Crem ONE 1B VP User manual

ONE

UM_EN

Part No.: 1964195

Rev.: 07

User Manual

ONE

MANUAL REVISIONS 3

NOTIFICATIONS 4

· Explanation of descriptions 4

GENERAL INFORMATION 5

· Introduction 5

· General instructions 5

· Intended use 6

· Warning and Precautions 6

TRANSPORT 9

· Packaging 9

· Delivery inspection 9

STORAGE AND DISPOSAL 9

· Long-term storage requirements 9

· Machine disposal requirements 9

TECHNICAL SPECIFICATIONS 10

· Machine data 10

· Machine description 11

· Accessories 11

BUTTONS AND CONTROLS 12

· 1B Version 12

· 2B versions 12

INSTALLATION AND START UP 13

· Machine positioning 13

· Filling the water tank 13

· Mains water connection 14

· Hydraulic supply selection 14

· Optimal working range 14

· Water lter requirements 15

· Drain connection checklist 15

· Electrical connection checklist 16

· Initial starting procedure 16

· Machine handling tips 16

OPERATION 17

Inserting the portalter in the group 17

Espresso brewing 17

· Dispensing hot water 17

Steaming and frothing milk 17

CLEANING AND CARE 18

Daily cleaning – At the end of each working day be sure to: 18

Weekly cleaning or Periodical cleaning and care – Once per week be sure to: 18

Weekly cleaning with espresso machine 18

detergent 18

Cleaning reminders 18

USER PROGRAMMING 1B 19

· User interface 1B 19

2Original instructions.

CONTENTS

ONE

USER PROGRAMMING 2B 19

· Adjusting boiler temperature 19

· User Interface 2B 19

· Summary chart 20

· Barista menu - Access & browsing 20

· Gradual soft preinfusion (GSP) menu (Rotary pump versions only) 20

· Temperature adjustment 20

· ECO mode 21

· Heating element On/O 21

· Clock menu 21

· Auto On/O menu 22

· Shot timer adjustment 22

· Counters menu 22

· Temperature units 23

· Date format 23

· USB communication (LFPP version only) 23

· Barista knob resolution (LFPP version only) 23

PRESSURE PROFILING MENU 24

· Manual mode: Access 24

· Manual mode: Initial PP pressure 24

· Manual mode: Run the shot 24

· Manual mode: Save recipe 24

· Recipe mode: Choose recipe 25

· Recipe mode: Recipe graph information 25

· Recipe mode: Run the shot 25

MACHINE ALERTS 26

· Alarms & Warnings 26

TROUBLESHOOTING 27

· Machine faults 27

· Brewing faults 27

· Limescale faults 27

3

Original instructions.

CONTENTS

MANUAL REVISIONS

Rev. # Date TSB# Description

01 2019 / 07 / 25 - Release rst draft for technical review.

02 2019 / 10 / 28 - Add programming information.

03 2019 / 11 / 12 - Add compliance and certication notes.

04 2019 / 11 / 14 - Combine EU and US version information into single user manual.

05 2020 / 04 / 03 257 Software update. 1B (1.05) / 2B (1.09)

06 2020 / 04 / 27 - Filter installation instructions added

07 2022 / 08 / 26 411 Compliance updates.

Software update to 1.14 (TSB411).

ONE

4Original instructions.

· Explanation of descriptions

There are ve dierent levels of notication intensity within

this manual, as identied by the signal terms: DANGER,

WARNING, IMPORTANT, NOTE and PRO TIP. The level of risk and

importance of the notication is determined by the following

denitions. Always observe the warnings to ensure safety and

prevent potential injury and product damage.

Important:

Alerts against unsafe practices. Observe Important

notications to ensure food safety, prevent possible

minor personal injury, or damage to the machine.

WARNING:

Indicates a potentially hazardous situation which, if the

WARNING is ignored, could result in serious injury or

even death.

DANGER:

INDICATES AN IMMINENTLY HAZARDOUS SITUATION

WHICH, IF NOT AVOIDED, WILL LIKELY RESULT IN

SERIOUS INJURY AND EVEN DEATH.

Note:

Gives additional information which may be helpful

during the operation, routine maintenance, and

cleaning of the machine.

Pro Tip:

Gives helpful hints and suggestions from the

manufacturer that take the guesswork out of choosing

settings and care intervals.

i

NOTIFICATIONS

ONE

5

Original instructions.

· Introduction

Thank you for choosing the ONE espresso machine.

We hope you enjoy it !

This manual contains important instructions regarding safe intended

use of the machine.

Do not discard this manual, it will be useful for future reference.

If damaged or lost, request a new copy from the manufacturer/

distributor or download a free PDF copy via:

www.creminternational.com/downloads

· General instructions

Machine installation and certain maintenance operations must only be

performed by qualied service personnel.

All safety instructions and warnings contained in this manual must be

observed at all times to ensure safe installation, use, and maintenance.

Do not attempt to remove covers or safety shields to access the interior

of this machine or make repairs. Repairs must be made by an authorised

technician or service centre.

Owners are liable for ensuring that users have been properly trained to

operate the machine and understand the potential risks involved.

The owner or installer will be liable for all non-authorised modication of

the machine.Non-authorised alteration or modication of the machine will

immediately void the manufacturer’s warranty.

This manual references the machine at the time of sale. The commercial

availability of subsequent versions including modications, upgrades or

adaptations does not oblige the manufacturer to apply any changes to this

machine, nor is it obliged to update the documentation supplied.

The manufacturer reserves the right to withdraw currently available

manuals whenever deemed appropriate and reasonable.

Periodically, some updates and changes may be required for this machine.

