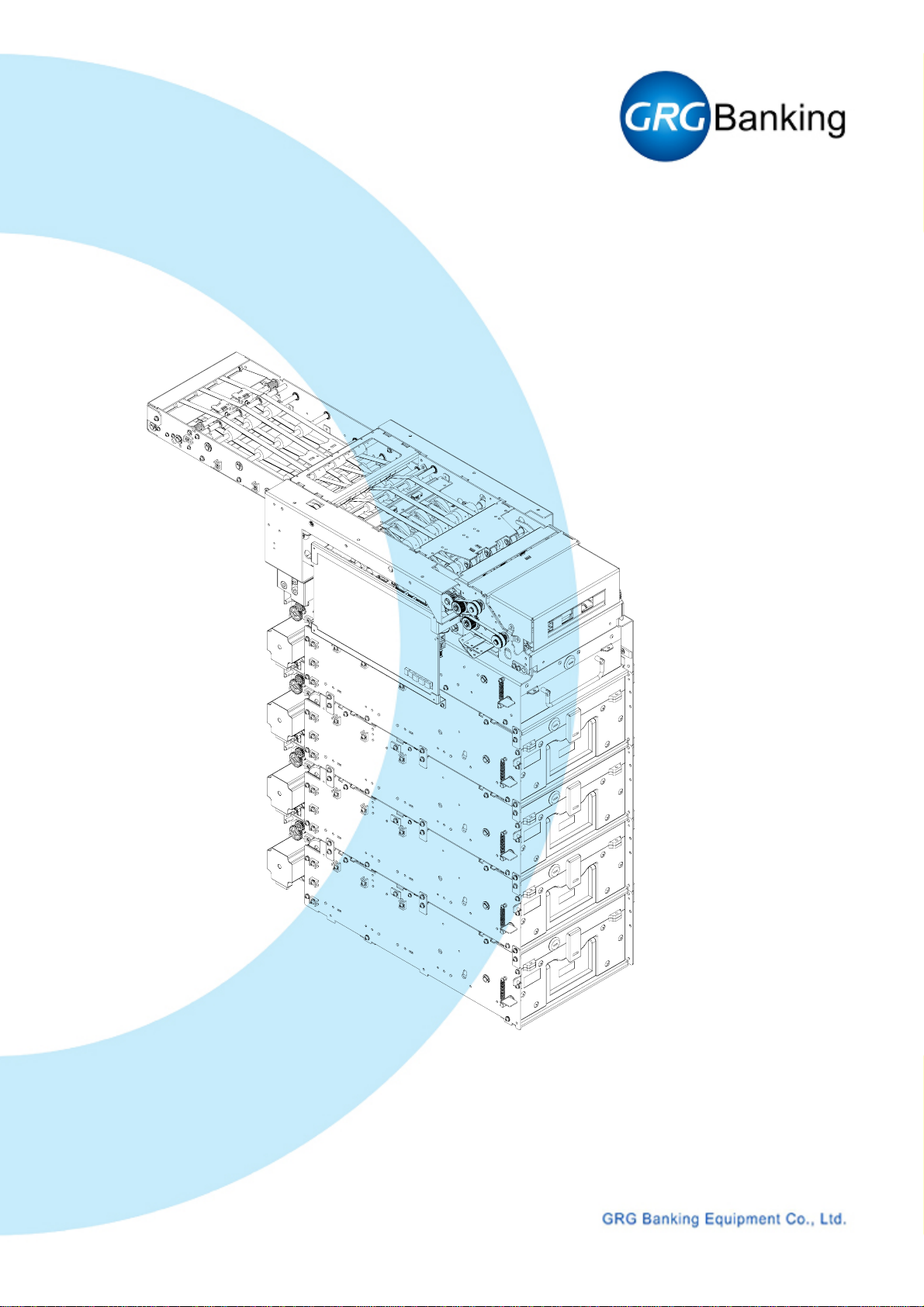

CRG CDM8240 User manual

Service Manual

CDM8240

(Level 2)

SN:YT2.291.036WHSC-JX2

Version:v1.0

Released date:2009-06-25

YT2.291.036WHSC-JX2

Revision Record

Version Date Page Description

V1.0 Jun. 2009 All Initial release

CDM8240 Sevice manual(Level 2) page i of iv

YT2.291.036WHSC-JX2

Contents

1NOTE FEEDER...............................................................................1

1.1 TOOLS................................................................................................................2

1.1.1 Standard service tools

..................................................................................2

1.1.2 Cleaning tools

..............................................................................................2

1.2 DISMOUNTING PARTS.............................................................................................3

1.2.1 Removing the note feeder

.............................................................................3

1.2.2 Removal of outter transport assembly

............................................................3

1.2.3 Removal of localizer, eccentric cam and eccentric cam fork

.............................4

1.2.4 Removal of counter rotating roller (CRR) assembly

.........................................4

1.2.5 Removal of upper transport assembly

............................................................5

1.2.6 Removal of lower transport assembly

............................................................6

1.2.7 Removal of pick motor

..................................................................................7

1.2.8 Removal of pick and separate assembly

........................................................8

1.2.9 Removal of gear and timing pulley

.................................................................9

1.2.10 Removal of transport shaft assembly

...........................................................10

1.3 REPLACING PARTS ..............................................................................................11

1.3.1 Replacement of gear and timing pulley

........................................................11

1.3.2 Replacement of pick motor

.........................................................................12

1.3.3 Replacement of CRR

.................................................................................13

1.3.4 Replacement of CRR guide plate

................................................................16

1.3.5 Replacement of elastomer assembly

...........................................................16

1.3.6 Replacement of pick and separate assembly

................................................17

1.3.7 Replacement of acceleration roller

...............................................................17

1.4 NF CLEANING ITEM..............................................................................................18

2NOTE CASSETTE.........................................................................19

2.1 TOOLS..............................................................................................................20

