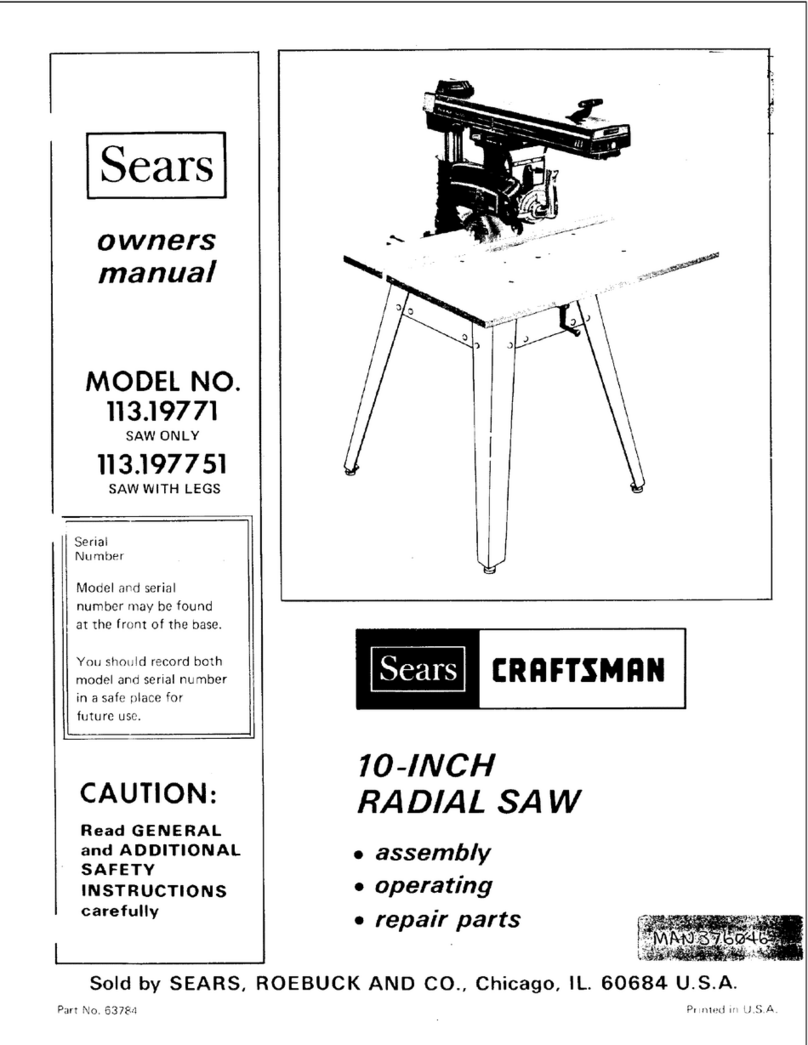

moving the motor support assembly towards or away from

the cradle. Motor should be allowed to rest or hang

against the belt to obtain the automatic belt tightening

feature- and belt should be snug. If adjustment is cor-

rect, clamp the motor support in place by tightening the

two square head set screws (part S-1267, fig. 4).

ADJUSTING MOTOR MOUNT TENSION, Tension

is adjusted by tightening the nut (part S-1215, fig. 4)

against the steel washer (part S-1261) and the spring

washer (part 6423). Nut should be tightened just enough

to reduce motor vibration when saw is operating. Do

NOT tighten nut to alocked position, or the stud will be

sheared off when blade is raised or lowered. A sliding

action is necessary because mount changes position as

blade is raised or lowered. Operate the saw by hand to

make certain that the belt has proper tension and that

mount changes position as it should.

If saw is to be driven by a large frame motor that cannot

be mounted on the motor support assembly, mount the

motor on motor rails. Use a 1/2-inch wide belt with a

minimum length of 80 inches. Adjust the position of the

motor until belt clears all obstructions through all po-

sitions of the saw blade.

If saw is to be driven from a line shaft, use abelt at least

100 inches long.

