Roth CM Manifold System

Installation Instructions

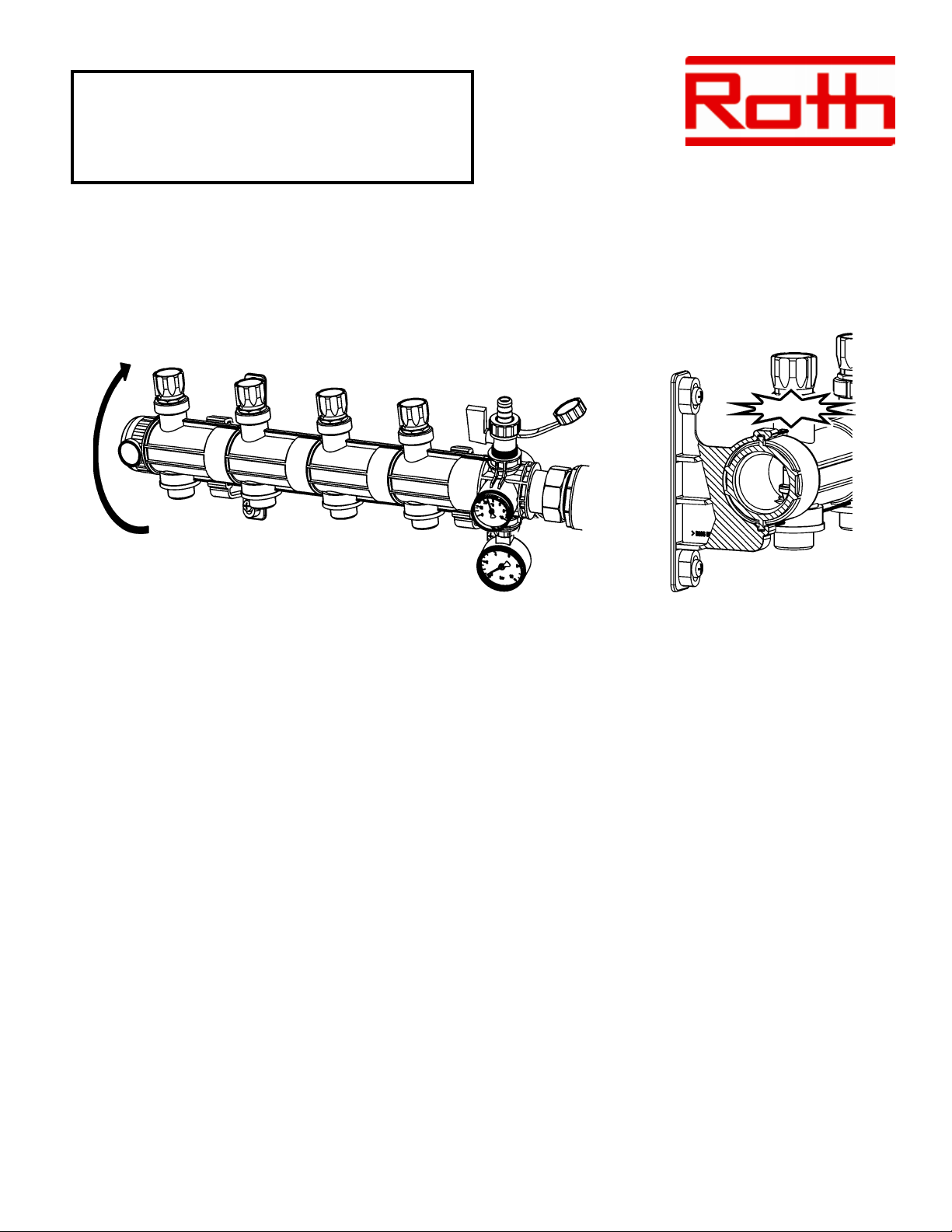

Pipe Connections

Supply and return connections

The pipe connections on the attached ball valves are 1 1/2” FPT. Use of a thread

sealant compatible with water service is recommended.

Loop Connections

Loop connections are standard threaded R-30 Euroconical compression tting

assemblies.

Care should be taken to ensure that the tubing ends are cut square, and that there is no debris

in the end of the tubing that may affect the integrity of the tting.

Loop tubing approach to the manifold should be carefully managed to allow for minimum bend

radius requirements and bend supports should be used if there are concerns for tubing kinking

during manifold and oor installation and nishing.