2.1.1 Standard service tools

................................................................................20

2.2 DISMOUNTING AND REPLACING PARTS.....................................................................20

2.2.1 Replacement of cassette ID magnet

............................................................20

2.2.2 Replacement of push spring

........................................................................21

3NOTE TRANSPORT......................................................................26

3.1 TOOLS..............................................................................................................27

3.1.1 Standard service tools

................................................................................27

3.2 DISMOUNTING PARTS...........................................................................................27

CDM8240 Sevice manual(Level 2) page ii of iv

YT2.291.036WHSC-JX2

3.2.1 Remove the note transport (NT)

..................................................................27

3.2.2 Removal of transport cover

.........................................................................27

3.2.3 Removal of count sensor holder and cable holder

.........................................28

3.2.4 Removal of solenoid assembly

....................................................................28

3.2.5 Removal of gear and count disk

..................................................................29

3.2.6 Removal of float roller spring and float roller collar

........................................29

3.2.7 Removal of gear

........................................................................................29

3.2.8 Removal of timing belt

................................................................................30

3.2.9 Removal of main motor

..............................................................................30

3.2.10 Removal of transport knob, timing pulley, idler and gear

................................31

3.2.11 Removal of thickness sensor assembly

........................................................31

3.2.12 Removal of BRTS_T plate, TES lower plate and TES_lower guide

.................32

3.2.13 Removal of sensors plates

..........................................................................32

3.2.14 Removal of drive shafts, diverter assembly and thickness detection shaft

........33

3.3 REPLACING PARTS ..............................................................................................34

3.3.1 Replacement of thickness sensor assembly

.................................................34

3.3.2 Replacement of TRANSPORT_RUBBER_ASSY

..........................................35

3.3.3 Replacement of impellers

...........................................................................35

3.3.4 Replacement of gear and timing pulley

........................................................36

3.3.5 Replacement of main motor

........................................................................36

3.3.6 Replacement of flat belts

............................................................................37

3.3.7 Replacement of timing belt

..........................................................................38

3.3.8 Replacement of Microswitch

.......................................................................39

3.3.9 Replacement of solenoid

............................................................................39

4NOTE STACKER ..........................................................................40

4.1 TOOLS..............................................................................................................41

4.1.1 Standard service tools

................................................................................41

4.2 DISMOUNTING PARTS...........................................................................................41

4.2.1 Removal of NS

..........................................................................................41

4.2.2 Removal of brush

.......................................................................................41

4.2.3 Removal of SCS Sensor

.............................................................................42

4.2.4 Removal of cam driver

................................................................................43

4.2.5 Removal of upper tansport assembly

...........................................................44

4.2.6 Removal of lower transport assembly

..........................................................45

4.3 REPLACING PARTS ..............................................................................................46

4.3.1 Replacement of brush

................................................................................46

4.3.2 Replacement of SCS Sensor

......................................................................47

4.3.3 Replacement of SLPS and SCPS sensor

.....................................................47

CDM8240 Sevice manual(Level 2) page iii of iv

YT2.291.036WHSC-JX2

4.3.4 Replacement of upper transport assembly

...................................................48

4.3.5 Replacement of lower transport assembly

....................................................49

5PRESENTER................................................................................51

5.1 TOOLS..............................................................................................................52

5.1.1 Standard service tools

................................................................................52

5.2 DISMOUNTING PARTS...........................................................................................52

5.2.1 Removing the presenter (long/short)

............................................................52

5.2.2 Removal of gear, timing pulley and timing belt

..............................................52

5.2.3 Removal of floating shaft torsion spring

........................................................53

5.2.4 Removal of floating bracket assy

.................................................................54

5.2.5 Removal of PCS assembly

.........................................................................56

5.2.6 Removal of PES assembly

..........................................................................57

5.2.7 Removal of flat belt

....................................................................................58

