Fluke 707

Calibration Information

8

2. The Loop Calibrator adjustment procedure is

password protected. At this point, a password is

needed to go forward. "PAS" is displayed on the

main display and "000" on the secondary display.

Enter the password "626" as follows:

1. Rotate the knob to add a 6 in the LCD of

the secondary display, push and release

the knob.

2. Rotate the knob to get 2 into the LCD,

push and release.

3. Rotate the knob to get a 6, push and

release.

If the password is correct, you'll be led through

all the adjust modes (source, mA read, V read),

otherwise the unit returns to normal operation. In

the adjust mode, the main display will show

"1.000 mA".

3. Connect the Loop Calibrator [+] terminal to the

HP 3458A I input, and the COMterminal to the

HP 3458A LO input. The Loop Calibrator will be

in mA source cal and "1.000 mA" is displayed. On

the secondary LCD, the last 3 digits from the

knob value are shown. Adjust the mA output by

tuning the knob until "1.000 mA" shows on the HP

3458A.

4. Press , "22.000 mA" is displayed. Adjust the

mA output by turning the knob until "22.000 mA"

is shown on the HP 3458A.

5. Press to go to mA measure adjust.

6. Disconnect the HP 3458A from the Loop

Calibrator.

7. Connect the test leads from the AUX terminals of

the Fluke 5520A to the terminals on the Loop

Calibrator (black to COM and red to [+]).

8. The Loop Calibrator will display "MEASURE" and

0.000 mA is displayed. On the secondary display,

the last 3 digits of the A/D reading are shown. Set

the 5520A to output 0.000 mA into the Loop

Calibrator. Press .

9. After a moment, the Loop Calibrator will display

24.000 mA. Set the 5520A to output 24.000 mA

into the Loop Calibrator.

10. Press to go to V measure adjust.

11. Connect the test leads from the output NORMAL

terminals of the Fluke 5520A to the input

terminals on the Loop Calibrator.

12. The Loop Calibrator will display "MEASURE" and

0.000 V. The Secondary display will show the

last 3 digits of the A/D reading. Set the 5520A to

output 0.000 V into the Loop Calibrator.

13. Press . After a moment, 25.000 V will

display on the Loop Calibrator. Set the 5520A to

output 25.000 V into the Loop Calibrator.

14. Press to complete the adjustment. The

calibration counter is incremented and the

calibration data is stored. The calibration count

will be on the main display and "CAL" on the

secondary display for 2 seconds.

The calibration adjustment procedure is complete.

To see the value of the calibration counter without

calibrating the unit, hold down at power up. The

software revision number is displayed for 2 seconds

followed by the calibration counter for 2 seconds.

