Crem spengler PSL50 Series User manual

PSL50 SERIES

CONTENTS

CONTENTS

MANUAL REVISIONS

INTRODUCTION

4 Cleaning and care overview

SERVICE MENU

5 Access service menu

DAILY CLEANING OVERVIEW

6 Daily cleaning tasks

6 Required equipment

DAILY CLEANING PROCEDURE

7 Step 1: Run Rinse function

8 Step 2: Empty drip tray

9 Step 3: Empty waste bin

WEEKLY CLEANING OVERVIEW

10 Weekly cleaning tasks

10 Required equipment

10 Dishwasher-safe parts list

WEEKLY CLEANING PROCEDURE

11 Step 1: Run Purification function

12 Step 2: Clean waste bin

13 Step 3: Clean spout adaptor, steam traps

14 Step 4: Clean canister chutes

15 Step 5: Clean drip tray

16 Step 6: Clean interior, replace waste bin

16 Step 7: Replace drip tray, cup grill

17 Step 8: Clean exterior, run Rinsing function, test functionality

2

PSL50 Series

MANUAL REVISIONS

Rev. #

Date

TSB #

Description

3

PSL50 Series

INTRODUCTION

PSL50 Series

Cleaning and care overview

Daily and Weekly Cleaning-

This manual has been optimised for cleaning and care of the dispenser and base

cabinet by a trained First Line Operator on a daily and weekly (or every 1000

servings, whichever comes first) basis. As such, it is expressly focused on cleaning

the dispenser in the most efficient manner possible while still guaranteeing excellent

hygiene is maintained. Please follow the steps in the order they are listed to minimize

down time and ensure that no areas are skipped or overlooked.

In order to guarantee that the dispenser always stays clean and hygienic, and

delivers excellent beverages at all times, all cleaning steps and cleaning/replacement

schedules must be followed exactly as they are listed in this manual. Failure to carry

out any of the cleaning and care steps in a timely manner will result in an unhygienic

environment which may result in off-tasting/low-quality beverages. Poor cleaning and

care habits will also shorten the total life-expectancy of the dispenser and may incur

damage which will not be covered under the dispenser manufacturer’s warranty.

In all instances pay special attention to information marked Note: or Important!:

since these details may require extra attention, or signal that a part should be

replaced during the cleaning visit. Additionally, information marked as Pro Tip:

offers time-saving hints and tricks that can make cleaning and care easier that

can be used at the First Line Operator’s own discretion.

If there are any questions as to the application, procedures, or care and

service requirements for the dispenser contact Spengler Technical Service,

the trained technician who installed/services the dispenser, or the

distributor who supplied the dispenser.

iNote:

This manual is designed for cleaning and care of the entire range of Spengler CL

and PSL50-based dispensers. As such some modules, parts, components and

systems may vary in appearance or description from what is shown slightly.