5.3 REPLACING PARTS ..............................................................................................59

5.3.1 Replacement of gear, timing pulley and timing belt

........................................59

5.3.2 Replacement of floating shaft torsion spring

.................................................60

5.3.3 Replacement of floating bracket torsion spring

..............................................61

5.3.4 Replacement of PCS sensor

.......................................................................63

5.3.5 Replacement of PES parts

..........................................................................64

5.3.6 Replacement of flat belt

..............................................................................65

CDM8240 Sevice manual(Level 2) page iv of iv

YT2.291.036WHSC-JX2

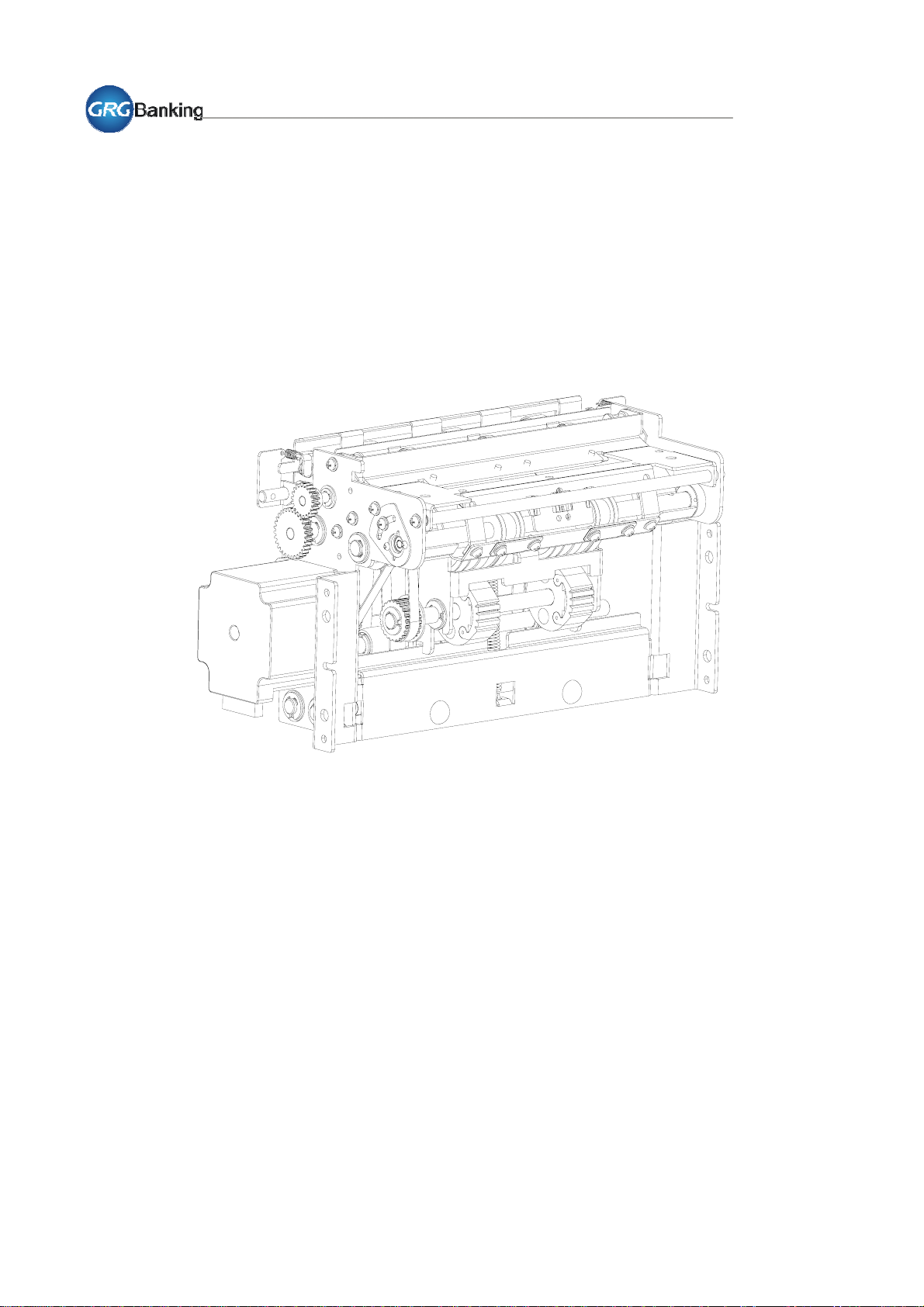

1 Note Feeder

YT4.029.039

CDM8240 Sevice manual(Level 2) Page 1 of 65

YT2.291.036WHSC-JX2

1.1 Tools

1.1.1 Standard service tools

Cross screwdriver

Slotted screwdriver

Long nose plier

Hexagonal screwdriver (M3, M4)

Force meter

1.1.2 Cleaning tools

Soft brush

Blower

Cloth

Alcohol

Grease lubricant

CDM8240 Sevice manual(Level 2) Page 2 of 65

YT2.291.036WHSC-JX2

1.2 Dismounting parts

1.2.1 Removing the note feeder

Refer to 《CDM8240Service Manual(Level 1)》 for the detailed operations on how to remove

the NF from CDM8240.

