Credence CTE701A User manual

Workstation

Monitor

Checker

User’s Guide

Credence Technologies, Inc.

Model CTE701A

Credence Technologies, Inc.

3601-A Caldwell Dr.

Soquel, CA 95073 U.S.A.

Tel. 831-459-7488 FAX 831-427-3513

www.credencetech.com

© 2006 Credence Technologies, Inc.

Ground Masteris registered trademark

of Credence Technologies, Inc.

Patent Pending. Made in U.S.A.

PUB01907

Limited Warranty

Credence Technologies, Inc. warrants Worskstation Monitor Checker to be free from defects in materials and

workmanship under normal use and service for a period of one (1) year from date of purchase directly from

Credence Technologies, Inc., or from its authorized distributors. This warranty extends only to the original

purchaser. This warranty shall not apply to any product or part of it which has been subjected to misuse,

neglect, accident or abnormal conditions of operation. Except to the extent precluded by applicable state

law, Credence Technologies will have no liability for any consequential, incidental, or special damages.

In the event of failure of a product covered by this warranty, Credence Technologies, Inc. will repair a

product returned to authorized distributor or, only if it was purchased directly from Credence Technologies,

Inc., to the manufacturer; provided the warrantorís examination discloses to the company’s satisfaction

that the product was defective and is qualified for to a warranty claim. Credence Technologies may, at its

option, replace the product or its components with new or factory-refurbished parts or as whole in lieu of

repair. With regard to a product returned within one year of its purchase, said repair or replacement will

be made without charge. If the failure has been caused by misuse, neglect, accident or abnormal

conditions of operation, repairs will be billed at a nominal cost. Warranty does not cover transportation

costs.

Procedure

qFollow instructions in BasicsBasics

BasicsBasics

Basics section

qConnect 3.5mm test cable to both the Checker and to Operator jack of

your monitor.

qDepress and keep pressed the “Wriststrap” button. Your monitor should

indicate good connection.

qWhile keeping Pass button, depress and keep pressed Body Voltage

“High” button.

qYour monitor should provide indication of excessive body voltage in

each polarity -- positive and negative. If you ordered Checker for WS Aware

with a single terminal for both operators (model CTC061-D), please see

special addendum. When Body Voltage Low button is depressed, no Body

Voltage indication should be present in the monitor.

Downloaded from Elcodis.com electronic components distributor

Thank you for purchasing Workstation Monitor Checker. With it, you will always

know whether your workstation monitors and ground monitors operate within

your specification parameters.

Workstation Monitor Checker model CTE701 is designed to verify proper opera-

tion of your dual wriststrap monitors, workstation monitors and ground monitors.

Checker simulates proper resistances and signals so that you can see whether the

response of your monitors complies with your specification.

Though the Checker has been designed to work mostly with Credence Technolo-

gies’ monitors, such as WS Aware®, Ground Master®, Iron Man Plus, Ground

Man and Ground Man Plus, it is also able to verify the performance of most

workstation and ground monitors on the market.

Checker presents certain loads and signals to the monitor that simulate specific

parameters of ground connections and wriststraps. Please note that not all

monitors have the same features.

What is included

Each workstation monitor Checker includes:

Workstation Monitor Checker model CTA701A 1ea.

9V Alkaline Battery 1ea.

Battery comes already installed in the Checker.

Ground Cable (banana to alligator clip) 1ea.

Ground Monitor Cable (banana to pin) 1ea.

3.5mm Male-to Male cable 1ea.

This User’s Guide 1ea.

Wriststraps

The Checker verifies proper operation of monitors of dual wriststraps, i.e. the

wriststraps that use two connections to an operator.

Setup

The Checker applies resistance of a certain value across the wriststrap terminal

input in order to simulate a wriststrap. In critical environments where the wriststrap

monitor is used the electrical resistance of an operator is specified to be 10MOhms

max. A good quality dual wriststrap has a1MOhm resistor in each half. It is up to

the user whether to account for these resistors or not. In case you account for these

resistors, then your limit would be:

10MOhms +1 MOhm + 1MOhm = 12 MOhms.

Limit is set by dip switch #1010

1010

10.

