Ifsituationsoccurwhicharenotcov-

eredinthismanual,usecareand

goodjudgment.Ifyouneedassis-

tance,contactyourSearsService

Centerorcall1-800-235-5878.

OPERATORSAFETY

• Alwayswearsafetyeyeprotection.

• Alwayswearlongpants,long

sleeves,boots,andgloves.Wearing

safetylegguardsisrecommended.

Donotgobarefootorwearsandals.

Stayclearofspinningline.

• Securehairaboveshoulderlength.

Secureorremovelooseclothingor

clothingwithlooselyhangingties,

straps,tassels,etc.Theycanbe

caughtinmovingparts.Beingfully

coveredalsohelpsprotectyoufrom

debrisandpiecesoftoxicplants

thrownbyspinningline.

• Donotoperatewhenyouaretired,

ill,upset,orundertheinfluenceof

alcohol,drugs,ormedication.

• Wearhearingprotection.

• Neverstartorruninsideaclosed

roomorbuilding.Breathingexhaust

fumescankill.

• Keephandlesfreefromoilandfuel.

UNIT/MAINTENANCE SAFETY

• Disconnect the spark plug before

performing maintenance except car-

buretor adjustments.

• Look for and replace damaged or

loose parts before each use. Look

for and repair fuel leaks before use.

Keep in good working condition.

• Replace trimmer head parts that are

chipped, cracked, broken, or dam-

aged in any other way before using

the unit.

