DUST

CONTROL

Place the saw at on the oor

near the wall to be undercut.

Make certain blade is set

parallel to the oor.

Make sure the blade holding

screw, and height locking

wing screws are tightened

securely. Handle ratchet

teeth should interlock and

three-arm knobs be tight-

ened securely (gure 10).

Always keep the handle in

the vertical position for gen-

eral undercutting.

Lower the handle for under-

cutting toe spaces (gure 11). Be sure to lock knobs.

Plug in the saw and grasp handles rmly with both hands.

Keep one hand on the switch handle and one hand on the

ratchet handle at all times. Depress the safety lock button,

then pull the power switch.

To start a cut, use the wall to push the blade guard back

and expose blade. DO NOT USE YOUR HAND!

First, plunge slowly to appropriate depth. Second, push

the saw forward. Move the saw from left to right only.

Don't force the saw; let blade cut at highest RPM pos-

sible. Do not pull the saw towards you or run in reverse.

Do not lift or angle the saw or kickback may result.

Remove the saw from the cut, and release the switch to stop.

Turn off and unplug saw.

Retract the height adjuster

so it is ush with the hous-

ing to allow clearance for

the Allen® wrench.

Push the spindle lock

button with one hand and

insert the Allen® wrench

into the blade screw with

other hand; then turn the

Allen® wrench until the

spindle engages with the

lock button (blade will

stop rotating).

Hold onto the plastic housing, then push hard on the Al-

len® wrench counter-clockwise to open. If the blade is

hard to remove, use a Vise Grip® to hold the blade.