Caution: Alu-Laser Plus tubing must be reamed with Roth Alu-Laser Plus reaming tool. This

puts a bevel on the inside of the pipe and allows the tting to be inserted into the pipe without

disturbing the o-rings on the tting. Failure to do so will cause leaks.

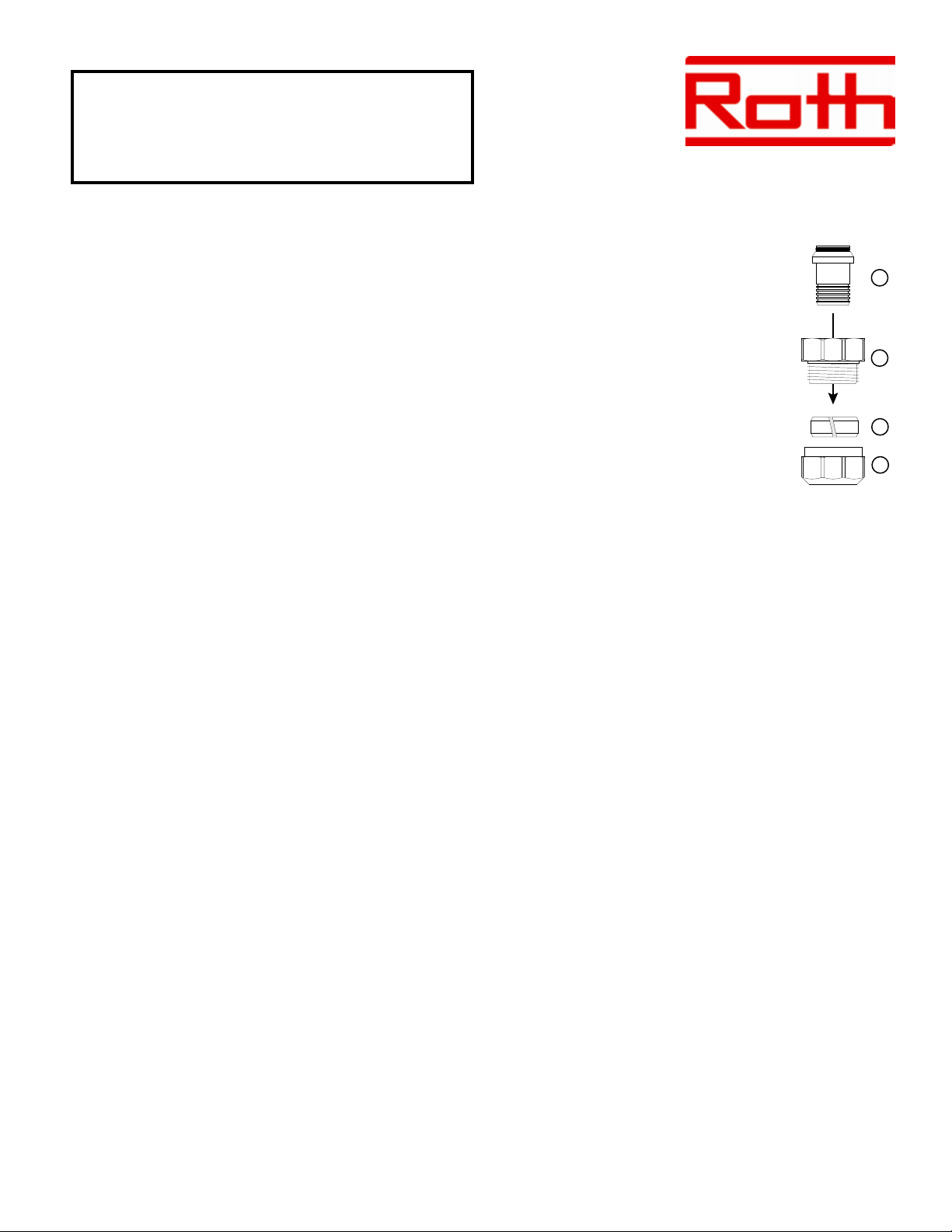

Attaching Tubing to Manifold

• Place compression nut onto tubing with thread opening facing tubing end

• Fit split ring over tubing and move away from end at least 2” (50mm)