In this event, a technician will be responsible for ensuring the change is

made in accord with manufacturer’s specications.

Note:

The manufacturer is not liable for damage to persons or property

resulting from failure to follow the instructions, warnings and precautions

listed in this manual when installing and using this machine.

GENERAL INFORMATION

ONE

6Original instructions.

· Intended use

· Warning and Precautions

The coffee machine has been designed and manufactured to make

espresso coffee and other hot drinks (e.g., steaming and frothing

milk). Do not use it for any other purpose.

The machine is intended to be used by trained personnel for

preparing foodstuffs.

This machine is not intended for use in industrial kitchens, domestic

kitchens, or similar locations.

The manufacturer will not be held liable for damage to persons

or property due to incorrect, improper or negligent use by

nonprofessional personnel.

The A-weighted sound pressure level is below 70 dB.

Install the machine in a location where these parameters will not be

exceeded:

- Maximum inlet water pressure: 0.6MPa (6 Bar) (87 psi).

- Minimum inlet water pressure: 0.1MPa (1 Bar) (14.5 psi)

- Maximum inlet water temperature: 25ºC (77ºF)

- Ambient temperature between +10ºC (40ºF) (min.) and +40ºC

(104ºF) (max.).

IMPORTANT SAFEGUARDS

When using electrical appliances, basic safety precautions must

always be followed, including the following:

Please read this user manual carefully before using the machine.

Install the machine in a horizontal position and away from heat

sources and flammable objects.

(US/CAN) Equipment is to be installed with adequate backflow

protection to comply with applicable federal, state and local codes.

Appliance is only to be installed in locations where its use

and maintenance is restricted to trained personnel. Access to

the service area is restricted to persons having knowledge and

practical experience of the appliance, in particular as far as

safety and hygiene are concerned.

This machine must only be installed on a water-resistant work

surface that is capable of adequately supporting the machine’s

weight.

GENERAL INFORMATION

ONE

7

Original instructions.

· Warning and Precautions

The appliance is not suitable for installation in an area where a

water jet could be used. This appliance must not be cleaned

with a water jet or a pressure washer.

The appliance is not suitable for outdoor use, where it would be

exposed to severe weather or extreme temperatures.

Use the inlet hose included with the machine to connect it to the

water mains in accordance with the national rules applicable in the

country where machine is installed. Never reuse damaged hoses.

The use of accessory attachments not recommended by the

appliance manufacturer may result in re, electric shock or injury

to persons.

Plug the machine into a properly installed, earth grounded

electrical outlet with line voltage that matches the specications

for the machine.

Always attach plug to appliance rst, then plug cord into the wall

outlet. To disconnect, turn any control to ″off″, then remove plug from

wall outlet.

For appliances not tted with a supply cord and a plug, means for

disconnection must be incorporated in the xed wiring in accordance

with the wiring rules.

Ensure that the power supply voltage does not fluctuate by more than

6%.

Do not let power cord hang over edge of table or counter, or touch

hot surfaces. To reduce the risk of injury, do not drape cord over the

counter top or table top, where it can be pulled on or tripped over

unintentionally by children or users.

Do not remove or disable any of the mechanical, electrical, or thermal

protection safety equipment.

If supply cord is damaged, it must be replaced by the manufacturer, its

service agent or similarly qualied persons in order to avoid a hazard.

In case of emergency, (e.g., the machine catches re or becomes

unusually hot or noisy), disconnect the power immediately and turn

off the water supply.

If the machine is not going to be used for an extended period of time,

disconnect the power. When disconnecting the power, pull the plug

rather than the cable.

Keep all hazardous packaging materials, such as plastic bags,

styrofoam, and staples, out of reach of children.

Before performing maintenance and/or moving the machine,

disconnect the machine from the power supply and wait for it to cool

down.

GENERAL INFORMATION

ONE

8Original instructions.

· Warning and Precautions

To ensure fault-free machine operation, only use manufacturer-

approved replacement parts and accessories.

When packed for storage, store the machine in a dry place with an

ambient temperature above 5ºC (41ºF). Boxes may be stacked up to three units

high of the same model. Do not place other heavy items on top of the box.

If the machine is likely to be exposed to temperatures below 0ºC (32ºF) during

handling and transport, make sure that service personnel empty the boiler and

water system. (The machine’s boiler and water system are empty when delivered

from the factory.)

To protect against fire, electric shock and injury to persons do not

immerse power cord or plugs in water or other liquid.

Place the machine out of reach of children.

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible

for their safety.

Children must be supervised so to ensure that they do not play with the

appliance.

Note: safety regulation not valid for Europe.

Specific safety regulation for Europe:

This appliance can be used by children aged from 8 years and above

and persons with reduced physical, sensory or mental capabilities or

lack of experience and knowledge if they have been given

supervision or instruction concerning use of the appliance in a safe

way and understand the hazards involved. Children shall not play

with the appliance. Cleaning and user maintenance shall not be

made by children without supervision.

Do not use the machine if the power cable or plug is damaged,

or the machine has been dropped. Contact a service technician for

repairs or to ensure that it is safe for use.

Do not place any liquids on the machine.

Do not touch the machine’s hot surfaces or dispensing equipment.

Use handles or knobs.

Do not touch the machine if your hands or feet are wet.

Do not operate the machine if any part except the dispensing

equipment is wet.

Do not block the vents with rags or other objects.

Do not insert foreign objects into the vents.

Check the drain regularly to make sure that waste water is emptying properly.

SAVE THESE INSTRUCTIONS

GENERAL INFORMATION

ONE

9

Original instructions.

· Packaging

The machine is shipped in a custom-designed carton which utilizes model-specic polystyrene

cushions to protect it from damage.

