Crane Electronics TorqueStar Plus User manual

1

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Operator’s Manual

TorqueStar Plus Data Collector

Manual 1293-01 Issue 1

Crane Electronics Ltd

Notice

ALL RIGHTS RESERVED. Reproduction of any part of this manual in any form whatsoever,

without the prior permission in writing from Crane Electronics Ltd is forbidden.

Copyright © December 2018 by Crane Electronics Ltd.

2

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Contents 2

CE Marking & Compliance 3

Product Disposal & About this Manual 4

Packing List 5

Spares & Accessories 5

Features & Dimensions 6

Specifications 7

Hardware 8

Technical Features 8

Icons 9

Start Up 10

Inputs 12

Charging your TorqueStar 13

Connecting a Transducer 13

Manual Transducer Set-up 14

Saving to USB 15

Settings 15

Power Settings 16

Date & Time Settings 17

Global Settings 17

Misc. Torque Settings 18

Settings Measurement 19

Measuring Screen 20

Measurement Options 22

Reading List 24

Statistics 25

Deletion 25

Warning Screens 26

CONTENTS

3

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Manufacturer: Crane Electronics Ltd

Address: 3 Watling Drive

Sketchley Meadows

Hinckley

Leicestershire

LE10 3EY

Tel: +44 (0)1455 25 14 88

Declares that the TorqueStar range has been assessed and complies with the requirements of the relevant CE

Directives.

This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in

particular installations. If this equipment does cause harmful interference to radio or television reception

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

CE MARKING

COMPLIANCE

Changes or modifications to the TorqueStar range not expressly approved by Crane Electronics Ltd could void

the user’s authority to operate the equipment.

4

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Applicable in the EU and other European Countries with separate collection systems

The symbol shown here and on the product means that the product is classed as Electrical or

Electronics Equipment and should not be disposed with normal commercial waste at the end

of its working life.

The Waste of Electrical and Electronics Equipment (WEEE) Directive (2012/19/EU) has been put in place to

recycle products using best available recovery and recycling techniques to minimise the impact on the

environment, treat any hazardous substances and avoid the increasing landfill.

For more detailed information about recycling of this product please contact your local authority or the

Company where you have purchased the product.

Battery disposal to take place in line with the AMENDED BATTERIES DIRECTIVE 2013/56/EU. Batteries must

not go to landfill. Check with local legislation.

Crane Electronics declares that this product does not contain any of the 191 Substances of Very High Concern

(SVHC’s) identified in the REACH Regulation in used articles make-up.

In Countries outside the EU:

If you wish to discard this product, please contact your local authorities and ask for the correct way of disposal.

Signed for & on behalf of Crane Electronics Ltd.

Name: B. M. Etter

Title: Safety & Environmental Advisor Signature of Issuer:

This manual covers the TorqueStar Plus version, working with our range of torque transducers and digital

torque wrenches.

Actual screen shots represented in this manual may differ slightly from those on the actual

TorqueStar unit, depending on the version.

For information on the operation of one of our digital torque wrenches or torque

transducers, please refer to their own manuals.

Software version TorqueStar Plus

PRODUCT DISPOSAL

ABOUT THIS MANUAL

5

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

The following Items are supplied with the TorqueStar Plus dependent on model specification purchased.

1 x TorqueStar Plus

1 x Calibration Certificate

1 x Quick Start Guide (with QR code link to operator’s manual)

1 x 5V PSU Power Adapter

1 x USB to Micro USB connection cable

1 x USB Flash Drive

1 x Carry Lanyard

All contents are supplied in a hard plastic case with foam insert.

Please ensure all items are present and notify Crane Electronics Ltd immediately of any shortages.

Additional Batteries 080159

5V PSU Power Adapter TSXXA – 0000 - CRPXXX

External battery charger TSXXA – 0000 - CRCXXX

USB to Micro USB connection cable 090301

Carry Lanyard 110385

Protective Case TSXXA – 0000 - CRTXXX

PACKING LIST

SPARES AND ACCESSORIES (with Product Code)

6

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

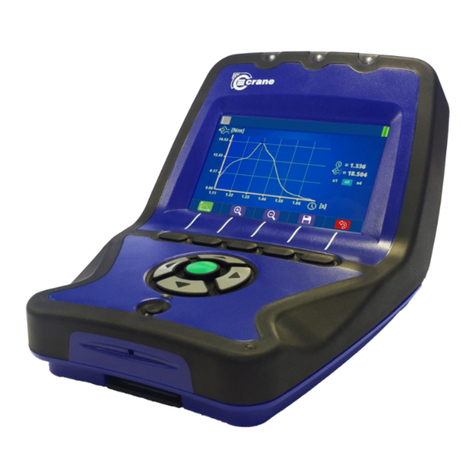

FEATURES AND DIMENSIONS

7

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Measurement Modes:

