CRE Technology GENSYS 2.0 Guide

“All-in-one genset control

and

paralleling unit ”

CRE Technology believes that all information provided herein is correct and reliable and reserves the right

to update at any time. CRE Technology does not assume any responsibility for its use. E & O E.

Technical documentation

GENSYS 2.0

GENSYS 2.0 CORE

GENSYS 2.0 LT

Part Number:

A53 Z0 9 0020

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

2

CRE Technology

130, Allée Victor Naudin

Zone des Templier

Sophia-Antipolis

06410 Biot

FRANCE

Phone: +33 (0)4 92 38 86 82

Fax: +33 (0)4 92 38 86 83

Website: www.cretechnology.com

Email: info@cretechnology.com

NOTE

Read this entire manual and all other publications pertaining to the work to be performed

before installing, operating, or servicing this equipment. Apply all plant and safety

instructions and precautions. Failure to follow instructions can cause personal injury and/or

property damage.

Motors, turbines and any other type of generator must be equipped with protections

(overspeed, high temperature, low pressure…) depending on the power plant).

Any changes of the normal use of the equipment can cause human and material damage.

For further information, please contact your CRE technology distributor or the After-Sales Service Team.

All CRE Technology products are delivered with one year warranty, and if necessary we will be happy to

come on site for product commissioning or troubleshooting. The company also provide specific trainings

on our products and softwares.

Technical support: +33 (0)4 92 38 86 86 (office hours: 8.30AM-12AM / 2PM-6PM GMT+1).

Email: support@cretechnology.com

SKYPE: support-cretechnology.com

INFORMATION

You can download the most up-to-date version of this documentation and different other

documentations relating to CRE technology products on our Web site

http://www.cretechnology.com.

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

3

Technical documentation history

Date

Version

Comments

Nov. 2008

A

Derived from GENSYS documentation. Starting point.

Jan. 2008

B

Correction and full explanation of several features.

Feb. 2008

C

Added menu references. Global revision by all the team.

Mar. 2009

D

Details added for the reset of alarms, faults, and data logging.

Details added for the semi auto mode.

July 2009

E

J1939 details added.

Modification of general wiring diagram.

Removal of USB connection.

Addition of Ethernet connection.

Sept. 2009

F

Firmware update using SD card added.

Chapter on GENSYS 1.0/GENSYS 2.0 compatibility added.

Extra information concerning analogue sensors.

Information concerning CEM compliance added.

Ethernet connection added and USB connection chapter updated.

Digital input parameter errors corrected.

Feb. 2010

G

Two phase/three phase system management added.

SD card archiving added.

Breaker management info added.

SD card flashing removed.

Start sequence.

July 2010

H

GENSYS 2.0 firmware v2.05

IP address can now be changed.

Support of Modbus TCP.

J1939 compatibility with Cummins QSX15G8

Automatic shutdown of the horn.

Corrections on PWM 500Hz documentation.

CANopen example changed.

April 2011

I

Enhanced semi-automatic mode description.

New chapter concerning optional power tank capacitor.

New: minimum wiring diagram.

Updated static paralleling diagram.

Updated maintenance cycles chapter.

Updated reference of digital input variables.

Updated custom logo size.

Updated CAN bus good practices.

Updated technical support contact.

Updated external automatic start module setup description.

Additional features starting from firmware v3.00:

CRE Config software compatibility.

Assisted manual mode.

Front panel button inhibition.

Firmware upgrade using SD card.

Generating an empty file template.

Import/Export/Delete TXT files on SD card.

Resetting factory parameters.

New methods to permanently store parameters in memory.

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

4

Date

Version

Comments

February 2012

J

Additional features starting from firmware v4.00:

Power plant up to 32 modules using CAN bus.

Support of FAT32 SDHC cards.

Automatic backup of new parameter values.

ASSISTED MANUAL mode activated by default.

Option 7: Enable/disable internal engine start sequence.

Interface with external start module without equation.

Fuel/water/oil filling without equation.

New menu organization.

Potential Alarm/Fault list.

Download of a CUSTOM language file.

Enhancements and modifications :

Update of schematics and graphs.

Maximal CT ratio value.

Maximum size of text file.

Available data space for SD card and internal FIFO loggers.

External power tank to be used only with a 12V battery.

August 2012

K

Compatibility with RDM 2.0 remote display module.

GENSYS 2.0 CORE and GENSYS 2.0 LT dedicated chapters.

Chapter 10.3, table 22 : AVR Leroy Somer R450 and Stamford MX341.

Chapter 13 .8 BSM II cable reference removed (not useful).

Chapter 15.3.2: Add J1939 display page of unknown SPN/FMI.

Chapter 17.3.12: Add the reset maintenance cycle page.

Chapter 15.7.1 : Safely remove your SD card.

Chapter 17.4.3.2 : LCD backlight adjustment through “System/Display

properties” menu.

Chapter 20.2 Accessories : Add A40W2 cable.

Chapter 20.1: Add reference of all GENSYS 2.0 family modules.

September

2012

L

New features supported by v4.03/v4.04:

Additional MODBUS support including:

Multiple TCP connections.

New function support (01, 02, 05, 0F).

Advanced rights management (read/write access).

Support of Modbus RTU over TCP in addition to

standard Modbus TCP protocol.

Chapter 17.3.9: configurable synchronization dwell timer

(E4108).

Updated wiring of standard CAN (DB9 connectors)

Table 7: Added frequency range of voltage measurements.