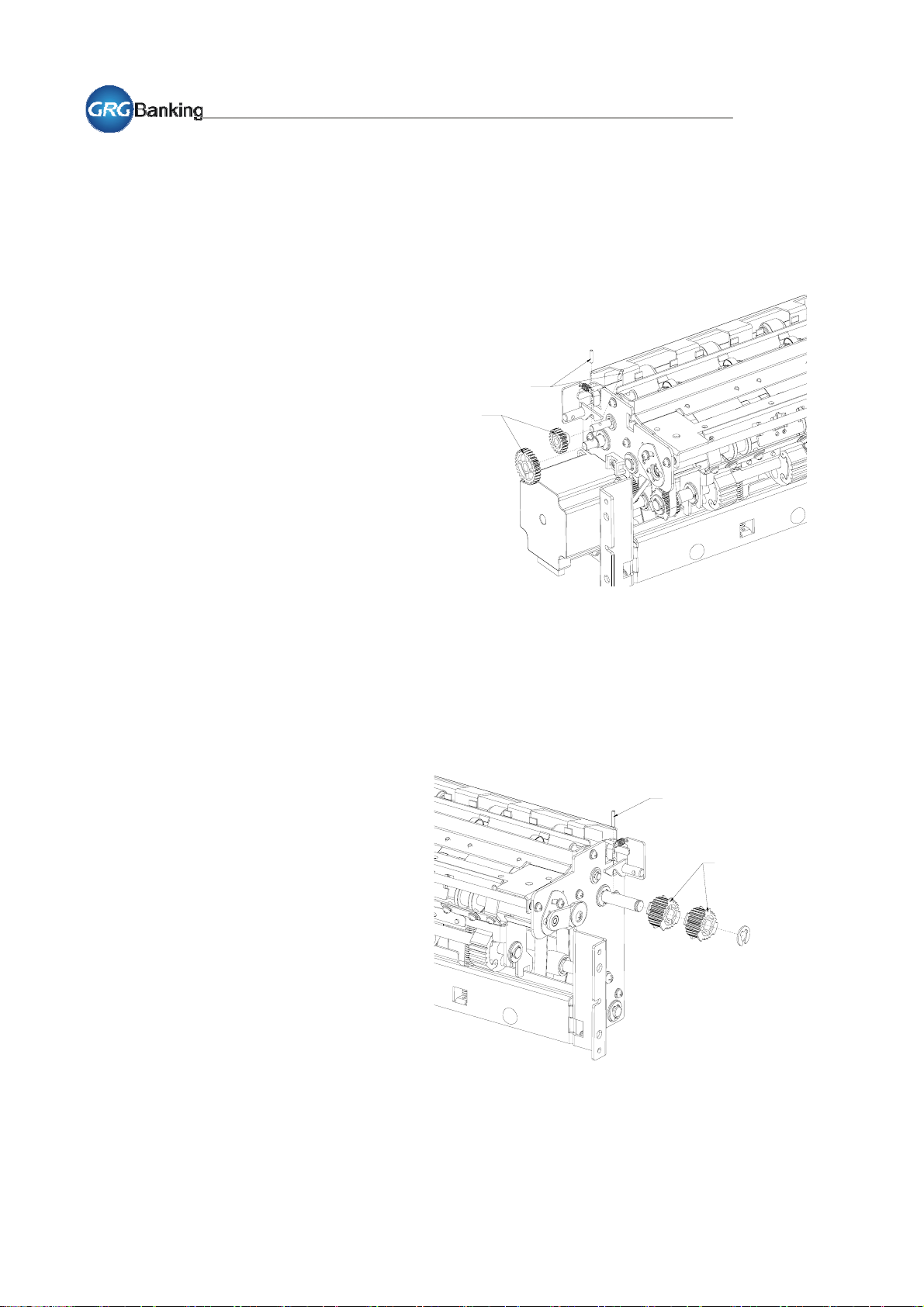

1.2.2 Removal of outter transport assembly

As is shown in the right picture,

remove the E rings and bearings

from the transport shaft, and then

remove 2 screws (combination

screw M3X8) from the short shaft.

Release the snap fits to unfold the

outer transport assembly, and take

it down.

Unfold

Short shaft

Outter transport

assembly

CDM8240 Sevice manual(Level 2) Page 3 of 65

YT2.291.036WHSC-JX2

1.2.3 Removal of localizer, eccentric cam and eccentric cam fork

Remove the screw (M3X6),

eccentric cam and eccentric cam

fork (be careful to protect the

one-way bearing from damage) on

right side of the separation roller

shaft.

Remove the localizers and CRR

eccentric cams on both sides of

counter rotating shaft (CRR shaft).

It is unnecessary to remove 2

screws (M2) securing the localizers

and eccentric cams.

Screws

Localizer

CRR eccentric cam Screws

Eccentric

cam

Eccentric

cam fork

1.2.4 Removal of counter rotating roller (CRR) assembly

Following the steps mentioned

above, remove the localizers,

eccentric cams and eccentric cam

fork.

And then remove 4 screws

(combination screw M3X6 and M3

X8, respectively) from the upper

fixing plate and top fixing shaft,

unfold the upper fixing plate, and

take down the CRR assembly.

