Next Wave Automation Piranha FX User manual

Next Wave Automation 3d Print Manual Page 1

Operations Manual

3d Printer Module

Next Wave Automation 3d Print Manual Page 2

Next Wave 3D Software

Table of Contents

Introduction

Pg. 3

Safety Warnings

Pg. 4

Setup of the 3D Printing Head on the Piranha Fx

Pg. 4

Leveling the 3D Platform

Pg. 9

Installing Next Wave 3D (NW3D)

Pg. 12

Setting Up your Machine’s Workspace

Pg. 12

NW3D –Importing and Manipulating a 3D Model

Pg. 14

Setting Printing Parameters

Pg. 14

Advanced Print Parameters

Pg. 23

Printing and Viewing your Model(s) Toolpaths

Pg. 25

Running a Print Job

Pg. 27

NW3D Print Head

Pg. 30

Appendix

Pg. 32

Comment [S1]:

Next Wave Automation 3d Print Manual Page 3

Introduction

Next Wave 3D is a modular 3D Printing Solution that allows users to

mix and match a variety of 3D printing components to create a 3D printed

model. While there are a multitude of 3D Printers available from all around

the world, Next Wave 3D allows a user to print sophisticated 3D models

using their Piranha Fx.

The Next Wave 3D System consists of the following...

3D Printing Software

Spindle Mounted 3D Print Head

3D Print Head Heater Control and Extruder Motor Driver unit

Machine Controller with Parallel Port type interface

Features of the Next Wave 3D Software

Imports many 3D File Formats

3ds

3d Studio

gts

GNU Triangulated Surface

lwo

Lightwave

obj

Wavefront

ply

Standard Triangle Format

Stl

Standard Tessellation Language

Layer by Layer View

Outputs standard Gcode for most Machine Controllers

Built-In Parametric Modeling of Gears, and Lithopane Images

Optimized Toolpaths

Water Tight Solid mending of meshes

Next Wave Automation 3d Print Manual Page 4

Next Wave Automation 3d Print Manual Page 5

***Safety Warnings***

Read this manual completely before making your first 3D Print

Burn Hazard:

The NW3D Print Head is capable of reaching temperatures in excess

of 300°C (575°F). Allow the Print Head to completely cool before servicing.

This may take 15 minutes or more. If in doubt, wear protective gloves.

The exit temperature of the Extruded Plastic will be at the Temperature of

the Nozzle. Do not touch the melted plastic as it may stick to your skin and

cause burns.

Fire Hazard:

Do not place flammable materials near the Print Head. Do not spray

flammable materials such as Hair Spray onto the Print Area when the Print

Head is hot.

Electric Shock Hazard:

The Cartridge Heater used in the NW3D Print Head runs at Mains

Voltage (either 110v in the USA or 220v in most other Countries). Do not

open the control box, service the Print Head, or move the Control Box

unless the main power cord is disconnected. Do not place the Control box

in an area that may be affected by moisture.

Mechanical Hazard:

Do not place fingers, loose clothing, or hair near the Print Head when

the machine is operating.

Setup of the 3D Printing Head on the Piranha Fx

Make sure power is turned off to the Piranha FX Controller,

Heating Element, and Piranha Hub

Next Wave Automation 3d Print Manual Page 6

Invert the router cradle by removing the 4 bolts from the back of

the router cradle. Turning the router cradle upside down, and

reattach the 4 bolts. Then place the router in the clamp.

Insert 3D printing head into router collet and tighten the collet

nut.

Next Wave Automation 3d Print Manual Page 7

Connect hub to controller using 20 pin ribbon cable.

Connect power adapter to the hub.

Power on the controller.

Power on the hub.

Attach the 3D printing head to the heating element.

Power on the heating element.

Wait for the temperature to reach 225 degrees.

REMEMBER: NEVER ADJUST THE 3D PRINTING HEAD WHILE THE

HEATING ELEMENT IS ON!