The machine’s carton features standardized handling symbols to explain proper shipping and storage methods.

The machine must remain in a horizontal position during the transport. Do not store or handle the machine except on its feet.

During transport protect the carton and machine from impact drops, crushing, shocks, moisture and exposure to extreme

temperature.

· Delivery inspection

Upon receipt and delivery ensure that the machine is in the exact condition described in the enclosed documentation, and that

all accessories are included. Missing items should be reported to the manufacturer or dealer immediately.

Damage caused during transport should be reported to the shipping agent and the machine’s distributor immediately.

Packaging materials are potentially dangerous and should be kept away from children.

The carton and all packing materials are recyclable and should be returned to a recycling centre

for disposal.

TRANSPORT

· Long-term storage requirements

Before storage for a month or more be sure to:

•Perform all weekly and periodic cleaning procedures described in this manual.

• Disconnect and roll up the power cord (this should be performed by a qualied person).

•Disconnect the machine’s water inlet hose from the domestic water supply and drain the boilers (this should be performed by a

qualied person).

• Clean the drip tray and exterior of the machine to remove any coee or other residue.

•Cover / re-pack the machine in its original carton and store it in a dry place where it will not be exposed to extreme

temperatures or humidity.

•When returning the machine to service after long-term storage, perform all weekly and periodic cleaning procedures and

reconnect the water and power supplies (this should be performed by a qualied person) before use.

STORAGE AND DISPOSAL

· Machine disposal requirements

If the machine ever needs to be scrapped and disposed of be sure to:

•Disconnect and roll up the power cord (this should be performed by a qualied person).

• Disconnect the machine’s water inlet hose from the domestic water supply and drain the boilers (this

should be performed by a qualied person).

•Pack up and ship/deliver the machine to a certied recycling centre.

Plug Region Part No. Description

Type F 16A EU/KO 160570 Power_Cord_1PhN_16A_Type_F

Nema 6-20P US/CAN 6165278 Power_Cord_UL_C19_Nema6-20P

Type G 13A UK 1605002 Power_Cord_1PhN_13A_Type_G

Type I 10A Aus 1605674 Power_Cord_1PhN_10A_Type_I

Nema 6-20P China 1605001 Power_Cord_UL_C19_Nema6-20P

List of original detachable power cord by plug type:

· Caution

• Risk of re and electric shock.

• Replace only with manufacturer’s

original cord set.

• Disconnect from power supply

before servicing.

ONE

10 Original instructions.

· Machine data

ONE Compliance codes Machine ID Dispensing

Control

System

Boiler

System

Group

Boiler

Volume

Machine

Weight Power Rating

ONE 1B

VP EAEB-I91F-13AP CREM8091

(AUS/UK/IL/CH) Manual Group

lever

1 steam boiler - 30 kg

66 lb

220-240V~

50-60Hz 1950W

ONE 2B

VP EEEB-I91F-13AP CREM8092

(AUS/UK/IL/CH)

Dual boiler:

1 steam boiler

+ 1 group boiler

1.5L

0.40 gal. 35 kg

77 lb

ONE 2B

RP-GSP EEEB-I91G-13AP CREM8093

(AUS/UK/IL/CH) Manual Group

lever + GSP

ONE 2B

RP-LFPP EEEB-I94G-13AP CREM8094

(AUS/UK/IL/CH/

KC)

Manual Group

lever

+ GSP + LFPP

All

versions:

Temperature control: PID Control

Steam wand: x1

Hot water outlet: x1

Boiler operating pressure: 0.8 to 1.3 bar / 12-19 psi

Steam boiler volume: 1.7L / 0.45 gal.

Water connection: 3/8” BSPP Internal thread

Ambient noise: < 70 db

ONE Compliance codes Machine ID Dispensing

Control

System

Boiler

System

Group

Boiler

Volume

Machine

Weight Power Rating

ONE 1B

VP EAJB-K91F-13BP

Commercial:

CREM8091US

*Domestic:

CREM8091DUS Manual Group

lever

1 steam boiler - 30 kg

66 lb

Commercial:

110-127V~

50-60Hz 1300W

*Domestic:

110-127V~

50-60Hz 1400W

ONE 2B

VP EEJB-K91F-13BP

Commercial:

CREM8092US

*Domestic:

CREM8092DUS

Dual boiler:

1 steam boiler

+ 1 group boiler

1.5L

0.40 gal. 35 kg

77 lb

Commercial:

110-127V~

50-60Hz 1300W

*Domestic:

110-127V~

50-60Hz 1400W

ONE 2B

RP-GSP EEJB-K91G-13BP

Commercial:

CREM8093US

*Domestic:

CREM8093DUS

Manual Group

lever + GSP

Commercial:

110-127V~

50-60Hz 1300W

*Domestic:

110-127V~

50-60Hz 1400W

ONE 2B

RP-LFPP EEJB-K94G-13BP

Commercial:

CREM8094US

*Domestic:

CREM8094DUS

Manual Group

lever

+ GSP + LFPP

Commercial:

110-127V~

50-60Hz 1300W

*Domestic:

110-127V~

50-60Hz 1400W

TECHNICAL SPECIFICATIONS

* Domestic models: For household use only

ONE

A

1 12

11

10

9

14

6

4

2

3

13

B1

B2

C

D1 / D2

8

7

A

7 gr

(0.25oz)

14 gr

(0.5oz)

18 gr

(0.64oz)

A

B

C

D

E

F

G

H

I

J

K

L

11

Original instructions.