Switch PSwitch P

Switch PSwitch P

Switch Positionosition

ositionosition

osition

Resistance, MOhmsResistance, MOhms

Resistance, MOhmsResistance, MOhms

Resistance, MOhms 1010

1010

10

12 0

10 1

Checker by default provides selected resistance plus 1MOhm, i.e. for 12MOhms

limit, it would provide 13MOhms, for 10MOhms limit it would provide 11MOhms.

When the Pass button is pressed, the Checker provides resistance 1MOhm less

than the limit, i.e. 11 and 9 MOhms accordingly.

Procedure

qFollow instructions in BasicsBasics

BasicsBasics

Basics section

qConnect 3.5mm test cable to both the Checker and to Operator jack of

your monitor. At this point the monitor should indicate failure.

qDepress the “Wriststrap” button. Your monitor should indicate good

connection.

Body Voltage

Quality wriststrap monitors can detect excessive voltage that an operator may

develop as a result of movement-caused tribocharge and touching energized ob-

jects. To test this ability of the monitor, first set the body voltage threshold by

depressing the Body Voltage button and turning the blue potentiometer while mea-

suring the voltage on the tip of the 3.5mm plug vs. ground. Red and green LEDs

alternatively blink indicating positive and negative voltage applied automatically.

Your wriststrap monitor must react to both polarities of excessive voltage on the

operator.

Keep in mind that the voltage applied directly to the terminal of the monitor is 1/2

of the voltage on the operator due to 1M resistors in the wriststrap. Set Body

Voltage on the Checker slightly higher than your monitor is calibrated for. For

example, if your monitor is calibrated to 2.5V body voltage, depress Wriststrap

and Body Voltage High buttons simultaneosly and set your Checker to 1.35V

which is slightly higher than 1/2 of 2.5V. Your Checker can be set up to 5V.

2 7

Downloaded from Elcodis.com electronic components distributor

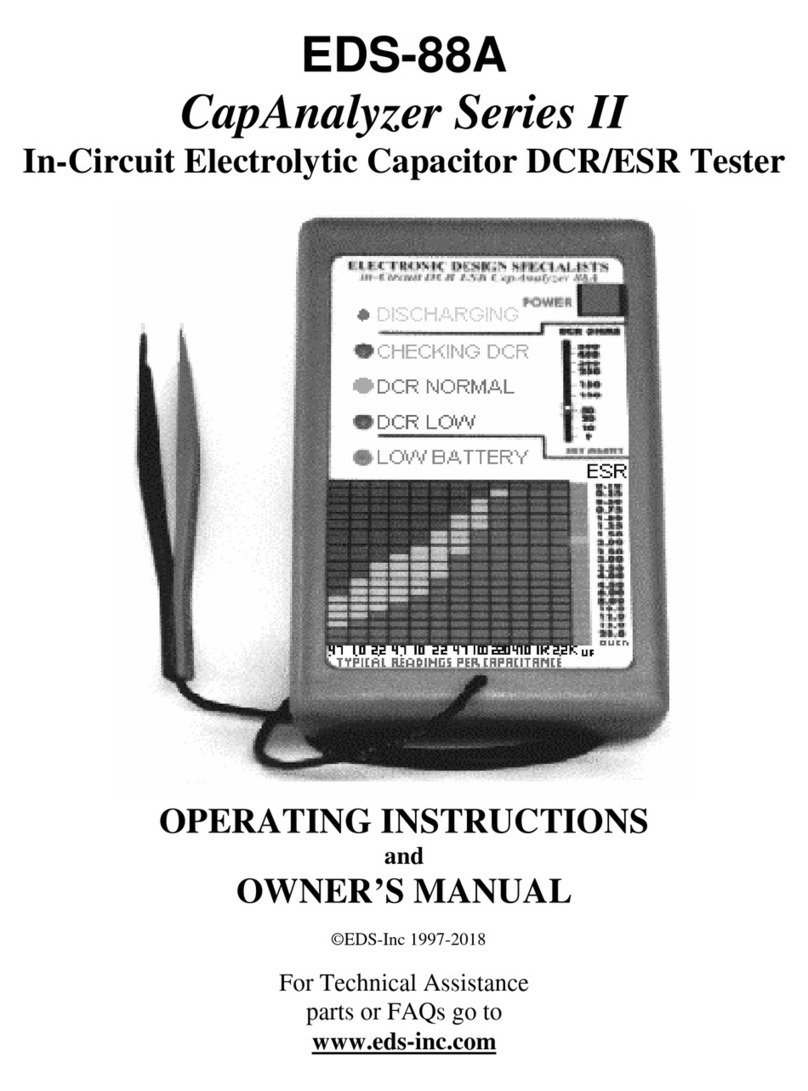

Quick Tour of your Checker

Checker uses 9V alkaline battery. Make sure that a fresh battery is installed prior

to performing any test. If you are not planning to use your Checker for a long time,

please remove the battery from the device.

