_e,

a. Hold the work piece firmly against the table surface

during at! cutting operations.

b_ Do not farce the work against the blade beyond the

cu#ing capacity of the bJade_ as it will produce ex_

treme difiicul? in folbwing the pa_em layout.

3_ 5efety D_i_g Operetie_,

CAU_|ON_ Always disconnect i_put cable

from power supply when adjusting the sow,

from one working poslt_on to another