Screws Fixing shaft

Screws

CRR

CDM8240 Sevice manual(Level 2) Page 4 of 65

YT2.291.036WHSC-JX2

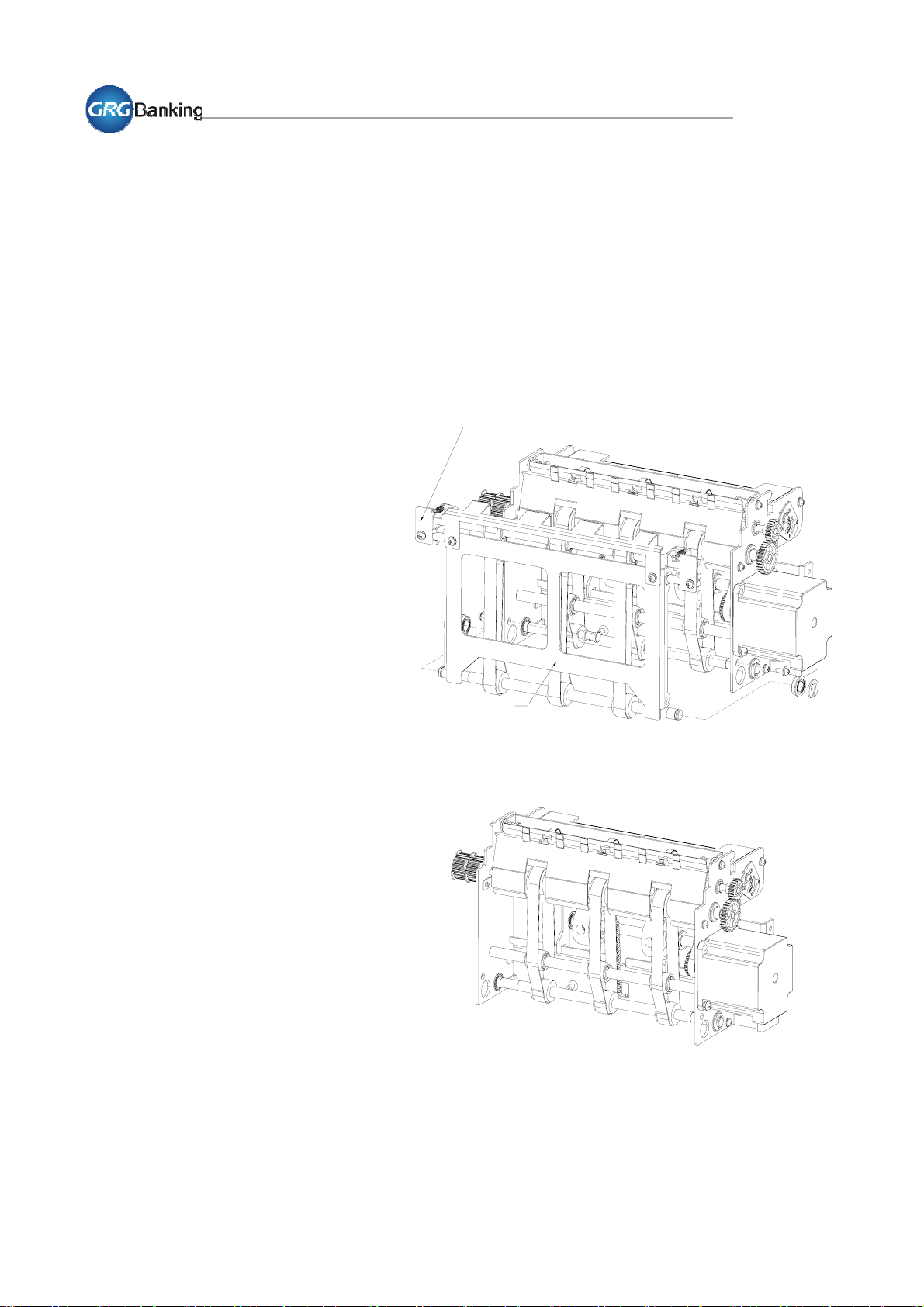

1.2.5 Removal of upper transport assembly

Following the steps mentioned

above, remove CRR assembly.

Remove 2 screws (combination

screw M3X8) from the short shafts

of upper transport assembly, and

then take down the upper transport

assembly.

Upper transport assembly

Short shafts

CDM8240 Sevice manual(Level 2) Page 5 of 65

YT2.291.036WHSC-JX2

1.2.6 Removal of lower transport assembly

Following the steps mentioned

above, remove upper transport

assembly.

Remove 2 screws (combination

screw M3X6 and M3X8,

respectively) on each side of the

lower transport assembly, and then

take down the lower transport

assembly.

Lower transport assembly

CDM8240 Sevice manual(Level 2) Page 6 of 65

YT2.291.036WHSC-JX2

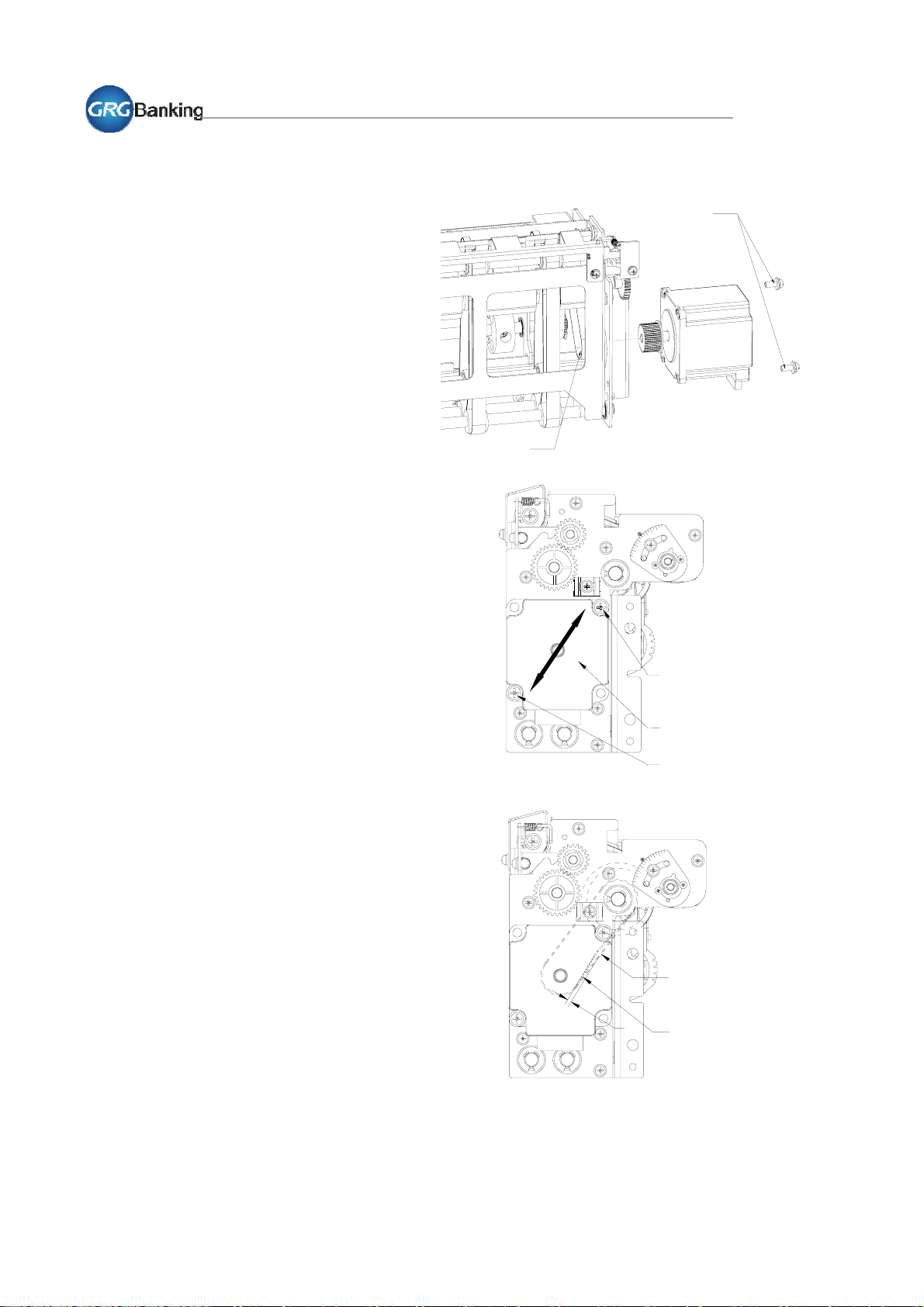

1.2.7 Removal of pick motor

Remove 2 screws (combination

screw M4X10) and release the

timming belt from the pick motor

pulley then take down the motor.

