CRE Technology UNIGEN 2.0 synchro User manual

UNIGEN 2.0 synchro

Slave Synchro Unit

USER MANUAL –TECHNICAL DOCUMENTATION

Part Number: A51V0 9 0020 A EN

Last Update: January 2017

User manual –technical documentation A51 V0 9 0020 A EN

2

Technical documentation history

Date

Version

Comment

January, 2017

A

Initial edition

A51 V0 9 0020 A EN User manual –technical documentation

3

Preamble

SETTINGS

The tables whose header have an orange-coloured background describe settings.

Settings (and readings) that show only in CRE Config, but not on the LCD, feature a purple border in

the HMI chapter as follows:

Setting

Label

Description

xxxx

xxx

Can be set in any HMI

xxxx

xxx

Can be set only in CRE Config

The setting content is referred to as [xxxx].

In the illustrations:

Digital inputs and outputs –whether direct or through CANopen –whose assignment is

preset in the CRE Config software application show as follows; the shown position has

no meaning.

Internal toggles preset through software show as switches with two throws. The code

xxxx or the name of the setting shows above:

SYMBOLOGY

Denotes a threshold monitoring

Denotes a control loop tuning (three

coefficients G, P, I)

Denotes the need to adjust the

amplitude and offset (center)

CRE Technology believes that all information provided herein is correct and reliable and reserves the

right to update at any time. CRE Technology does not assume any responsibility for its use.

You can download the most up-to-date version of this documentation and different other

documentations relating to UNIGEN 2.0 on our web site http://www.cretechnology.com.

Digital

input

Digital

output

xxxx

assignment assignment

User manual –technical documentation A51 V0 9 0020 A EN

4

Content

1Presentation......................................................................................................................... 7

1.1 Generator automatic control ...................................................................................................... 7

1.2 Breakers control .......................................................................................................................... 7

1.3 Human machine interface........................................................................................................... 8

1.4 Setting and supervision utility..................................................................................................... 9

2Installation ......................................................................................................................... 10

2.1 On-desk-ethernet setup ............................................................................................................ 10

2.1.1 Setting the PC connection ............................................................................................. 10

2.1.2 Changing the UNIGEN 2.0 IP address............................................................................ 11

2.1.3 Hostname ...................................................................................................................... 11

2.1.4 Copyright ....................................................................................................................... 11

2.2 In-panel installation................................................................................................................... 12

2.2.1 Unpacking...................................................................................................................... 12

2.2.2 Installation..................................................................................................................... 12

2.2.3 Wiring the unit............................................................................................................... 13

2.2.4 Connection diagrams..................................................................................................... 18

3Applications........................................................................................................................ 20

3.1 Synchronization......................................................................................................................... 21

3.1.1 Configuration................................................................................................................. 21

3.1.2 Tuning............................................................................................................................ 22

3.1.3 Manual synchronization................................................................................................ 22

4Operation ........................................................................................................................... 23

4.1 Protections ................................................................................................................................ 23

4.1.1 General .......................................................................................................................... 23

4.1.2 Audio or visual annunciator .......................................................................................... 23

4.2 Potential Alarms/Faults catalog ................................................................................................ 24

4.2.1 Generator electrical fault .............................................................................................. 24

4.2.2 Engine and battery ........................................................................................................ 24

4.2.3 Analog inputs................................................................................................................. 24

4.2.4 Communication ............................................................................................................. 24

4.2.5 Reset.............................................................................................................................. 24

4.3 Breaker management................................................................................................................ 25

5Commissioning ................................................................................................................... 26

5.1 Introduction............................................................................................................................... 26

5.2 Analog speed governor output ................................................................................................. 27

5.3 Analog AVR (Auto Voltage Regulator) control .......................................................................... 29

5.4 Speed/voltage controlled by contacts/pulses........................................................................... 31

5.4.1 Setup.............................................................................................................................. 31

5.4.2 Speed calibration procedure ......................................................................................... 32

