Table of Contents

5

1. INTRODUCTION............................................................................................................. 7

1.1. Who Should Use...........................................................................................................7

1.2. Purpose and Scope......................................................................................................7

1.3. Manual Version and Change Record............................................................................7

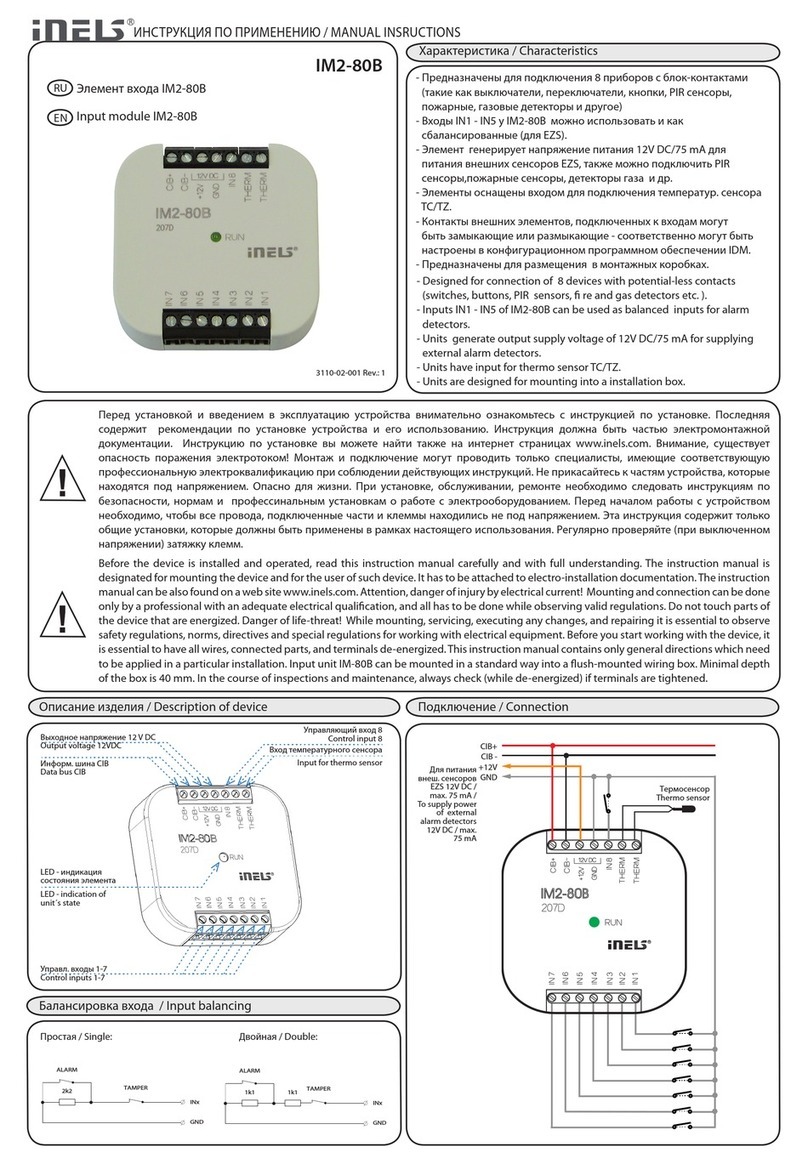

Figure 1-1: Model M3528M2.........................................................................................................7

1.4. Symbol Conventions Used in this Manual and on Equipment.......................................8

2. PRODUCT DESCRIPTION................................................................................................ 9

2.1. Related Products..........................................................................................................9

2.2. Part Number Breakdown ..............................................................................................9

2.3. General Specifications..................................................................................................9

Table 2-1: General Specifications Chart.......................................................................................9

2.4. General Precautions and Safety Warnings.................................................................10

3. INSTALLATION INSTRUCTIONS...................................................................................... 11

3.1. Environment...............................................................................................................11

3.2. Unpacking ..................................................................................................................11

3.3. Mounting.....................................................................................................................11