Track – Real time torque

Peak – Capture of the highest torque

Pulse – Special measurement algorithm for use with impulse tools, incorporating pulse count

Click – Special measurement algorithm for use with click tools

Force – Capture of peak force during cycle

Audit – Special measurement algorithm that measures torque after joint moves a certain angle

Measurement Units:

Torque – Nm, lbft, lbin, MNm, Ncm, kgcm, kgm, kNm, klbft, Nmm, ozin

Force – kg, kkg, lb, klb, N, kN

Physical Measurements:

Auto Bi-directional torque; angle*; pulse count; RPM in track mode*; cycle time duration (*when using rotary

transducer).

Compatible Input Devices:

IS, UTA, and Multi, including WrenchStar Multi, cable products compatible, Analog or digital.

Plug & Play Transducer Data:

Auto ID of all Crane UTA/Multi products. The following information is read from the chip in the transducer -

torque range, angle encoder data, serial number, calibration due date.

Data Storage:

999 readings in storage mode.

Basic Statistics:

Count, range, mean, min, max, standard deviation.

Advanced Statistics (Available in TorqueStar Plus only with an upgrade):

Cm, Cmk, Cp, Cpk

Auto Print / Data Output:

Easy selectable output to AutoPrint or CSV. Interface to simple PC package that outputs the print data to an

Excel spreadsheet.

Cycle Status Indication:

Audible buzzer and LED HI/OK/LO torque status. User definable.

Operating Languages:

English, Chinese, Czech, French, German, Italian, Hungarian, Spanish, Swedish, Polish, Portuguese, Turkish.

SPECIFICATIONS

8

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Construction:

High strength injection moulding. Protective rubberised trim to alleviate secondary damage. Soft rubber trim

surrounding tough internal chassis. Can survive 1.8m drop.

Display:

Colour Backlit 4”screen (86mm x 52mm)

Keypad:

Easy clean keypad. 11 Keys including 5 function keys, 5 soft directional keys and on/off key.

Power:

Universal 5V charger or USB charger.

Power Management:

User selectable auto power-off: Between 0 - 200 minutes. Screen contrast and brightness adjustment.

Battery Pack:

Lithium Ion - User swappable. Charge time: 3 hours with appropriate charger current. Chargeable via USB or

5V charger.

Input/output ports:

25 pin ‘D’ type transducer port (female) (digital or analogue).

Micro USB (2.0) for power and export.

Standard USB type A (On The Go).

5V DC power port for use with mains power DC charger.

Zero Stability:

<± 0.1% FSD/ °C.

Static Accuracy:

± 0.25% FSD of connected transducer.

Operating Environment:

Temperature: -20 to +50 °C.

Humidity 10-75% non-condensing.

Ingress protection rating: IP45.

Torque Measurement

Display to 5 significant figures. Sample every 20 micro seconds.

Angle Measurement:

Quadrature phase input. Display angle to 0.1 degrees, Sample every 1000 micro seconds.

Warranty:

12 months parts and labour against faulty workmanship or materials.

HARDWARE

TECHNICAL FEATURES

9

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Measurement Modes:

Settings:

Languages:

Transducer Screen:

Statistics screen:

ICONS – TorqueStar Plus

Peak

Click

Track

Pulse

Audit

Settings

Date/Time

Global

Misc.

Torque

Information

Misc.

Power

English

French

German

Italian

Swedish

Spanish

Portuguese

Hungarian

Chinese

Polish

Czech

Turkish

Transducer

Edit

Refresh

Delete

Back

Back

Statistics

Save

Print

Peak Angle

Force

10

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Reading List Screen:

Turning on your TorqueStar:

Turn on the TorqueStar by pressing the on/off button situated below the arrowed keypad. Pressing this button

whilst the TorqueStar is on will turn it off.

The first screen you will see is as below.

1) Model

2) Transducers available

3) Serial Number S/N, Torque Module latest

release, HMI Module latest release,

Keyboard latest release

4) Advised calibration due date for this data

collector

5) Features unlocked

It confirms what version of TorqueStar you have. In the screenshot above it tells you that you can use

Analogue and Digital Transducers only. RF Transducers can only be used with the TorqueStar Pro.

In the top right hand corner it will show the current level of battery life and whether it is being charged or not.

Charging is denoted by a lightning flash.

The Serial Number of the model you have is displayed, along with the latest software release for the Torque

module, HMI Module and Keyboard. The opening screen also shows the Calibration due date of the model you

have.