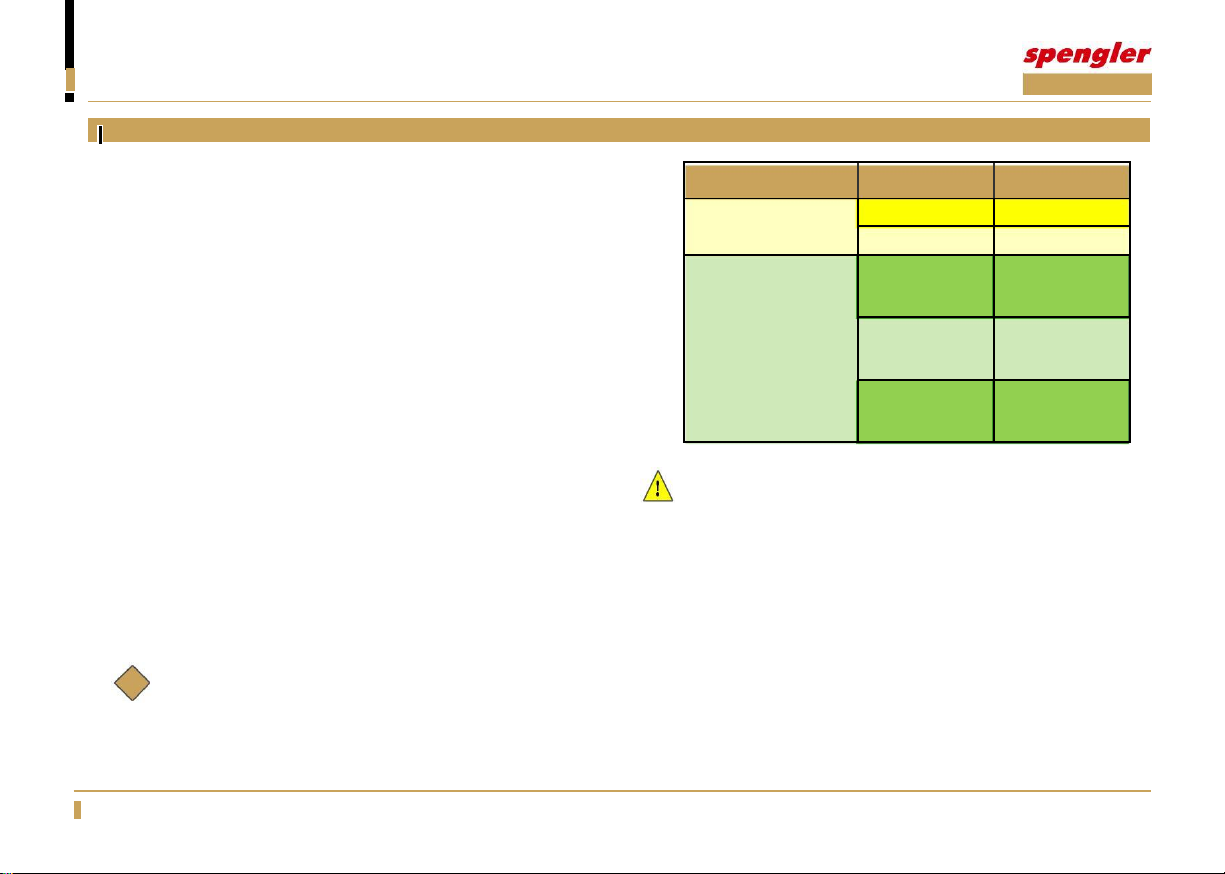

Responsible Person:

Task:

Reference:

First Line Operator

Daily Cleaning

Daily Cleaning

Weekly Cleaning

Weekly Cleaning

See Spengler

Semi-annual Service

PSL50 Series

Service Manual

See Spengler

Service Technician

Annual Service

PSL50 Series

Service Manual

See Spengler

Bi-annual Service

PSL50 Series

Service Manual

Important:

Daily and weekly cleaning shall only be performed by the First Line

Operator while following all required safety practices as outlined

during the training session(s).

The Semi-annual, Annual and Bi-annual Services (see Service Manual for

details) shall only be performed by a trained technician using all required

safety equipment as outlined during the training session(s) whilst

adhering to local safety standards & practices using service kits from the

original equipment manufacturer.

4

SERVICE MENU

PSL50 Series

Access service menu

01

02

03

AB

C

Open door.

Press Service On (A) to enter. Press Service Off (B) to exit.

Press Return icon (C) to return to user menu.

5

Service menu will appear (access level 255 will be

granted)

Press Program to access basic service functions. Follow on-

screen pop-up messages.

Input relevant PIN number to gain required level of

access.

DAILY CLEANING OVERVIEW

PSL50 Series

Daily cleaning tasks

The cleaning tasks listed below are to be done on a daily basis to guarantee

great tasting drinks and good dispenser hygiene. Step-by-step instructions

are provided on the following pages.

1. Run Rinse function

2. Empty drip tray

3. Empty waste bin

Important:

Daily and weekly cleaning shall only be performed by the First Line

Operator while following all required safety practices as outlined

during the training session(s).

Required equipment

The following cleaning equipment/consumable items are required to

perform the daily cleaning procedure:

•Door key

•Cleaning cloth/sponge

•Mild kitchen cleaning spray

•Waste bin liner

6

DAILY CLEANING PROCEDURE

PSL50 Series

Step 1: Run Rinse function

01

02

03

A

Open door. Service menu will appear. Press Rinsing. Follow Close door (A). Place a 2L container

on-screen pop-up messages. (B) under outlets.