A51 V0 9 0020 A EN User manual –technical documentation

5

5.4.3 Voltage calibration procedure....................................................................................... 32

5.5 Tests .......................................................................................................................................... 32

5.5.1 Individual check............................................................................................................. 32

6Human-machine interface................................................................................................... 34

6.1 Security and operations through the front panel ..................................................................... 34

6.1.1 Security level and password.......................................................................................... 34

6.1.2 HMI status ..................................................................................................................... 35

6.1.3 Navigation in LCD .......................................................................................................... 35

6.1.4 Edition............................................................................................................................ 36

6.2 Supervision................................................................................................................................ 36

6.3 Web server ................................................................................................................................ 37

6.4 Display menu............................................................................................................................. 38

6.5 CONFIGURATION menu............................................................................................................. 41

6.6 SYSTEM menu............................................................................................................................ 45

6.7 DEDICATED PAGES..................................................................................................................... 48

6.7.1 Faults and alarms........................................................................................................... 48

6.7.2 Information.................................................................................................................... 48

7Communication buses......................................................................................................... 49

7.1 Modbus TCP .............................................................................................................................. 49

7.1.1 Capabilities .................................................................................................................... 49

7.1.2 Configuration................................................................................................................. 49

7.1.3 Description .................................................................................................................... 49

7.2 CANopen extension modules .................................................................................................... 52

7.2.1 Hardware....................................................................................................................... 52

7.2.2 Configuration................................................................................................................. 53

7.2.3 Mapping......................................................................................................................... 53

7.3 J1939 Communication............................................................................................................... 54

7.3.1 Overview........................................................................................................................ 54

7.3.2 Search engines list......................................................................................................... 54

8Resources for setup & maintenance .................................................................................... 56

8.1 File transfer ............................................................................................................................... 56

8.1.1 UNIGEN 2.0 -> PC file transfer....................................................................................... 56

8.1.2 PC -> UNIGEN 2.0 file transfer....................................................................................... 57

8.1.3 Firmware upgrade ......................................................................................................... 57

8.2 Text file descriptioN .................................................................................................................. 57

8.2.1 Variable naming............................................................................................................. 57

8.2.2 Text file description....................................................................................................... 58

8.3 I/O lines ..................................................................................................................................... 60

8.3.1 Digital inputs.................................................................................................................. 60

8.3.2 Digital and relay outputs ............................................................................................... 62

User manual –technical documentation A51 V0 9 0020 A EN

6

8.3.3 Analog inputs................................................................................................................. 65

9Maintenance ...................................................................................................................... 67

9.1 Upgrading the software............................................................................................................. 67

9.2 Adding a custom HMI language ................................................................................................ 67

9.3 Troubleshooting ........................................................................................................................ 67

10 APPENDIX........................................................................................................................... 71

10.1 MTU J1939 communication....................................................................................................... 71

10.2 CAN bus good practices............................................................................................................. 73

10.3 Control Loop Tuning.................................................................................................................. 75

10.4 Potentiels Alarms-faults Table .................................................................................................. 76

A51 V0 9 0020 A EN User manual –technical documentation

7

1PRESENTATION

UNIGEN 2.0 SYNCHRO is a panel mounting electronic unit meant for the control of a single, two or three-

phase low-voltage generator. It is designed to work as a slave of a PLC unit. UNIGEN 2.0 SYNCHRO can

be used to synchronize one generator with an other power source.

UNIGEN 2.0 capabilities include:

PMS

ILS

SYNCHRO

Acquisition of the engine speed and the generator AC voltages

x

x

x

Acquisition of the generator AC currents

x

x

Generator electrical protections

x

x

x

PID control in load sharing mode

x

x

Control of actuators ; it is compatible with most speed governors (ESG)

and AVR regulators

x

x

x

Synchronization before coupling

x

x

Analog inputs for reading resistive sensors

x

x

x

Extension by CANopen units (Wago, Beckhoff, VIPA, etc) : up to 32 extra

digital inputs and 32 extra digital outputs

x

x

x

Link to a PLC or a SCADA via Modbus TCP

x

x

x

The engine-generator may have an Electronic Control Unit with CAN J1939 interface. J1939 and

CANopen interfaces can coexist –on a second CAN media –provided they use the same bit-rate.