Back

Readings

Print

Add

Comment

Delete

Comment

1

2

3

4

START UP

5

11

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

If you press the green button or wait the TorqueStar will load its settings for a few seconds and the load screen

will be displayed.

If no transducer is plugged in then this screen will appear.

Please connect a transducer. See ‘Connecting a Transducer’

set up.

If a transducer is already plugged in then depending on what Span Nm it will automatically populate the LSL,

Target torque and USL. If the transducer has angle this will also automatically be populated.

If you wish to change the LSL, Target Torque and USL then you will see that there is a cyan line under the

populated limits. You can toggle using the up and down arrow keys to highlight the angles limits as well. Press

the green button and you will be taken to the screen below.

Torque Angle

12

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Use the left and right arrows to move to the Limit that you wish to change. When highlighted press the green

button. To change the Limits use the Up and Down arrows and the Left and Right arrows to go to another

number. Once you have set the desired number, press the green button. Continue following the process until

all your limit settings are correct.

If you are changing a transducer or changing the Limits then this will reset all the results.

If all is OK then press the green ‘tick’.

If this screen isn’t displayed then press the back button

to return to the measuring screen.

TorqueStar Plus has connectivity using

the following;

1) Micro USB

2) USB

3) 25-way D-type female transducer

port

4) 5V DC Power Supply

INPUTS

4

1

2

3

13

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Charging can be done in two ways:

1) Connect Micro USB on the TorqueStar to USB on a

laptop/PC or USB charger.

2) Connect the 5V DC port with a DC power supply.

Plug the male 25-way D-type connection on the transducer to the

female connection port on the back of the TorqueStar Plus.

All Crane UTA transducers will automatically be recognised.

Industry Standard (IS) Transducers will have to be manually inputted

(See transducer set-up).

You can store up to 10 x IS transducers. Use 1 x UTA transducer and have 10 x IS stored or you can connect 5 x

UTA transducers at simultaneously time by using a 5-Way transducer switching box.

5-Way auto transducer switching box:

Allows connection of up to 5 transducers and the capability to switch between

them with ease. Automatic recognition of UTA’s and no hardware modifications

required to connect. Uses 25-way D-type interface.