04

Press Start (A). Wait for rinsing to

finish (B).

B WARNING:

Cleaning water is very hot!

A

7

B

A

DAILY CLEANING PROCEDURE

PSL50 Series

Step 2: Empty drip tray

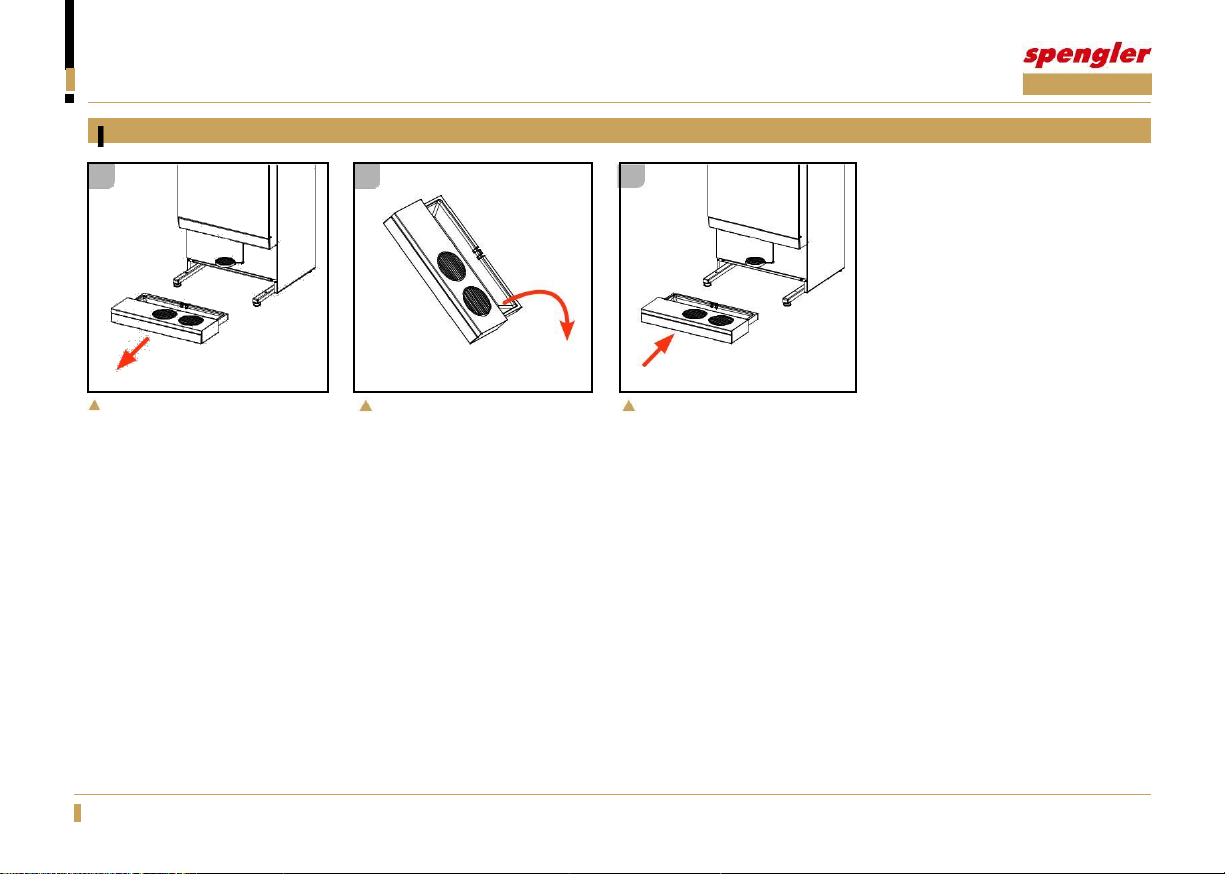

01

02

03

Remove drip tray. Empty waste water. Replace drip tray.

8

DAILY CLEANING PROCEDURE

PSL50 Series

Step 3: Empty waste bin

01

02

03

04

Open door. Remove waste bin. Remove used bin liner. Clean waste bin. Dry after washing.

