OPERATINGINSTRUCTIONS

The

CrainSuper

Saw

is

desiqned

for

undercuttino

wooden

door

jambs,

rholdings,

base,inasonry,tile,

orston6,to

allow

newfloor

coveringsto befitunderneath.Donotuse

this

sawforsandingfloors,

cuttingmetal,or

anyother

purpose

notdescribedinthis

instructionmanual.

SAFETYFIRST!Forsafeoperation,

please

take time to

carefullyread

alltheinstructionsand

rulesinthis

booklet.

SAFEW GLASSES:

Alwayswear

safety

glasses

when

us-

ingapower

tool.Usefaceordustmaskif

cuttingoperation

isdusty.

EARPROTECTION:

Wear

ear

plugs

when

usingthis

saw.

BLADE

GUARD:Theblade

guard

attachedtoyour

sawis

foryour

safetyandprotection.lf itbecomes

damaged,do

not

operate

your

sawuntilithasbeenrepaired.

Alwaysleave

blade

guard

intheoperating

position

when

usingthesaw.

DOUBLE-INSULATED:Thistoolis

constructedwithtwo

separate

layers

ofelectrical

insulation.

Atool

built

withthis

insulation

system

doesnotneedto be

grounded.

DANGEROUSENVIRONMENTS:Keepwork

areaclean;

clutter

invites

accidents.

Donotuse

thesawondampor

wetfloors.Besurethatthereis

good

lighting.

ACCIDENTAL

STARTING:

To

avoidaccidentalstarting,

do

not

carry

the

saw

with

fingerson

the

switch.

CORD

ABUSE: Never

carry

toolsbythecordoryank

the

cordtodisconnectfromanoutlet.Keepthecord

awayfrom

heat,oil,andsharp

edges.

EXTENSION

GORD:

Tominimize

power

loss

andprevent

over-heating,usemaximum

of25feetlong

and

16AWG.

KEEPBLADES

CLEAN

ANDSHARP: Usingadullblade

will

place

a

heavyload

on

your

sawand

increase

thedanger

ofkickback.Forreplacement,

useonlyCrain

#821

Carbide-

Tipped,

#805Masonryor#822DiamondBlades.