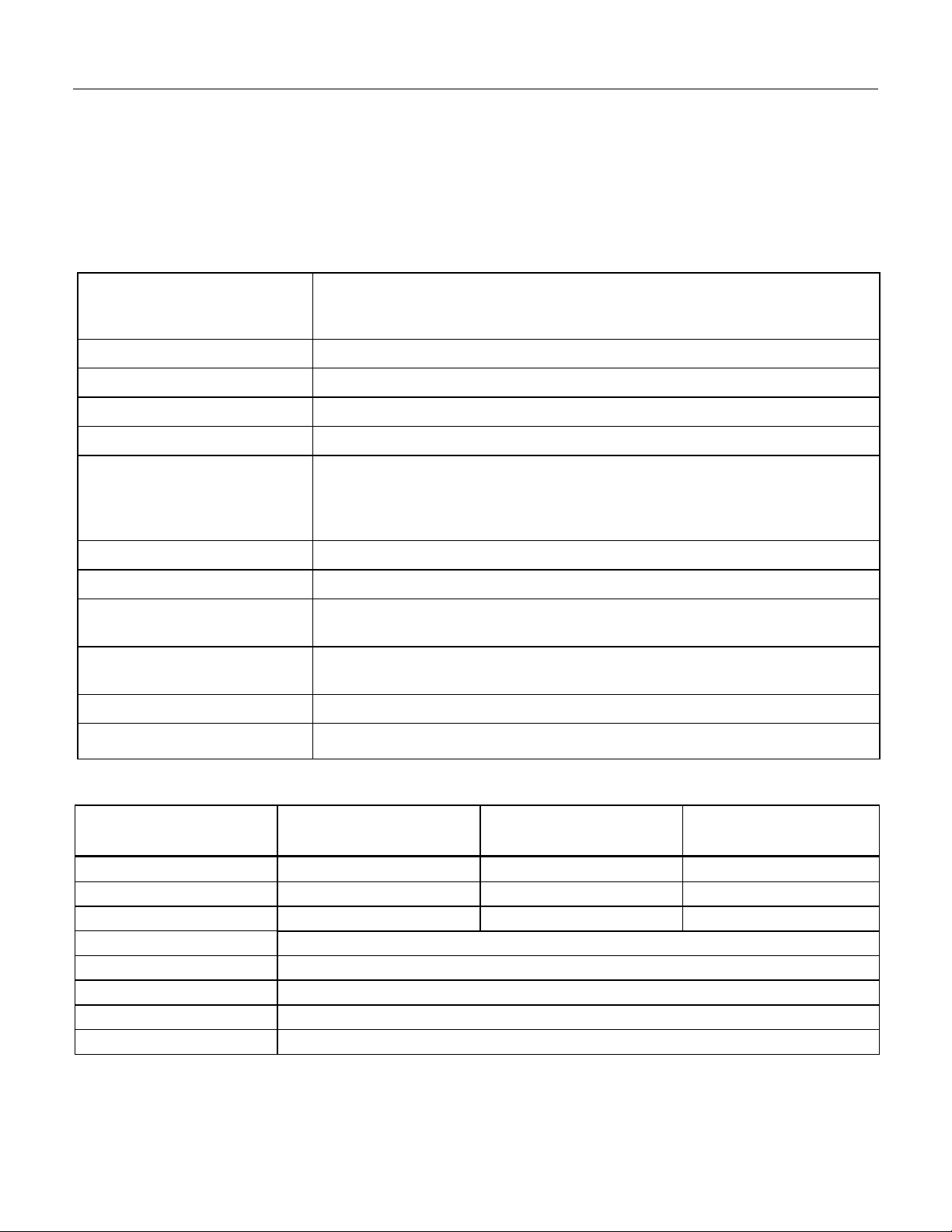

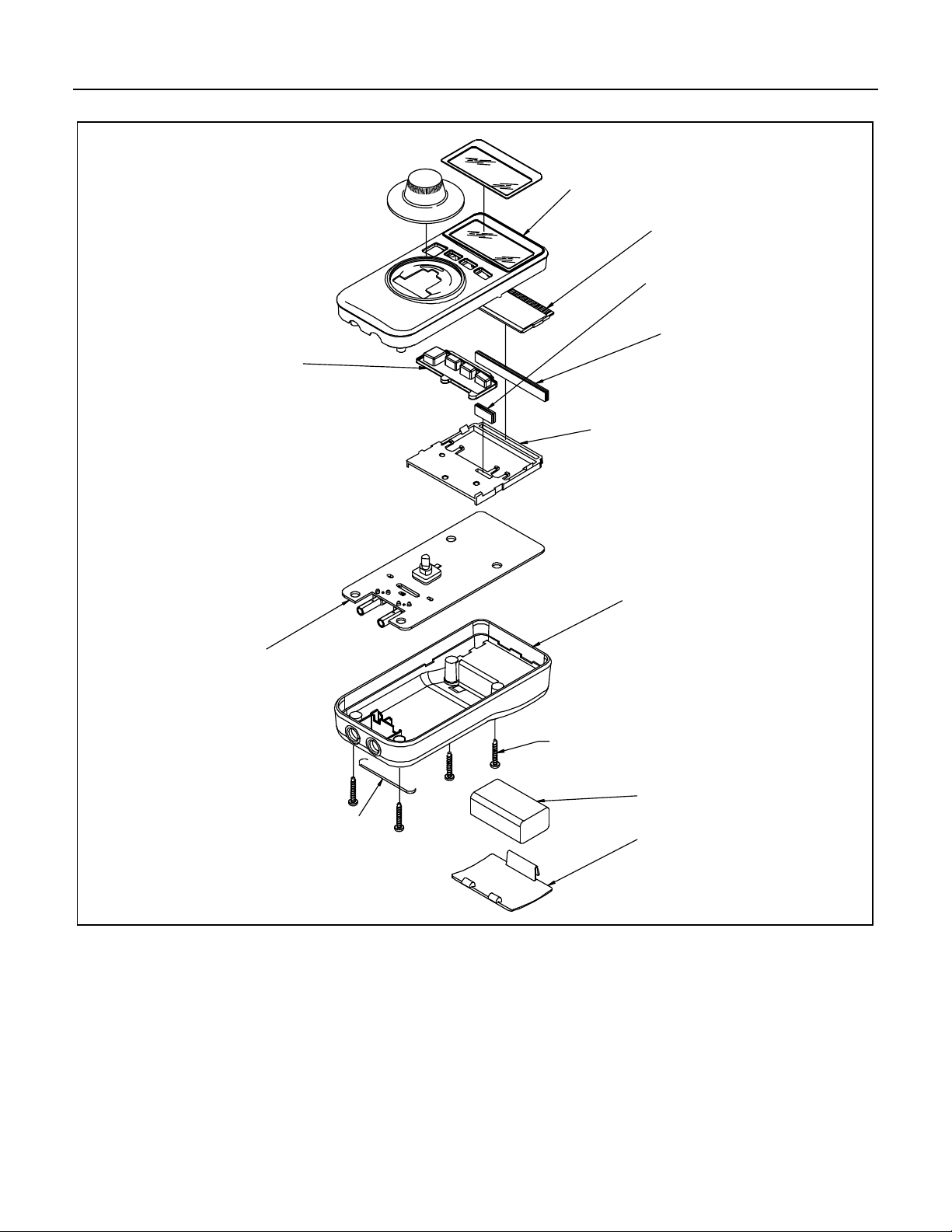

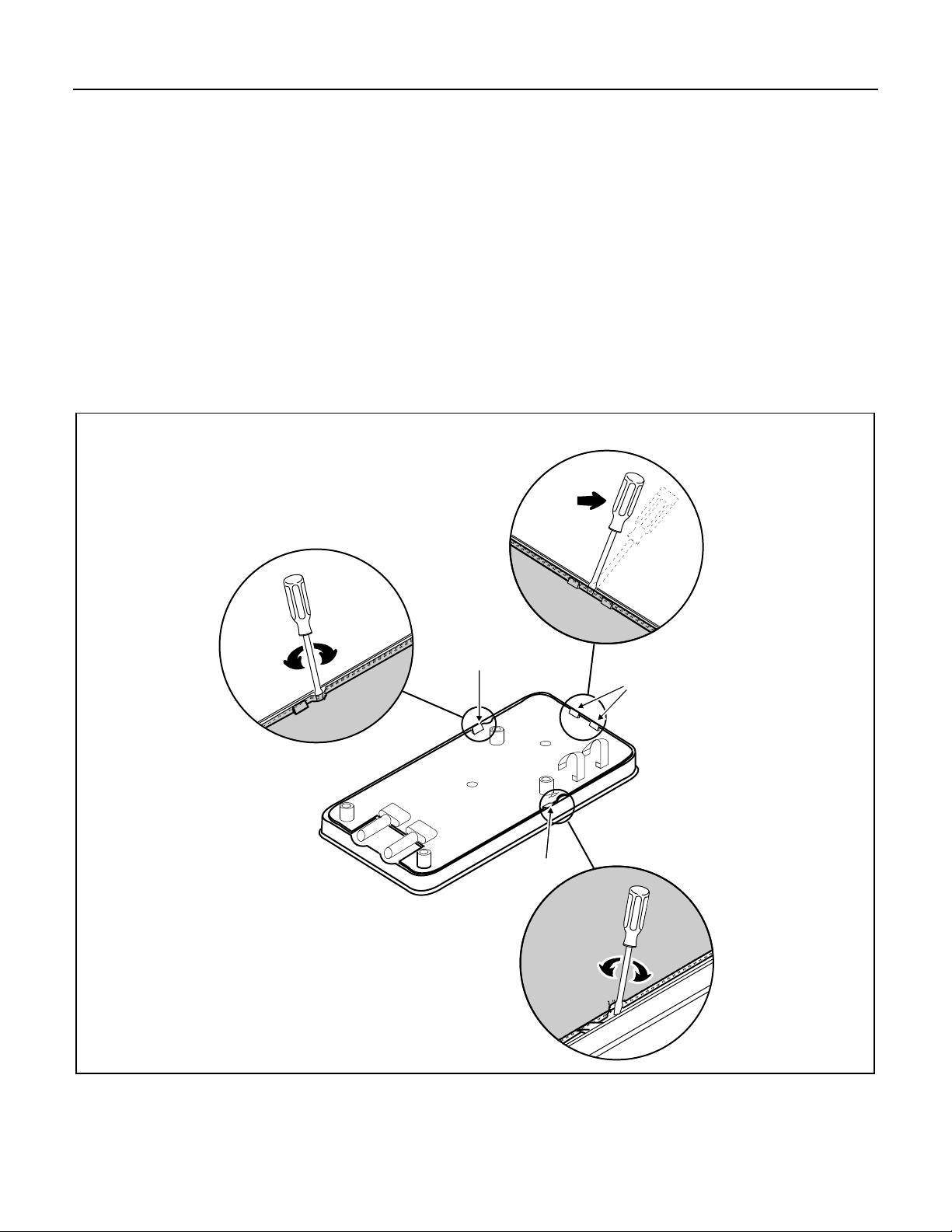

User-Replaceable Parts

User-replaceable parts, are listed in and shown in

Figure 4 and Table 5.