Power Switch and LED

High (Fail) and Low (Pass)

switches for EMI on Metal

Grounds

High (Fail) and Low (Pass)

switches for Metal Grounds

Pass (Low Limit)

switch for Wriststraps

High (Fail) and Low

(Pass) switches for

body voltage on

operator

Soft Ground

Pass Switch

Threshold Setting

Switches

3.5mm Jack for

Wriststrap Monitor Test

Banana Jack for

Ground Test

Banana Jack for

Reference Ground

Body Voltage Set

Potentiometer and

LEDs

Low Battery and Power LEDs

depress EMI “High” button. In Ground Master you should see green light

indicating good ground connection and blinking red light indicating

presence of EMI. In WS Aware the ground light should be pulsed yellow

light or continuous yellow (older models). Release “High” EMI button and

depress “Low” EMI button while keeping “Pass” Metal Ground button

depressed. No EMI indication should be present on the monitor. For

other monitor use these monitors’ User’s Guides for information on their

proper operation and indication.

Dissipative (Soft) Grounds

This test verifies proper operation of soft (dissipative) ground monitoring such as

of mats, dissipative plastics, etc.

Setup

Ground ResistanceGround Resistance

Ground ResistanceGround Resistance

Ground Resistance

Setup switches allow you to set the parameters in accordance with your

specification. Dissipative ground resistance setting is done using switches 1...4.

Switch PSwitch P

Switch PSwitch P

Switch Positionosition

ositionosition

osition

Monitor Alarm ThresholdMonitor Alarm Threshold

Monitor Alarm ThresholdMonitor Alarm Threshold

Monitor Alarm Threshold 11

11

122

22

233

33

344

44

4

1000 MOhms 0001

200 MOhms 0011

100 MOhms 0111

10 MOhms 1111

All other switch positions are unused for this purpose.

Pressing “Soft Ground” push-button switch will result in load with slightly lower

resistance than the alarm threshold.

Procedure

When measuring dissipative grounds, allow some time -- up to 30 seconds --

for the monitor to react properly -- often a delay is built into indication of failure

of soft ground to allow for noise rejection.

qFollow instructions in BasicsBasics

BasicsBasics

Basics section

qPlug banana end of red cable of the Checker into the Ground Under

Test jack of the Checker

qPlug the thin tip of red cable into soft ground terminal of your monitor.

Make sure that the contact is good.

qGround monitor shall indicate failure (typically, red light on the monitor).

A momentary “blink” of pass light on the monitor (typically green) when the

button is depressed is acceptable.

qDepress “Soft Ground” button on your Checker. Ground monitor shall

indicate good ground (typically green light). Allow up to 30 seconds for

alarm to trigger for some monitors.

qAfter release of “Soft Ground” button the ground monitor shall indicate

failure. Allow up to 30 seconds for alarm to trigger for some monitors.

6 3

Downloaded from Elcodis.com electronic components distributor

Basics

For all tests make sure that:

qMonitor under test itself is properly grounded and is operational.

qDisconnect all wires from the monitor under test that go to the

monitored grounds. Leave ground connection of the monitor itself con-

nected to a known good ground

qConnect banana end of the black grounding cable of the Checker into

the Reference Ground jack of the Checker and the alligator clip end of this

cable to a ground terminal of the monitor under test.

qTurn the Checker on.

Metal Ground

This test verifies proper operation of your monitor on metal ground monitoring as

well as EMI detection.

Settings

Ground ResistanceGround Resistance

Ground ResistanceGround Resistance

Ground Resistance

Setup switches allow you to set the parameters in accordance to your specification.

Metal ground impedance setting is done using dip switches 5...8.