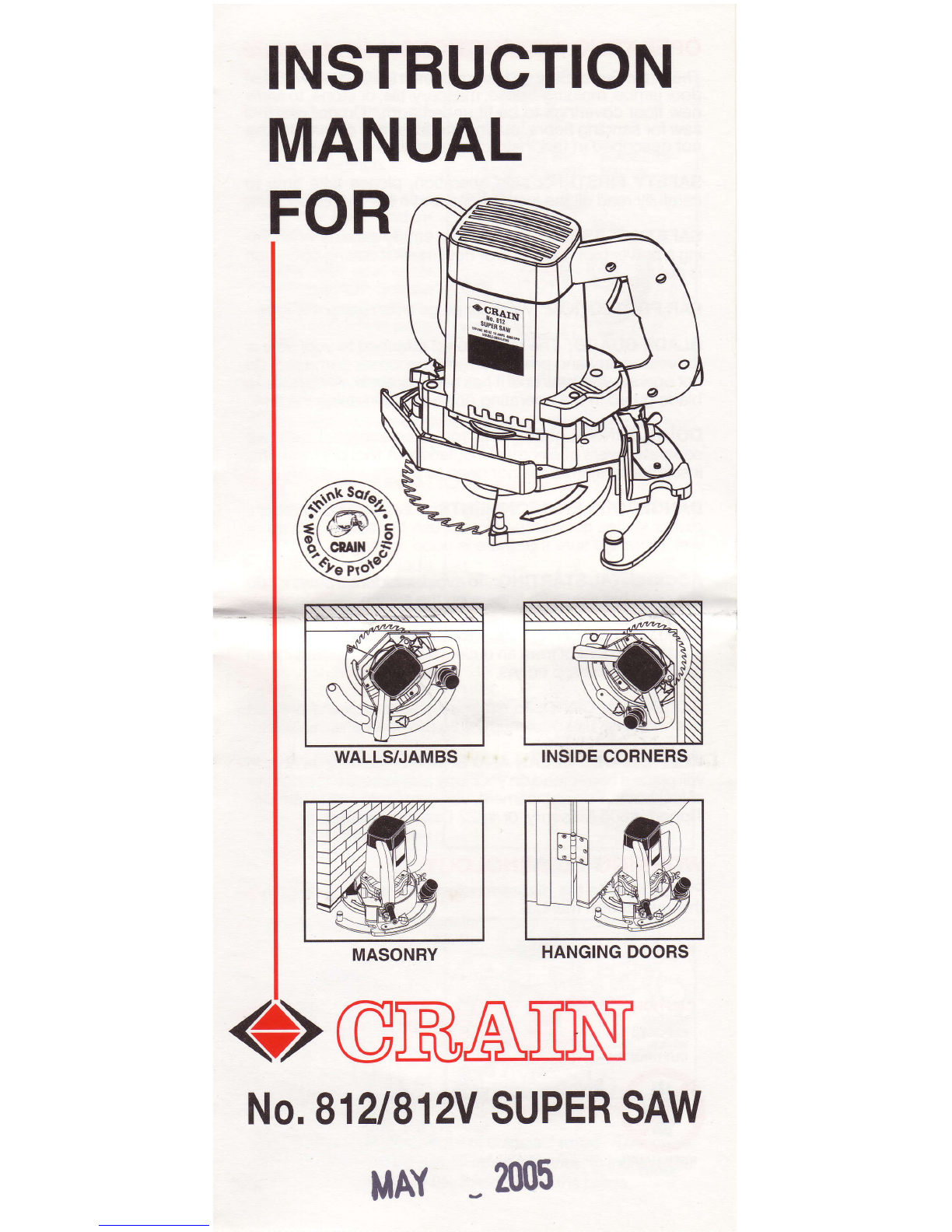

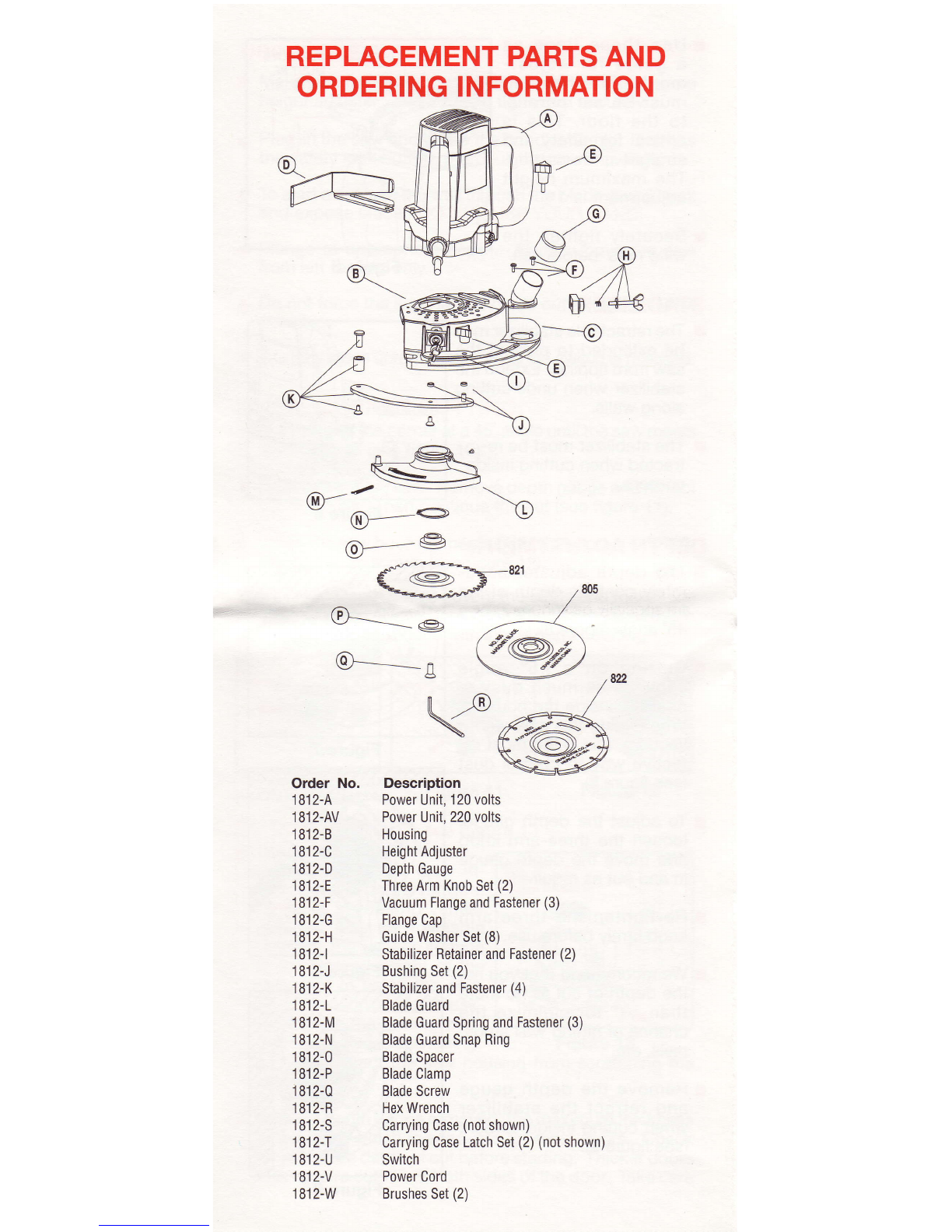

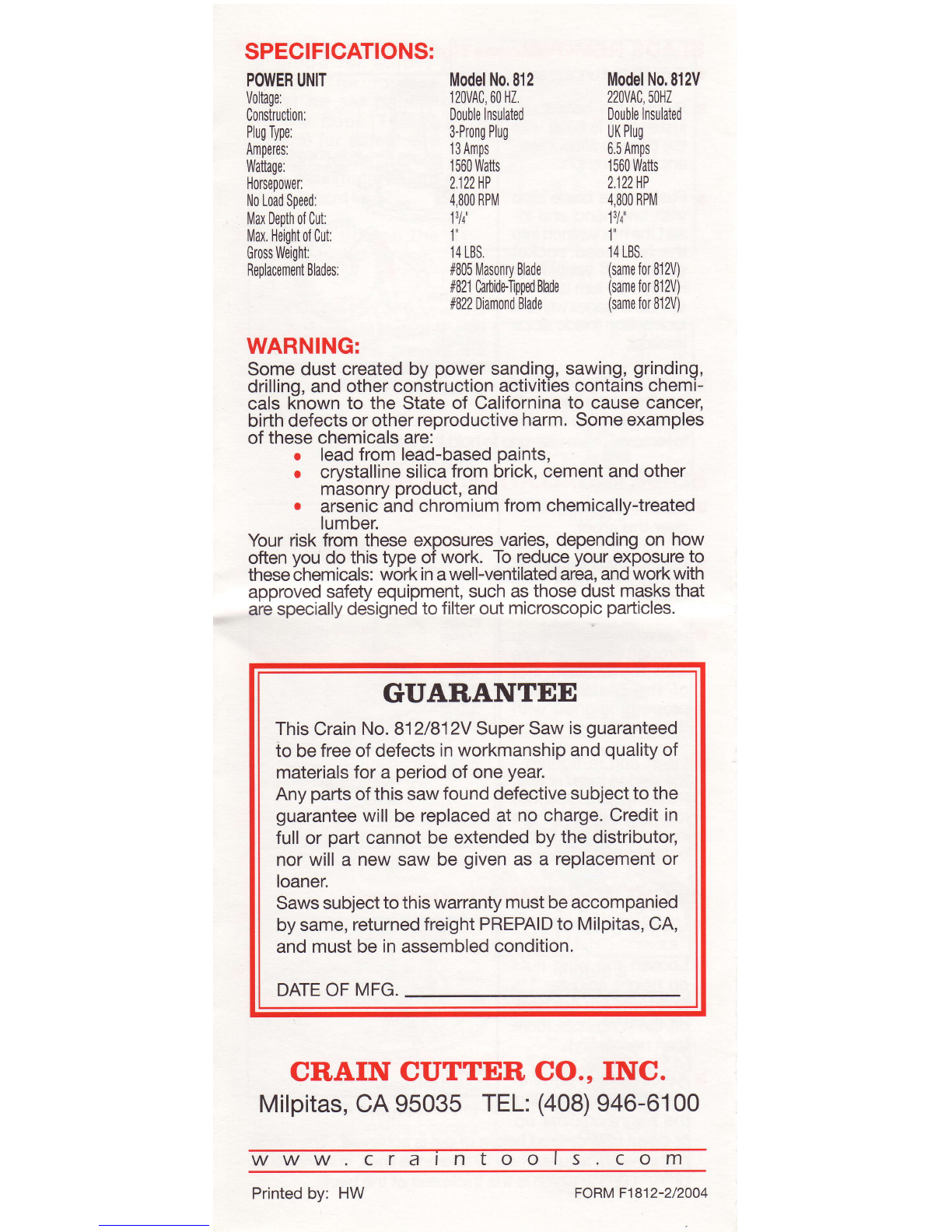

WORKINGTERMINOLOGY

Pleasereferto thediagrambelowfortheterms

used

in

thisinstructionmanual. TRIGGER

HANDLE

Figure1

CAUTION!

BLADE

EXPOSED

WHILE

CUTTING!

KEEPHANDS

AWAY! HEIGHT