05

Place new bin liner in the waste bin.

06

Replace waste bin.

Secure with retaining ring.

9

WEEKLY CLEANING OVERVIEW

PSL50 Series

Weekly cleaning tasks

The cleaning tasks listed below are to be done on a weekly basis (or after every

1,000 servings if the daily expected average is exceeded) to guarantee great

tasting drinks, good dispenser hygiene and to prevent premature dispenser/parts

failure. Step-by-step instructions are provided on the following pages.

1. Run Purification function

2. Clean waste bin

3. Clean spout adaptor, steam traps

4. Clean canister chutes

5. Clean drip tray

6. Clean interior, replace waste bin

7. Replace drip tray, cup grill

8. Clean exterior, run Rinsing function, test functionality

Important:

Daily and weekly cleaning shall only be performed by the First Line

Operator while following all required safety practices as outlined

during the training session(s).

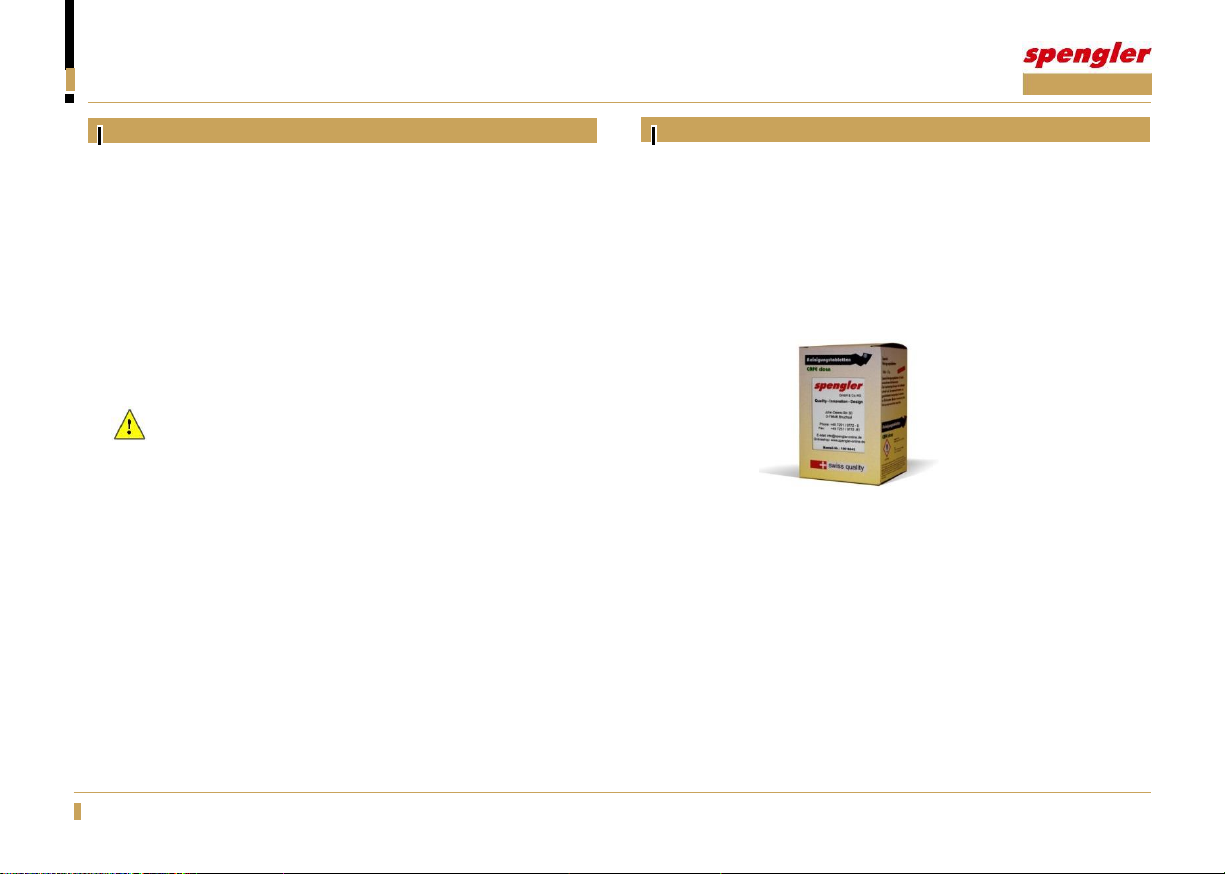

Required equipment

The following cleaning equipment/consumable items are required to

perform the weekly cleaning procedure.