The engine speed is derived from the AC frequency.

1.1 GENERATOR AUTOMATIC CONTROL

Two separate cascade control systems are used:

Primary control (UNIGEN)

Secondary control

Speed

ESG control

ECU or ESG

Voltage

AVR control

AVR

The generated voltages and currents are measured in true RMS and used to calculate the load demand

across the aggregate. The synchronization requests drive the primary control which, according to its

configuration:

Produces an analog signal Speed out+, sends pulses “+/- f” to digital outputs or writes to J1939

bus.

Produces an analog signal AVR out+ or sends pulses “+/- U” to digital outputs.

1.2 BREAKERS CONTROL

Compared to UNIGEN 2.0 PMS, UNIGEN 2.0 SYNCHRO does not allow to control the breaker. A digital

output called « Synch check relay » is activated when the breaker can be closed (Synchronization or

dead bus bar)

User manual –technical documentation A51 V0 9 0020 A EN

8

1.3 HUMAN MACHINE INTERFACE

LCD screen characteristics:

Size: 40 x 70mm - 1.50 x 2.75in

Pixels: 64 x 128

Back light: 50 cd/m2 typical, configurable

Contrast: configurable

Type: STN

Back-lit auto-off LCD

The led blinks after a fault arises.

Acknowledged by pressing the lower button

The led blinks after an alarm arises.

Acknowledged by pressing the lower button

Press to access:

.the Fault page if new fault occurred (Fault

blinks)

.the Alarm page if new alarm occurred (Al.

blinks)

.pages with 2 statuses (Power and Engine) and

10 readings of special interest.

Press again to return.

Led Gen. ready

Navigation/Edition

(see below)

Bus status led

(lit when live)

GeneratorBreaker status led

(lit when closed)

Keyboard:

Keys

Navigation mode

Edition mode

Cyclic navigation through menu & settings list

Used to change the value of a setting. Hold down to change

faster

Cyclic navigation through pages when an item

is selected in a menu and validated

–

Shift

Used with to in/decrease LCD luminosity

Used with to adjust LCD contrast

When in manual mode and breaker is open, used with to

increase/decrease:

speed command on Speed control page

voltage command on Voltage control page

Used with to reset alarms and faults

Esc

Return to parent menu (3 times to home) or

preceding menu

Setting change rejection and return to the Navigation mode

Enter

Page opening / switch to Edition mode

Validation of the new setting and return to Navigation mode

A51 V0 9 0020 A EN User manual –technical documentation

9

1.4 SETTING AND SUPERVISION UTILITY

A Windows™ PC with the software application CRE Config 2.70 or later must be connected on the

rear Ethernet socket, generally via a switch in a star network:

This allows you to preset all the UNIGEN 2.0 units when they are on desk: a text file that reflects the

first UNIGEN 2.0 unit’s configuration can serve as a template to deploy the setup to the other

UNIGEN 2.0 units in the cluster. The CRE Config multi-tabbed interface makes it easy.

Once all UNIGEN 2.0 units are mounted, CRE Config can be used to set them up and monitor the

generators. The CRE Config features a Scada section that can be used in particular as an event console to

UNIGEN 2.0:

UNIGEN 2.0

CRE Config/Scada

Event

console

Time

Label

Variable

State

0h00

Breaker fault

xxxx

1

Information

display

Information

Power

Engine

Prod request 1

Mode AUTO

Label

Variable

Value

Prod request

xxxx

1

Mode

xxxx

AUTO

Event

logger

2,000

2

1

User manual –technical documentation A51 V0 9 0020 A EN

10

2INSTALLATION

2.1 ON-DESK-ETHERNET SETUP

2.1.1 Setting the PC connection

Connect UNIGEN 2.0 to a PC with a 100Ethernet

cord

Direct connection to PC: use a crossover cord.