3.4. Wiring and Customer Connections.............................................................................11

Figure 3-1: Typical Interconnection Diagram..............................................................................12

3.4.1. Power Wiring.....................................................................................................................12

3.4.2. I/O Wiring..........................................................................................................................12

Table 3-1: Wiring Specifications .................................................................................................13

4. OPERATION ............................................................................................................... 15

4.1. Functional Description................................................................................................15

4.2. Features.....................................................................................................................15

4.2.1. Connectors........................................................................................................................15

4.2.2. Jumpers ............................................................................................................................16

Table 4-1: Setpoint Range Jumper Configurations ....................................................................16

4.2.3. Potentiometers..................................................................................................................17

Table 4-2: Setpoint Adjustment Sensitivity.................................................................................17

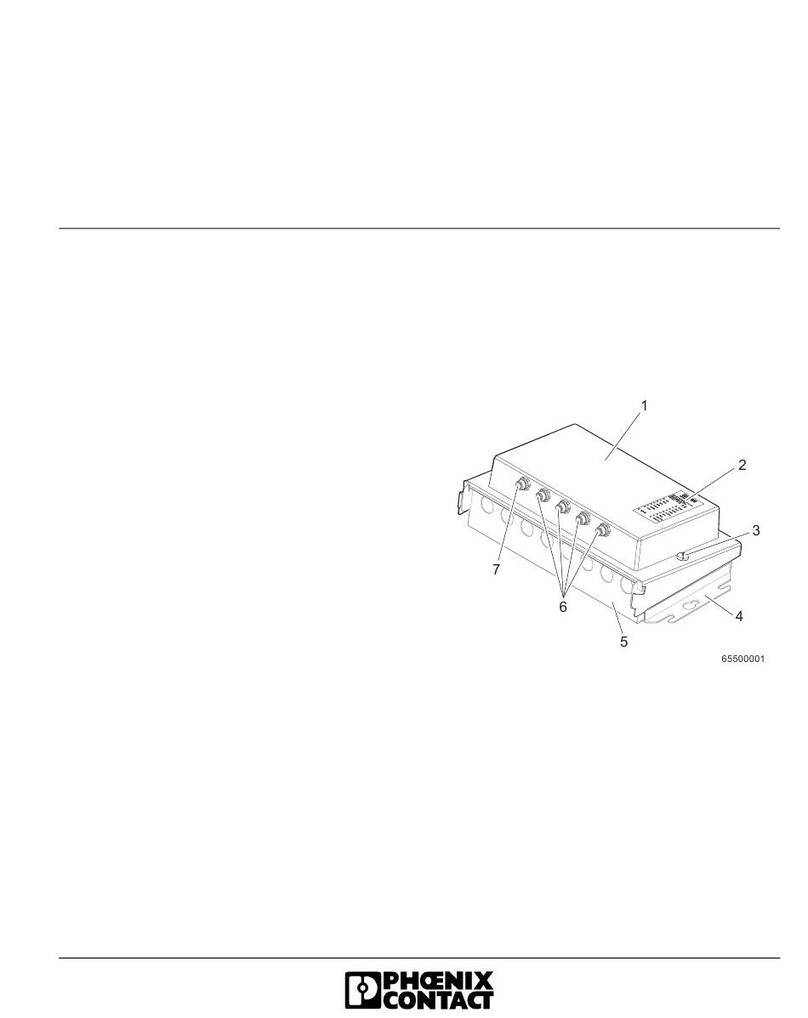

Figure 4-1: Front View ................................................................................................................18

5. MAINTENANCE AND TROUBLESHOOTING ...................................................................... 19

5.1. Troubleshooting..........................................................................................................19

6. ENGINEERING DATA ................................................................................................... 21

6.1. Ratings Charts............................................................................................................21

Table 6-1: M3528M2 Ratings Chart............................................................................................21

Table 6-2: Recommended Settings............................................................................................21

6.2. Dimensions and Mechanical Drawings .......................................................................21

Figure 6-1: M3528M2 Chassis Dimensional Outline ..................................................................21

NOTES........................................................................................................................................21