· Accessories

UNITS For 1B versions For 2B versions

(A) 2-spouts porta lter x1 x1

(B) Filter basket 7 & 14 Gr x1 x1

(C) Filter blind x1 x1

(D) Brush x1 x1

(E) Cleaning tablets x1 x1

(F) Water tank lter x1 x1

(G) Drain Hose x1 x1

(H) Water Hose x1 x1

(I) Filter basket 18 Gr - x1

(J) Tamper - x1

(K) Extra steam nozzle - x1

(L) Milk Jar - x1

TECHNICAL SPECIFICATIONS

· Machine description

Pos Description

9 Brewing lever

10 Hot water tap

11 Hot water knob

12 Digital display (1B version)

12.1 OLED display (2B versions)

13 Water connection selector

(US versions only)

14 Pressure proling knob

(2B PID R-LFPP versions only)

Pos Description

1 Water tank lid

2 Steam knob

3 Power switch

4 Steam wand

5 Brewing group

6 Double pressure gauge

7 Drip tray

8 Drain connection

Length A B1 B2 C D1 D2

mm 420 300 311 458 88 102

inch 17 12 12 18 3 4

ONE

1 2

K2

K1

K3 K4

K2

K1

12 Original instructions.

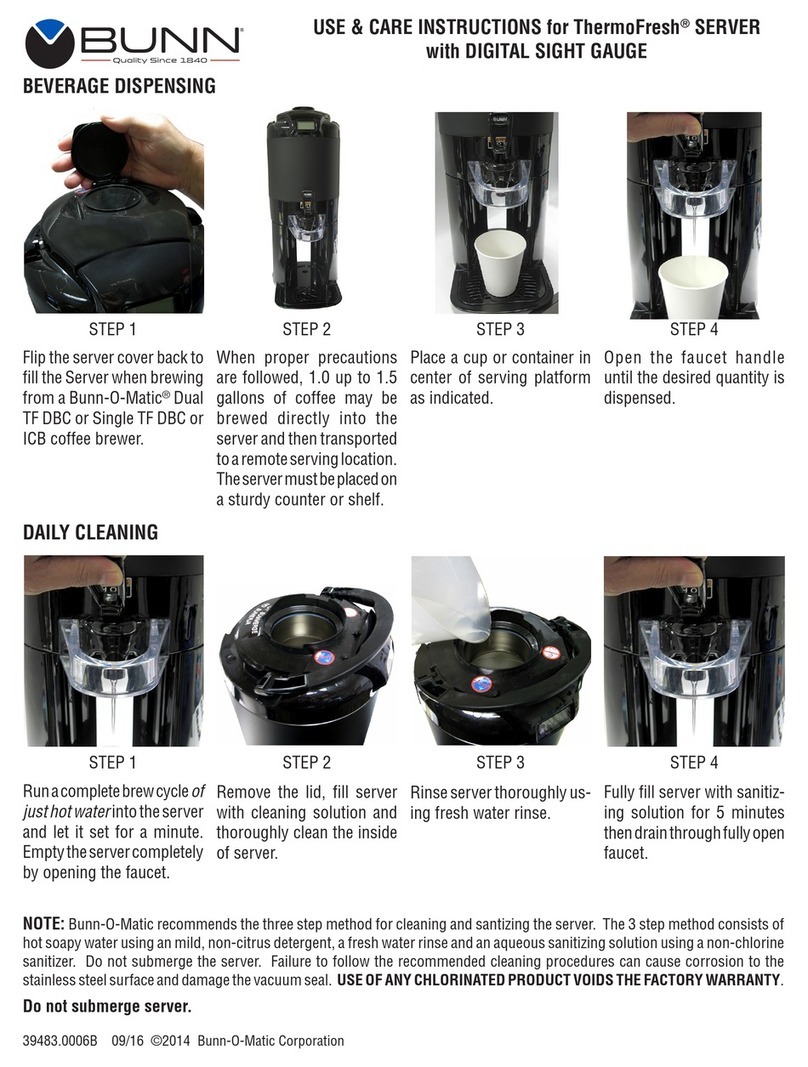

ONE 1B Dual is controlled by a combination of manual control knobs, buttons and a brewing lever

for dispensing.

