INOXPA NL Manual

This manual suits for next models

15

Table of contents

Other INOXPA Control Unit manuals

INOXPA

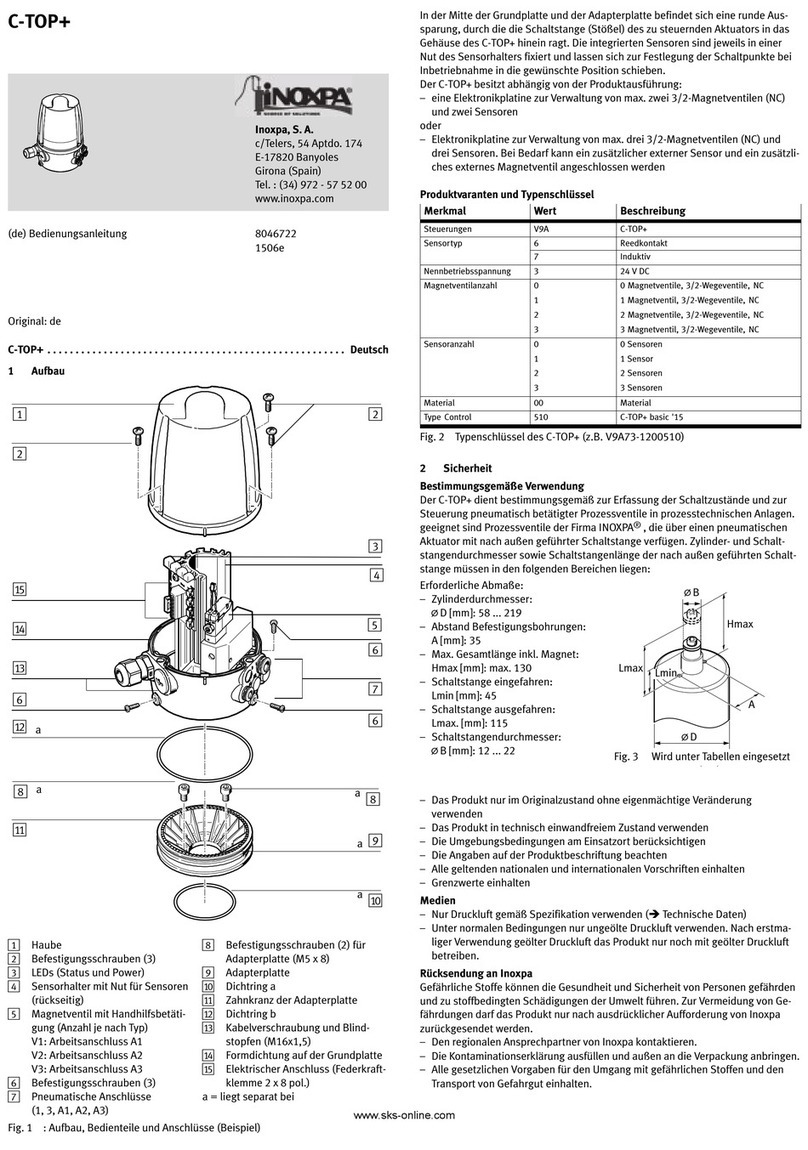

INOXPA C-TOP+ User manual

INOXPA

INOXPA 74700 Manual

INOXPA

INOXPA OVERFLOW VALVE Manual

INOXPA

INOXPA BALL Installation and user guide

INOXPA

INOXPA Check Manual

INOXPA

INOXPA INNOVA J Installation and user guide

INOXPA

INOXPA INNOVA F Manual

INOXPA

INOXPA INNOVA G Manual

INOXPA

INOXPA C-TOP S Manual

INOXPA

INOXPA OVERFLOW Manual

INOXPA

INOXPA INNOVA S Manual

INOXPA

INOXPA PHARMAVALVE Installation and user guide

INOXPA

INOXPA C-TOP+ User manual

INOXPA

INOXPA INNOVA F Ex Manual

INOXPA

INOXPA C-TOP+ User manual

INOXPA

INOXPA VEEVALV Manual

INOXPA

INOXPA INNOVA D Manual

INOXPA

INOXPA INNOVA F Installation and user guide

INOXPA