•Door key

•Cleaning cloth/sponge

•Mild kitchen cleaning spray

•Glass cleaning spray

•Waste bin liner

•Spengler cleaning tablets (article number 10018243)

10

WEEKLY CLEANING PROCEDURE

PSL50 Series

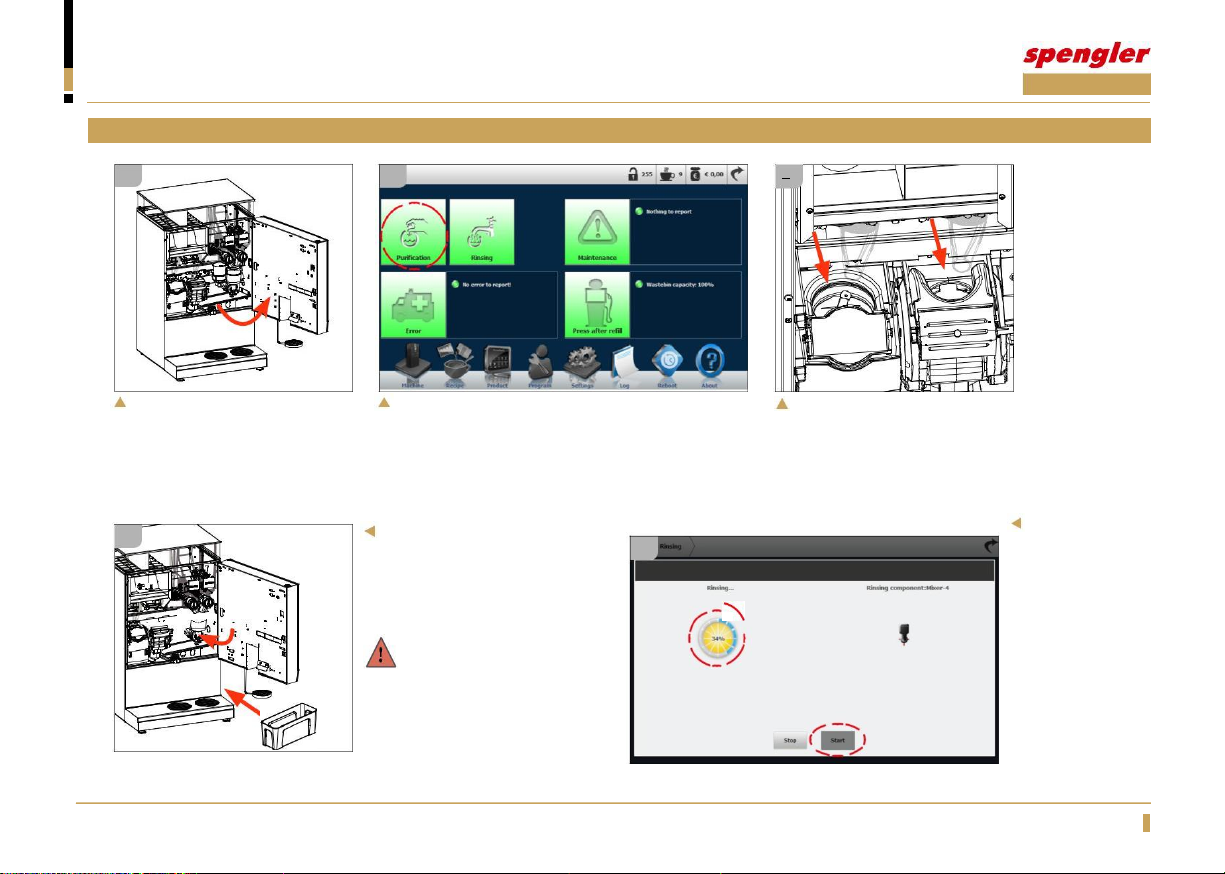

Step 1: Run Purification function

01

Open door.