Switch PSwitch P

Switch PSwitch P

Switch Positionosition

ositionosition

osition

Resistance, OhmsResistance, Ohms

Resistance, OhmsResistance, Ohms

Resistance, Ohms 55

55

566

66

677

77

788

88

8

1 1111

2 0111

3 1011

4 0011

5 1101

6 0101

7 1001

8 0001

9 1110

10 0110

11 1010

12 0010

13 1100

14 0100

15 1000

16 0000

Pressing a “Fail” push-button switch will result in resistance that is 1 Ohm

higher than set above, pressing the “Pass” push-button switch will result in

resistance that is 1 Ohm less. For example, if your factory is using 10 Ohms as

specification for ground impedance, then the monitor set to 10 Ohms should

pass at 9 Ohms and fail at 11 Ohms.

EMIEMI

EMIEMI

EMI

The checker provides high frequency signal to test EMI detection threshold. EMI

level is set using dip switch 99

99

9. The checker provides two different levels of high

frequency signal -- “elevated” and “normal.” In position 1 the EMI level is

“elevated,” in position 0 the level is “normal.” Pressing “High” push button

switch will result in high signal level within its range, pressing “Low” push

button will result in low signal within its range. Note that internal EMI generator

drive may be insufficient to drive extremely low load, such as 0 or 1 Ohm.

Procedure -- Metal Grounds

qFollow instructions in BasicsBasics

BasicsBasics

Basics section

qPlug banana end of red cable of the Checker into the Ground Under

Test jack of the Checker

qPlug the thin tip of red cable into the ground terminal of your monitor.

Make sure that the contact is good.

qDepress the “Fail” button on the Checker. Ground monitor shall

indicate failure (typically, red light on the monitor). A momentary “blink” of

pass light on the monitor (typically green) when the button is depressed is

acceptable.

qDepress the “Pass” Metal Ground button on the Checker. Ground

monitor shall indicate good ground (typically green light on the monitor).

qWhile keeping the “Pass” Metal Ground button pressed, simultaneously

1...4 5...8

Places of contact for metal grounds test for WS Aware and Ground

Master monitors. In other monitors it may vary. In all cases disconnect

monitor from monitored tool and bench grounds for the test.

