CraftUnique CraftBot User manual

1

CraftBot

CraftBot

THE ULTIMATE 3D PRINTER

USER

MANUAL

2

CraftBot

TABLE OF CONTENTS

INTRODUCTION 3

IMPORTANT 4

WARNINGS 4

CAUTION! 5

CONTENTS OF THE BOX 5

INTRODUCING THE CRAFTBOT 3D PRINTER 6

UNPACKING THE CRAFTBOT PRINTER 7

ASSEMBLING THE CRAFTBOT PRINTER 7

1. Install the lament guide tube holder 7

2. Install the lament guide tube 8

3. Install the lament spool holder 8

4. Mounting the lament spool 8

5. Attaching the power cord 8

USING THE CRAFTBOT PRINTER 9

1. Switching on the appliance 9

2. Setting the language 9

3. Selecting the heat measurement 9

4. Leveling the build plate 9

5. Loading the lament 10

6. Removing the lament from the extruder 11

7. Printing objects from the usb ash drive 11

8. Navigating the build plate and the extrude 12

9. Adjusting the lighting 13

10. Activating the fans 13

11. Using craftware to convert 3d design into printing commands 13

12. Cleaning and maintenance 15

13. Trouble shooting 16

14. Firmware update 16

15. Applying a new layer of protective kapton sheet to your build plate 17

16. Guarantee 18

17. Limitation of liability 18

APPENDIX 19

Technical Specication 19

3

CraftBot

INTRODUCTION

Congratulations on your purchase of CraftBot 3D printer and welcome to the word of 3D crafting! At

CraftUnique we believe that 3D printing opens a new window to enhance creativity. It oers outstanding

crafting experience even without prior programming or 3D printing experience.

How does the printer work? The CraftBot 3D printer makes solid, three-dimensional objects out of

melted plastic lament. Design Your objects with the help of a 3D design program. Then use the

CraftWare program (downloadable from www.craftunique.com/craftware) to transform Your 3D design

les into printing instructions for the CraftBot 3D printer. Transfer this to Your CraftBot 3D printer via

USB drive or USB cable. The CraftBot 3D printer will melt plastic laments and squeeze it out onto the

building plate in thin lines to print your object layer by layer.

4

CraftBot

IMPORTANT

Read this user manual carefully before you use the appliance and save it for future reference.

All information in this User Manual is subject to change at any time without notice and is provided for

convenience purposes only. CraftUnique reserves the right to modify or revise this User Manual in its

sole discretion and at any time. By using the manual you agree to be bound by any modications and/or

WARNINGS

• Check if the voltage indicated on the bottom of the appliance corresponds to the local mains voltage

before you connect the appliance.

• Do not immerse cord, plug or main body in water or any other liquid. This may cause electrical

shock.

• Do not use the appliance if the plug, the mains cord or the appliance itself is damaged or not

operating properly.

• If the mains cord is damaged, you must have it replaced in order to avoid a hazard.

• Only connect the appliance to grounded wall socket.

• Keep the mains cord away from hot surfaces.

• Do not let the mains cord hang over the edge of the table or worktop on which the appliance stands.

• Keep the appliance and its cord out of the reach of children.

• This appliance can be used by children aged from 8 years and above and by persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge only under supervision

and adequate instruction concerning use of the appliance in a safe way and if they understand the

hazards involved. Cleaning and user maintenance shall not be made by children.

• Children can receive great educational benets from designing 3D objects, but the printing process

should not be done by small children.

• Do not touch moving parts or heated elements, it can cause injuries.

• Never reach inside the machine when turned on. Dierent parts of the machine (mainly the extruder

and heated build plate) operate at very high temperatures and can cause severe burns.

• Never leave the CraftBot 3D printer unattended while it is plugged in, and in operation.

• Make sure that the power supply is o and that the power cord is disconnected before servicing.

Allow at least 5 minutes for the device to cool down after unplugging it before reaching inside to

service.

• Always turn o the printer and disconnect from the computer when it is not being used.

5

CraftBot

CONTENTS

OF THE BOX

It’s time to unpack additional

parts. Below you can see con-

tents of the box. First of all, check

the list to make sure nothing is

missing!

1. Filament guide tube holder

2. Filament guide tube

3. Filament spool holder

4. Filament spool

5. Hex wrenches (5x)

6. USB Flash storage

7. USB A-B cable

8. AC power cable

9. Spacer card

1

4

7

2

5

8

3

6

9

CAUTION!

• Make sure to level the build plate properly before use.

• Make sure not to force anything, whether it be during unpacking, setup, operation or service.

• Service and oil the suggested parts as often as recommended. Use only substances recommended

by CraftUnique.

• The CraftBot 3D printer melts plastic during printing. Plastic odors are emitted during this operation.

Make sure to set up the CraftBot 3D printer in a well-ventilated area.