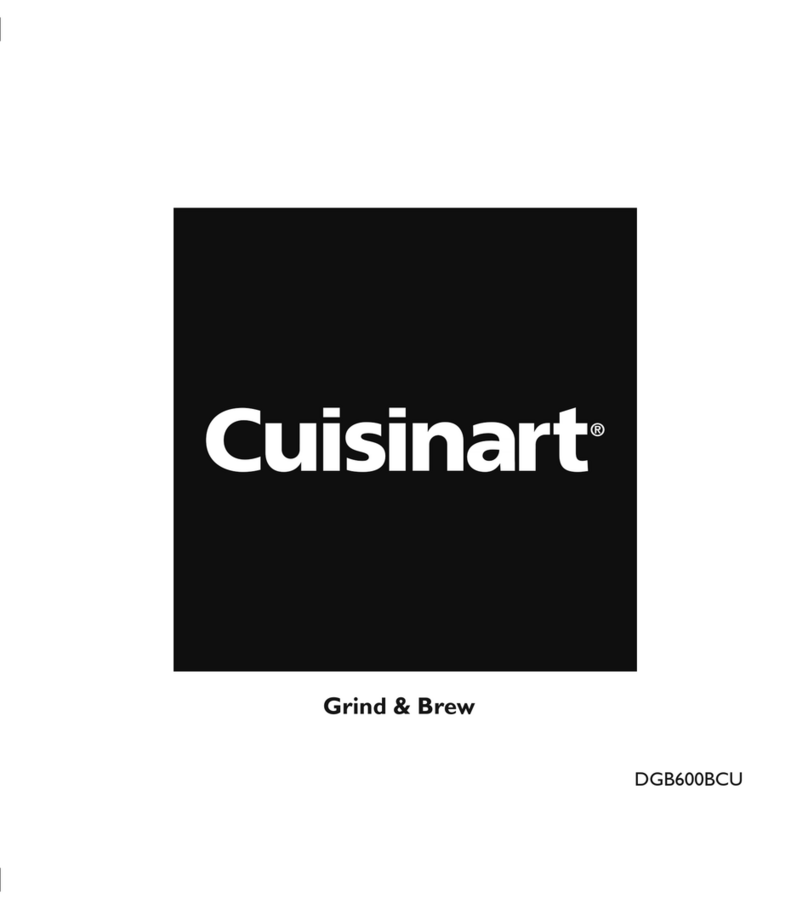

All ONE 2B verions is controlled by a combination of manual control knobs, buttons and a brewing lever for dispensing. 2B LFPP is

also equiped with a pressure proling knob.

4 buttons

OLED display

Shot timer

Temperature

1. Tank empty / rell signal

2. Heating signal

Shot timer

Temperature

Volume (2B LFPP)

Heating

Tank empty/rell

Several alarms

K1. Standby mode

K2. Barista menu (Advanced settings)

K3. Eco-Mode

This machine features a group display for monitoring o:

This machine features a OLED display for monitoring o:

Pressure proling knob

(Only 2B LFPP model)

· 1B Version

· 2B versions

BUTTONS AND CONTROLS

Digital

display

2 buttons

ONE

13

Original instructions.

MIN. 10 cm /4 in.

MIN. 30 cm /

12 in.

Install within 0-3º horizontal.

· Machine positioning

DANGER: Avoid spills inside the machine, always turn the machine o

when relling the tank. If spills occur, turn the machine o and unplug

the power supply until the machine is completely dry to avoid RISK OF

SHOCKS.

Note:For water quality specs,

please refer to ’Water ltration

requirements’

Note:The machine has a position

switch that blocks all functions if

the tank is out of position.

Note:The machine has a capacitive sensor that detects when the tank is

empty. Therefore, the water tank should only be removed and relled when

espresso is not being brewed.

i

i

i

Option 1:

• Remove the top panel/cup warming tray.

• Remove the water tank.

• Fill the tank with clean, fresh drinking water (max.

volume = 1.8L / 0.48 gal.).

• Replace the water tank in the machine.

• Replace the top panel/cup warming tray.

• When the boiler is lled and heated, the machine is

ready for use.

Option 2:

• Remove the top panel/cup warming tray.

• Using a pitcher, carefully ll the tank with clean, fresh

drinking water (max. volume = 1.8L / 0.48 gal.). Avoid

spills inside the machine.

• Replace the top panel/cup warming tray.

• When the boiler is lled and heated, the machine is

ready for use.

· Filling the water tank

INSTALLATION AND START UP

1. Installing the machine in the service area must be performed by a qualied person.

As the machine may be quite heavy, at least two strong, capable individuals are

recommend to work together to lift and position the machine. Consult the Technical

Specications page for the specic machine model being installed for machine

weight and dimensions details. Contact a service technician to do this task if you are

not condent about performing the steps below.

2. Position the machine on a level, sturdy, and water-resistant surface approximately

110cm (43 inch) above oor level for ease of access and usage.

3. Adjust the feet to ensure that it dispenses coee evenly to all cups.

4. Ensure enough free space is available above (>30cm / >12inch) and behind (>10cm

/ 3.94 inch) the machine to ensure easy cleaning and maintenance and adequate

ventilation.

Important: Leave an air gap of at least 30cm (11.8 inch) above the machine and 10cm (3,94 inch) behind it to ensure

adequate ventilation. The machine must be installed on a level surface from front-to-back and side-to-side to ensure

proper hydraulic function and drainage. Conrm with a spirit level or digital angle gauge. Do not install the machine if the

machine or installation surface it is wet. Allow it to dry completely and ask a service technician to ensure that none of the

electrical components have been aected.

ONE

TANK

TAP

Water Supply Selector

14 Original instructions.

Important: To prevent limescale build up in the

boiler and other components, a water-softening

system must be installed in-line ahead of the

machine. Read more on section for water lter

requirements.

Important: Use the inlet hose included with the

machine to connect it to the water mains in accordance

with the national rules applicable in the country where

machine is installed. Never reuse damaged hoses

The default water supply mode parameter in the technical programming menu is set to use the machine in Tank mode.

Water supply mode must be adjusted once the machine is intented to be used plumbed:

- Dual mode (Not In US): Automatic water reservoir relling enabled if the machine is plumbed.

- Tank mode: Automatic water reservoir relling disabled. Water reservoir supply only.

- Net mode (US only): Plumbed mode only. Intended for machines with water supply selector.

Programming instructions available on Service Manual.

For specic US models:

This models have a manual selector located at the bottom of the machine that must be set manually if the machine is plumbed.

· Hydraulic supply selection

After the machine is connected of disconnected from the water mains, follow instructions of 'Hydraulic supply selection' section to

set up the machine accordingly.

Important: Machines equipped with the water inlet selector tap are

intended to work on ‘TANK’ (pour over) position or ’TAP’ (plumbed)

position. The automatic water reservoir dual function is not available on

these models and it will work like TANK ONLY’.

INSTALLATION AND START UP

1. Connecting the machine to the domestic water supply must be performed by a qualied person. Contact a service

technician to do this task you are not condent about performing the steps below.

2. Attach the included water inlet hose to the back of the machine and torque both ttings with a wrench (3/4" BSPP elbow

end to machine, straight end to 3/8" BSPP mains).