04

A

A

02

Service menu will appear. Press Purification.

Close door (A). Place a 2L container

05

(B) under outlets.

WARNING:

Cleaning water is very hot!

03

Place one cleaning tablet inside each

brewer.

Press Start (A).

Wait for

cleaning to

finish (B).

B

A

11

B

WEEKLY CLEANING PROCEDURE

PSL50 Series

Step 2: Clean waste bin

01

Open door.

02

03

04

Remove waste bin. Remove used bin liner. Clean waste bin. Dry after washing.

05

Place new bin liner in the waste bin.

Secure with retaining ring. Set aside.

iNote:

For a dispenser mounted on a base cabinet, the waste bin inside the

dispenser is replaced with a waste chute to direct waste into the bin located

inside the cabinet. Removal and cleaning of these items is simple, and

necessary cleaning and care steps are the same as listed above.

12

WEEKLY CLEANING PROCEDURE

PSL50 Series

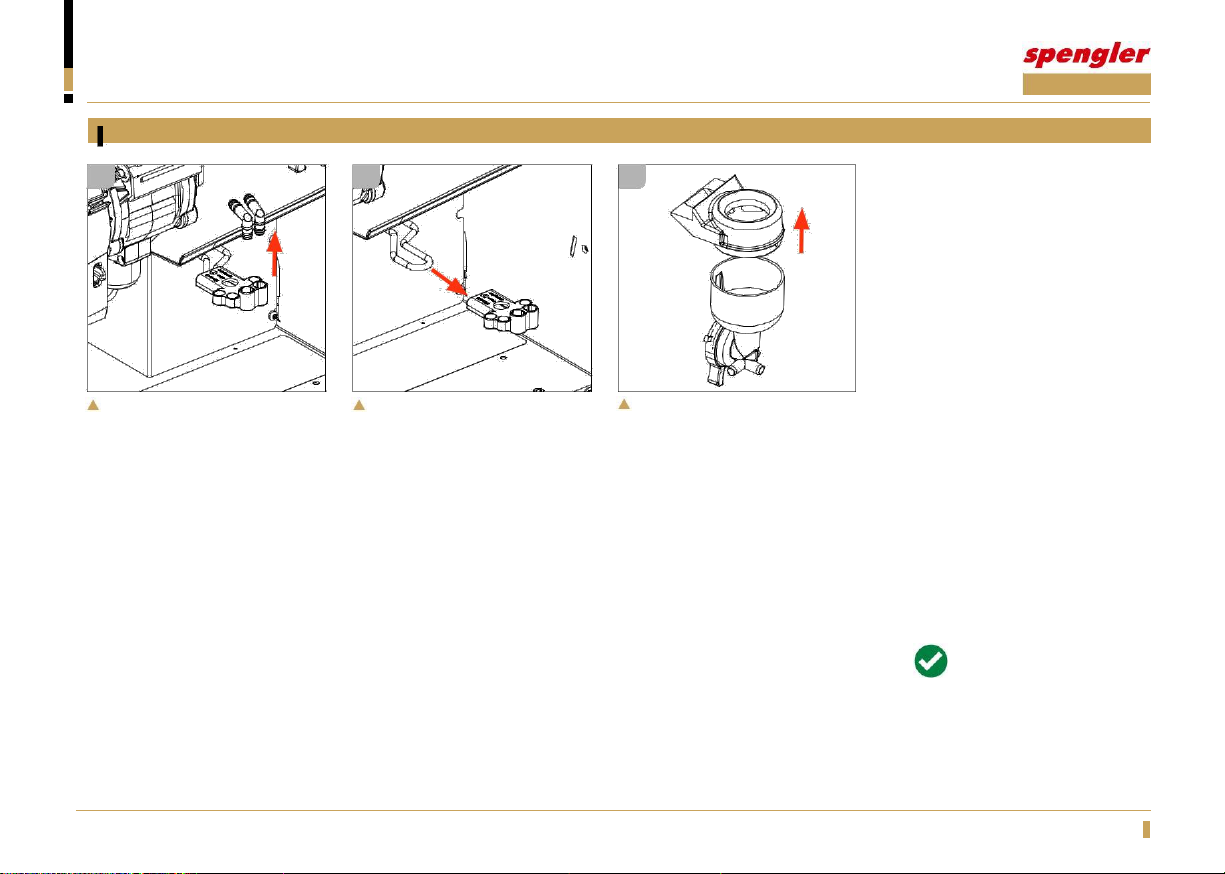

Step 3: Clean spout adaptor, steam traps

01

02

03

Disconnect ingredient spouts

from spout adaptor. Keep tubes

connected to mixers/brewers for

now.

Pull spout adaptor forward to

separate it from support arm.

Wash spout adaptor under

running water and scrub any dried

coffee/ingredient residue with a

brush to remove it. Dry after

washing. Reassemble in reverse

order.

Pull steam trap straight up to remove

it from mixer (repeat for each mixer.

Wash all parts under running water

and scrub any dried coffee/ingredient

residue with a brush to remove it.

Dry after washing. Reassemble in

reverse order.

Pro Tip:

Save time by exchanging dirty

parts with clean spares and

washing and drying the dirty

parts later (in a dishwasher if

dishwasher-safe) then reusing

them during the next weekly

cleaning.

13

WEEKLY CLEANING PROCEDURE

PSL50 Series

Step 4: Clean canister chutes

01

02

A

B

Close canister outlet gates by rotating

Wash chutes under running water and

so arrows point straight up (A) to

scrub any dried coffee residue with a

prevent spillage. Remove ingredient

brush to remove it. Dry parts washing.

chutes by pulling straight down (B).

03

B

A

Snap chutes back onto canister outlets

(A). Reopen canister outlet gates by

rotating so arrows point straight down

(B).

Pro Tip:

Save time by exchanging dirty

parts with clean spares and

washing and drying the dirty