Chapter 15.3.2: Note on Cummins CPG / G Drive ECU firmwares.

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

5

You can download the most up-to-date version of this documentation and different other documentations

relating to GENSYS 2.0 on our Web site: http://www.cretechnology.com.

Documentations available on CRE Technology Web site:

A53 Z0 9 0020 x-EN is the GENSYS 2.0 technical documentation (this manual). This documentation

is generally used for product integration.

A53 Z0 9 0031 x-EN is the translation help tool to download a CUSTOM language file.

A53 Z0 9 0020 x-EN is the Complete variable list with labels, units and limits in English, in PDF

format. This documentation is generally used as reference during the integration phase.

A53 Z0 9 0030 x- is the Complete variable list with labels, units and limits in all languages, in EXCEL

WORKBOOK format. This documentation is generally used as reference during the installation

phase. It is generally called “EXCEL FILE”.

NOTE

Read this entire manual and all other publications pertaining to the work to be performed

before installing, operating, or servicing this equipment. Apply all plant and safety

instructions and precautions. Failure to follow instructions can cause personal injury

and/or property damage.

Contact your CRE Technology distributor for course training.

NOTE FOR GENSYS 2.0 LT

This logo indicates that the function described in the chapter is not available in GENSYS

2.0 LT modules.

The main features unavailable in GENSYS 2.0 LT are the support of custom equations and

CANopen extension I/O. If you ever need one of these features, please use a standard

GENSYS 2.0 module.

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

6

Table of content

1OVERVIEW........................................................................................................................................................ 14

1.1 EUROPEAN UNION DIRECTIVE COMPLIANCE CE ...................................................................................................... 14

1.2 ENVIRONMENT ............................................................................................................................................. 14

1.3 CHARACTERISTICS .......................................................................................................................................... 15

2GENSYS 2.0 CORE ............................................................................................................................................. 16

2.1 DESCRIPTION................................................................................................................................................ 16

2.2 USER INTERFACE WITH A RDM 2.0.................................................................................................................... 16

2.3 USER INTERFACE USING DIGITAL INPUTS .............................................................................................................. 16

3GENSYS 2.0 LT .................................................................................................................................................. 17

4DESCRIPTION.................................................................................................................................................... 18

4.1 FRONT PANEL ............................................................................................................................................... 18

4.2 REAR PANEL –CONNECTORS ............................................................................................................................ 23

5USER INTERFACE .............................................................................................................................................. 30

5.1 SECURITY LEVEL AND PASSWORD ....................................................................................................................... 31

5.2 LOCAL NAVIGATION........................................................................................................................................ 32

5.3 REMOTE CONTROL USING A PC (ETHERNET CONNECTION) ....................................................................................... 34

6OPERATING MODE ........................................................................................................................................... 40

6.1 ASSISTED MANUAL MODE ................................................................................................................................ 40

6.2 AUTOMATIC MODE ........................................................................................................................................ 43

6.3 TEST MODE.................................................................................................................................................. 43

6.4 SEMI-AUTOMATIC MODE ................................................................................................................................. 44

6.5 MANUAL MODE ............................................................................................................................................ 45

7START SEQUENCE ............................................................................................................................................. 46

8PREDEFINED CONFIGURATION ......................................................................................................................... 48

8.1 SINGLE GENERATOR IN CHANGE-OVER MODE ........................................................................................................ 48

8.2 SINGLE GENERATOR IN NO-CHANGE-OVER MODE ................................................................................................... 51

8.3 GENERATOR PARALLELING WITH DIGITAL BUS........................................................................................................ 52

8.4 GENERATORS PARALLELING WITH GENSYS 2.0 AND PARALLEL LINE MODULES .............................................................. 53

8.5 MULTIPLE GENERATORS WITH STATIC PARALLELING ................................................................................................ 54

8.6 SINGLE GENERATOR PARALLELED WITH MAINS....................................................................................................... 56

8.7 POWER PLANT PARALLELED WITH MAINS USING MASTER 2.0 OR GCR ...................................................................... 61

8.8 POWER PLANT PARALLELED WITH SEVERAL MAINS USING MASTER 2.0 OR GCR BY MAINS ............................................. 63

9INSTALLING AND COMMISSIONING A GENSYS 2.0 APPLICATION...................................................................... 64

9.1 MINIMUM WIRING DIAGRAM ........................................................................................................................... 64

9.2 COMPLETE WIRING DIAGRAM ........................................................................................................................... 65

9.3 INSTALLATION INSTRUCTIONS ........................................................................................................................... 66

9.4 BEFORE COMMISSIONING ................................................................................................................................ 68

9.5 DURING COMMISSIONING................................................................................................................................ 68

10 DEDICATED I/O LINES ....................................................................................................................................... 72

10.1 SPEED GOVERNOR INTERFACE ........................................................................................................................... 72

10.2 SPEED AND VOLTAGE CONTROL WITH CONTACTS/PULSES ........................................................................................ 77

10.3 ANALOGUE AVR (AUTO VOLTAGE REGULATIOR)CONTROL ...................................................................................... 80

10.4 RELAY OUTPUT ............................................................................................................................................. 83

10.5 CRANK/FUEL/STARTER 2/ STARTER 3FUNCTIONS ................................................................................................. 86

10.6 WATER PREHEAT/PRE-LUBRICATION/PRE-GLOW FUNCTIONS.................................................................................. 87

10.7 AIR FAN ...................................................................................................................................................... 88