6

CraftBot

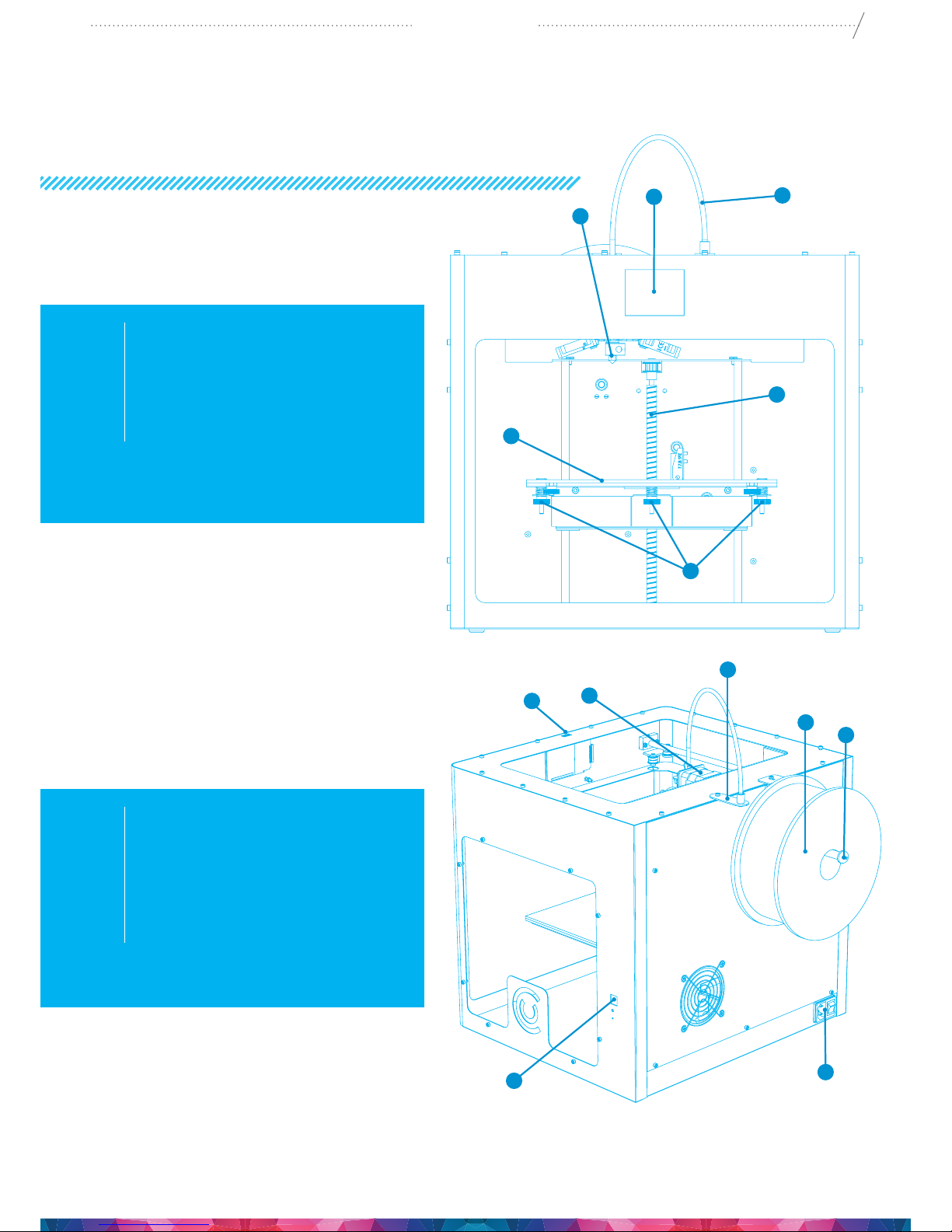

3

12

4

6

5

7

8

9

13

12

10

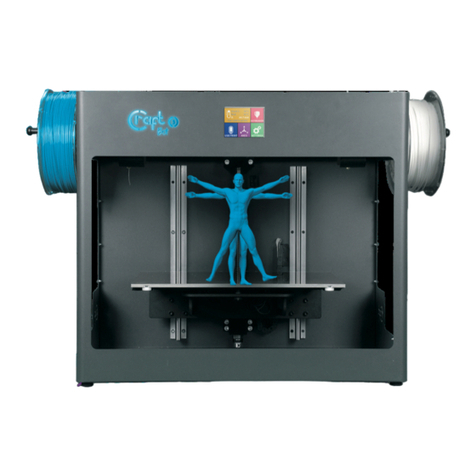

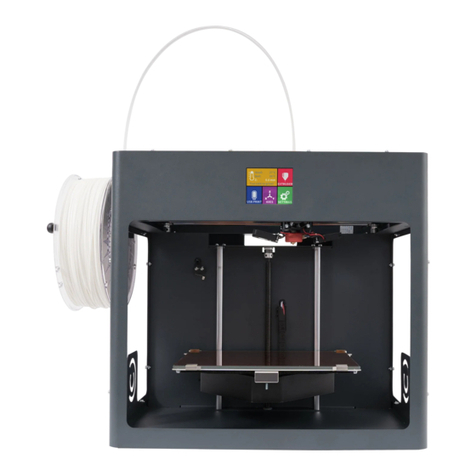

INTRODUCING THE

CRAFTBOT 3D PRINTER

1. Touchscreen LCD display

2. Filament guide tube

3. Nozzle

4. Removable build plate

5. Leveling knobs

6. Z axis rod

7. Filament spool holder

8. Filament spool

9. Filament guide tube holder

10. Extruder

11. USB-A for ash drive

12. USB-B socket

13. AC power socket and ON/OFF switch

11

7

CraftBot

UNPACKING

THE CRAFTBOT PRINTER

1. Place the CraftBot box on the ground on a level surface. Make sure that there is a lot of open space

around you.

2. Open the box with care, not to damage the contents if using a blade.

3. Remove the protective foam insert. You will nd the Quick Starter Guide located within the top

protective foam insert.

4. There is a cradle inserted, which contains the accessories (including a pen drive with a copy of

the CraftBot User Manual) and a spool of lament. Remove the cradle with care as it supports the

extruder during shipping.

5. Now you will nd the CraftBot 3D printer itself completely enclosed in a protective plastic bag. Open

the plastic covering.

6. Firmly grasp the frame of the CraftBot. Consider its weight. Request physical help if needed. Make

sure not to touch the extruder or the electronic panel inside the appliance! Lift it from the plastic

and out of the box.