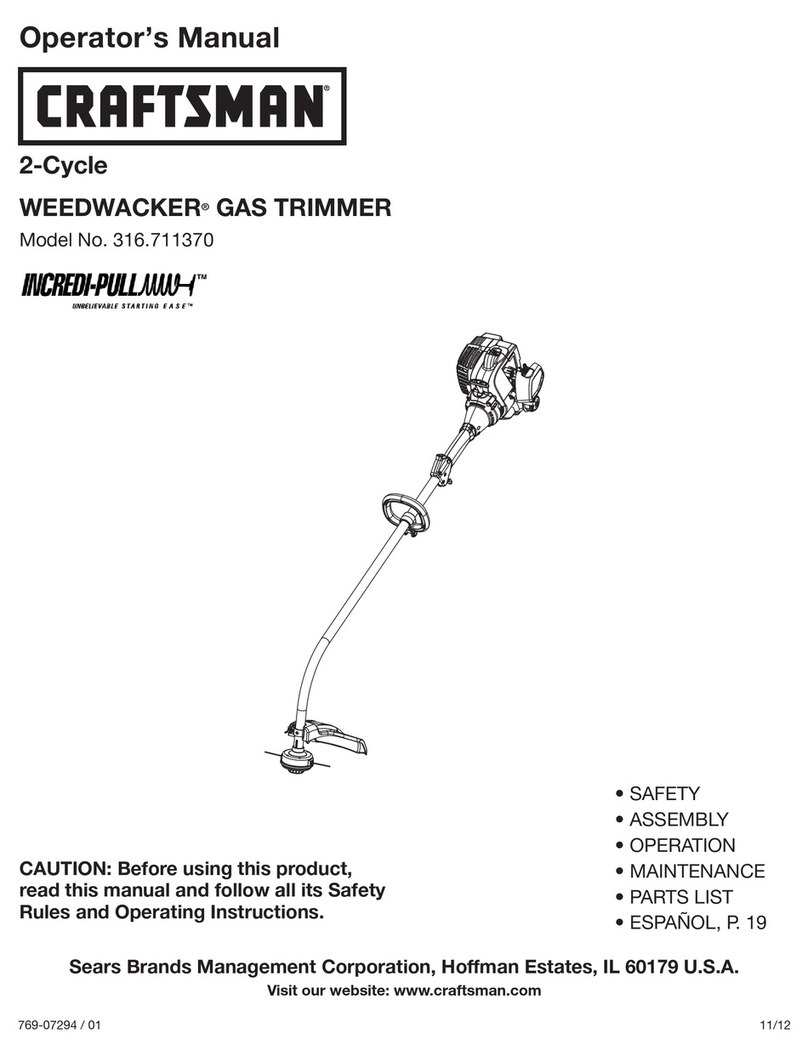

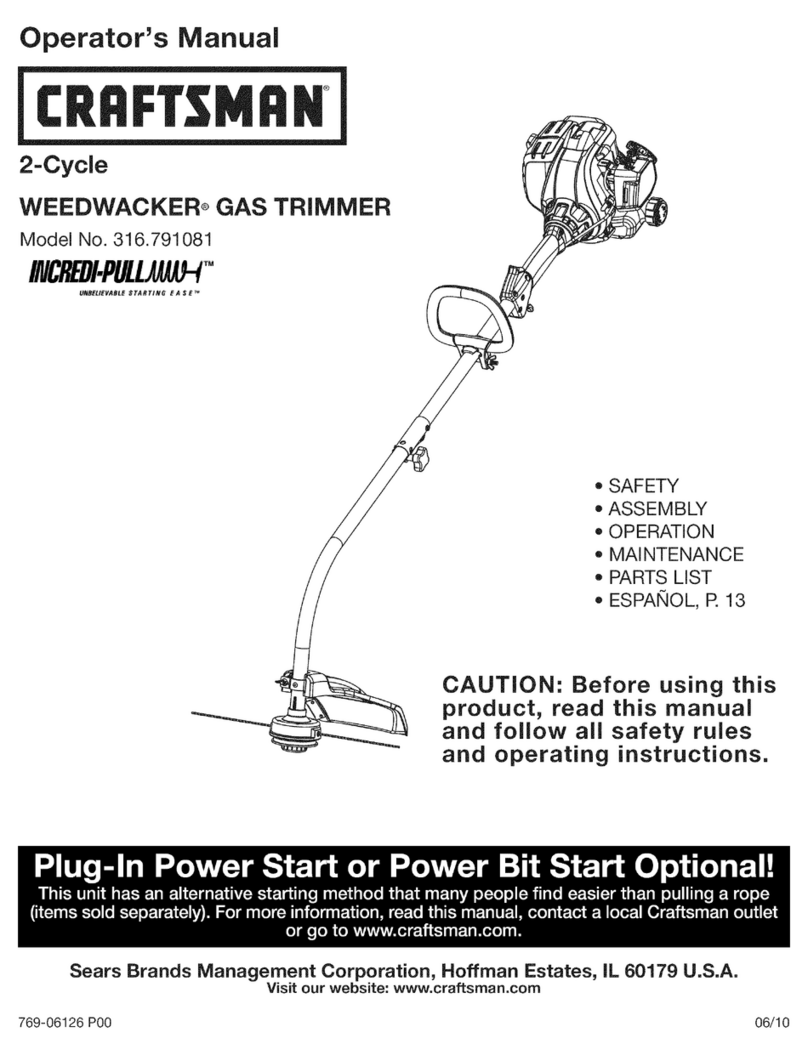

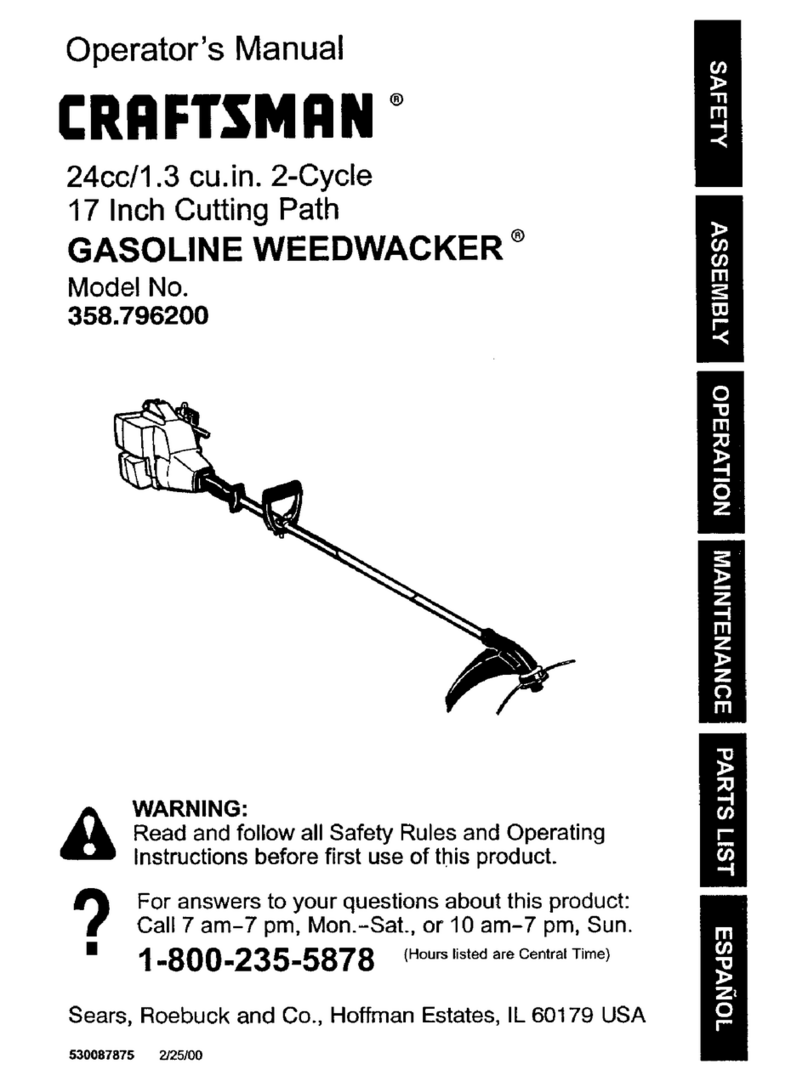

• Make sure unit is assembled correct-

ly as shown in this manual.

• Make carburetor adjustments with

lower end supported to prevent line

from contacting any object.

• Keep others away when making car-

buretor adjustments.

• Use only recommended Craftsman

accessories and replacement parts.

FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near

fuel or the unit.

• Wipe up all fuel spills.

• Move at least 10 feet (3 meters)

away from fueling site before starting

engine.

• Stop engine and allow to cool before

removing fuel cap.

CUTTING SAFETY

• Use only for trimming, scalping, mow-

ing and sweeping. Do not use for edg-

ing, pruning or hedge trimming.

• Inspect the area before each use.

Remove objects (rocks, broken

glass, nails, wire, etc.) which can be

thrown by or become entangled in

line. Hard objects can damage the

trimmer head and be thrown causing

serious injury.

• Keep firm footing and balance. Do

not overreach.

• Keep all parts of your body away

from muffler and spinning line. Keep

engine below waist level. A hot muf-

fler can cause serious burns.

• Cutting on left side of the shield will

throw debris away from the operator.

TRANSPORTING AND STORAGE

• Allow engine to cool; secure unit be-