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

7

10.8 FUEL FILLING/COOLANT FILLING/OIL FILLING....................................................................................................... 89

10.9 ANALOGUE LOAD SHARING LINE ........................................................................................................................ 91

10.10 WATCHDOG OUTPUT ................................................................................................................................. 92

11 I/O LINES.......................................................................................................................................................... 93

11.1 DIGITAL INPUT .............................................................................................................................................. 93

11.2 DIGITAL OUTPUTS .......................................................................................................................................... 97

11.3 ANALOGUE INPUT (VIA CRE CONFIG SOFTWARE) ................................................................................................. 101

12 PROTECTIONS................................................................................................................................................. 106

12.1 DISABLE .................................................................................................................................................... 106

12.2 GENERATOR ELECTRICAL FAULT ....................................................................................................................... 106

12.3 MAINS ELECTRICAL FAULT .............................................................................................................................. 106

12.4 ALARM ..................................................................................................................................................... 106

12.5 FAULT (SOFT SHUT DOWN)............................................................................................................................ 106

12.6 SECURITY (HARD SHUTDOWN)........................................................................................................................ 106

12.7 DROOP ..................................................................................................................................................... 106

12.8 HELP +FAULT (SOFT SHUT DOWN) .................................................................................................................. 106

12.9 HELP +GEN.ELECTRICAL FAULT ...................................................................................................................... 107

12.10 POTENTIAL ALARMS/FAULTS LIST ................................................................................................................ 107

13 ADDITIONAL FUNCTIONS................................................................................................................................ 111

13.1 LOAD SHARING USING INTEGRAL (DE-DROOPING)................................................................................................. 111

13.2 OPERATOR CONTROLLED RETURN TO MAINS ....................................................................................................... 113

13.3 MAINS ELECTRICAL FAULT .............................................................................................................................. 113

13.4 GENERATOR ELECTRICAL FAULT ....................................................................................................................... 115

13.5 GENSYS 2.0 WITH EXTERNAL AUTOMATIC START MODULE .................................................................................... 116

13.6 REMOTE START UPON EXTERNAL PULSE ............................................................................................................. 118

13.7 SAFETY INHIBITIONS ..................................................................................................................................... 119

13.8 USE OF BSM II WITH GENSYS 2.0 ................................................................................................................. 121

13.9 GENSYS 2.0 WITH TEM COMPACT................................................................................................................. 124

13.10 G59 NORM (ACCESS LEVEL -1) ................................................................................................................... 125

13.11 SCADA.................................................................................................................................................. 125

13.12 HOW TO SET A GPID ............................................................................................................................... 126

13.13 AUTOMATIC LOAD /UNLOAD ..................................................................................................................... 127

13.14 HEAVY CONSUMER (MARINE SEQUENCE) ....................................................................................................... 131

13.15 NON-ESSENTIAL CONSUMER TRIP (MARINE SEQUENCE) ..................................................................................... 133

13.16 PHASE OFFSET (DYN11 AND OTHER) ............................................................................................................ 136

13.17 VOLTAGE SYSTEM (120°THREE PHASES,180°TWO PHASES,SINGLE PHASE).......................................................... 137

13.18 MAINTENANCE CYCLE ............................................................................................................................... 138

13.19 FRONT PANEL INHIBITION .......................................................................................................................... 139

14 TEXT FILE & PLC .............................................................................................................................................. 140

14.1 INTRODUCTION ........................................................................................................................................... 140

14.2 VARIABLE NAMING ...................................................................................................................................... 140

14.3 TEXT FILE DESCRIPTION ................................................................................................................................. 141

14.4 PLC PROGRAMMING LANGUAGE ..................................................................................................................... 147

14.5 VARIABLES................................................................................................................................................. 149

14.6 SYNTAX EXAMPLES ....................................................................................................................................... 150

14.7 GENSYS 1.0 –GENSYS 2.0 COMPATIBILITY .................................................................................................... 152

14.8 RESETTING TO FACTORY PARAMETERS ............................................................................................................... 154

14.9 DONWLOAD A CUSTOM LANGUAGE FILE ......................................................................................................... 154

15 COMMUNICATION ......................................................................................................................................... 155

15.1 CAN BUS GOOD PRACTICES ............................................................................................................................ 155

15.2 COM1: CRE TECHNOLOGY INTER-MODULES CAN BUS ........................................................................................ 157

15.3 COM2: CAN PROTOCOLS (CANOPEN,J1939, MTU MDEC): ............................................................................. 164

15.4 COM3: USB............................................................................................................................................. 182

15.5 COM4: ETHERNET ................................................................................................................................... 182

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

8

15.6 COM5: MODBUS RTU ON SERIAL PORT RS485............................................................................................... 184

15.7 COM6: SD CARD........................................................................................................................................ 188

16 SUPPORT/TROUBLESHOOTING....................................................................................................................... 195

17 MENU OVERVIEW........................................................................................................................................... 198

17.1 MENU INTRODUCTION.................................................................................................................................. 198

17.2 DISPLAY MENU......................................................................................................................................... 198

17.3 CONFIGURATION MENU ........................................................................................................................... 205

17.4 SYSTEM MENU.......................................................................................................................................... 225

17.5 DEDICATED SCREENS .................................................................................................................................... 234

18 USEFUL INFORMATION................................................................................................................................... 237

19 PRECAUTIONS ................................................................................................................................................ 239

20 REFERENCES ................................................................................................................................................... 241