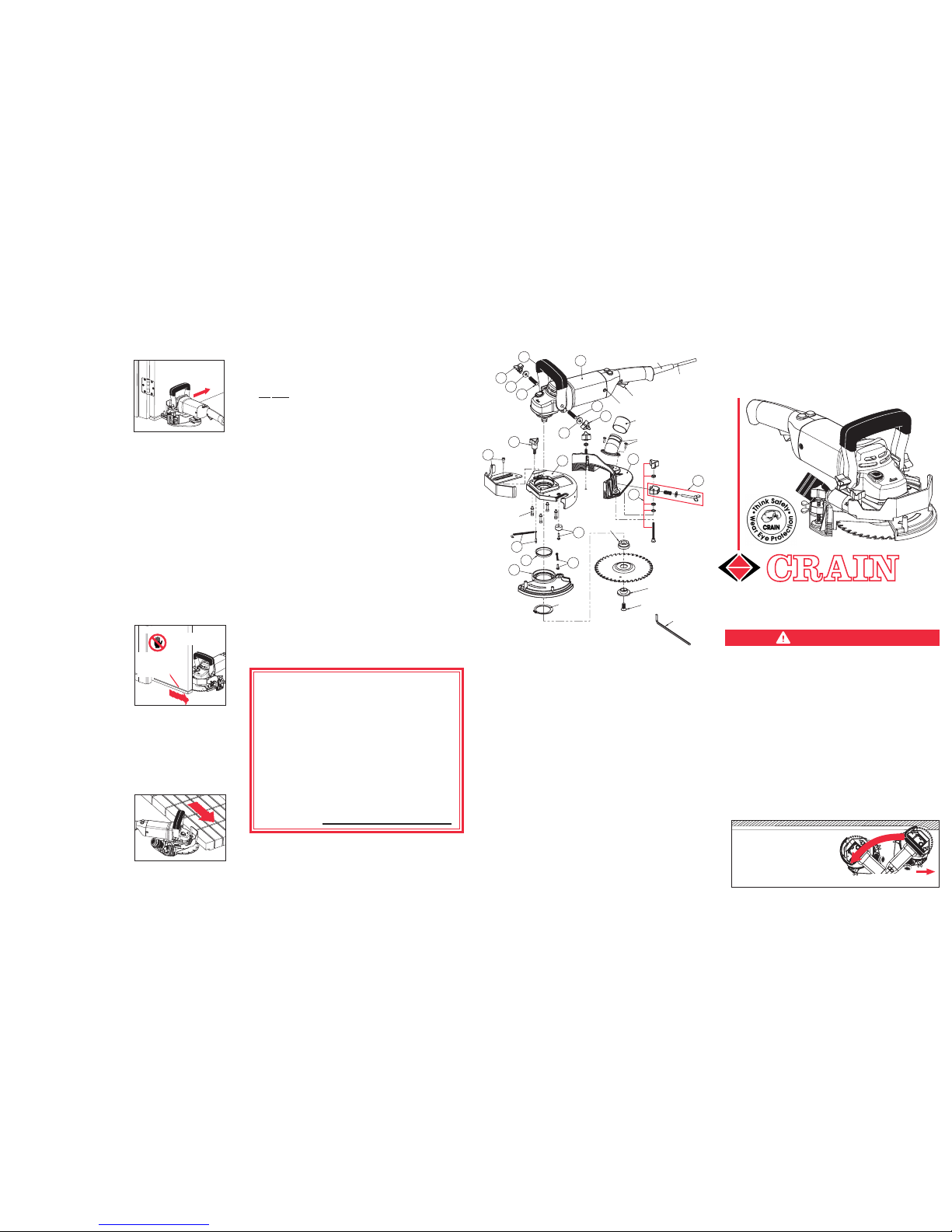

Figure 3

SAFETY FIRST

HANDLES:

In use, keep both hands on the handles at all times.

KICKBACK HAZARDS: While cutting, do not force the

saw. Also, keep the housing at on the oor and the blade

parallel to the oor at all times. Angling may cause powerful,

dangerous kickback. Keep the saw RPMs high. Using a

dull blade will place a heavy load on your saw and increase the

danger of kickback. Use only Crain replacement blades.

EYE & EAR PROTECTION: Always wear safety glasses when

using a power tool. Wear ear plugs when using this saw.

BLADE GUARD: The blade guard attached to your saw is

for your safety and protection. If it becomes damaged, do

not operate your saw until it has been repaired. Keep the

blade guard in operating condition when using the saw.

DOUBLE-INSULATED: This tool is constructed with two

separate layers of electrical insulation. A tool built with this

insulation system does not need to be grounded.

DANGEROUS ENVIRONMENTS: Keep work area clean;

clutter invites accidents. Do not use the saw on damp or

wet oors. Be sure that there is good lighting. This saw

may throw sparks. Make certain that ammable materials,

especially explosive vapors, are not present. Use face or

dust mask if cutting operation is dusty.

ACCIDENTAL STARTING: To avoid accidental starting, do

not carry tool while plugged in or with ngers on switch.

CORD ABUSE: Never carry tools by the cord or yank the

cord to disconnect from an outlet. Keep cords away from

heat, oil, and sharp edges.

EXTENSION CORD: To minimize power loss and prevent

overheating, use maximum of 25 feet long and 16 AWG.

HAIR & CLOTHING: Keep all loose hair and clothing away

from the spinning blade at all times.

The Heavy-Duty Undercut Saw is designed for undercut-

ting afxed wooden door jambs, moldings, base, as well

as masonry and stone, to allow new oor coverings to be

t underneath. Do not use this saw for sanding oors,

cutting metal, or any other purpose not described in this

instruction manual.

WORKING TERMINOLOGY: Figure 1

BLADE INSTALLATION: see Figure 3

BLADE HEIGHT ADJUSTMENT: see Figure 4

A depth gauge adjustment scale is engraved on the

depth gauge with twelve 1/8" increments (gure 6).

We recommend the depth of

cut be set to no more than 1/2"

to minimize the chance of hit-

ting wall studs, nails, etc.

When undercutting wood

base, set depth to cut wood

only. Cutting sheetrock

makes dust that can dam-

age the saw over time.

To adjust the depth gauge,

loosen the depth gauge

three-arm knob and slide the

depth gauge in or out.

The depth adjuster accurately

controls the depth of cut at

any of three angles: straight-

on (gure 7), 45˚ left (gure 8),

or 45˚ right (gure 9).

Cutting at a 45˚ angle is easiest

to push the saw (gure 8).

For dust control, cutting at the

45˚ right angle is preferred.

This angle captures as much

dust as possible inside the

housing. When using this

saw with a vacuum, this is

DEPTH ADJUSTMENT:

Unplug the saw. Loosen the two height locking wing

nuts one to two turns.