Connection through a switch: use a direct cord; a

crossover cord such as 3-m long A53W1 is OK if the

switch manages it.

Power up UNIGEN 2.0 using a stabilized power

supply

Power supply range: 8…35VDC

Open Windows control panel

Click:

Local network (Windows XP)

Network and Sharing Center / View status

(Windows Vista)

Open Network and Sharing Center/Change

adapter settings/(Connection to) LAN/

Properties (Windows 7 & 8)

Click Parameters (Windows XP) or Properties

(Windows Vista or 7 or 8)

A51 V0 9 0020 A EN User manual –technical documentation

11

Select TCP/IP or TCP/IP v4, and click Properties

Enter a PC address that differs from the one of the

UNIGEN 2.0 only by the last number, & click OK

Last number: 0 … 255; avoid 0 and 255 as they are

often taken for other purposes

2.1.2 Changing the UNIGEN 2.0 IP address

To change UNIGEN 2.0 IP address, in CRE Config (or on LCD), navigate to “System/Network

configuration (resp. About)”.

UNIGEN 2.0 supports the DHCP function: in this case, UNIGEN 2.0 must be connected on a network

with a DHCP server. During the power-on sequence, UNIGEN 2.0 is assigned an IP address by the

DHCP server. If DHCP process fails, the fixed IP address is used (factory setting: 192.168.11.1).

Note: Contact your network administrator to configure your router and module(s) to your needs.

2.1.3 Hostname

You can assign an alias to UNIGEN 2.0, in addition to the IP address; enter it in CRE Config to get

connected.

To change this alias, in CRE Config navigate to System/Network configuration.

Maximum length: 16 characters. With Windows, the last character defines the type of service (0 is

the usual value).

Allowed characters: reduced ANSI set; "-" and "." are allowed except at the start and end.

2.1.4 Copyright

UNIGEN 2.0 Ethernet communication uses the open source lwIP TCP-IP stack. Read

copyright/disclaimer below. More details on lwIP Web site:

http://savannah.nongnu.org/projects/lwip/

Copyright © 2001-2004 Swedish Institute of Computer Science. All rights reserved.

Redistribution and use in source and binary forms, with or without modification, are permitted provided that

the following conditions are met:

1. Redistributions of source code must retain the above copyright notice, this list of conditions and the following

disclaimer.

2. Redistributions in binary form must reproduce the above copyright notice, this list of conditions and the

following disclaimer in the documentation and/or other materials provided with the distribution.

3. The name of the author may not be used to endorse or promote products derived from this software without

specific prior written permission.

THIS SOFTWARE IS PROVIDED BY THE AUTHOR ``AS IS'' AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE AUTHOR BE LIABLE FOR ANY DIRECT, INDIRECT,

INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO,

PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS

INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT

LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS

SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

User manual –technical documentation A51 V0 9 0020 A EN

12

2.2 IN-PANEL INSTALLATION

The unit is designed for panel mounting, which provides user with access only to the front panel.

WARNING

THE UNIT IS NOT GROUNDED

Take all measures against Electronic Static Discharges.

Do not try to open the unit.

Failure to follow these instructions may damage the unit

Environmental requirements:

Operating temperature: -30°C (-22°F) … 70°C (158°F); LCD display slows down a bit under -5°C

(23°F). Avoid direct exposure to the sun

Storage temperature: -40°C (-40°F) … 80°C (176°F)

Altitude: up to 2,000 m (6,561 ft); on higher altitudes, recommended max. AC voltage : 100VAC

2.2.1 Unpacking

Make sure the packaging contains:

the unit

four caps + screws packaged apart

a delivery bill

Unpack and keep the packaging in event of return.

Make sure the unit does not show scratches or visible defaults. Otherwise describe them on the RMA

sheet (downloadable from CRE technology Web site).