20.1 PRODUCT REFERENCE ................................................................................................................................... 241

20.2 OPTIONS ................................................................................................................................................... 241

20.3 ACCESSORIES.............................................................................................................................................. 242

21 CRE TECHNOLOGY .......................................................................................................................................... 243

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

9

List of figures

Figure 1 –Panel cut-out............................................................................................................................................. 15

Figure 2 –GENSYS 2.0 front panel.............................................................................................................................. 18

Figure 3 –Rear panel................................................................................................................................................. 23

Figure 4 –User interface............................................................................................................................................ 30

Figure 5 –Default screen saver .................................................................................................................................. 30

Figure 6 –Password input mode display .................................................................................................................... 31

Figure 7 –Main menu................................................................................................................................................ 32

Figure 8 –Browser link description............................................................................................................................. 32

Figure 9 –Contextual keys for input mode ................................................................................................................. 33

Figure 10 - CRE Config software................................................................................................................................. 34

Figure 11 - Typical GENSYS 2.0 Web pages................................................................................................................. 35

Figure 12 - Ethernet configuration page..................................................................................................................... 39

Figure 13 - Assisted manual mode without main paralleling....................................................................................... 41

Figure 14 - Assisted manual mode with main paralleling ............................................................................................ 42

Figure 15 - Semi-automatic mode .............................................................................................................................. 44

Figure 16 –Typical start sequence for fuel engines..................................................................................................... 46

Figure 17 –Power plant in change-over mode without paralleling.............................................................................. 48

Figure 18 –Typical sequence in change-over mode on mains failure........................................................................... 49

Figure 19 - Typical sequence in change-over mode on start request............................................................................ 50

Figure 20 –Power plant in change-over without paralleling ....................................................................................... 51

Figure 21 - Power plant with several generators ........................................................................................................ 52

Figure 22 - Generator paralleling with parallel lines ................................................................................................... 53

Figure 23 - Static paralleling with 4 generators coupled together in emergency situation ........................................... 54

Figure 24 - Example with 4 generators paralleled together in emergency situation..................................................... 54

Figure 25 - Paralleling with mains.............................................................................................................................. 56

Figure 26 - Typical sequence in No Break CO mode on start request ........................................................................... 57

Figure 27 - Typical sequence in No Break CO mode on mains failure........................................................................... 58

Figure 28 - Typical sequence in permanent mode on mains failure ............................................................................. 59

Figure 29 -Typical sequence in permanent mode on start request............................................................................... 60

Figure 30 - Power plant paralleling with mains........................................................................................................... 61

Figure 31 - GCR

GENSYS 2.0 wiring diagram.......................................................................................................... 62

Figure 32 - Power plant paralleling with several mains............................................................................................... 63

Figure 33 - Minimum wiring diagram......................................................................................................................... 64

Figure 34 - Complete wiring diagram ......................................................................................................................... 65

Figure 35 –Mounting kit ........................................................................................................................................... 66

Figure 36 - Mounting brackets on GENSYS 2.0............................................................................................................ 66

Figure 37 - Earth grounding....................................................................................................................................... 67

Figure 38 –Power supply circuit breaker.................................................................................................................... 67

Figure 39 - Interconnection of all battery negatives.................................................................................................... 68

Figure 40 - Speed output............................................................................................................................................ 72

Figure 41 –Connection with EFC Cummins................................................................................................................. 75

Figure 42 - PWM dynamic.......................................................................................................................................... 76

Figure 43 - Caterpillar PEEC and ADEM connections ................................................................................................... 76

Figure 44 - Speed and voltage control with Contacts / Pulses ..................................................................................... 77

Figure 45 - Speed and voltage control pulses.............................................................................................................. 79

Figure 46 - Voltage output......................................................................................................................................... 80

Figure 47 - Breakers wiring ........................................................................................................................................ 83

Figure 48- Undervoltage coil...................................................................................................................................... 85

Figure 49 - Connections for water preheat, pre lubrication and pre glow .................................................................... 87

Figure 50 - Connection for air fans ............................................................................................................................. 88

Figure 51 - Connections for filling............................................................................................................................... 89

Figure 52 - Fuel filling diagram .................................................................................................................................. 90

Figure 53 - Filling example......................................................................................................................................... 91

Figure 54 - Wiring parallel lines ................................................................................................................................. 91

Figure 55 - Change over with one digital input setup as "Mains electrical fault" ....................................................... 114

Figure 56 - Permanent Mains paralleling with one digital input setup as "Mains electrical fault" .............................. 115

Figure 57 - Permanent Mains paralleling and generator electrical fault.................................................................... 115

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

10

Figure 58 - Wiring GENSYS 2.0 and Auto Start Module ............................................................................................. 116

Figure 59 - External start sequence .......................................................................................................................... 117

Figure 60 - Wiring GENSYS 2.0 to BSM II................................................................................................................... 121

Figure 61 - Wiring GENSYS 2.0

TEM.................................................................................................................... 124

Figure 62 - Typical GPID controller ........................................................................................................................... 126

Figure 63 –Automatic load/unload.......................................................................................................................... 128

Figure 64- Automatic load/unload sequence ............................................................................................................ 128

Figure 65 - Unload according power ........................................................................................................................ 130

Figure 66 - Heavy Consumer Control with active power analysis............................................................................... 132

Figure 67 - Heavy Consumer Control with number of gensets analysis ...................................................................... 132