Part Number: TO-899-09CR-0-0

RS232 Cable Port to Port: CBL-757-0-0-0-0

CONNECTING A TRANSDUCER

CHARGING YOUR TORQUESTAR

2

2

1

1

14

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

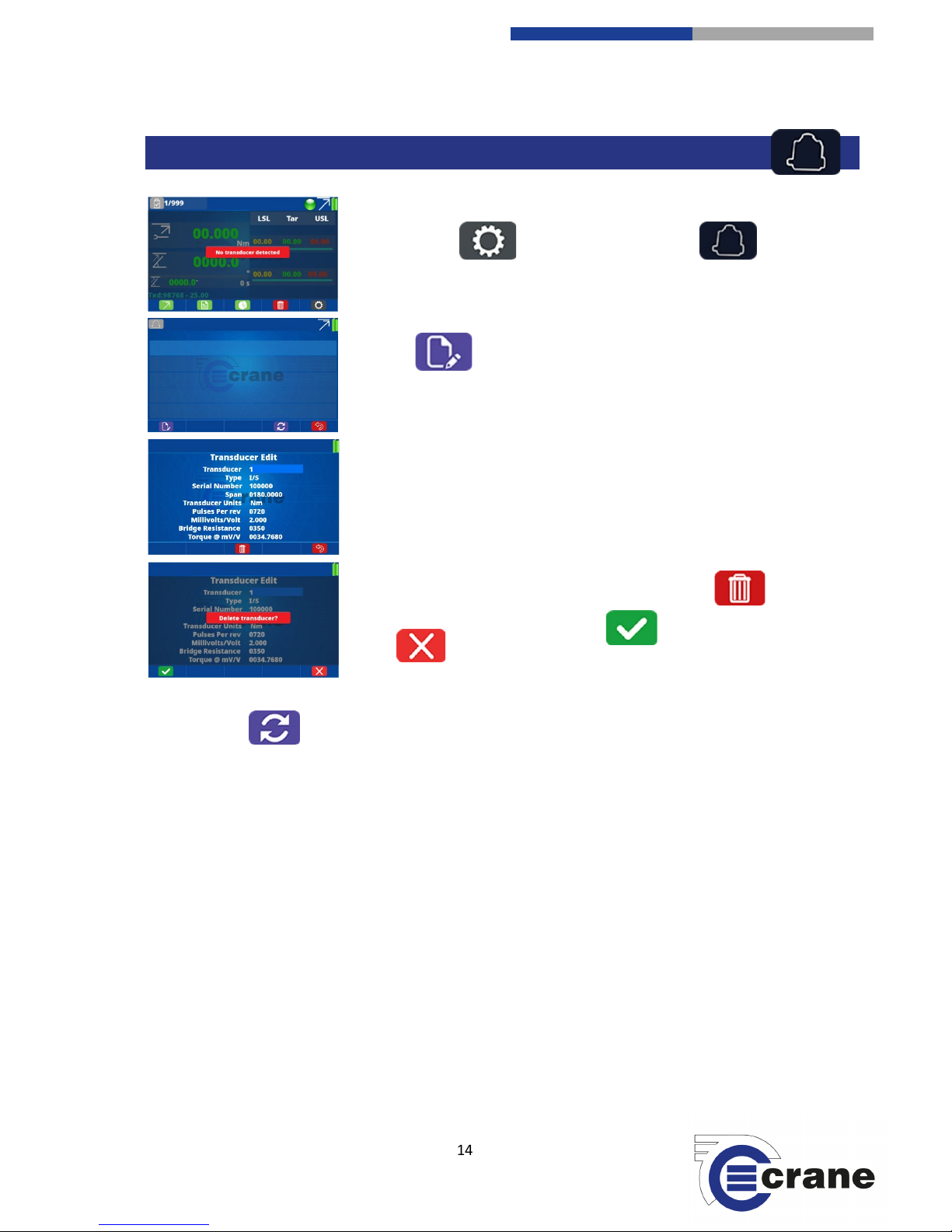

To manually set up an IS or force transducer select the settings icon from

the main screen and then the transducer icon.

You will come to this screen enabling you to set up a transducer. Press the

edit icon to manually input the type of transducer you wish to

connect.

Change the transducer properties by using the Left and Right key. Use the

Up and Down arrows to navigate the screen.

You can also delete a transducer by pressing the delete icon and

press the green button or the green ‘tick’ to accept and the red

‘cross’ to not delete.

You can always refresh to pair a UTA to the TorqueStar if you have one attached or search for one by pressing

the refresh icon.

Transducer: Set the number of the transducer as you see fit. The TorqueStar can store 10 transducers.

Type: Scroll down to type if you are adding an Industry Standard (IS) transducer or Force. All Crane transducers

are recognised. The same will work for RF (TorqueStar Pro only). Use arrows to change from IS to Force.

Serial number: To input the serial number, use the keypad to highlight the serial number. Press the green

button on the keypad to highlight the first digit. Use the Up and Down arrows to change this digit and move

left and right to highlight additional digits for editing. Once completed press the green button.

Span: To input the span use the same process as for inputting a serial number.

Transducer units: Select the measurement unit that you wish to use by using the left and right arrow keys.

Available are: Nm / lbft / lbin / MNm / Ncm / kgcm / kgm / kNm / klbft / Nmm / ozin if IS transducer and N,

kN, Kg, kkg, lb, klb if Force transducer.

Pulses per revolution (PPR), Millivolts/Volt, Bridge resistance, Torque @ mV/V: To input these details, follow

the same process as inputting a serial number. Millivolts/Volt can be between 0.500 to 8.000. Bridge

resistance cannot be 0000.

MANUAL TRANSDUCER SET UP

15

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Saving readings to a USB device:

Insert a USB device into the back of the TorqueStar. The standard USB socket can be located at the rear of the

unit and is sealed with a plastic protector. Remove the protector and insert the USB device.

USB port protector. Insert USB.

When clicking on the Save Icon, you will be asked to insert a USB Stick. The USB Icon will

appear on the screen.

The USB Memory Stick icon will automatically go green and save the readings to the USB Stick

if attached.

Saves in folder \Crane\Export

Filename [MeasureMode] Date_Time.csv

Date & Time format altered in settings and represents time of export.

Settings can be accessed by pressing the Settings Icon: The first setting screen is the measure

mode settings (see later).

SETTINGS

SAVING - USB

16

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

The ‘Back’ icon will take you back to the previous screen.

will take you to further settings icons as follows:

Transducer Splash Screen Misc.

Power Date & Time Global Miscellaneous Torque

Click on the Settings Icon. Click on the Miscellaneous Icon. Click on the Power Icon.

You can change the ‘Power Off’ time by using the Up and

Down arrows to highlight the current minutes. Use the Left

and Right arrows to toggle between time limits. You can set

‘Never Off’ or between 1 – 200 minutes.

The same process is followed to change the ‘Backlight Off’

setting. The ‘Buzzer’ can be toggled on or off and the

‘Brightness’ can be changed from 20% - 100%. A lower

brightness saves battery power. ‘Battery’ level is an indicator

to the unit’s power status. If an external power source is

connected, then it will show as 100%.