parts later (in a dishwasher if

dishwasher-safe) then reusing

them during the next weekly

cleaning.

14

WEEKLY CLEANING PROCEDURE

PSL50 Series

Step 5: Clean drip tray

01

Remove drip tray.

05

02

Empty waste water.

Wash all parts under running

water and scrub any dried

coffee residue with a brush to

remove it. Dry all parts.

Reassemble in reverse order.

03

04

Remove cup shelf by gripping and Remove cup shelf grill by rotating up

rotating inside edge of shelf and away from support stem.

upward approx. 2cm then slide it

forward.

15

WEEKLY CLEANING PROCEDURE

PSL50 Series

Step 6: Clean interior, replace waste bin

Step 7: Replace drip tray, cup grill

01

02

01

02

Use mild kitchen detergent and damp Replace waste bin. Replace drip tray. Replace adjustable cup grill onto

cloth/sponge to remove any dried-on support stem.

coffee or ingredients on any of the

interior surfaces. Dry all damp surfaces

after cleaning.

16

WEEKLY CLEANING PROCEDURE

PSL50 Series

Step 8: Clean exterior, run Rinsing function, test functionality

01

02

03

Inspect interior of dispenser to

confirm all parts are replaced

properly and all tubes are routed

correctly.

04

Close and lock door. Clean

exterior painted and bare metal

panels and plastic and glass

surfaces with glass cleaner.

Make a test drink using as

many ingredients as

possible to confirm all parts

are reinstalled and working

correctly.

Run Rinsing function (see Daily Cleaning Procedure,

Step 1 for details if necessary). When finished, open

door and check for leaks.

Important!:

Making test drinks is a critical step to ensure that all parts have been reinstalled

correctly to ensure that the dispenser is fully functional for future users.

Pro Tip:

If the first test drink is not satisfactory try making one more test drink

using the same recipe then check it again. Due to handling, some

ingredients may not be settled and/or dispensed properly until after the

dispenser has cycled once or twice. If the second test drink is still

unsatisfactory, unlock and open the door and perform a visual

inspection to determine if any part has not been reinstalled correctly.

Make adjustments as necessary then try the test drink(s) again.

17

www.creminternational.co.uk

Table of contents

Other Crem Coffee Maker manuals