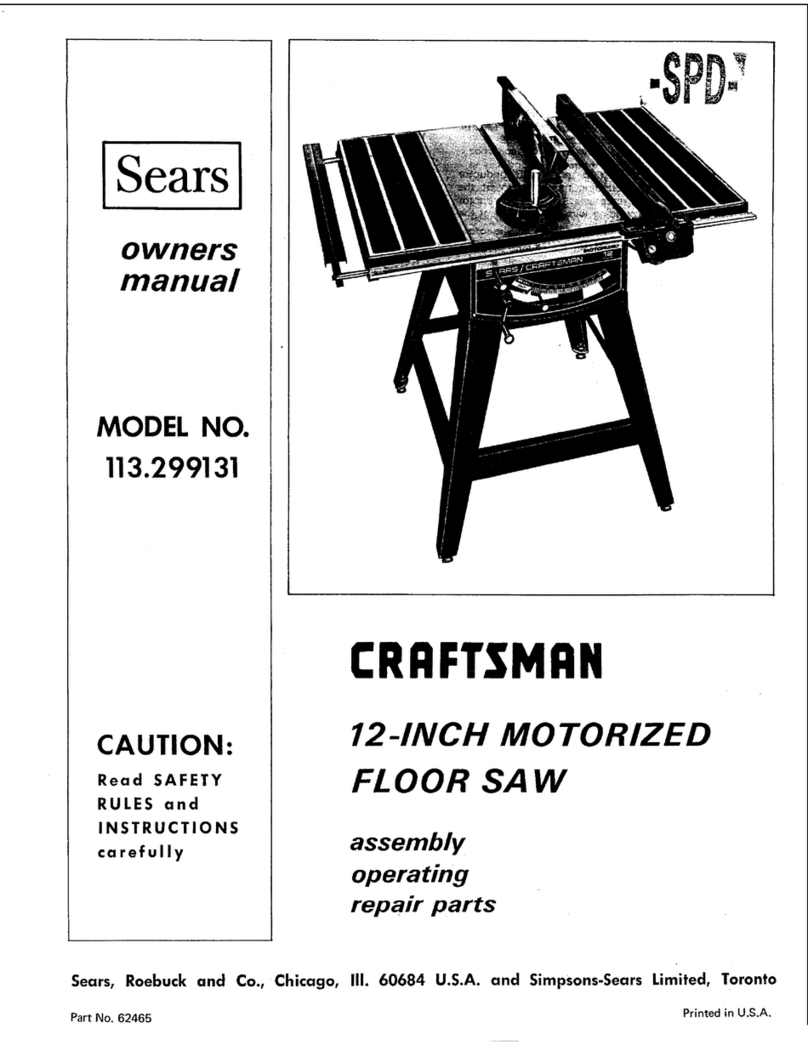

PLACEMENT OF MITER GAGE- The miter gage as-

sembly (K, fig. 1) can be used in either one of the two

table grooves.

This saw is designed to be used with a3450 rpm motor.

Motor should be 3/4 hp (for light duty) or one hp (for

heavy duty)- in either an AC motor of arepulsion-

induction or capacitor type, or a compound-wound DC.

The motor shaft center siaould be approximately 4inches

above the bottom of the motor base. If this dimension

varies appreciably from 4inches, it may be necessary to

obtain abelt of adifferent length. If a 1750 rpm motor

with a 4-5/8-inch shaft center height is used, a 5-inch

motor pulley and a 46-inch belt must be purchased. If

the motor shaft center height varies greater or smaller

than the above dimension, a correspondingly greater or

smaller belt length should be used. _hese may be ordered

through any Sears Retail Store or Mail Order House.