Turn the two height adjustment three-arm knobs clock-

wise to increase blade height and counter clockwise to

decrease height.

It is best to turn both

height adjustment three-

arm knobs at the same

time to ensure the blade

is set parallel with the

oor.

Both the front of the

height adjuster and the

inside of the height ad-

Figure 9

Figure 11

Figure 8

Figure 10

Figure 7

CAUTION!

BLADE EXPOSED

WHILE CUTTING

KEEP HANDS

AWAY!

SWITCH

RATCHET

HANDLE

MOTOR

HOUSING

DEPTH GAUGE

ADJUSTMENT

SCALE

HEIGHT LOCKING

WING SCREW

DEPTH GAUGE

THREE-ARM KNOB

BLADE

GUARD

DEPTH

GAUGE

SPINDLE

LOCK

BUTTON

Figure 12 Figure 13 Figure 14

Cut towards the corner at 45˚ angle (see gure 12) until

the depth gauge meets the right wall (see gure 13).

Stop and unplug saw. Fully retract depth gauge and

continue the cut.

Push saw into the corner as shown (see gure 14).

WARNING: Depth gauge covers the blade and makes the

saw safer to use. Always unplug the saw and reset the

depth gauge when inside corner cutting is complete.

INSIDE CORNER CUTTING:

Figure 2

BLADE REMOVAL: see Figure 2

BEST FOR

PUSHING

DUST

CONTROL

HEIGHT

ADJUSTMENT

THREE-ARM

KNOB

REFERENCE

LINES

USING THE SAW:

Figure 6

DEPTH GAUGE

THREE-ARM

KNOB

0"

1/2"

1/4"

EACH

LINE IS 1/8"

DEEP

45º LEFT

ANGLE

SWITCH HANDLE

STRAIGHT

ON

45º

RIGHT

ANGLE

ALLEN®

WRENCH

Unplug the saw.

Place the blade spac-

er over the spindle.

Place the blade on top

of the blade spacer.

Place the blade clamp

through the arbor hole

of the blade with the

bottom slot of the

blade clamp prop-

erly aligned with the

spindle.

Insert and re-tighten

the blade screw. Push

in the spindle lock to

tighten. Be sure to

tighten rmly before use.

BLADE

SPACER

ALLEN®

WRENCH

BLADE

SCREW

BLADE

CLAMP

#821,

#805, or

#822

MUST

ENGAGE

SPINDLE

SPINDLE

UNPLUG THE SAW. REMOVE ALLEN®

WRENCH BEFORE STARTING.

UNPLUG THE SAW. REMOVE ALLEN®

WRENCH BEFORE STARTING.

VISE

GRIP®

BLADE

SCREW

Figure 4

juster have 10 reference lines, in 3/32" increments (.093", one

blade thickness - gure 5).

Max. height is 1".

To prevent saw kickback, the blade must be set parallel to the

oor. This can be ensured by checking from the front of the

saw that, on BOTH sides of the blade housing, the number

of lines below the bottom

edge of the blade hous-

ing are the same (gure 4)

,

OR by turning the saw

over and making sure the

bottom edge of the blade

housing is completely

parallel with a reference

line (gure 5).

It may be easiest to set

the saw blade at on

top of the new ooring

to be t beneath the desired undercut, and turn the height

adjuster three-arm knobs clockwise until the height ad-

juster rests at on the oor. From that point, for a snug t

with the new oor, adjust height down by one reference

line (one blade thickness).

Securely tighten the height locking wing screws before use.

HEIGHT ADJUST-

ER THREE-ARM

KNOBS

HEIGHT

LOCKING

WING SCREW BOTTOM

EDGE OF

HOUSING

REFERENCE

LINES

NEW FLOOR TO

BE INSTALLED

HANDLE REMOVED FOR CLARITY -

DON’T USE WITHOUT HANDLE!

REFERENCE

LINES

REFERENCE

LINES

WING

SCREW

HEIGHT ADJUSTER BOTTOM EDGE

OF HOUSING

BOTTOM

EDGE OF

HOUSING

RATCHET

TEETH

THREE-ARM

KNOB

the most effective angle to

control dust (gure 9).

Re-tighten the three-arm

knob rmly before use.

Figure 5

TOE

SPACE