Next Wave Automation 3d Print Manual Page 8

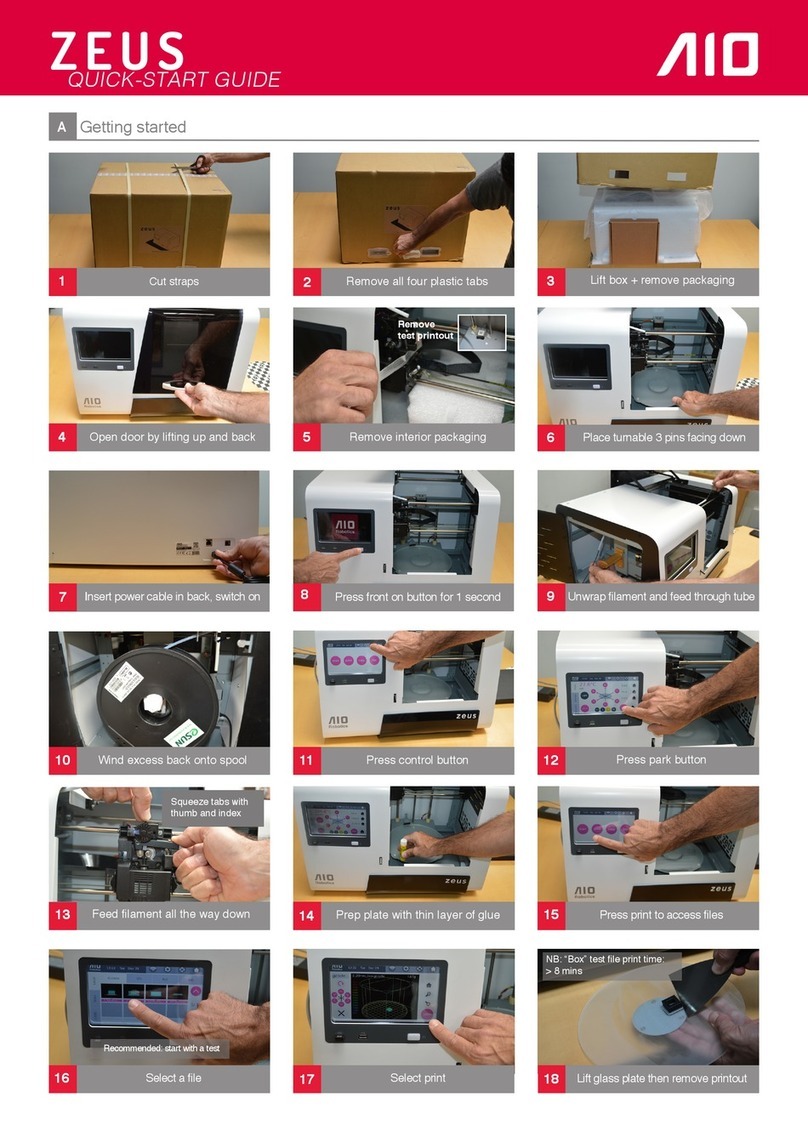

Attaching the filament

Make sure that all previous filament is ran through the 3D printing

head before adding more

To do this, you need to access the A axis (fourth axis)

There are two ways to access the A axis

The easiest is to use the “feed” button located on the home

screen of the LCD.

This option slowly jogs the A axis in small increments

Next Wave Automation 3d Print Manual Page 9

oSimply hold the feed button for 1 second at a time

The other option is to switch access from the Z axis to the A

axis on the LCD home screen

Add the filament through the opening on the side of the printing

head

Jog it through in small increments, as shown in previous steps.

To replace the filament, cut off the end of the filament that is

currently being fed through the 3D printing head

Next Wave Automation 3d Print Manual Page 10

Then, gently sand the edge of the new filament that will be

added, just enough to make it smooth and straight.

Make sure that you feed the previous filament in a few more

times

Add the new filament following the “Add Filament” steps above

Leveling the 3D Building Platform (glass panel)

The 3D building platform comes ready to use and should be level. The following

guide will assist you in checking the plate to make sure it is level, and the steps to

take if it is not.

You will find bolts in all four corners of the building platform.

These bolts are attached to industrial t-slot nuts

With the bolts and t-slot nut on the build platform, slide the t-slot

nuts into the t channel of the CNC Piranha

Position it roughly in the center of the base and tighten down the

bolts

Position the 3D printing head over the top of the glass at the far

end of the Y Coordinate

Run the 3D printing head towards the front of the Piranha

Next Wave Automation 3d Print Manual Page 11

Note any difference in the space between the glass and the 3D

printing head

Raise the 3D printing head, and move it out of the way to gain

access to the glass

Pull the glass up and apply masking tape to level out the

difference you saw between the 3D printing head and the glass

Repeat this process until there are no significant differences

Please note that .001-.01 is not a significant difference

Once leveled, re-insert the glass

Apply painters tape to any area that will be used for 3D printing

After the tape is applied, use denatured alcohol to remove the

film on the top of the painters tape

Running the 3D Printer

Move the 3D printing head to the point of origin

Zero the X and Y axis

Move the Z axis slowly down, until a piece of paper can barely fit

under the nozzle of the 3d head and the Glass surface

Next Wave Automation 3d Print Manual Page 12

Zero all axis’

The system is now ready to run your program.