2.2.2 Installation

Preparation

1. Cut out the panel to 220x160 mm minimum (8.7 in x 6.3 in)

2. Make sure the cut-out is smooth and clean

Mounting

0

Tool: cross-head screwdriver size 1

1

Pass the unit through the panel

2

In the rear, cover each of the four spacers

with a cap

3

Screw a cap against the panel

4

Repeat on the diagonally opposite spacer

5

Repeat on the other diagonal and tighten

equally (do not overtighten)

A51 V0 9 0020 A EN User manual –technical documentation

13

2.2.3 Wiring the unit

Tool: insulated screwdriver Ø2.5 mm (0.1 in), tightening torque: 0.8 Nm (7 lb-in) max.

Accessories: 4, 5, 6, 8, 15 & 18-terminal cable connectors, protective gloves, carpet if the floor is wet.

WARNING

THE UNIT IS NOT PROTECTED

Use external fuses:

Bus bar and Generator phases: 100mA/600VAC

Battery positive: 5A/40VDC

Install the fuses as near as possible the unit, in a place easily accessible to the user.

The disconnection device must NOT be fitted in a flexible cord.

Failure to follow these instructions may damage the unit

General procedure

1. Make sure the cable connectors are NOT plugged

2. Take on protective gloves

3. Connect the wires on each cable connector in accordance with the National Wiring Regulations

4. Plug each cable connector onto the related connector

1. 5. Plug a direct Ethernet cord (RJ45, male-male, 100 m max., 100; a crossover cable

such as 3-m long A53W1 is OK if the switch manages it or if the link to PC is direct) and lock

the rear door.

Recommandations

Wires section: 2.5 mm² (AWG13).

To avoid ElectroMagnetic Interferences, shield cables appropriately; for CAN bus, see the Appendix

CAN bus Good practices.

Segregation: keep power cables separate from the CAN bus cables. The latter can be installed in the

same duct as the low level DC I/O wires (under 10V).

If power & communication cables have to cross each other, do it at right angles to avoid crosstalk:

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

The unit must only be installed and serviced by qualified electrical personnel

Apply appropriate personal protective equipment (PPE) & follow safe electrical work practices

Turn off power before installing or removing fuses, and before installing the unit

Use a properly rated voltage sensing device to confirm the power is off

Do not use renewable link fuses in fused switch

Failure to follow these instructions will result in death or serious injury

l

l

!

User manual –technical documentation A51 V0 9 0020 A EN

14

Overview

Relay

outputs

Mains & Gen AC voltages

Analog

inputs

8-35VDC / Digital outputs / Digital inputs

CAN2 Speed / AVR CAN1

output

A51 V0 9 0020 A EN User manual –technical documentation

15

Upper blocks

Block and mark

Description

Note

Breaker commands

Normally open. Breaking capacity: 5A, 240VAC

Relay 1

Relay 1 +

Relay 1 -

Relay 2

Relay 2 +

Relay 2 -

AC voltages

100-480VAC,measure range: 35 …75HZ,100mA max; accuracy: 1%

fsd

N

Bus/Mains N

Option

L3

Bus/Mains L3

These lines must be protected externally with 100mA/600VAC

fuses. Use two PTs of 2VA (Phase-to-phase)

L2

Bus/MainsL2

L1

Bus/Mains L1

N

Generator N

Option

L3

Generator L3

These lines must be protected externally with 100mA/600VAC

fuses. 1VA (Phase-to-neutral)

L2

Generator L2

L1

Generator L1

Analog inputs

0-500

Common

Connect it to Battery –

Input 3

Free input

Input 2

Free input

Input 1

Free input

Shield

GND

Ground plane

DANGER

EXPOSED TERMINALS

Do not touch terminals L1, L2, L3 nor use non-insulated tools near them. These terminals are

unprotected and will expose the user to dangerous voltages

Failure to follow this instruction will result in death, serious injury or equipment damage

l

l

!