7. Place the CraftBot 3D printer on a stable and level surface with sucient space surrounding.

ASSEMBLING

THE CRAFTBOT PRINTER

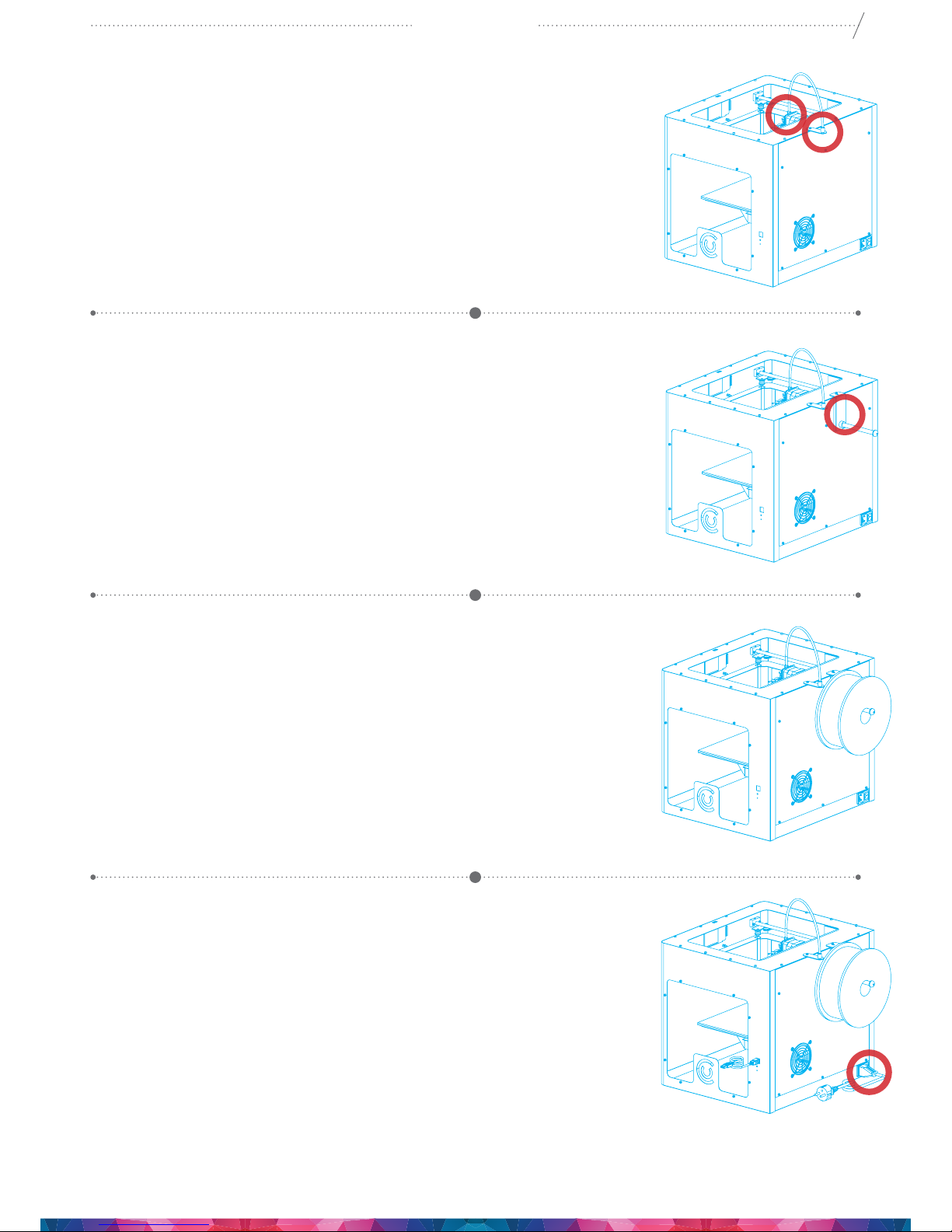

1. INSTALL THE FILAMENT GUIDE TUBE HOLDER

• Select the desired position for the tube holder. Keep in mind that the spool holder must be installed

directly next to the guide tube holder.

• Locate the guide tube holder.

• Using a hex wrench, install the guide tube holder onto the top of the CraftBot.

3 4 6 7

8

CraftBot

2. INSTALL THE FILAMENT GUIDE TUBE

• Locate the lament guide tube.

• Insert one end of the lament guide tube into the guide tube holder

on top of the CraftBot appliance.

• Push the other end into the hole on the top of the extruder.

3. INSTALL THE FILAMENT SPOOL HOLDER

• Locate the lament spool holder.

• Using a hex wrench, install the lament spool holder next to the

lament guide tube holder.

4. MOUNTING THE FILAMENT SPOOL

• Open the box containing the PLA lament and remove the lament

spool from the bag.

• Fit the lament spool onto the lament spool holder so that the lead

end keeps its course when the lament is fed into the guide tube

holder.

5. ATTACHING THE POWER CORD

• Ensure that the power switch on the CraftBot is set to the OFF position.

• Find and then insert the AC power cord into the power input on the

back of the CraftBot.

9

CraftBot

USING

THE CRAFTBOT PRINTER

1. SWITCHING ON THE APPLIANCE

• Switch on CraftBot by the ON/OFF button located on the back part of the appliance.

2. SETTING THE LANGUAGE

• Navigate to the right with the arrow.

• Choose LNG.

• Select the desired language.

• Conrm selection.

• Use the left arrow to get back to the main menu.

3. SELECTING THE HEAT MEASUREMENT

Temperature can be displayed in Celsius or Fahrenheit or Kelvin.

• Select „Settings” on the LCD menu.

• Navigate to the right with the arrow.

• Press the ⁰C/⁰F button.

• By touching the button, the scale will change from Fahrenheit to

Celsius, to Kelvin.

• Select the preferred temperature measurement.

• Use the left arrow to get back to the main menu.

4. LEVELING THE BUILD PLATE

The optimal position of the building plate is 0.3 mm from the extruder

and it must be leveled evenly. CraftBot has a leveling procedure which

ensures that the extruder and the heated build plate are at optimal

distance. A smaller gap or uneven levelling may lead to the damaging

of the kapton cover of the build plate or the extruder.

• Select „Settings” on the LCD menu.

• Select the Leveling icon – three crossed circles which represent the three knobs and screw.

• Follow the step-by-step instructions on the LCD screen:

• Turn all three black knobs holding the build plate all the way to the right until the springs in between

have been compressed fully and the knobs begin to feel tight. (There is one knob at the front in the

middle and two in the back left and right corners of the build plate). Do not force them!

• Locate the .3mm spacer card in the cardboard cradle among the other accessories. This card will

ensure the optimal distance between the build plate and the extruder. Please keep it for future use

as well.

• The preprogrammed leveling process will rst set the front center point. Place the spacer card above

the front center black knob on the build plate, then press the right arrow on the screen. Adjust the

front center knob if needed based on the instruction on the screen.

10

CraftBot

• Repeat the process with the two back knobs. First the right back, then the left back knob will be adjusted.

Before switching from knob to knob, please remove and replace the leveling card as necessary.

• Process is repeated twice to make sure that all 3 knobs are in the correct position.

• As a result, the building plate should be evenly calibrated.

• You can return to the main menu by pressing the right arrow.