Timing belt Pick motor

CDM8240 Sevice manual(Level 2) Page 7 of 65

YT2.291.036WHSC-JX2

1.2.8 Removal of pick and separate assembly

As is shown in the right picture.

Following the steps mentioned

above, remove upper and lower

transport assembly.

Using a long nose plier, remove the

Feeder spring, then remove c-clip

on the left, eccentric cam on the

right and bearings from the

separation roller shaft, take down

the pick and separate assembly.

Note: Please don’t remove the

timming belt in pick and separate

assembly.

Pick and separate assembly

Feeder spring

CDM8240 Sevice manual(Level 2) Page 8 of 65

YT2.291.036WHSC-JX2

1.2.9 Removal of gear and timing pulley

Remove the fixing pins from the left

of acceleration roller shaft and

transport shaft to take down 2

gears.

Remove the timing pulley from the

right of transport shaft.

Pin

Gear

Pin

Timing Pulley

CDM8240 Sevice manual(Level 2) Page 9 of 65

YT2.291.036WHSC-JX2

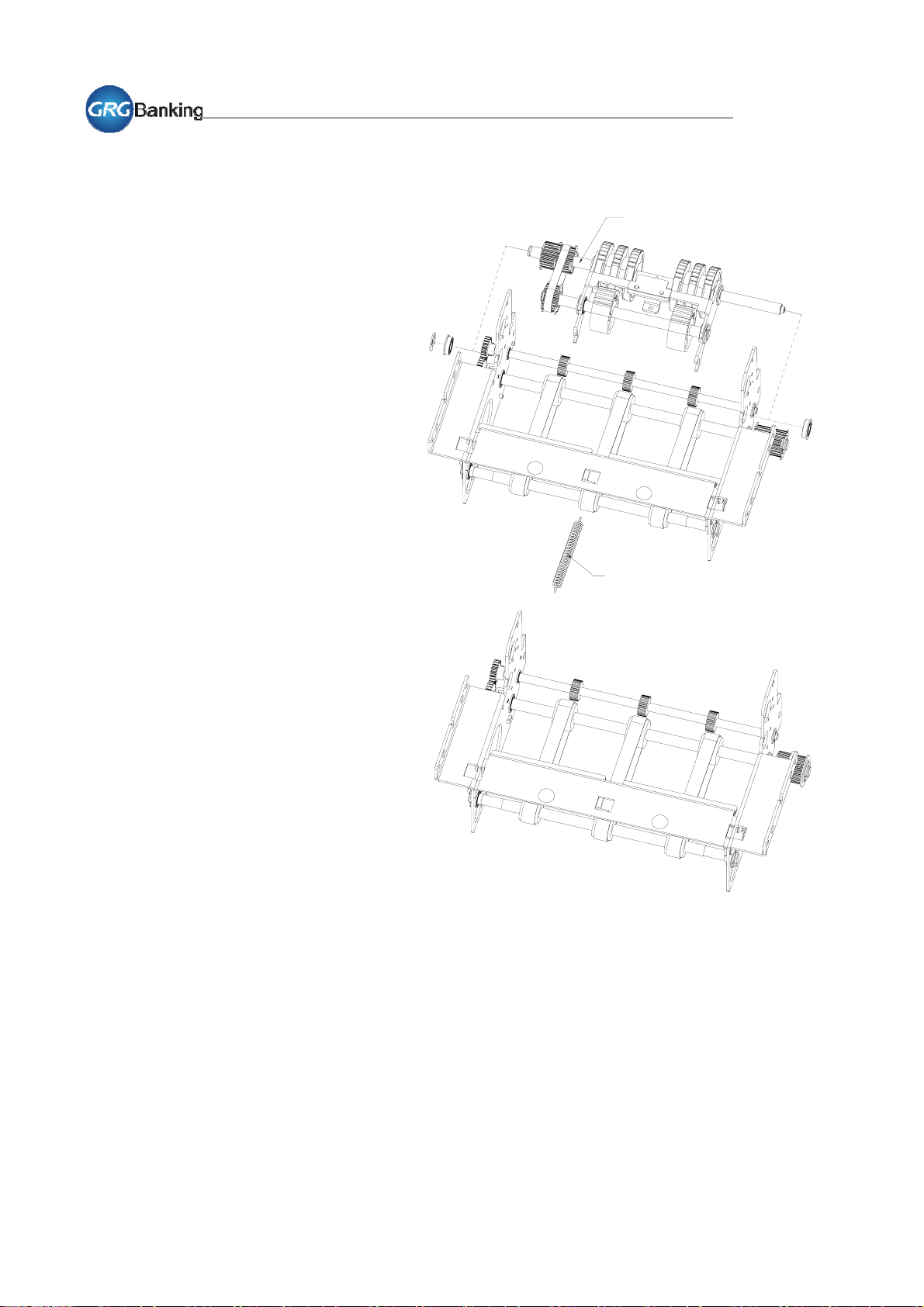

1.2.10 Removal of transport shaft assembly

Following the steps mentioned

above, remove upper and lower

transport assembly.

Remove the fixing screws from the

transport shaft (IM) to take down

the shaft, and then remove the E

rings and bearings from the

transport shaft (IU), acceleration

roller shaft and transport shaft (IL)

to take down the shafts and belts

(235mm). Transport shaft

(IL) assembly

Transport shaft

(IU) assembly Transport shaft

(IM) assembly

Accelaration Roller

Belt

(235mm)

CDM8240 Sevice manual(Level 2) Page 10 of 65

YT2.291.036WHSC-JX2

1.3 Replacing parts

1.3.1 Replacement of gear and timing pulley

Place the gear (teeth number=30)

onto the end of transport shaft (IU),

ensure the hole in the gear aligns

with the hole in the shaft, and then

push and glue the fixing pin into

the hole to fasten the gear using a

long nose plier.