User manual –technical documentation A51 V0 9 0020 A EN

16

Lower blocks

WARNING

RISK OF EQUIPMENT DAMAGE

As a protection against polarity reversal, install a 6A fuse between Battery positive lug & terminal 8-35VDC +.

Connect battery negative to GENSYS terminal 8-35VDC–with 2.5 mm² (AWG13) cable.

Failure to follow this instruction can damage the controller

Block and Mark

Description

Note

8-35VDC

NOT protected against polarity reversal

-

Power supply -

2.5mm² (AWG13)

+

Power supply +

8…35VDC,consumed current: 130 mA at 24V (standby & operation)

Shield

GND

Generator chassis

Digital outputs

Free solid state output. State 1 at the supply voltage (max: 1.8A).

Protected against short circuits. A reactive load is supported. Not

isolated from power.

1

Synch check relay

2

Other free

outputs

3

4

5

6

Digital inputs

Free digital input with 10kΩ pull-up.

Accepts NO or NC contact to 0V.

Not isolated from power.

1

GE breaker

feedback

2

UNIGEN Activation

3

Other free inputs

4

5

6

7

8

9

CAN2: J1939-Extensions

Isolated CAN bus J1939/CANopen. Twisted pair. See CAN appendix

CAN L

Blue wire

CAN H

White wire

Resistor –

Strap to CAN H when inner resistor must be inserted (bus ends)

Shield

0V

Connect the cable shield herein

Speed

Compatible with most speed governors. Isolated from power

Out

Speed output

±10V analog output to speed governor

A51 V0 9 0020 A EN User manual –technical documentation

17

Block and Mark

Description

Note

common

Speed reference

Twisted pair; length < 5m (16ft) if unshielded, < 50m max if shielded

AVR

Compatible with most regulators. Isolated from power

Out

AVR output +

Analog output ±10V

common

AVR output –

Twisted pair; length < 5m (16ft) if unshielded, < 50m max if shielded

CAN1: Inter UNIGEN

Isolated CAN© bus, use twisted pair. Refer to the CAN appendix

CAN L

White wire with a blue strip (when using a CRE cable)

CAN H

Blue wire with a white strip (when using a CRE cable)

Resistor –

Strap to CAN H when inner resistor must be inserted (bus ends)

Shield

0V

Connect the cable shield herein

WARNING

RISK OF EQUIPMENT DAMAGE

Switch off the unit before plugging or unplugging the CAN bus connector or disconnecting wires

Failure to follow this instruction can damage the CAN transmitter/receiver

Note: Crank dropout: the unit survives for 70 ms at 24V, and 20ms at 12V.

User manual –technical documentation A51 V0 9 0020 A EN

18

Other systems of voltage

If Biphase 180° is selected in CRE Config, connect voltages and currents to terminals L1-L3 (and N),

resp. I1-I3 (and common).

If Monophase is selected, connect voltages and currents to the terminals L1-N, resp. I1 and common.

2.2.4 Connection diagrams

These diagrams show that the Potential Transformers can be connected in various ways:

Star (wye) on generator side (1 insulated high-voltage terminal per PT) ; the ratio is for example

Vee on bus side (2 insulated high-voltage terminals per PT) ; the ratio is for example

A51 V0 9 0020 A EN User manual –technical documentation

19

User manual –technical documentation A51 V0 9 0020 A EN

20

3APPLICATIONS

Starting from the default settings, just enter the installation specification:

Setting

Label

Value

2000

Count of gen.

1 ≤ N ≤ 32

2001

GE Number

1 to 32 (differs for each UNIGEN 2.0 on the CAN bus)

Only in island operation

Setting

Label

Value

2002

Dead Bus manag.

No[0], Yes [1]

Digital inputs

Relays

Mandatory

Generator breaker feedback

UNIGEN Activation

Mandatory

Synch check relay

After the engines have started, the UNIGEN 2.0 with an active « UNIGEN activation » signal :

-Set the digital output « Synch check relay » if the bus bar is unpowered (with an election in

island operation)

-Synchronize the generator if the bus bar is powered. The digital output « Synch check relay »

is set once the breaker can be closed.