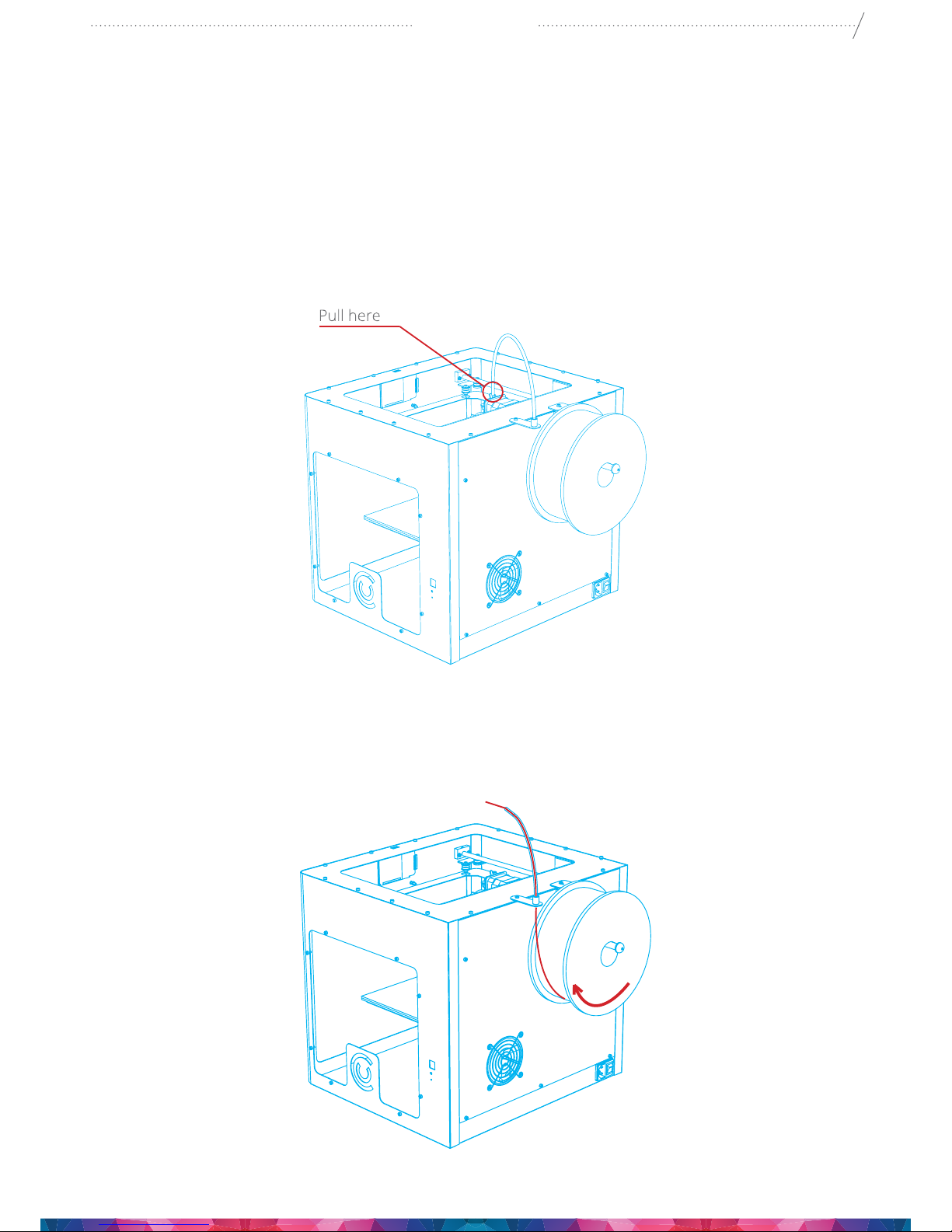

5. LOADING THE FILAMENT

1. Remove the lament guide tube from the insert hole on the top of the extruder.

2. Insert the lament from the spool into the end of the lament guide tube where it attaches to the

lament guide tube holder. Make sure that the lament spool feeds toward the guide tube holder

(from the bottom up) so that the lament keeps its course. This way you avoid any unnecessary

bending of the lament. To have a clean edge, cut the end of the lament with scissors, if needed.

3. Feed the lament all the way through the guide tube until it comes out the other end.

11

CraftBot

4. Move the extruder switch on the top of the extruder to the left into the “unlocked” position. This will

allow the lament to bypass the gears. Push the lament into the extruder hole as far as it will go.

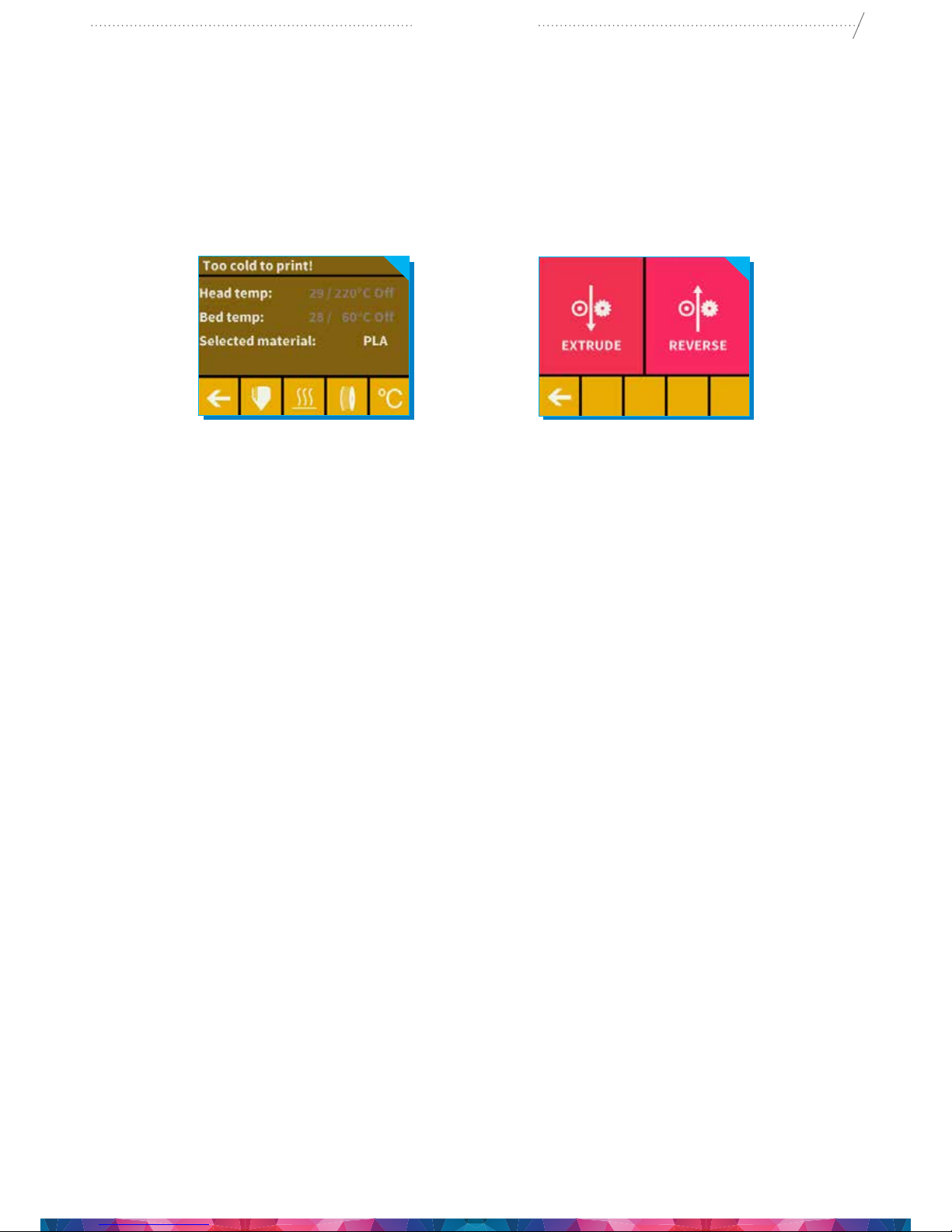

5. On the LCD screen main menu select either the extruder or the thermometer icon from the extruder

menu, press the thermometer button. At this point you will see a new menu indicating the “Head

temp” and “Bed temp”. You can select the extruder icon and the bed icon (line with 3 wavy lines

above) to commence heating. One the extruder is fully heated, you may start the printing process.

6. When you see the lament begin to extrude, return the extruder switch to the right, into the “locked”

position.

7. You can also use the “extrude” menu in the touchscreen to push for lament out of the nozzle.

8. Re-insert the lament guide tube back into the hole at the top of the extruder.

6. REMOVING THE FILAMENT FROM THE EXTRUDER

Never remove the lament from the extruder if the extruder is cold! Always preheat the extruder before

removing or changing laments. Removing the lament from a cold extruder might damage it! You

don’t have to remove the lament between prints.

1. Heat up the extruder (see section 10.5.)

2. Once the extruder reaches the target temperature of your lament (keeping in mind that dierent

materials such PLA, ABS, and PET have dierent temperature characteristics), press the “extrude”

button briey, and then touch the “reverse” button and hold a short while. Once the gears have

begun to retract the lament you will be free to pull it out from the printer and then load a new

lament.