Figure 68 - Non essential consumer trip alarm (1) .................................................................................................... 134

Figure 69 - Non essential consumer trip alarm (2) .................................................................................................... 134

Figure 70- Non essential consumer trip output setting.............................................................................................. 135

Figure 71 - Non essential consumer trip timers......................................................................................................... 135

Figure 72 - Non essential consumer trip diagram ..................................................................................................... 135

Figure 73 - Phase offset example ............................................................................................................................. 136

Figure 74 - Voltage system ...................................................................................................................................... 137

Figure 75 - Network topologies................................................................................................................................ 155

Figure 76 - Example of CAN connection between 3 modules ..................................................................................... 156

Figure 77- Example CAN bus fault ............................................................................................................................ 158

Figure 78 -Broadcasting data between multiple units............................................................................................... 158

Figure 79 - Analogue and digital data broadcast example ........................................................................................ 161

Figure 80 - CAN bus inhibition schematic (example) ................................................................................................. 163

Figure 81 - Modular remote CANopen I/O extension module .................................................................................... 165

Figure 82 - CANopen coupler wiring ......................................................................................................................... 165

Figure 83 - MDEC: GENSYS2.0 connexion.................................................................................................................. 178

Figure 84 –MDEC Screens ....................................................................................................................................... 180

Figure 85 –Synchroscope ........................................................................................................................................ 202

Figure 86 –Modification by variable number ........................................................................................................... 224

Figure 87 - Modbus rights access screen.................................................................................................................. 230

Figure 88 –Compilation result screen ...................................................................................................................... 233

Figure 89 –Download logo screen ........................................................................................................................... 233

Figure 90 –Faults screen ......................................................................................................................................... 235

Figure 91 –Information screen ................................................................................................................................ 236

Figure 92 –Speed regulation details ........................................................................................................................ 237

Figure 93 –Voltage regulation details...................................................................................................................... 238

Figure 94 - Several generators warning.................................................................................................................... 239

Figure 95 - One generator with mains warning ........................................................................................................ 239

Figure 96 –Access to CRE Technology...................................................................................................................... 243

Figure 97 - CRE Technology distributors ................................................................................................................... 244

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

11

List of tables

Table 1 –Digital input functions ................................................................................................................................ 16

Table 2 - LCD screen characteristics ........................................................................................................................... 18

Table 3 –Display panel keys ...................................................................................................................................... 19

Table 4 –Service panel keys....................................................................................................................................... 20

Table 5 –Control panel keys ...................................................................................................................................... 21

Table 6 –Control panel led’s...................................................................................................................................... 22

Table 7 –Inputs/ outputs description.......................................................................................................................... 29

Table 8 –Authorization levels and passwords ............................................................................................................ 31

Table 9 –Typical basic change-over configuration...................................................................................................... 48

Table 10 - Typical no change over basic configuration ................................................................................................ 51

Table 11 - Typical basic multi Generator configuration............................................................................................... 52

Table 12 - Typical basic configuration for GENSYS 2.0 with parallel line modules ........................................................ 53

Table 13 - Paralleling with mains ............................................................................................................................... 55

Table 14 - Typical basic mains paralleling configuration ............................................................................................. 57

Table 15 - Paralleling with mains configuration.......................................................................................................... 61

Table 16 - GENSYS 2.0 / GCR configuration ................................................................................................................ 62

Table 17 - Power plant paralleling with several mains configuration........................................................................... 63

Table 18 - Speed governor parameters....................................................................................................................... 75

Table 19 - PWM parameters...................................................................................................................................... 76

Table 20 - Parameters speed and voltage control with Contacts / Pulses .................................................................... 77

Table 21 - AVR: Gain and offset ................................................................................................................................. 80

Table 22 - AVR parameters ........................................................................................................................................ 82

Table 23 - Used variables for breakers setting ............................................................................................................ 83

Table 24 - Breaker control configuration .................................................................................................................... 84

Table 25 –Filling parameters in automatic mode....................................................................................................... 89

Table 26 - Filling parameters in automatic mode with equations................................................................................ 90

Table 27 - Input parameters ...................................................................................................................................... 93

Table 28 - Input validity domain................................................................................................................................. 94

Table 29 - Input direction domain .............................................................................................................................. 94

Table 30 - Input functions .......................................................................................................................................... 97

Table 31 - Digital outputs function........................................................................................................................... 101

Table 32 - Oil pressure calibration points ................................................................................................................. 102

Table 33 - Water Temp calibration points ................................................................................................................ 103

Table 34 –Potential Alarm/Fault list........................................................................................................................ 110

Table 35 –Integral inhibition.................................................................................................................................... 113

Table 36 -Mains electrical fault................................................................................................................................ 113

Table 37 - Generator electrical fault......................................................................................................................... 115

Table 38 - Wiring GENSYS 2.0 and Auto Start Module............................................................................................... 116

Table 39 - Wiring GENSYS 2.0

TEM...................................................................................................................... 125

Table 40 - Parameters load/unload threshold .......................................................................................................... 129

Table 41 –Parameters used during load/unload according to power ........................................................................ 130

Table 42 - Settings heavy consumer ......................................................................................................................... 131

Table 43 - Settings non-essential consumer.............................................................................................................. 133

Table 44 - Voltage system........................................................................................................................................ 137

Table 45 - Front panel inhibition .............................................................................................................................. 139

Table 46 - Label definition bloc ................................................................................................................................ 142