fore storing or transporting in vehicle.

• Empty the fuel tank before storing or

transporting the unit. Use up fuel left

in the carburetor by starting the en-

gine and letting it run until it stops.

• Store unit and fuel in area where fuel

vapors cannot reach sparks or open

flames from water heaters, electric

motors or switches, furnaces, etc.

• Store unit so line limiter cannot acci-

dentally cause injury. The unit can be

hung by the tube.

• Store unit out of reach of children.

SPECIAL NOTICE: This unit is not

equipped with a temperature limiting

muffler and spark arresting screen

which meets the requirements of Cali-

fornia Codes 4442 and 4443. All U.S.

forest land and the states of California,

Idaho, Maine, Minnesota, New Jersey,

Oregon, and Washington require by

law that many internal combustion en-

gines be equipped with a spark arres-

tor screen. If you operate in a locale

where such regulations exist, you are

legally responsible for installing and

maintaining the operating condition of

these parts. Failure to do so is a viola-

tion of law. Contact a Sears Service

Center for the correct parts.

SPECIAL NOTICE: Exposure to vibra-

tions through prolonged use of gaso-

line powered hand tools could cause

blood vessel or nerve damage in the

fingers, hands, and joints of people

prone to circulation disorders or abnor-

mal swellings. Prolonged use in cold

3