7. PRINTING OBJECTS FROM THE USB FLASH DRIVE

1. Save the printing command le created by CraftWare slicer program on a USB ash drive. The pen

drive provided with CraftBot has design samples saved on it. (3D designs must be converted into

a printing command le with the help of the CraftWare slicer software. For details on this go to

chapter „Using CraftWare” or to www.craftunique.com/craftware)

2. Insert the USB drive into the USB slot located on the top front of the appliance (above the LCD screen).

3. Select the USB Print option from the main menu.

4. Scroll down with the arrow to select the object’s le name.

5. Push the printer icon in the left corner.

6. The appliance will heat up the extruder and the build plate to the desired heat.

7. Printing will start if the required operational temperature is reached – until then you will see the

current heat along with the status message: „Now printing „le name”. Heating”

8. During printing the status of the print is displayed on the LCD screen, indicating progress, based

upon a percentage of the job completed.

12

CraftBot

9. Please make sure that you have enough lament for the selected project. The quantity is pre

calculated by CraftWare.

10. After the object has been printed, remove it by gently pushing it aside with one hand while holding

onto the printing plate with the other one.

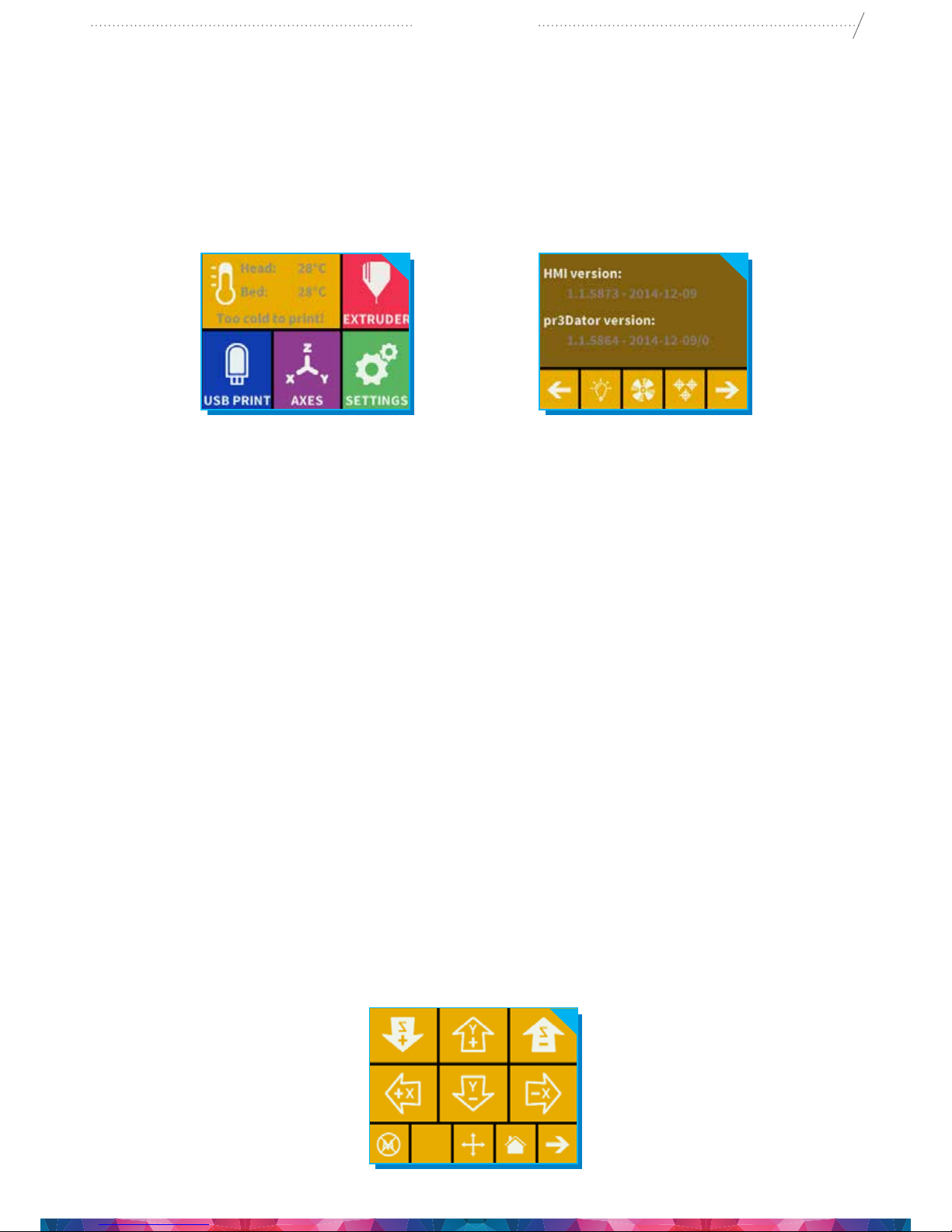

8. NAVIGATING THE BUILD PLATE AND THE EXTRUDER

Select the AXES on the menu.

The rst “back” button will, of course, return you to the main menu.

1. Extruder at „home” position

The small house icon indicates the „home” position of the extruder which is this location the front

left corner of the build plate. By pushing this icon, the extruder will move into „home position”.

2. Individual position settings

You can reset the extruder and the build plate to the “home” or “zero” position.

You can either set each axis one at a time (X, Y or Z), or do all three of them at once by touching the

appropriate button.

If the individual house icons are white, then this means that the motors of each highlighted icon are

engaged. To disengage the motors, click on the icon in the far right bottom corner (M with an X through

it), and you will see all of the house icons turn black. The motors have now been disengaged and you

can freely move the extruder by hand if you wish to do so.

The directional button to the right of the “home” button can be used to move along the X, Y or Z axis

using the motors. After clicking on this button you will be redirected to another display in which you will

see six dierent arrow buttons.

Note that this option can only be used if all of the motors are already activated and the house icons

are all white. If the house icons are black, then nothing will happen. In this case, after clicking on the

direction button, you will see all of the arrows in the color grey. To activate the motors, return to the

“home” icon and home in; the house icons will now turn white and you can go on to the direction display

and move the extruder and bed as you see t.

13

CraftBot

9. ADJUSTING THE LIGHTING

10. ACTIVATING THE FANS

Select Settings (indicated by a gear) on the LCD screen.

Select the fan control icon (indicated by a rotating fan).

Fan Control: Activate and deactivate the fans before or during printing to match your preferences.