Load the TAP file onto a USB flash drive.

oNOTE: A SanDisk flash drive is recommended.

Insert USB drive into the Piranha Pendant (refer to Piranha

Manual for detailed instructions)

Select the USB tab Select target file

Press Run.

Next Wave Automation 3d Print Manual Page 13

1. Installing Next Wave 3D (NW3D)

NW3D Requires:

Windows Operating System (Vista, XP, 7, 8, 10)

2GB Ram

OpenGL capable Graphics Card.

Installing NW3D:

Double click on the downloaded Next Wave 3D-Setup.exe to begin

the install.

Follow the prompts associated with the Installation of the

Software.

Registration for the Software See Apendix.

That's it! You can now run the Next Wave 3D Software.

2. Setting Up your Machine’s Workspace

NW3D is an add-on to your existing CNC Machine. Several

parameters should be set before you make your first print. The Work

Envelope of your machine should be set so that you can get Visual

Feedback of the scale and location of the print job. You will also need to set

and calibrate your machines 4th axis to deposit the correct amount of

plastic if you are using the optional NW3D Motion Controller. These

requirements are handled through an Initialization Script that is located in

your MyDocuments/Next Wave 3D/Config/default.gsc file. This file contains

several Scripts containing both standard and custom NW3D Gcodes. These

Gcodes set up both the general NW3D Software as well as more specific

commands for the optional NW3D Motion Controller. The Initialization

Script is edited by going into the Setup Tab and clicking on the Set Print

Parameters.

Next Wave Automation 3d Print Manual Page 14

3. NW3D –Importing and Manipulating a 3D Model

NW3D supports a wide range of 3D File Formats for Printing. Each

Model can be Scaled, Translated, or Rotated anywhere in your 3D Printers

work envelope.

Importing your 3D Model:

Click the Add 3D Model Button

The Model is automatically placed at the 0,0 Origin.

Next Wave Automation 3d Print Manual Page 15

If this is the first model added to the Print Job, it will automatically be

selected. If there are multiple Models for this Print Job, any model may be

selected by right clicking on the Model once. A selected Model will turn

Blue while an unselected Model will be Yellow. If only one Model is

available, it will always be selected regardless of color. The model's

features will be displayed each time a model is selected.

At this point, you can visually Rotate and Zoom around the Model by

using the Mouse buttons. Dragging the Left mouse button will Rotate the

display while using the Mouse Wheel will Zoom the display. To Snap the

View to a specific Model, select the model first with the Right mouse

button (it will turn Blue), and then Double-click the Left mouse button to

target the model. To return to the Table View, make sure that no Model is

selected (Right click anywhere in table space), and double click the Left

mouse button.

If a Model is selected, it can be Scaled, Rotated, Translated, and

Repaired. By default, many 3D File formats are expected to be saved in

Millimeters (STL for example). To Scale the Model and make it either Larger

or Smaller, enter a value for the Scale Factor and press the Enter key. There

are several pre-defined Scale buttons that allow you to instantly scale the

Model from:

Multiply by 10

Multiply by 1

Multiply by 1

To Translate a Model and move it around the 3D workspace, enter

new values for the 3 X, Y and Z Position entry boxes. The entries represent

the X, Y and Z axes respectively. In any of these boxes, pressing the Enter

key will invoke the Model translation. The Position can depict the Lower

Left Corner of the Bounding Box of the Model or it can represent the Center

of the Model depending on the Position Alignment control. When Corner is

selected, the Model will be placed by its Lower Left corner. Likewise, if

Center is checked then the Model will be positioned according to its Center.

If a model is selected (by clicking on it with the Right mouse button), you

can also Drag the model around your Work Envelope by holding the Right

mouse button down while dragging.

Next Wave Automation 3d Print Manual Page 16

Advanced Model Fix Option: Most 3D model formats for 3D printing are

expected to yield a "water tight" 3D Solid object. This is not always the case

and from time to time you may find yourself with a model that will have

broken layers due to a leaky model. You can try to fix these models using

the automatic mesh mending utility built into NW3D. This utility will

guarantee a water tight model but may also distort the model if the model

has large holes in it (models made up of Surfaces rather than a Solid). Three

options are available for fixing the model: Rough, Smooth, and Sharp. The

Rough option will create a Block representation of the model. The Smooth

option will round off all sharp corners in the model. The Sharp option will

preserve the Sharp corners that exist in the model. In all cases, NW3D will

create a new model and append .fixed to the model's filename and reload

the fixed model.