3. Purge at least 20 liters of water from the domestic water supply before connecting the machine to it to ush out any

debris that may be in the plumbing system that would otherwise accumulate inside the boilers.

4. The domestic plumbing system should be tted with a brass 3/8” BSPP male pipe tting and an in-line shut-o valve.

Connect the 180cm water inlet hose included with the machine to the domestic water supply and tighten the line ttings

with a wrench to 15 ft. lbs. / 20N-m.

· Mains water connection

Note: For a suitable performance of the machine, maximum inlet water pressure must be 0.6 MPa (6 Bar) (87 psi). For

Norway, Sweden, Finland and Denmark, where the net pressure can reach 1.0MPa (10 Bar), install a pressure reducer in

case water pressure exceeds this range.

i

Pro Tip: Signicantly exceeding this operating range will result in excessive steam, high energy usage, unexpected

emergency machine shutdown due to safety valve activation and possibly premature machine failure. Setting the

temperature too low will resulting poor coee extraction, slow group boiler heating, and low/no steam.

· Optimal working range

1B models 2B models

Steam Boiler 116ºC to 122ºC / 0.8 bar to 1.3 bar

241ºF to 252ºF / 116 psi to 189 psi

Group Boiler N/A 88ºC to 96ºC

190ºF to 205ºF

ONE

15

Original instructions.

Filter.

Part no:

6163022

A ltration device is provided with the accesories of the machine to be installed inside the tank.

For 1st use:

- Take the reservoir out of the machine. Fill it with cold water and immerse the lter for 2 min. Put the lter

upwards to ensure that no air is trapped inside.

- Empty the tank and t the lter inside the reservoir bottom valve. Push down to lock into place.

- Fill the reservoir again with cold water before placing it in position inside the machine.

- Set the reminder on top of the lter for replacement. Recommended each 2 months.

Important:Always maintain the water ltration device or system in accordance with the manufacture’s specications.

Failure to routinely maintain the ltration device or system will result in limescale build-up inside the machine’s hydraulic

system which will eventually result in machine failure. Please read more under the cleaning and care section.

Internal ltration device (Water tank supply)

External ltration device (Water mains supply)

1. Ensure that a water ltration device or system is installed in-line in the domestic water supply ahead the machine to prevent

contamination inside the machine’s hydraulic system. Contact a service technician to do this task if you are not condent about

performing the steps below.

2. Open the water tap and allow the lter to ll (if new/previously unused). Then the machine’s steam boiler will begin to ll. Check

carefully around the service area for leaks or drips. If leaks/drips are detected turn o the tap immediately and check/

tighten any leaking ttings.

Only use safe drinking water with a hardness rating between the parameters on the following table. If the hardness value is below

this limit, corrosion of hydraulic components is likely. If the value is higher, lime-scaling inside the boiler will occur. In both cases,

the proper function of the machine and quality and taste of the coee will be negatively aected.

If drinking water is not within the ratings shown above, a water lter must be installed inline ahead of the espresso machine.

Failure to install a water lter will result in voiding of the warranty and any damage resulting from limescale buildup will be the

responsibility of the owner.

· Water lter requirements

Important:Reservoir with lter must be fed only with unsoftened cold potable water.

Water of unsafe or unknown microbiological quality may not be used.

Value French Hardness German Hardness T.D.S.

Range 5-8 ºfH 3-5 ºdH 90-150 ppm

INSTALLATION AND START UP

1. Connect one end of the exible drain tube to the drain cup outlet.

(It is located under the machine. Contact a service technician to do

this task (if you are unsure how to access this area of the machine).

2. Connecttheotherendofthedraintubetothedomesticplumbingdrainage

system in the service area.

3. Removethescrewofthe drainholeat thebottomof thedriptray and

replace/reinstall it with the grill.

Pro Tip: Ensure that the drainage tube is not twisted and

that it is below the level of the drain cup to prevent

trapping water and other residue in the tube which could

mold or produce bad smells. Adjust the height of the

machine with the feet if needed.

WARNING!: Some models are equipped with boiler

drainage. Emptying the boiler must be performed by

qualied personnel.

· Drain connection checklist

Flexible drain tube Drain cup

ONE

16 Original instructions.

DANGER!: If supply cord is damaged, it must be replaced

by the manufacturer, its service agent or similarly qualied

persons in order to avoid a hazard and SERIOUS INJURY OR

DEATH!

1. The machine should only be connected to the power supply by qualied personnel. The following safety instructions should be

obeyed at all times.

2. EnsurethattheelectricalrequirementsstatedontheTECHNICALSPECIFICATIONSandontheratingsplatelocatedunderthedriptray

inside the machine match the specications of the power supply.

3. Ensure that the domestic electrical supply where the machine is being installed is rated for and able to provide the power

required by the machine. Insucient power supply, wiring, grounding, or insulation can result in overheating and

possibility of re.

4. The coee machine must be connected to an earth grounded electrical outlet that complies with the regulations in force in the

country of installation.

5. Ensurethatacircuitbreakerengineeredforthepowerconsumptionofthemachineisinstalledtoprotecttheelectricalsupply,

as specied on the ratings plate located under the drip tray.

6. Never connect the machine to the power supply via extension cords, plug adapters, or shared outlets.

· Electrical connection checklist

Machine: Machine:230Vac Ph+N 115Vac Ph+N

Blue

Brown NEUTRAL

PHASE

Yellow/Green

Supply cable

Blue

Brown NEUTRAL

PHASE

Yellow/Green

Supply cable

INSTALLATION AND START UP

Important: The manufacturer will not be held

liable for damage to persons, animals or property

resulting from incorrect installation of the coee

machine.