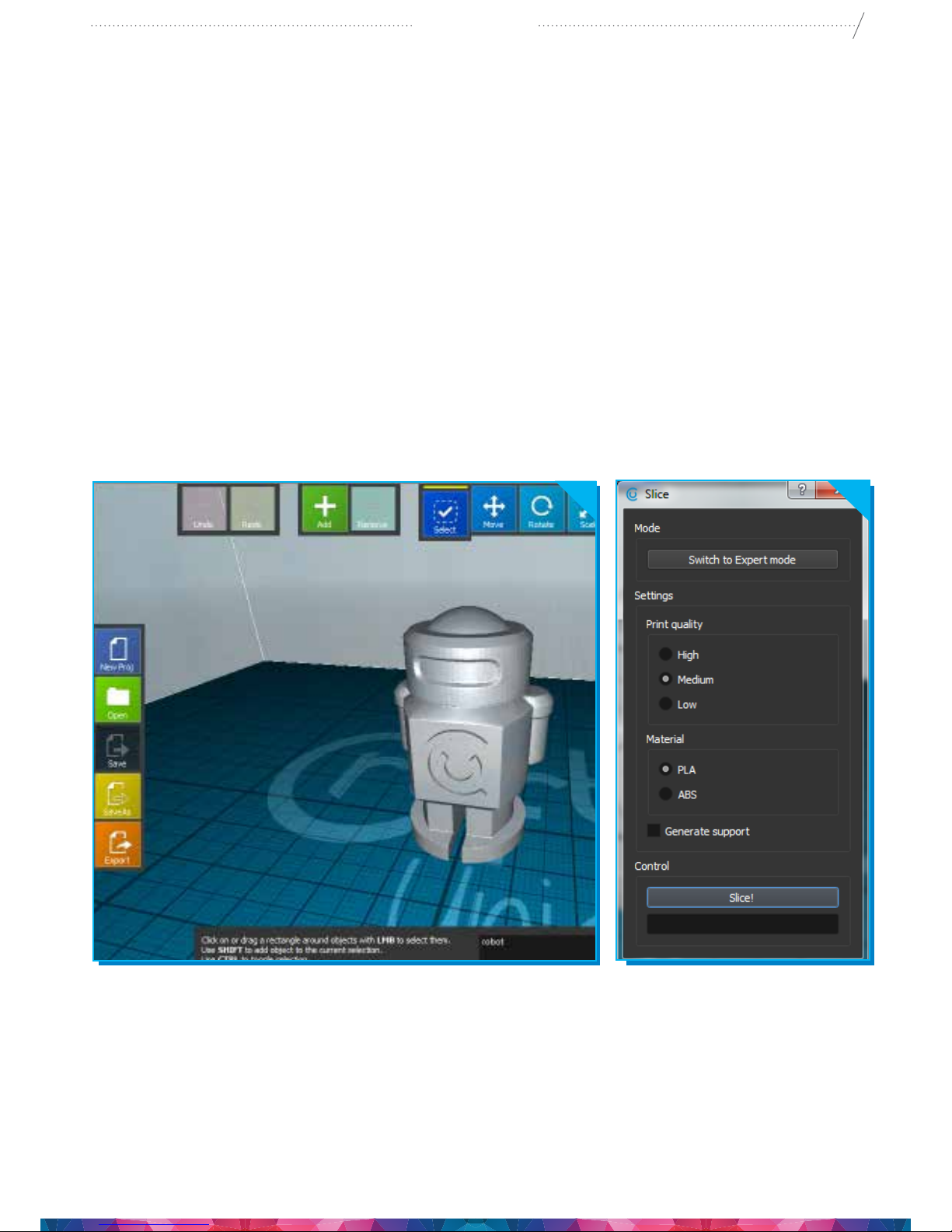

11. USING CRAFTWARE TO CONVERT 3D DESIGN INTO PRINTING COMMANDS

To print a 3D object CraftBot needs toolpath information generated from 3D object les like .obj or .stl.

Toolpath information is simply called “gcode”. CraftWare software converts 3D designs into printing

commands for the CraftBot 3D printer. CraftWare has been developed by CraftUnique with the aim of

easing and perfecting the printing process.

Select Settings (indicated by a

gear) on the LCD screen.

Select the light control icon

by touching the light bulb

button. You will see a vari-

ance pop up on the screen:

two dierent touchscreen

sliders.

Adjusting the lighting: Move

the line from the left to the

right to vary the brightness

of either the interior LED

lighting of the CraftBot or

the LCD display backlighting.

14

CraftBot

1. Download the CraftWare slicer software

• Open a new browser session on the computer where you’d like to install CraftWare.

• Go to www.craftunique.com/craftware

• Scroll down the page to select the latest version of CraftWare.

• Select the Windows or MAC/OSX version according to your operation system.

• Download the installer.

• Open the installer and follow the directions to install the software.

2. Open the CraftWare software

Once CraftWare has been opened up, you will see a virtual build platform which represents your CraftBot’s

real build plate. You can add objects, .stl les onto this virtual build plate and get an impression of what

the real life print will look like.

3. Importing your design objects

Click on the “Add” button located in the top row of icons. Select the 3D design plan you must print. The

selected object will appear at the center of the virtual build plate.

4. Generating the toolpath information (gcode)

Click on the „SLICE” button to the right side of the screen. A new screen pops up with options to specify

the printing quality and material to be used.

5. Saving the gcode

Save the generated gcode onto a USB drive or send information directly to the CraftBot if connected via USB

cable. For detailed user’s instruction of CraftWare download the User’s Manual from www.craftunique.com.

15

CraftBot

12. CLEANING AND MAINTENANCE

IMPORTANT! Cleaning and lubrication should only be conducted while the extruder and built plate

are cold. Please allow the CraftBot 3D printer to cool down at least 30 minutes before cleaning or

maintenance.

CLEANING

Clean the metal housing of the CraftBot by wiping with a damp cloth.

Cleaning the build plate

Remove the build plate by unscrewing the 2 white screws located in the front of the plate. Clean the

plate with window cleaner. Wipe clean with a dry cloth or paper towel.

LUBRICATING

The CraftBot printer should be lubricated at least once after every 50 hours of use or every 6 months.

Tools needed for lubrication:

• PTFE based spray lubricant or grease

• 2 separate lint-free rags or thicker stronger paper towels

• personal protection such as gloves and safety glasses/goggles

• lighting to see the interior of the CraftBot correctly (lamp)

1. Move the build plate and the extruder to the „Home” position – see chapter 13 for more information.

2. Once the extruder and bed are in the home position, turn the CraftBot printer o and unplug it

from the electrical outlet.

3. If you look beneath the build plate you will see three rods that run vertically in which the build

platform moves up and down on. The two outside rods are smooth and the center rod is threaded.

These three rods are known as the “Z-axis rods”.

4. Place a folded paper towel or a lint-free rag behind the center rod. This rag is used to protect

other areas of the printer from any overspray that may occur.

5. LUBRICATE ONLY THE PARTS RECOMMENDED IN THIS MANUAL!

6. Spray the threaded Z-axis rod at a relatively close distance to reduce overspray. Make sure the

lubricant reaches the inside of every thread (if using grease, spread with hand wearing gloves).