Table 47 - Custom logo labels .................................................................................................................................. 143

Table 48 - Accuracy codes........................................................................................................................................ 144

Table 49 –Units codes............................................................................................................................................. 144

Table 50 - Variables with customizable unit/accuracy values.................................................................................... 146

Table 51 - Available instructions .............................................................................................................................. 149

Table 52 - DB9 pin out ............................................................................................................................................. 155

Table 53 - Maximal length / communication speed .................................................................................................. 156

Table 54 - Speed communication (COM1 & COM2)................................................................................................... 156

Table 55 - CAN bus fault .......................................................................................................................................... 157

Table 56 - Broadcast data sent on inter module CAN bus.......................................................................................... 159

Table 57 - Broadcast data received from inter module CAN bus................................................................................ 160

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

12

Table 58 - Analogue and digital data broadcast example ......................................................................................... 161

Table 59 - CAN bus inhibition variables .................................................................................................................... 162

Table 60 - Tie breaker example ................................................................................................................................ 163

Table 61 - CANopen input and output variables........................................................................................................ 166

Table 62 - CANopen configuration example.............................................................................................................. 167

Table 63 - J1939: Analog measure or J1939.............................................................................................................. 168

Table 64 - J1939: Manufacturer/ECU list.................................................................................................................. 169

Table 65 –J1939: Measurement list......................................................................................................................... 172

Table 66 - Unknown SPN/FMI .................................................................................................................................. 173

Table 67 - J1939: Alarms/faults list .......................................................................................................................... 174

Table 68 - J1939: trames RX custom......................................................................................................................... 175

Table 69 - J1939: Custom engine configuration ........................................................................................................ 176

Table 70 - MDEC connexion ..................................................................................................................................... 178

Table 71 - Important parameters............................................................................................................................. 179

Table 72- Modbus functions handled ....................................................................................................................... 184

Table 73: 32 bits variables (Use function 0x10)......................................................................................................... 185

Table 74 - Modbus configuration parameters........................................................................................................... 185

Table 75 - COM5 terminals ...................................................................................................................................... 185

Table 76 - Modbus parameters for Alerm/Fault management .................................................................................. 186

Table 77 - Modbus communication example ............................................................................................................ 187

Table 78 –SD card backup –File size ....................................................................................................................... 191

Table 79 –Active timers 1/2 .................................................................................................................................... 204

Table 80 - Active timers 2/2 ..................................................................................................................................... 204

Table 81 –Power plant configuration ...................................................................................................................... 206

Table 82 - Automatic load/unload Configuration...................................................................................................... 207

Table 83 - Load dep stop Configuration.................................................................................................................... 207

Table 84 –Generator ½Configuration ..................................................................................................................... 208

Table 85 - Generator 2/2 Configuration ................................................................................................................... 208

Table 86 - Generator electrical fault Configuration................................................................................................... 209

Table 87 - AVR control Configuration ....................................................................................................................... 209

Table 88 - Mains/Bus Configuration......................................................................................................................... 210

Table 89 –Mains electrical fault configuration......................................................................................................... 210

Table 90 –External/internal start sequence configuration........................................................................................ 211

Table 91 - Configuration reglages démarreur ........................................................................................................... 211

Table 92 –Checking before starting configuration ................................................................................................... 211

Table 93 –Speed control settings configuration ....................................................................................................... 212

Table 94 –Speed governor control configuration ..................................................................................................... 212

Table 95 - J1939/MDEC configuration...................................................................................................................... 213

Table 96 –J1939 protection configuration ............................................................................................................... 213

Table 97 –Generator protections configuration ....................................................................................................... 214

Table 98 –Mains protections configuration ............................................................................................................. 214

Table 99 –Engine/battery protections configurations .............................................................................................. 215

Table 100 –Digital outputs configuration ................................................................................................................ 216

Table 101 –Relay outputs configuration .................................................................................................................. 217

Table 102 –Breakers configuration.......................................................................................................................... 217

Table 103 –Engine timers configuration .................................................................................................................. 218

Table 104 –Mains timers configuration ................................................................................................................... 219

Table 105 –Synchro check relay configuration ......................................................................................................... 219

Table 106 –Phase synchro PID configuration ........................................................................................................... 220

Table 107 –kW sharing loop PID configuration ........................................................................................................ 221

Table 108 - Ramp/constant kW PID configuration .................................................................................................... 221

Table 109 - PID Hz loop configuration ...................................................................................................................... 222

Table 110 - PID kVAR sharing loop ........................................................................................................................... 222

Table 111 - PID cos(φ) loop configuration ................................................................................................................ 222

Table 112 –Reset of maintenance cycle................................................................................................................... 223

Table 113 - Date and time settings........................................................................................................................... 225

Table 114 –Meters reset ......................................................................................................................................... 225

Table 115 –Meters preset ....................................................................................................................................... 226

Table 116 –Screen saver mode................................................................................................................................ 227

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

13

Table 117 –Screen saver ......................................................................................................................................... 227

Table 118 –Language selection ............................................................................................................................... 228

Table 119 –Ethernet configuration.......................................................................................................................... 229

Table 120 –Modbus configuration........................................................................................................................... 229

Table 121 –SD card configuration ........................................................................................................................... 230

Table 122 - Cable reference ..................................................................................................................................... 242

Table 123 - CRE Technology product reference......................................................................................................... 242

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

14

1Overview

1.1

European Union directive compliance ce

The EMC Directive (89/336/EEC) deals with electromagnetic emissions and immunity. This product is tested

by applying the standards, in whole or in part, which are documented in technical construction file CEM

2004/108/EC, which replaces directive CEM (89/336/EEC) relative to electromagnetic emissions as from

July 20th 2009.