Similarly, fit another gear (teeth

number=20) to the acceleration

roller shaft, make sure two gears

joggled with each other completely.

Note:Please make sure the fixing

pins are firmly fixed with glue and

prevent the pins from moving out.

Pin

Gear

Insert the fixing pin into the hole on

the right end of transport shaft (IU)

and place the timing pulley on the

shaft.

Fit c-clip in the groove on the shaft

to protect the pulleys from moving

out.

Pin

Timing pulley

CDM8240 Sevice manual(Level 2) Page 11 of 65

YT2.291.036WHSC-JX2

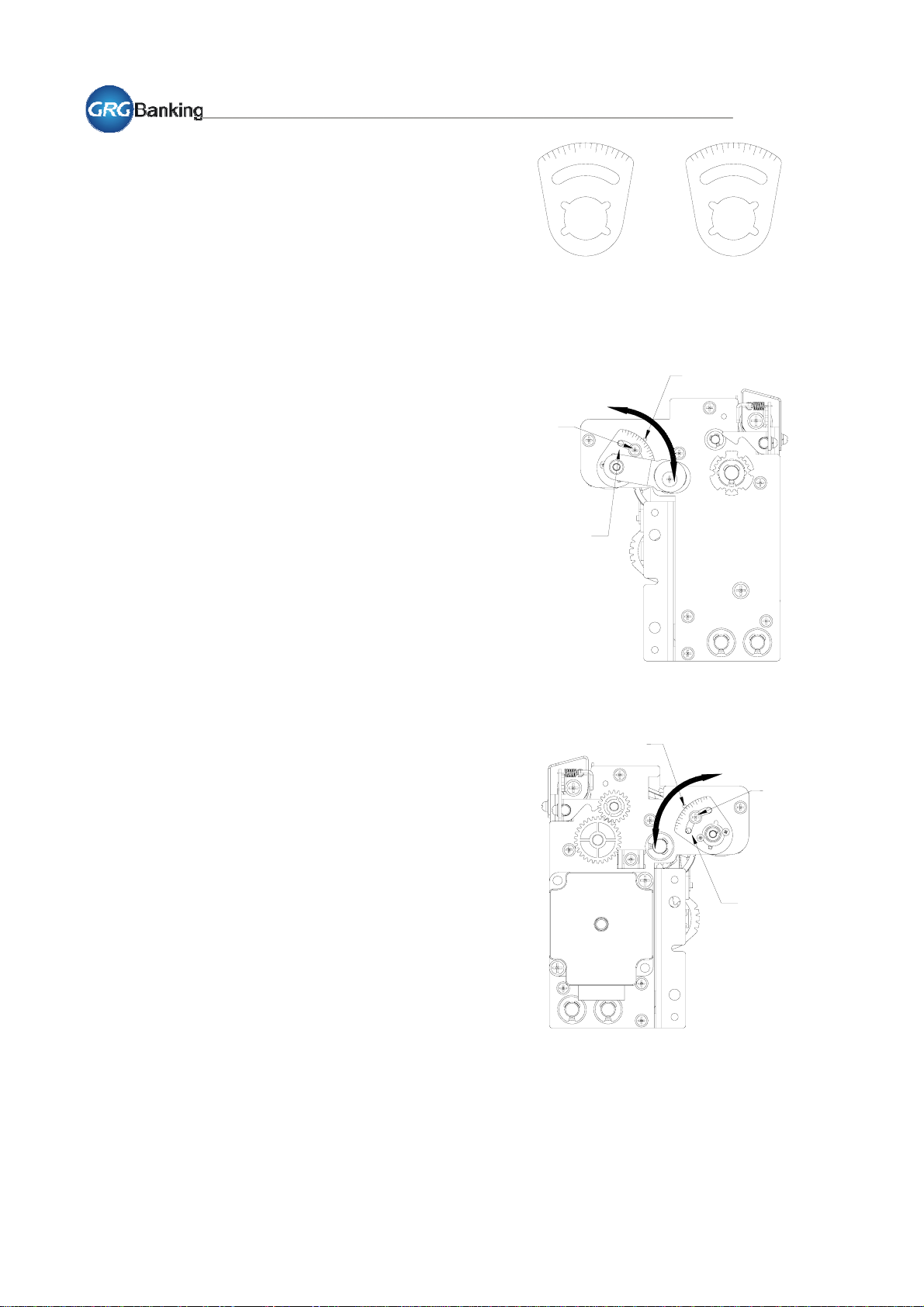

1.3.2 Replacement of pick motor

Fit the timing pulley to pick motor,

put the belt onto the timing pulley

while securing the pick motor onto

the left frame of note feeder by

tightening 2 screws (combination

screw M4X10).

Then follow the adjust instructions

to adjust the timming belt tension. Timing belt

Screws

Belt tension adjustment

Step 1: Release the 2 fixing screws

securing the pick motor.

Step 2: Move the pick motor in the

direction shown in right picture,

and make the belt tension

P=150±50gf while the belt

displacement A=1 mm.

Timing belt

P

Fixing Screw

Pick motor

Fixing Screw

A

CDM8240 Sevice manual(Level 2) Page 12 of 65

YT2.291.036WHSC-JX2

1.3.3 Replacement of CRR

Insert and make sure CRR shaft

ends into the holes on both sides of

note feeder frame, and then fit the

localizers and eccentric cams,

eccentric cam fork (be careful to

protect the one-way bearing from

damage) to the shaft.

