Makita LS002G User manual

Other Makita Saw manuals

Makita

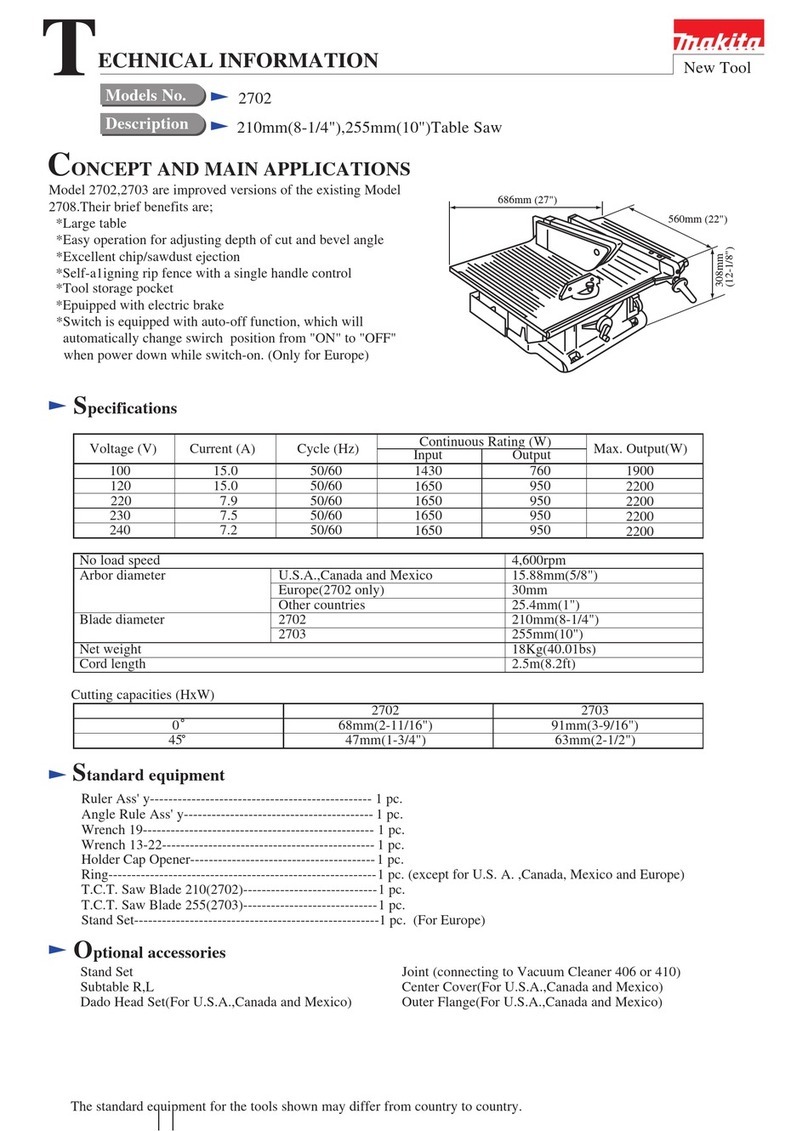

Makita 2702 Manual

Makita

Makita MLT100N User manual

Makita

Makita LS0714 Manual

Makita

Makita LS003G User manual

Makita

Makita SP6000J1X User manual

Makita

Makita M2401 User manual

Makita

Makita UC3020A User manual

Makita

Makita JR3000 User manual

Makita

Makita LS1214 User manual

Makita

Makita LS002G User manual

Makita

Makita M2300 User manual

Makita

Makita LS1216 User manual

Makita

Makita LS1011 User manual

Makita

Makita 5092D User manual

Makita

Makita LS1212 User manual

Makita

Makita LS1216L User manual

Makita

Makita DPB181 User manual

Makita

Makita DLS211 User manual

Makita

Makita 5603R User manual

Makita

Makita MLT100 User manual