This product is developed to respect harmonized norms:

EN 55099:2009

EN 55099:2010

EN 55088:2008

2006/95/EC (replaced directive 73/23/EEC since January 16th 2007).

SAE J1939/71, /73, /31

Other standards:

EN 61326-1: 2006 (Industrial location)

EN 55011

EN 61000-3-2

EN 61000-3-3

Note: This is a class A product. In a domestic environment this product may cause radio interference. The

user is responsible for taking the necessary precautions.

1.2

Environment

Temperature

Operating: 0…+55°C

Storage: -30…+70°C

Humidity: 5 to 95%

Altitude 2000m maximum (according to EN 61010-1 standard)

Tropic proof circuits for normal operation in humid conditions.

Front panel: IP65 protection.

Back panel: IP20 protection.

A53 Z0 9 0020 L En Technical documentation

Chapter : Overview

15

1.3

Characteristics

Size: 248x197x57mm (9.76x7.76x2.24in)

Weight: 1.9kg (4.2oz)

Panel cut-out:

Figure 1 –Panel cut-out

Note: Cut-out must be cleaned and de-burred before mounting.

228 mm

/8.98 in

177 mm

/6.97 in

A53 Z0 9 0020 L En Technical documentation

Chapter : GENSYS 2.0 CORE

16

2GENSYS 2.0 CORE

2.1

Description

The GENSYS 2.0 CORE can control a single or a multiple generating sets power plant. You can combine this

module with one RDM 2.0 remote display.

GENSYS 2.0 CORE can be connected to the RDM 2.0

GENSYS 2.0 CORE is a Generator management module

Several power plants possibilities

Same motherboard as the GENSYS 2.0 product family

GENSYS 2.0 CORE is able to perform all GENSYS 2.0 features.

GENSYS 2.0 CORE can be controlled using different ways:

Connected to a RDM 2.0 remote display module.

Remotely using your favorite Internet Web browser and by using digital inputs programmed

to be used as AUTO/ MAN, START/STOP, OPEN/CLOSE GENERATOR BREAKER, OPEN/CLOSE

MAINS BREAKER buttons.

2.2

User interface with a RDM 2.0

The RDM 2.0 is a remote display module that is connected through Ethernet to the GENSYS 2.0 CORE. This

way GENSYS 2.0 CORE can be easily controlled and set up in the same way as a GENSYS 2.0 module.

Please refer to the RDM 2.0 technical documentation “A53 Y0 9 0020 x En- Technical documentation” to

connect your GENSYS 2.0 CORE to a RDM 2.0.

2.3

User interface using digital inputs

According to your application, some digital inputs can be used to simulate the control panel buttons of a

GENSYS 2.0. You have to select the following input functions to simulate the button.

Value

Function

Description

2227

Manual start request

To be selected if a remote start command is to be installed.

2228

Manual stop request

To be selected if a remote stop command is to be installed.

Note: this is not an emergency stop.

2336

Gen. breaker Close

manual

To be selected if manual remote close button for genset

breaker is programmed.

2337

Gen. breaker Open

manual

To be selected if manual remote open button for genset

breaker is programmed.

2338

Mains breaker Close

manual

To be selected if manual remote close button for Mains

breaker is programmed.

2339

Mains breaker Open

manual

To be selected if manual remote open button for Mains

breaker is programmed.

2260

Auto mode forced

GENSYS 2.0 CORE will never switch to manual mode.

2261

Manual mode forced

Will switch GENSYS 2.0 CORE into manual mode.

Table 1 –Digital input functions

A53 Z0 9 0020 L En Technical documentation

Chapter : GENSYS 2.0 LT

17

3GENSYS 2.0 LT

The GENSYS 2.0 LT is a GENSYS 2.0 that doesn’t feature the following functionalities:

Support of custom PLC equations.

Support of remote CANopen inputs/outputs extension modules.

This logo appears in various chapters of this document. It indicates that the described

function is not available on GENSYS 2 .0 LT.

A53 Z0 9 0020 L En Technical documentation

Chapter : Description

18

4Description

4.1

Front panel

Figure 2 –GENSYS 2.0 front panel

The display panel allows setting up and monitoring of the GENSYS 2.0 configuration and the power plant it

controls. It provides a large LCD display and a keypad. See chapter below, for more details about the

functions of LEDs & Keys.

LCD characteristics

Value

Unit

Viewing area

240x128

dots

114x64 (4.49x2.52)

mm (in)

30x16

Characters

Character size (small font)

2.7x3.6 (0.1x0.14)

mm (in)

(standard font)

3.6x3.6 (0.14x0.14)

mm (in)

(large font)

9.45x9.45 (0.37x0.37)

Back light

60

cd/m²

LCD mode

STN

Table 2 - LCD screen characteristics

A53 Z0 9 0020 L En Technical documentation

Chapter : Description

19

4.1.1

Display panel

The five dedicated keys of the display panel allow direct access to special menus or functions. See chapter

“User interface” for more details concerning the functions of front panel LED and keys.

Table 3 –Display panel keys

Key

Navigation mode

Input mode

(during parameter modification)

Navigation

bar

Scroll / select menus and parameters.

Change parameter value.