7. Make sure not to overlubricate, spray only the minimum required amount!

8. Do not spray the other two rods directly! Spray the towels and wipe it onto the rods.

9. Remove the rag from the CraftBot interior.

10. Plug in and power up the CraftBot and move the build plate to the lowest point (“Axes” menu,

home position and then go to the directional menu and press the Z down arrow until the bed

reaches the lowest point).

11. Turn the CraftBot printer o and unplug it from the electrical outlet.

12. Place a second clean rag on top of the heated build plate to protect the components and Kapton

from any overspray.

13. Repeat the process for the top side of the Z-axis rods the same as you performed on the bottom

side: protective rag behind threaded rod, spray, wipe excess lubricant on other two outside rods.

14. Power up the CraftBot once again and raise the build plate back up to the highest position (set the

X, Y and Z to the home position).

15. Turn the CraftBot printer o and unplug it from the electrical outlet.

16. Wipe any excess lubricant o from the bottom side of the Z-axis rods.

17. Power up your CraftBot once again and move the build plate back to the lowest point.

18. Turn the CraftBot printer o and unplug it from the electrical outlet.

19. Wipe any excess lubricant o from the top side of the Z-axis rods.

20. Power up the CraftBot once again and raise the build plate back up to the highest position.

21. Turn the CraftBot printer o and unplug it from the electrical outlet. The motors will now disengage

so that you can move the extruder freely by hand.

16

CraftBot

22. Use an oiled rag to lubricate the X and Y axis rods. Do not spray from above! Move the extruder

back and forth by hand to both extremes of the axes. When the extruder moves absolutely

smoothly you are nished.

13. TROUBLE SHOOTING

PREVENTING/FIXING A CLOGGED EXTRUDER

The number one inconvenience that you will run across when 3D printing is clogging of the extruder.

But we have good news for you! This problem can be easily avoided by following a few simple rules of

“3D printing etiquette”.

First, always wait until the extruder and heated build plate are fully heated to their maximum intended

print value before inserting the lament. Inserting the lament at a lower temperature is just asking for

a clog.

When unloading or changing the lament: always heat up all the way rst and then “extrude” for 5

seconds and immediately “reverse” aiding the lament retrieval by pulling a little bit on the lament end

going into the extruder with your hand.

If the extruder is clogged, clean out the passage way of the extruder. You can use one of the small

hex wrenches coming with your CraftBot to do so. Heat up to 250°C while the extruder is empty and

push any excess lament out by plunging the hex wrench down into the passage way; make sure to

do adequately but not in a violent way which would damage the machine, and always take precautions

because the extruder is very hot!

It is especially important to clean out as much old lament leftover between using dierent laments, as

the dierent characteristics of the laments’ properties (even printing the same material in a dierent

color) can cause clogs from inconsistencies. For example: you must heat up to 250°C to clear out any

extra ABS before using PLA.

Clogging is the most common problem in every 3D printer and cannot be prevented 100%, but if you

follow these simple steps you will prevent 95% of occurrences.

If you still cannot clear the passage with just this method, you may want to move onto the next method

by following these next steps to actually remove the nozzle itself…

Removing the nozzle

To clean out the extruder properly by removing the nozzle you will need to remove the nozzle while

heated up to 250°C using both a 7mm and 11mm wrench for the two nuts located on the nozzle itself

and the channel end to the top side of the extruder. Make sure to use an oven mitt (for example) to

protect yourself from burns. You will also need to disconnect the fan assembly and remove the entire

piece by unfastening two bolts connecting it to the top of the extruder.

Most importantly, make sure to hold the red rubber part stationary at all times so that you do not

damage the wires running into it, you can use a wrench to do so. Please make sure that none of the

wires are disconnected! The removed nozzle can be unclogged with a pin or replaced with a new one.

14. FIRMWARE UPDATE

From time to time you may want to look into updating your rmware (the special software which

provides control over the functions of your CraftBot). New versions are released periodically on our

website, and you can nd them bundled with our CraftWare slicer software here:

www.craftunique.com/craftware

17

CraftBot

For a step-by-step process on how to update to our newest rmware please check the following video:

https://www.youtube.com/watch?v=S0k99lYU9SA

From time-to-time you may encounter a trac jam scenario when attempting to upload this new

rmware; in some cases your CraftBot screen will go completely blank and even seem to be „non-

functional”… but do not worry! This situation can be easily remedied by following these easy steps to

„erase” and „reset” both your PCB and LCD.

Make sure that the machine is turned o and disconnected from the electrical outlet. To access the PCB

rst, remove the back plate of your CraftBot by unscrewing the bolts securing it to the main frame using one

of the hex wrenches provided in the set which came with your CraftBot. Be sure to take notice of the wires

connecting the back plate fans to the interior; you should be able to easily disconnect these by reaching

inside as soon as the plate rst comes lose. After the plate is o, you will see the PCB board. Before you do

anything here, you will need to also prepare the LCD for erase and reset following these steps:

Take a look at your LCD display located at the middle top front of the CraftBot 3D printer. You will need

to get around to the back of the LCD to erase and reset. For the best access to this part of the board

you may want to remove the lid of your CraftBot by loosening the bolts using once again, your trusty

hex wrench included with your CraftBot. Make sure to watch out for the LED wire connecting the lid to

the rest of the CraftBot! You can disconnect this wire by reaching in and unplugging it from the back of

the LCD rst.

Now that the lid has been removed, you may or may not need to remove the back protective plate of

your LCD panel, depending on the version of LCD that you own. The latest version of the LCD has the

„erase” and „reset” buttons located on the side, so removal of the plate is not necessary. For everybody

else, use your hex wrench to loosen the bolts and remove the plate. Be careful not to drop the bolts or

damage the belts. Inside you will see the two buttons, „erase” and „reset”.

Now you can plug in and power up your CraftBot. At this point the screen should still be blank and your

CraftBot should still be unresponsive. For the LCD, push both buttons at the same time and release.

For the PCB, use two pieces of lament to insert into the „erase” and „reset” ports at the same time

(the same eect as pushing a button). Now you can turn the CraftBot o and wait at least 5 seconds

before turning back on. From this point proceed to the rmware update mentioned previously and

after uploading you should have a 100% operational CraftBot 3D printer!

15. APPLYING A NEW LAYER OF PROTECTIVE KAPTON SHEET TO YOUR BUILD PLATE

Build plate Kapton sheets get worn out in time, or can be damaged by the nozzle due to incorrect

leveling. Reapplying a new Kapton sheet is essential to maximize print qualities if the old one has issues.

To reapply a new Kapton sheet, take the build plate out of the machine and remove the old sheet by

striping it o of the aluminum plate. Clean the surface of the aluminum plate with acetone. Remove

the protective sheet on the new Kapton in order to apply the sticky side, apply some window cleaning

liquid onto the plate and the sticky side of the sheet to help you to correctly position the sheet. Align the

Kapton to the front side of the plate (the side where screws stick out) on the corner. Once the positioning

is correct, squeeze out the liquid from between the plate and the sheet with a thin but solid object, like

an unused credit card. Place the protective sheet (which was removed to open up the sticky part) on

the building Kapton to prevent scratches and damages during application. Start from the center of the

plate and move horizontally and vertically. Once all the liquid has been squeezed out and the sheet is

applied properly, put the plate somewhere to dry. Allow the sticky part to rest for a day before using.