Shut down the upper fixing plate to

proper position, and tighten 4 fixing

screws (combination screw M3X6

and M3X8, respectively).

Fit the eccentric cam to the

separation roller shaft and tighten

the fixing screw (screw M3X6).

Note: After replacement, please

follow the adjustment and test

instructions to adjust the gap.

CRR

Screws

Screws CRR

Fixing shaft

Eccentric

cam fork

CRR eccentric cam Screws

Eccentric

cam

Screws

Localizer

CDM8240 Sevice manual(Level 2) Page 13 of 65

YT2.291.036WHSC-JX2

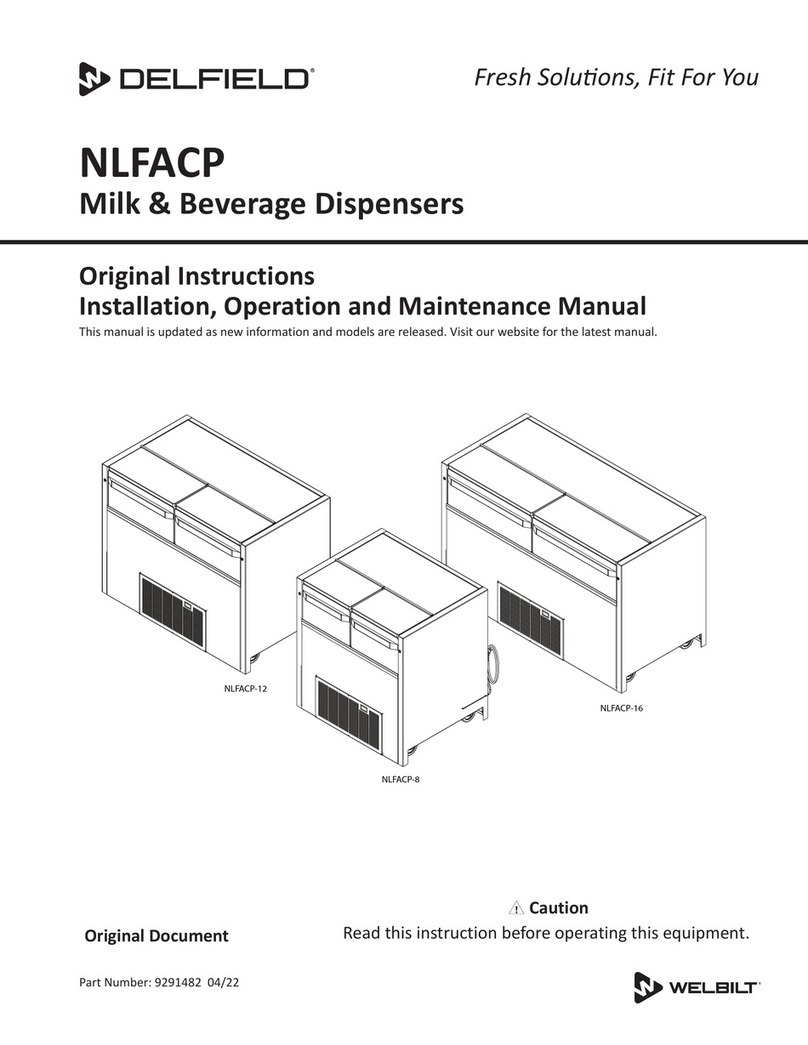

Gap adjustment

Step 1:

Loosen the screw on one side of NF frame.

Step 2:

Dial the Localizer to the very scale, and

make sure the scale is at the mark. Turn

localizer on the left clockwise and localizer

on the right counter-clockwise will make the

gap bigger. Otherwise, the gap will become

smaller.

Step 3:

Fasten the screw.

Step 4:

Following the Step 1 to Step 3 mentioned

above, adjust the scale on the other side. If

possible, the scales on both sides should be

same.

Note:Before and after the adjustment, it’s

strongly recommended that the scale should

be taken down as a record for recovery,

tracking and some other uses.

-8

0

+8

Right Side

0

-8

+8

Left Side

Localizer

Gap is bigger

To adjust the gap, loosen the screw,

dial the localizer to the very scale.

Screw

Mark

Mark Gap is bigger

Screw

Gap is smaller

Left Side

Gap is smaller

Localizer

Right Side

CDM8240 Sevice manual(Level 2) Page 14 of 65

YT2.291.036WHSC-JX2

Gap test

Step 1:

Follow the “Gap Adjustment” mentioned above to adjust the gap.

Step 2:

Use toolplus to test dispense, at least 1000 pcs note for each NF adjusted.

If reject too much notes, such as double note and long note, the gap should be adjusted to

decrease 1 or 2 scales.

If note is hard to be separated, such as skew note, damaged note and even jammed note, gap

should be adjusted to increase 1 or 2 scales.

Step 3:

Once adjusting the gap, “Gap Test” should be done to make sure note dispense is ok.

Note:During the maintenance, each time gap adjustment and test should be done if

pick-separate assembly or CRR is replaced. However, if just disassemble and assemble

pick-separate assembly or CRR without replacement, it’s necessary to adjust to the former

scale taken down as a record, and then follow the steps above to test.

CDM8240 Sevice manual(Level 2) Page 15 of 65

Table of contents

Popular Dispenser manuals by other brands

Welbilt

Welbilt Delfield NLFACP Original Instructions Installation, Operation and Maintenance Manual

SureShot

SureShot FlavorShot AC-FS10 Technical & service manual

SureShot

SureShot AC2-GP Operation manual

New Air

New Air Magic Chef Top Loading Water Dispenser manual

SureShot

SureShot AC2-GP-1-G38 Operation manual

Fillmaster Systems

Fillmaster Systems Auto user guide