Ground Master CTC065-3

Insert test pin into opening for the wire --

do not use screw as contact point

G1, G2

WS Aware CTC061

4 5

Downloaded from Elcodis.com electronic components distributor

Table of contents

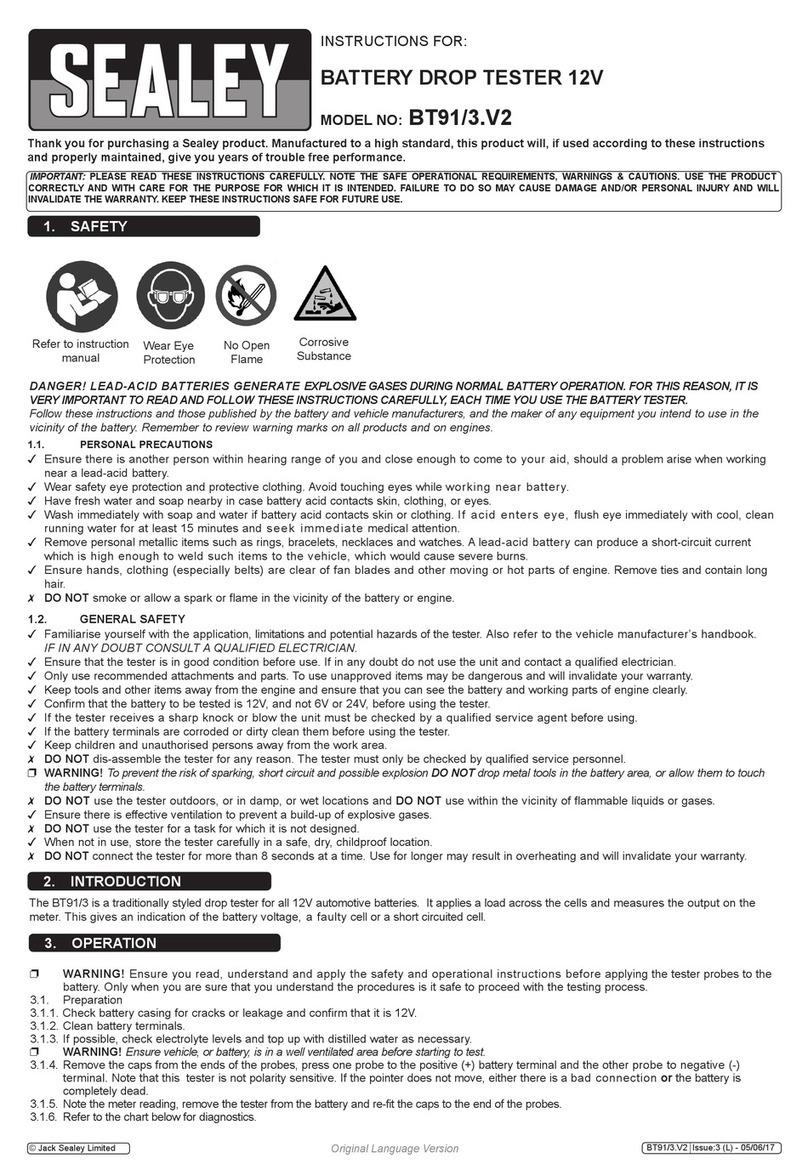

Popular Test Equipment manuals by other brands

Sealey

Sealey BT91/3.V2 instructions

Martindale Electric

Martindale Electric EZ365 instruction manual

Rohde & Schwarz

Rohde & Schwarz RTC1000 Getting started

TAKAYA

TAKAYA APT-9411 Series Operator's guide

Tru-Test

Tru-Test EziWeigh user manual

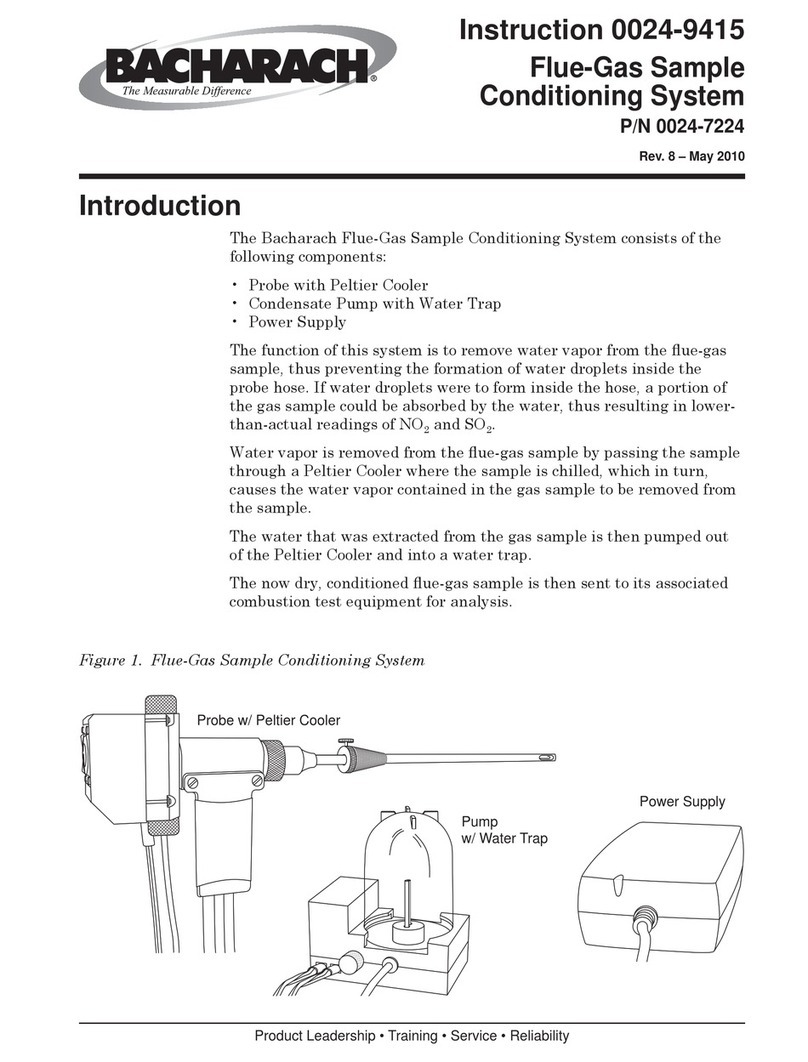

Bacharach

Bacharach Flue-Gas Sample Conditioning System Instruction