18

CraftBot

16. GUARANTEE

For special conditions relating to product guarantee, see the „Guarantee Statement” on a separate

sheet, delivered with the product as well.

17. LIMITATION OF LIABILITY

With the exceptions included in the regulations concerning the guarantee and to the greatest extent

permitted by the relating act, CRAFTUNIQUE Ltd. is not responsible for any direct, indirect, specic,

stochastic or consecutive damage claims which are stem from the breaching of the terms of guarantee,

respectively any other legal theory, included, but not limited to

• the loss of usability

• the loss of income, the loss of actual or expected prot (including the prot from contract), the loss

of expected saving, loss of business, loss of opportunity,

• the loss of a fair name and injury to a fair name,

• the loss, injury or perishing of data,

• any indirectly or consecutively caused damage or loss, including the damage caused by the changing

of equipment/installation or property, respectively

• the cost of the restoration or reproduction of data stored or used on the Product.

The restriction above does not refer to the CRAFTUNIQUE Ltd.’s legal liability for intentional, serious

negligence and/or default.

Certain jurisdictions does not allow the exclusion or limitation of accidental or consecutive damage,

therefore if such jurisdiction regulates the guarantee, the restrictions above does not refer to You.

19

CraftBot

APPENDIX

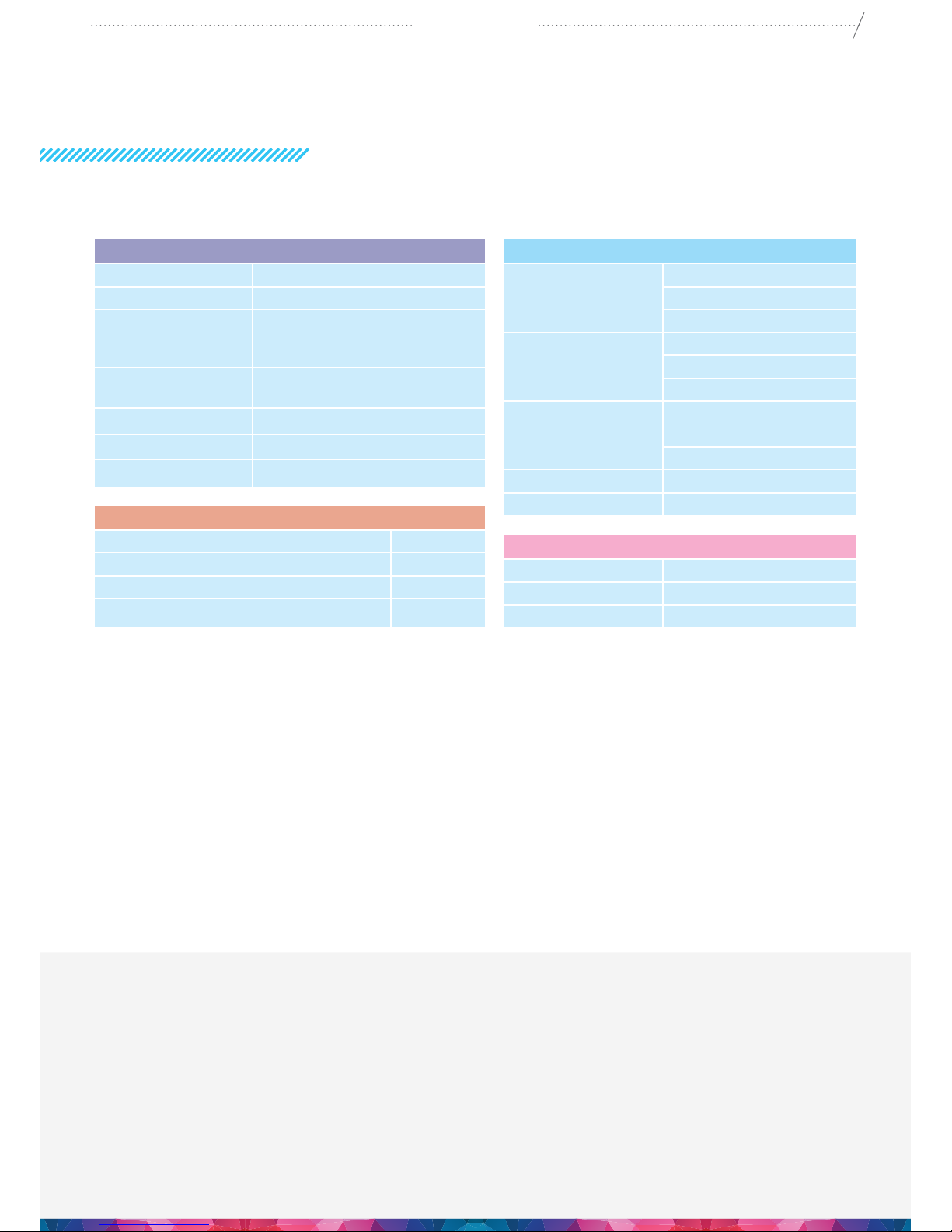

TECHNICAL SPECIFICATION

Concerning any problems or enquiries, you can contact us at:

PRINTING

Printing technology: Fused Filament Fabrication (FFF)

Build volume: 25x20x20 cm

Layer resolution: 100 micron (ultra)

200 micron (high)

300 micron (medium)

Position precision: X,Y: 4 micron

Z: 2 micron

Filament diameter: 1.75 mm

Nozzle diameter: 0.4 mm

Print speed: 50-200 mm/s

Physical dimensions

Frame dimensions: X: 40 cm

Y: 36 cm

Z: 37 cm

With all parts

attached:

X: 40 cm

Y: 46 cm

Z: 45 cm

Shipping box: X: 46 cm

Y: 42 cm

Z: 43 cm

Weight: 14 kg

Shipping weight: 17 kg

SOFTWARE

Software package: CraftWare

File types: OBJ/STL/CWPRJ

Supports: Windows 7 and above

TEMPERATURE

Ambient temperature: 15-32 °C

Storage temperature: 0-32 °C

Operating nozzle temperature: 180-260 °C

Operating heated build plate temperature: 50-110°C

Other manuals for CraftBot

1

Table of contents

Other CraftUnique 3D Printer manuals

Popular 3D Printer manuals by other brands

XYZ Printing

XYZ Printing da Vinci Color mini user manual

Prusa Research

Prusa Research Original Prusa SL1 user manual

Stratasys

Stratasys Fortus 900mc Operation and maintenance guide

Objet

Objet Alaris30 user guide

Stratasys

Stratasys Fortus 360mc Service manual

Geeetech

Geeetech Acrylic I3 Pro Assemble Instruction