CAUTION

Under no circumstances should a5-inch motor

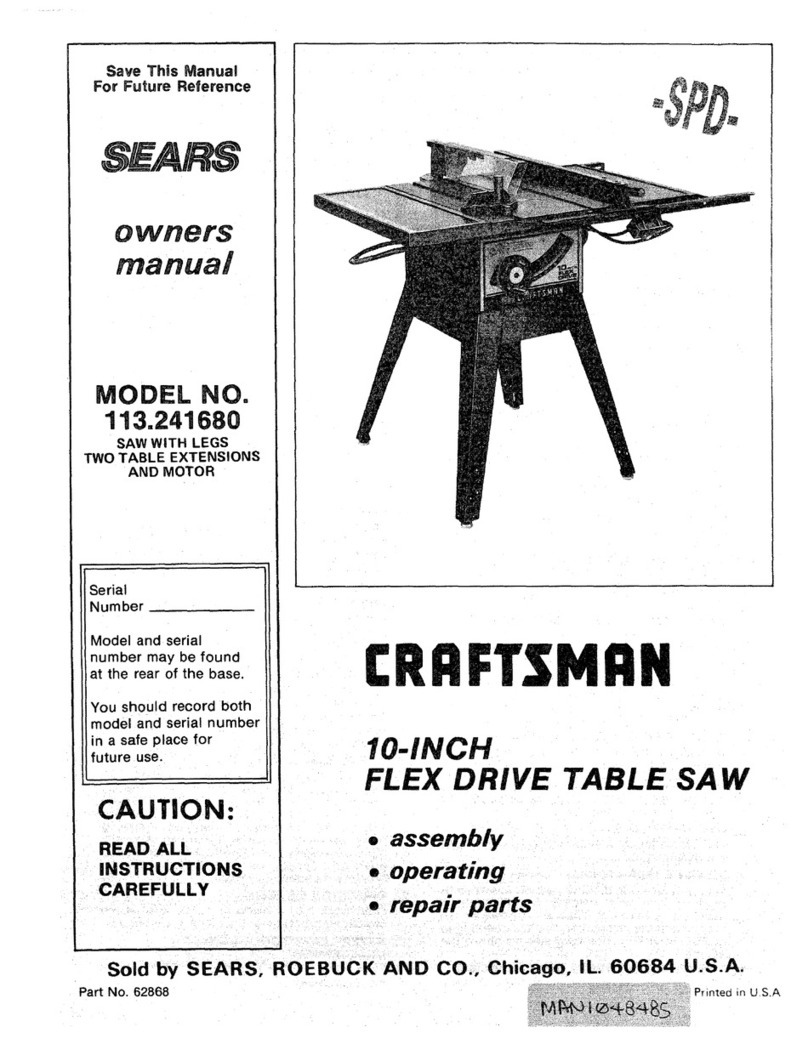

Figure 2

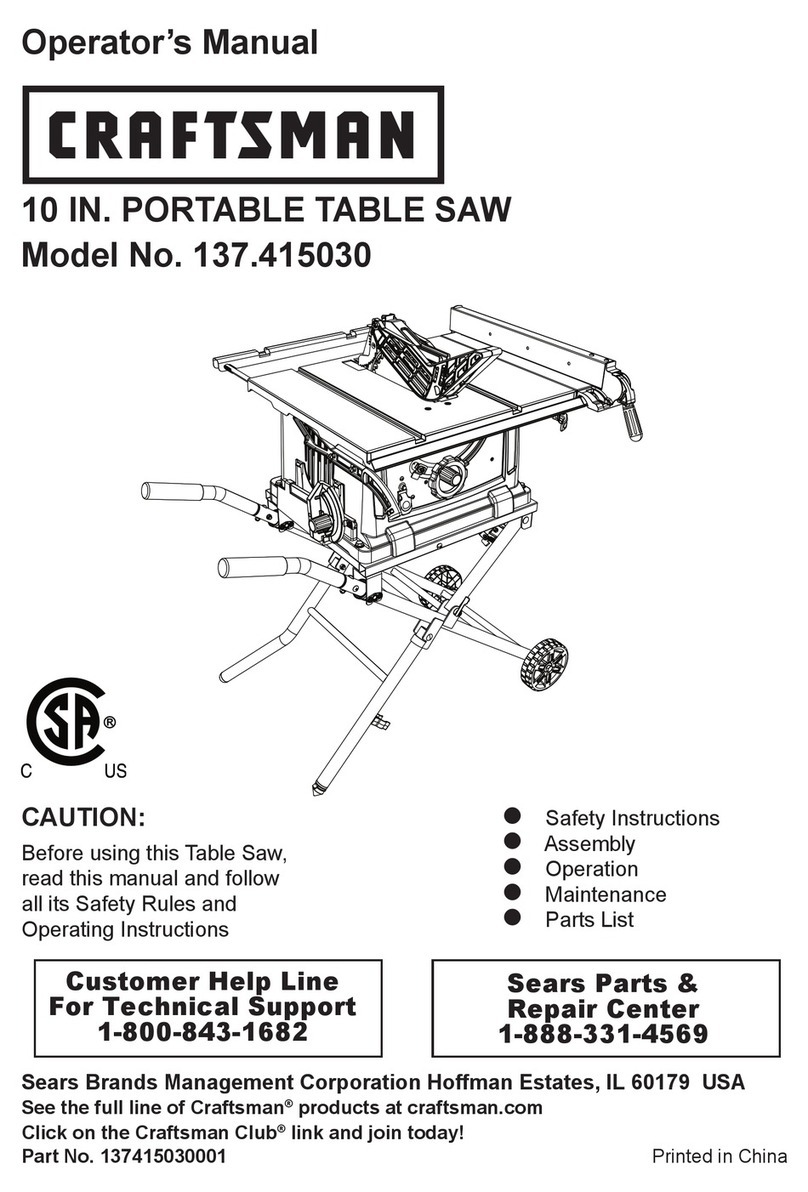

ELEVATION HAND WHEEL (A)- on the front of

the saw, controls elevation of the blade.

CLAMP SCREW HANDLE (D) on front of saw, locks

the tilt mechanism in any desired position. The

clamp screw handle operates like a socket wrench.

Tilt mechanism should always be locked before start-

ing work and should always be unlocked before

attempting to change the angle of tilt.

TILT HAND WHEEL (B) on left side of saw, con-

trois the angle of tilt. The saw blade can be tilted

from 0°to 45 °, as indicated on the TILT GAGE

(C). If the angle of cut (tilt) must be extremely_

accurate, the angle of the saw blade should be

checked with a protractor or with a board which is

known to be cut at the exact angle required.

RIP FENCE (E) -- is operated by pushing in the FENCE

KNOB (F) so that it engages apinion gear with

the teeth on RACK (H). Turning the knob (F),

after pushing it in, will cause the rip fence to move

accurately across the table. When the knob (F) is

pulled out to disengage pinion gear, the rip fence

can be moved across the table by hand. Keep the

saw table and rip fence clean. Dirt may prevent the

rip fence from obtaining proper alignment. Tapping

the fence lightly to assist the mechanism to find its

natural position, will help to maintain alignment of

the fence with the blade.

CAM CLAMP LEVER (G)m is used to clamp the rip

fence in place after it has been moved to the position

desired.

MITER GAGE (J) w is used in table grooves as a guide

for the workpiece when the fence is not used. The

angle of the gage can be adjusted by loosening

CLAMP KNOB (K) and positioning gage as indi-

pulley be used with a 3450 rpm motor. The saw

blade speed resulting from such apulley ratio cated by the dial and pointer on (J).

would be dangerous. Do not use a 2fi_-inch MITER GAGE STOP ROD (L)--can be adjusted in

motor pulley _Tith a 1750 rpm motor --_is will length by loosening WING NUT (M). TI_ rod is

not ive satisfactory saw erformance, useci as a positioning guide for the end of the work-

gPptece.

The ¸ their uses. See figure 2.

_3_

CAUTION

Under no circumstances sh_d a blade with a

diameter greater than 10 inches: be _ with

this saw.