Notes:

After the closure of the breaker, speed output and voltage output are equal to 0 percent..

In island operation, each generator is controlled by a UNIGEN 2.0 SYNCHRO. Communication by CAN

Bus allows to close the breaker on a dead bus bar by avoiding simultaneous closures.

If the generators are not yet started, when they lose the CAN bus, a downgraded mode is enforced;

the generator couplings are phased in: the generator #n cannot close its breaker before

[2306]/10 + 7 x n (seconds)

Table of contents

Other CRE Technology Control Unit manuals

Popular Control Unit manuals by other brands

TUYA

TUYA WB2L datasheet

ICP DAS USA

ICP DAS USA ET-6000 Series user manual

SMART-SCAN

SMART-SCAN MAGSAFE 785-093 Installation Sheet Guide

evaton technologies

evaton technologies Link user manual

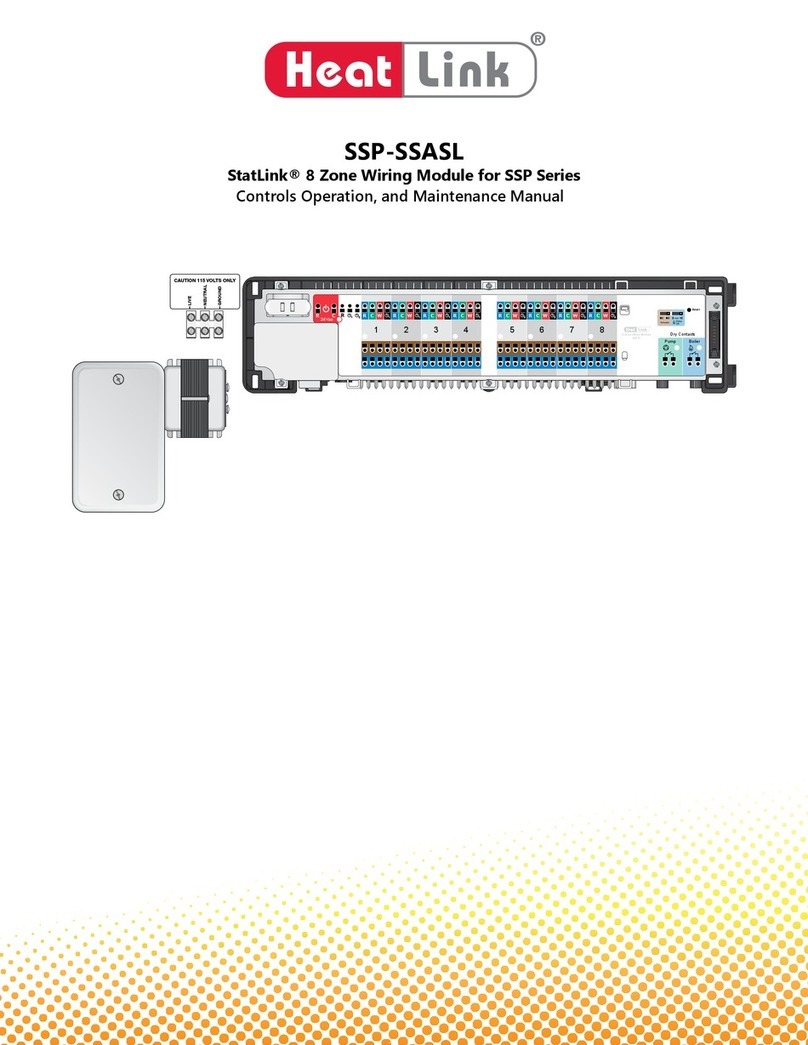

HeatLink

HeatLink StatLink SSP Series Operation and maintenance manual

Siemens

Siemens SINUMERIK Series Function manual