Enter

Enter a menu / switch to Input mode

Validate parameter and return to

‘Navigation mode’

Shift

Used with other keys only ([+], [-], I).

Not used.

+

Shortcut to special function.

Increase speed in manual mode.

Increase voltage when associated

with Shift key in manual mode.

Not used.

-

Shortcut to special function.

Decrease speed in manual mode.

Decrease voltage when associated

with Shift key in manual mode.

Not used.

Esc

Return to parent menu.

Discard parameter changes and

return to ‘Navigation mode’

A53 Z0 9 0020 L En Technical documentation

Chapter : Description

20

4.1.2

Service panel

Key

Function

Buzzer

This key will stop the alarm horn.

Fault

Direct access to the Fault menu.

An associated red LED indicates the Fault status of the generator.

Pressing this key will switch to the associated menu, showing active faults.

Pressing a second time on the same key will switch back to the menu displayed

beforehand.

Fault archive can be deleted in the System/ Date Time meter/. Data logging --reset

menu

Alarm

Direct access to the Alarm menu.

An associated orange LED indicates the Alarm status of the generator.

Pressing this key will switch to the associated menu, showing active alarms.

Pressing a second time on the same key will switch back to the menu displayed

beforehand.

Alarm archive can be deleted in the System/ Date Time meter/. Data logging --reset

menu

Info

1. Direct access to global monitoring page (user configurable).

2. Save parameters in flash storage when pressed with SHIFT: this action is called

“SHIFT-I”

Pressing this key will switch to the associated menu, which is custom made and

contains parameters the user wants to monitor easily.

Pressing a second time on the same key will switch back to the menu displayed

beforehand.

Bulb

LED test: pressing this key will turn on all GENSYS 2.0 LEDs. It is a simple test to

check the LEDs and the keypad.

Table 4 –Service panel keys

Other manuals for GENSYS 2.0

1

This manual suits for next models

2

Table of contents

Other CRE Technology Control Unit manuals

Popular Control Unit manuals by other brands

Parker

Parker 20K Installation and operation manual

Emerson

Emerson Copeland 3290262 technical information

BFT

BFT PERSEO CBE quick start guide

Simplex

Simplex 2004 Series installation guide

Holzworth Instrumentation

Holzworth Instrumentation HSM Series Quick start operation guide

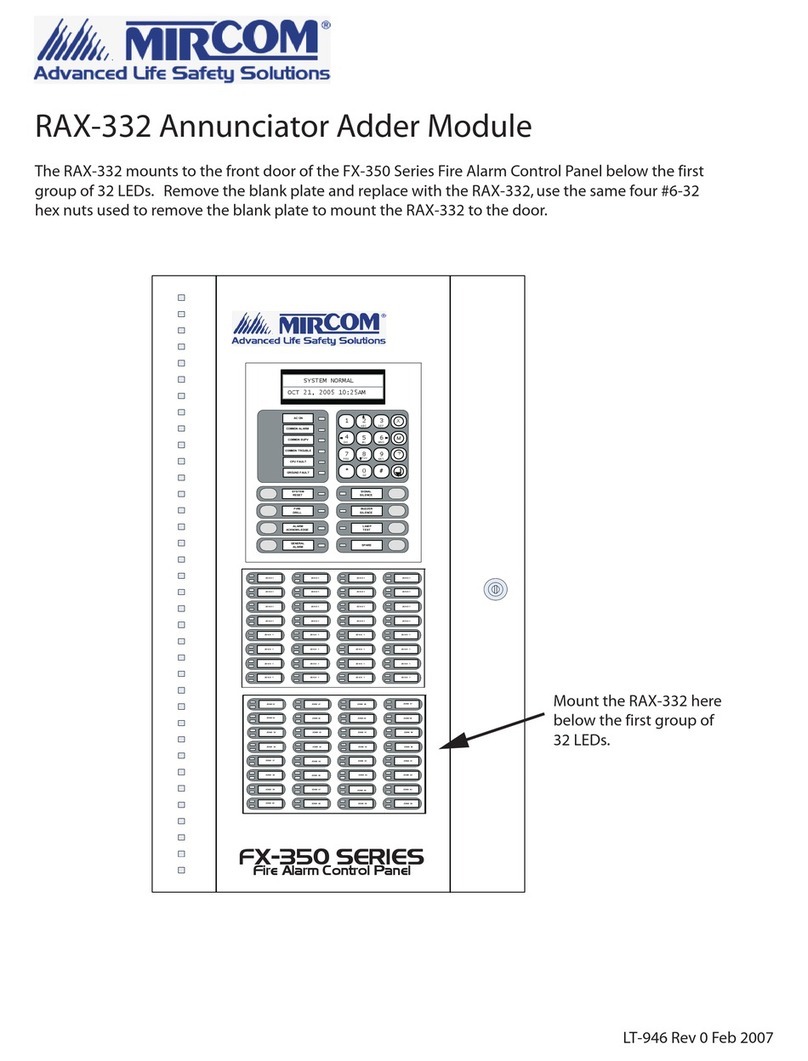

Mircom

Mircom RAX-332 quick start guide

Honeywell

Honeywell JADE W7220 installation instructions

Yoshitake

Yoshitake DP-200 Series manual

Roth

Roth CM Manifold installation instructions

Belden

Belden Grass Valley HCO-1822 Guide to installation and operation

Girard Systems

Girard Systems 98GC1102 Installation & programming guide

ALZA

ALZA MS-105B user manual