After carry out the machine installation, follow the next steps for the rst start up:

1. Ensure the machine’s tank is full of water or domestic water supply is opened at the tap. For the rst installation is

recommended to rell the water tank manually.

2. Open the steam tap and turn the main power switch on. The machine will rell automatically the steam boiler rst (you will hear

the pump working).

3. The pump will stop when the steam boiler is completely lled. Close the steam tap.

3a. On 1B versions, when the heating signal lits up, pull the group lever up until water starts to brew in the group head.

Then, pull the lever down and wait until the heating signal turns o.

3b. On 2B versions, a 1st installation routine is enabled by software. So, the machine will require to pull the group lever

up by showing the icon (g. 1) on the display. A 90s countdown will start to rell the group boiler. Ensure that water is

coming out of the group head when the countdown arrives to 0. Now the heating process will start. Wait until both boilers

are heated up.

4. Open the steam tap to ensure that it is working and release the air inside the boiler.

5. Check again if water tank needs to be relled and proceed to operate with the machine.

Do not place wet cups directly on the cup shelf. Always thoroughly dry any cups

before storing them on the warming shelf.

WARNING!:Allowing water to drip into the machine can cause mechanical

and electrical damage.

· Initial starting procedure

· Machine handling tips

ONE 2B 1st start up group boiler rell icon

ONE

17

Original instructions.

1. Placeapitcher(orotherheatresistantvessel)underthe

hot water outlet.

2. Open the tap.

3. When the desired amount of hot water is dispensed,

close.

WARNING!: Never place hands and ngers directly

under the hot water outlet during dispensing to avoid

scalding or serious burns.

· Dispensing hot water

OPERATION

Inserting the portalter in the group

Group gasket is

worn out and

needs to be

replaced.

Align the portalter's two

anges with the two slots in the

group housing.

Insert the portalter and rotate it counterclockwise

until the handle is approximately perpendicular to

the face of the coee machine.

Installed

correctly.

Espresso brewing

1. Unlock and remove the portalter from the group head.

2. Fill the lter basket with espresso-grind coee (approx. 7g for single or 14g for a double espresso).

3. Compact the coee.

4. Insert the lled portalter into the group head and lock it into the correct position.

5. Place the cup(s) under the portalter.

6. Pull up the group lever to begin brewing.

WARNING!: Never try to open the portalter while the

machine is in operation! The pressurised hot water could

cause scalding or serious injury. After dispensing has nished,

wait at least 3 seconds before removing the portalter.

Pro Tip: When not in use store the portalter

inserted in the group to keep it warm. This is

important to maintain optimal brewing temperature

while the espresso is dispensing.

Steaming and frothing milk

1. Place the steam wand over the drip tray and open the steam

knob/handle for a few seconds to allow condensed water to

be ejected. Close the steam knob/handle when only steam is

coming out.

2. Immerse the steam wand into the milk, making sure the wand

tip is submerged. Open the steam knob/handle again to begin

steaming or frothing the milk. Always keep the tip of the steam

wand submerged in the milk while steaming!

3. Once the milk reaches the desired temperature, close the

knob/handle and wait for the steaming to stop, then remove

the pitcher.

4. After steaming/frothing is nished, position the steam wand

over the drip tray and open the steam knob/handle again for

a few seconds to purge any milk remaining in the wand. Then

wipe down the outside of the steam wand with a damp cloth

to prevent nozzle blockage and to keep it clean.

WARNING! Do not remove the pitcher or allow

the steam wand to extend out of the milk while

steaming/frothing, it may cause serious burns and

injuries.

Frothing

Steaming

ONE

18 Original instructions.

Daily cleaning – At the end of each working day be sure to:

Steam and Hot

Water

1. Position the steam wand over the drip tray and open the steam tap for one minute to fully ush the

wand. Repeat for each steam wand.

2. Clean the steam wand and the water tap. Be sure that the nozzles are not clogged or partially blocked

with milk or other residue. If it’s necessary to remove them for cleaning, be careful not to deform or dam-

age any of the components during removal.

Group Head and

Portalters

1. Clean the shower plate and the group gasket with a soft brush to remove and coee residue.

2. Run the ushing cycle for each group at the end of each day to prevent coee residue drying and build-

ing up inside the brewing groups.

Drip Tray &

Bodyworks

1. Clean the external surfaces of the machine, paying special attention to the glass and stainless steel parts

to remove any coee residue and smudges and ngerprints.

2. Clean the drip tray and the stainless steel insert grid under running water.

Daily ushing

1. Place the blind lter in the emptied portalter, then lock the portalter into the brewing group.

2. Pull up the group lever and keep the pump working for 10 sec and stop 5 sec. Repeat at least 5 times.

3. After cleaning, remember to remove the blind lter and store it in a safe place for the next usage.

4. Clean the internal side of the portalter before replacing the espresso lter. If needed, let the portalter

soak into warm water or use cleaning detergent for espresso machines.

WARNING!: Do not open the group or remove the portalter until the cleaning has nished! This will

release steam and hot water which could result in burns.

Weekly cleaning or Periodical cleaning and care – Once per week be sure to:

Group Head Run the cleaning cycle for each group at the end of each week to thoroughly clean the group head, shower

plate and portalter to ensure great coee taste. See Weekly cleaning with espresso machine detergent

section for details.

Drain Hose If the drain hose is installed, clean the drain cup by slowly pouring one liter of warm water into it to

dissolve and remove any build-up of coee residue that often accumulates inside the drain cup and tube.

Tank Remove and clean the water tank with detergent and a soft brush if needed. Rinse properly.

Water Tank Filter

The water tank lter must be replaced when the expiration date is reached (2 months since installation).