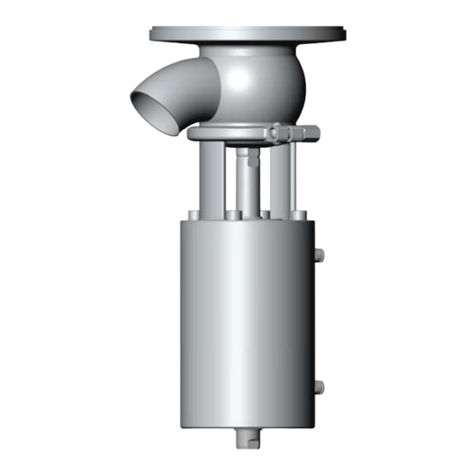

INOXPA INNOVA P Manual

INOXPA

INOXPA INNOVA T Manual

Popular Control Unit manuals by other brands

Endress

Endress E-RMA LAN Translation of the original operating manual

Jetter

Jetter JX3-BN-CAN user manual

Rockford Fosgate

Rockford Fosgate iPod Interface Module Installation & operation

Lucent Technologies

Lucent Technologies Stinger STGR-LIM-48 Guide

ATEQ

ATEQ G6 Series manual

New Focus

New Focus 6209 user guide

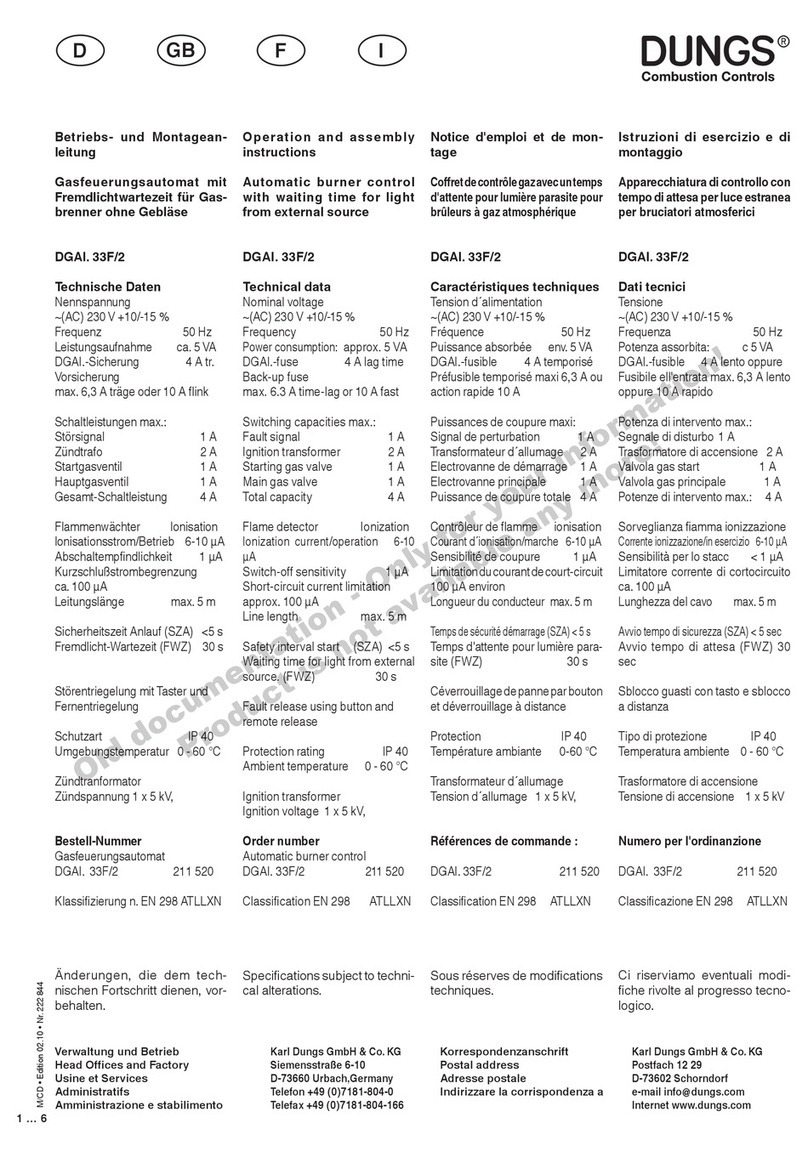

Dungs

Dungs DGAI. 33F/2 Operation and assembly instructions

Advantech

Advantech PCL-832 manual

CRE Technology

CRE Technology UNIGEN Plus Technical documentation

IFM

IFM CR2011 Device manual

Philips

Philips LCN7700 installation instructions

Thermo Scientific

Thermo Scientific Orion VERSA STAR VSTAR-RD reference guide