POWER SETTINGS

17

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Click on the Settings Icon. Click on the Miscellaneous Icon. Click on the Date/Time.

Date Format – Using the Up and Down arrows you can navigate.

Highlight the ‘Date Format’ and press of the left or right arrows to

change the format. There are three to choose from:

DD/MM/YYYY, MM/DD/YYYY, YY/MM/DD.

Date – To change the date, highlight the current date stored, press

the green OK button and use the Up and Down arrows to change

the dates. A Left or Right keys switch between day, month and

year. To save press the green button.

Number Format – Dot or Comma for decimal place.

Time Format – Set how you want the time displayed. HH:MM:SS, HH:MM using the left and right arrow keys.

Time – Highlight the current time, press the green OK button and then you can use the arrow keys to change

the time, using the Left and Right arrows to move between the hours, minutes and seconds.

Click on the Settings Icon. Click on the Miscellaneous Icon. Click on the Global Icon

Language Settings.

Use the left and right arrow keys to change the language in the TorqueStar. Available languages are: English,

French, German, Chinese, Polish, Hungarian, Italian, Portuguese, Spanish, Turkish, Swedish, Czech.

DATE & TIME SETTINGS

GLOBAL SETTINGS

18

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Click on the Settings Icon. Click on the Miscellaneous Icon. Click on Misc. Icon

Use the Up and Down arrows to navigate and use the left

and right arrows to set the user requirement.

-Stream to USB updates torque value to USB

continuously whilst taking readings. Stream is on

Micro USB port.

-The span of connected transducer can be added to

stream.

-FIFO is First In First Out. If off, it can only take 999

readings. If on, you can see the last 999 readings.

-Auto Print sets print out for the end of results and in

reading list. Press to access Auto Print set-

up.

Auto-print set up.

Use the left and right arrows to change the settings, use

the up and down arrows to scroll through the menus.

If you have a TorqueStar Plus you can purchase an

upgrade to ‘graphs’. Once purchased, access via the

miscellaneous settings icon, press the unlock icon. Use

the arrow keys to input the code to upgrade.

When in the reading list, pressing the green button will

show a graph of the readings. Graph analysis is only

available in TorqueStar Plus via upgrade or is as standard

for the TorqueStar Pro.

The icon switches between Torque vs Time,

Angle vs Time and Torque vs Angle.

MISCELLANEOUS TORQUE SETTINGS

READING TRACE

UNLOCK CODE

19

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

A red cross (cursor) will highlight feature found on that measure mode. You can zoom in (except on Torque vs.

Angle)

The up and down arrow keys change the speed of cursor movement. The parameter values at the cursor

position are displayed on the right hand side of the graph. The plus and minus icons allow you to zoom in and

out of the trace. Zoom in centres on the cursor and you can zoom in until all trace points are displayed.

The save icon saves the results.

Save to folder \Crane\Traces\ [MeasureMode] Date_Time.csv

If taking more than 999 readings (FIFO on) they will only see traces for the last 998 readings.

Using the Up and Down arrows on the device you can

select the setting that you require. Using the Left and

Right arrows will change the setting to what you require.

Once completed you can press the return key to go back

to the measurement screen.

Units = Displayed torque units

Direction = Clockwise, Anti-clockwise, Auto

Cycle end time = 0.2s, 0.5s, 1.0s, 2.0s, 5.0s, 10.0s

Freq. response = (Hz) 75, 151, 256, 307, 384,

542, 768, 921, 1024, 1536, 2304, 3072, 4608

The menu slot is the number from the left of

screen that measure icon occupies

Audit angle shown when measure mode is Audit.

SETTINGS MEASUREMENT SCREEN

20

Crane Electronics Ltd

The force in torque management

Crane Electronics Ltd

Watling Drive

Sketchley Meadows

Hinckley LE10 3EY

Tel: +44(0) 1455 25 14 88

www.crane

-electronics.com

Measuring Screen:

The symbols across the top of the screen are:

Icon appears relevant to the screen you are currently in.

The TorqueStar has 999 readings capability. Number of readings are displayed.

(Changes from /999 to +000 when it has more than 999 FIFO readings)

If this Icon is Green it means that everything is ready to measure.

If this icon is Red then something needs to be actioned and it cannot take a measurement.

Current ‘Measurement Mode’ is displayed

Battery level indicator. A flash will appear when charging.

THE MEASURING SCREEN

Other manuals for TorqueStar Plus

2

Table of contents

Other Crane Electronics Data Logger manuals