Use the following steps to recharge your water softener.

1. Switch the machine o and remove the top panel/cup warming tray.

2. Remove the lter from the tank and install the new one. (follow instructions from "Water lter

requirements" section.

3. Replace the top panel/cup warming tray and switch the machine on.

Water mains

lter

If an external softener is installed, follow and perform the maintenance instructions and respect the

replacing or recharging periods described by the manufacturer.

Weekly cleaning

with espresso

machine

detergent

1. Place the blind lter in the emptied portalter, add espresso detergent in the blind lter, then lock the

portalter into the brewing group.

2. Pull up the group lever and keep the pump working for 10 sec and stop 5 sec. Repeat at least 5 times.

3. After cleaning, with detergent, the group needs to be ushed. So repeat the process 2 more times to ush

out any remaining detergent. Then remove the blind lter and store it in a safe place for the next usage.

Pro Tip: Run the cleaning cycle for each group at the end of each week to thoroughly clean the group

head, shower plate and portalter to ensure great coee taste.

Professional espresso machine detergent. Part no: 1104171

Cleaning reminders

To keep the machine looking and working like new, always follow all the cleaning and care instructions provided in this manual.

For safety always turn the machine o at the main power switch when cleaning the exterior surfaces.

All exterior surfaces must be cleaned with a damp, lint-free cloth that will not scratch the machine, glass surfaces can be cleaned

with a streak-free glass cleaner and a dry cloth.

Do not use aggressive cleaning detergents, solvents or degreasers. These may damage the plastic and rubber parts, and will

leave unwanted residue

WARNING!: Do not open the group or

remove the portalter until the cleaning has

nished! This will release steam and hot water

which could result in burns.

Pro Tip: To adjust the service alarms ( ),

please go to the Service Manual.

(QR Cove page)

CLEANING AND CARE

ONE

K3 K4

K2

K1

L1 L2

K2

K1

19

Original instructions.

The machine is equipped a programmable interface that allows users to set or adjust the following features and parameters with

guidance from the digital display.

Use the following steps to adjust the boiler temperature:

Press the K3 for 5 seconds untill ’t1’ is shown on group display.

Within 5 seconds, press K2 or K3 to increase or decrease the programmed temperature.

When the desired temperature is adjusted, just wait 5s until the display shows ’t1’ again.

Then you can turn the machine o and on again, or wait 5s to come back to main screen.

Selection buttons K2 - K3

· User interface 1B

· Adjusting boiler temperature

USER PROGRAMMING 2B

USER PROGRAMMING 1B

The ONE 2B machines are equipped with a programmable ’Barista’ interface that allows users to set or adjust the following

features and parameters with guidance from the digital display:

Power o/on (without using the main switch).

GSP (Gradual Soft Preinfusion) settings. (Rotary Pump versions only).

Adjust the steam and group boiler temperatures.

ECO & Stand-by mode settings (set up energy saving mode timers).

Heating elements On/O.

Clock and Date settings (adjust current time and date).

Shot screen time.

Counters (volume of water cycled, service intervals, and number of coees dispensed, etc.).

Temperature units

Date format

USB interface (LFPP version only)

Barista knob resolution (LFPP version only)

· User Interface 2B

Selection buttons K1 - K2 - K3 - K4

ONE

20 Original instructions.

To access to the Barista menu, just press K2 (gure 1).

Then you can browse through the menu using the buttons K1 & K2 (gure 2 & gure 3).

Press home icon (gure 4) to come back to idle screen.

The icons of each parameter will be shown on the down side of the display and you can access by using K3 & K4.

· Barista menu - Access & browsing

On Barista menu, access to GSP (gure 5) settings.

GSP allows to select the preinfusion time while the machine gradually increases the pump pressure up

to the adjusted brewing pressure.

When activated, choose the GSP time between 2 to 30 sec. Default setting 2 sec.

Use the arrows (gure 6 & 7) to adjust each setting. Then use the icon (gure 8) to conrm.

· Gradual soft preinfusion (GSP) menu (Rotary pump versions only)

Figure Icon

1

2

3

4

Figure Icon

5

6▲

7▼

8

USER PROGRAMMING 2B

On Barista menu, access to Temperature (gure 9) settings.

Use the following steps to adjust the main steam boiler and group boiler temperatures individually:

Group boiler (gure 10): Set temperature of the group boiler

Steam boiler (gure 11): Set temperature of the steam boiler

Use the arrows (gure 6 & 7) to adjust each setting. Then use the icon (gure 8) to conrm.

Pro Tip: Depending on the types/proles of coee typically brewed, it may be useful to set a dierent

temperature on the group boiler to extract the very best avour from each espresso.

· Temperature adjustment

Figure Icon

9

10

11

6▲

7▼

8

Figure Icon Description

1 Barista Menu

2 Arrow (left)

3 Arrow (right)

4 Home screen

5 Preinfusion

6 ▲Arrow (up)

7 ▼Arrow (down)

8 Enter / Conrm button

9 Temperature settings

10 Group Boiler

11 Steam Boiler

12 ECO-mode (energy saver)

13 Stand-by mode

14 Heating element enabled

15 Heating element disabled

16 Clock settings

Figure Icon Description

17 Time scheduling

18 Turn o

19 Disable

20 Enable

21 Shot screen timer

22 Counter menu

23 001 Total Counters

24 Cleaning/Service counters

25 Reset partial counters

26 Temperature units (Cº) or (Fº)

27 Date format menu

28 USB communication

29 Import logo

30 Import recipe

31 Export recipe

32 Barista knob resolution

· Summary chart

This manual suits for next models

3

Table of contents

Other Crem Coffee Maker manuals