4. NW3D –Setting Printing Parameters

In order to print properly, certain variables associated with the

NW3D Software need to be set according to your machines capabilities.

Clicking the Set Print Parameters button in the Setup Tab will bring up the

Print Parameters setup dialog window.

Next Wave Automation 3d Print Manual Page 17

A full set of Parameters can be saved in a single Configuration for

later use. By default, the last used set of parameters will be set the next

time you run the NW3D Software. Selecting a specific Config from the Drop

Down entry box will load the parameters for this Config and allow

Editing/Saving of these Config settings.

Type a unique name in the Config entry box to start a new set of

Printing Parameters. After you have set all of the parameters for the new

Config, press the Save Config button to store these parameters for later

print jobs. You may also select a Config and permanently remove it by

clicking the Delete Config button.

The Configuration group is also where you set the master Inch/MM

setting for your Config. The values for all parameters will default to MM or

Inch units depending on this selection. The output Gcode file from NW3D

will also have its Units (G20 or G21) set according to this setting.

Layer Parameters:

Next Wave Automation 3d Print Manual Page 18

Nozzle Diameter: This is the Diameter of the exit Nozzle of your 3D Print

Head. If you are using the NW3D Print Head, the standard Nozzle is 0.016 in

or 0.4 mm.

Layer Thickness: This will set the thickness of each individual layer. For

best results, it should be no more than the Nozzle Diameter above. A

smaller thickness will yield a smoother, higher resolution part at the

expense of a longer print time. A value of approximately 2/3 the Nozzle

Diameter is a good place to start.

Toy Car @ 0.010 In. Layer Height Same Car @ 0.005 In. Layer

Height

Foundation:

The Foundation is an area under the Model(s) that support the print

a small distance above the printing platform. It is typically used for printing

materials that have a high degree of shrinkage such as ABS or to prepare a

Level surface for the part. The Foundation consists of a thicker Base Layer

and thinner Top Surface Mesh layer.

Thickness: Here you will set the Height of the Foundation's Base Layer.

The Foundation is usually a heavier/thicker layer and a value of

approximately 1.5 times the Nozzle Diameter is usually sufficient.

Base Density: The Base layer of the Foundation does not need to be a

full solid layer to perform its function. It is common to make the

Next Wave Automation 3d Print Manual Page 19

Foundation Base a Mesh to save time and material. The Base Density is a

value from 1 –100% with a typical useful range of 10-25%.

Feedrate: Here you set the Feedrate that will be posted to the output

Gcode file for the Base layer. The Top surface layer will use the same

feedrate as the Print layers. For the best ratio of speed and quality, a

feedrate of 30 is recommended.

Top Density: The density of the Top Surface layer of the Foundation.

This should be a much denser mesh layer than the Base Layer. A density of

50-75% should suffice. Lower densities will make it easier to remove the

Model from the Foundation but may not completely support the Model(s)

in all areas.

Top Thickness: This sets the thickness of the Top Surface area of the

Foundation. It should generally be less than the Layer Thickness to promote

adhesion to the Foundation's base layer. ½ to 2/3 of the Layer Thickness is

typical.

Make Foundation: Check this box to enable the creation of the

Foundation. If you are printing directly to your machines table surface and

do not require a Foundation, leave this unchecked.

Foundation Settings Printed Foundation

Next Wave Automation 3d Print Manual Page 20

Shell:

The Shell is the outside surface of a 3D Printed Model. A typical 3D

Print will consist of a Shell and its Fill.

Straight Shell Contour Shell

Wall Thickness: This is the number of passes that make up the outer

Shell. Usually 2 or 3 passes will create a decent and hard outer surface.

Contour or Straight: The Top and Bottom of the Model's Shell will

always be a solid area. Selecting Contour will create this Solid Surface area

using a series of offset contours. Selecting Straight will create this area

using a series of straight line segments.

Feedrate: This is the feedrate that will post out to the output Gcode file

for your machine. You will want to keep this value within your machine’s

capabilities. A faster feedrate will get the job done quicker, but might

sacrifice quality on loose machines. Typical values range from 50-200 Inch

per Minute (20 –160 MM per Second).

Print Inside/Out: Selecting this option will organize the Print to make

the Shell from the Inside Out. This is the default setting. Some Models

might benefit from Outside/In depending on the Overhang areas of the

Model itself. Experimentation is recommended.

Adhesive Overlap: The percentage that each filament will overlap a

previously deposited filament. A value of 0% will have no overlap. A value

of 50% will have a 50% coverage over the previously printed filament.

Typically, 10% will suffice but Models with steeper overhangs may benefit

from a larger value.

Table of contents