• Insert tting into tubing until all barbs are covered

• Insert euroconical end of tting into manifold until o-ring is seated

• Push split ring up against tting

• Thread and tighten nut onto manifold

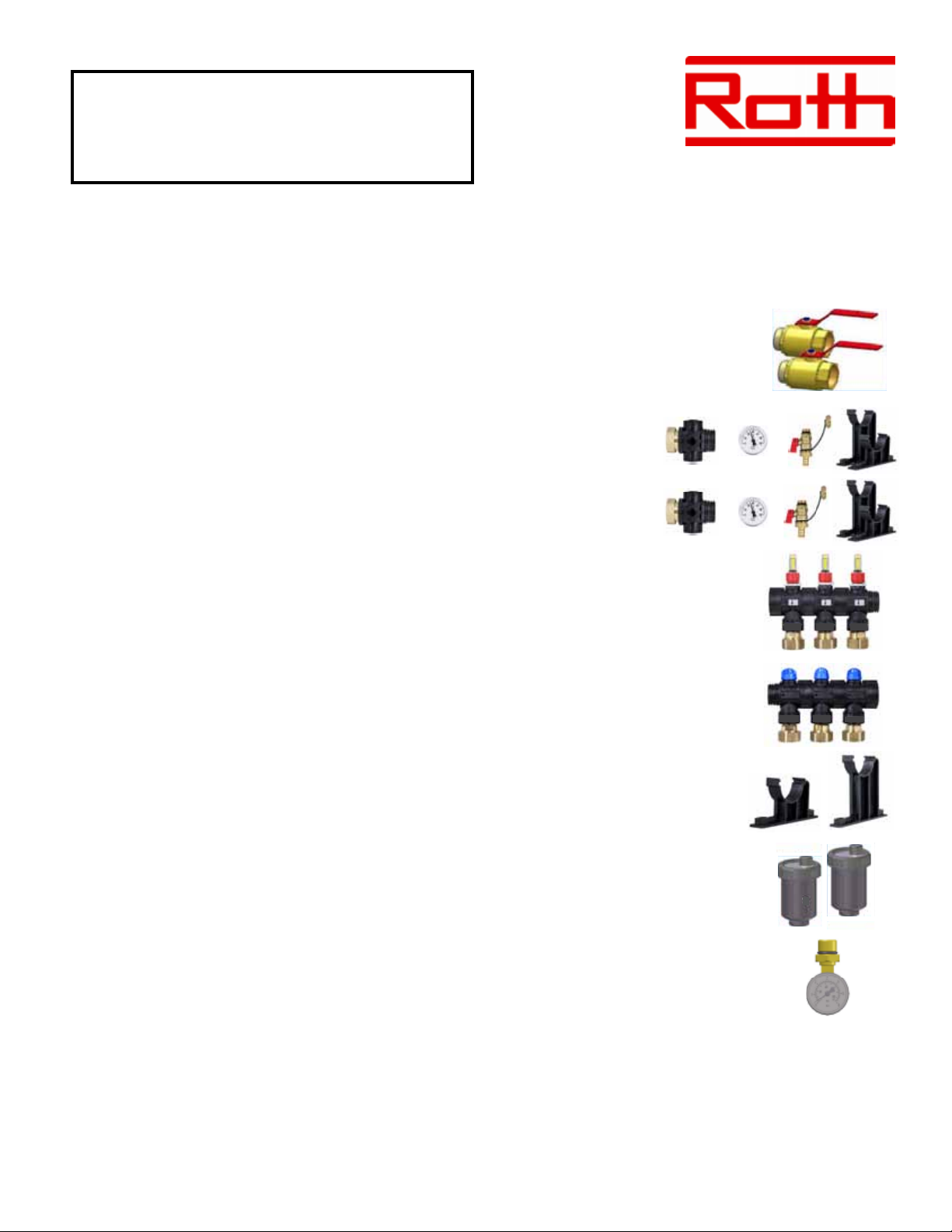

Roth Product # Description

PEX/PE-RT Fittings

2335001410 Manifold Tubing Fitting Assembly - 3/8” pkg of 10

2350003021 Manifold Tubing Fitting Assembly - 1/2” pkg of 10

2350003022 Manifold Tubing Fitting Assembly - 5/8” pkg of 10

2335001034 Manifold Tubing Fitting Assembly - 3/4” pkg of 2

Alu-Laser Plus Fittings

2347131300 Manifold Tubing Fitting Assembly - 3/8” pkg of 10

2347002331 Manifold Tubing Fitting Assembly - 1/2” pkg of 10

2347002332 Manifold Tubing Fitting Assembly - 5/8” pkg of 10