Part Number: 9291482 04/22 9

Section 3 Operation

Lid Operation

Operating the unit for extended periods of time with the lid

open may result in product temperature change. For best

operation, leave the lid open no longer than 2 hours during

peak usage.

Evaporator Fan Operation

Depending on the units requirements, units may have

evaporator fans that run continually or cycle on and off when

power is applied. If you have a unit that you notice the fan is

cycling, please see the operations sequence below.

When the refrigerator is initially powered up or immediately

following a power outage the unit will begin cooling after a

3-6 minute delay. During normal operation the evaporator

fan pulses independently of the compressor as dictated by

the controller as follows:

1. During the cooling mode, compressor and evaporator

fan run simultaneously.

2. During the compressor off mode, evaporator fan pulses

three minutes on and three minutes off.

3. During an actual defrost event other than the off-cycle

defrost, compressor stays off but the evaporator fan

runs continuously.

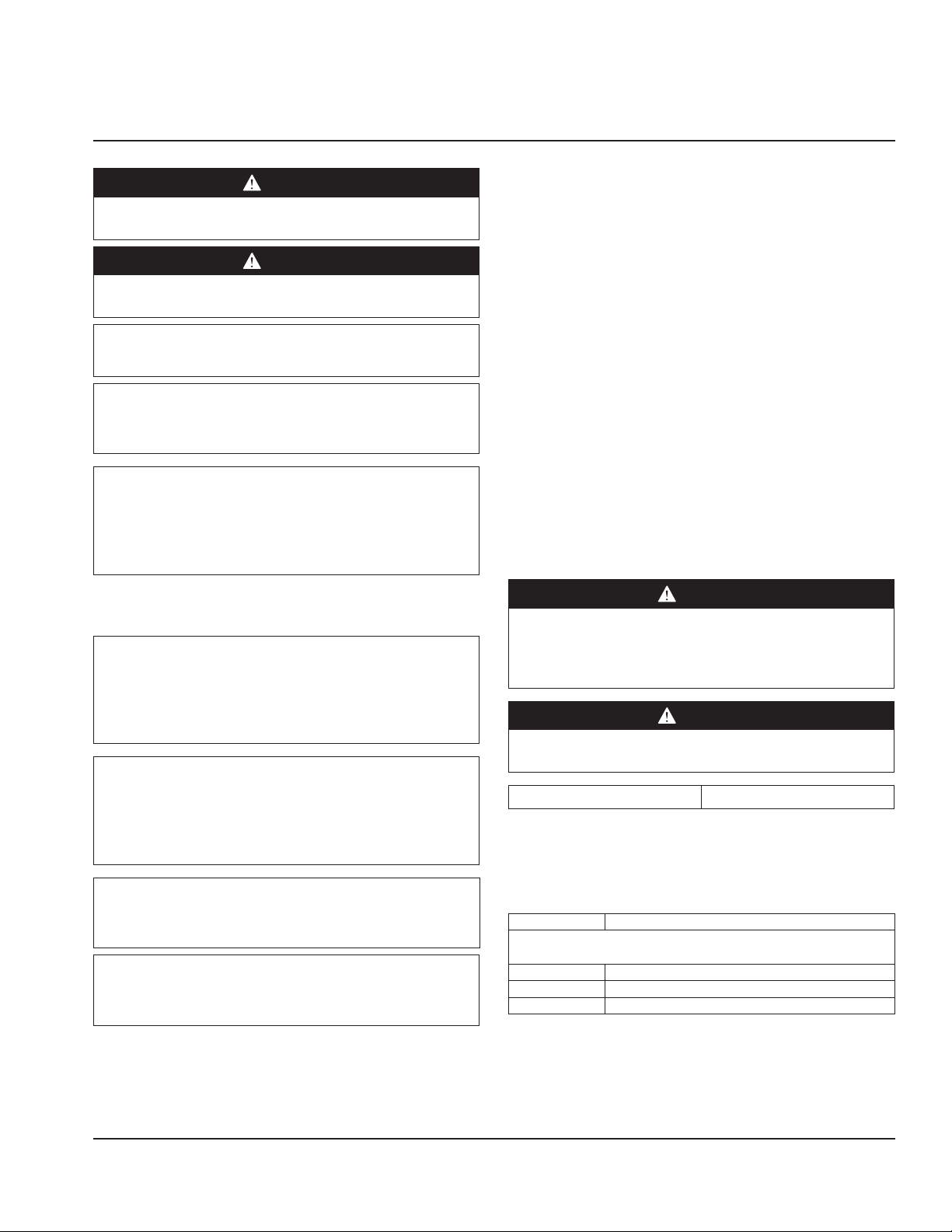

Cooling Cycle Defrost Cycle

Compressor On Compressor Off Compressor Off

Evaporator Fan On Evap Fan Cycles On

3-Min, Off 3-Min

Evaporator Fan On

CONTROLS

At Start Up

1. At initial start-up or anytime power is disconnected, then

reconnected to the unit, the control will go into defrost

mode.

2. The control will enter a DEFROST mode and the display

will read dEF. The compressor and condenser fan as well

as the evaporator fan will remain off until this initial

defrost is complete. This initial defrost cycle may take up

to 35 minutes to complete.

3. The display will continue to read dEF for an additional 30

minutes while the cooling cycle cools the box to the set

temperature.

4. Then the digital thermostat will display box temperature.

Normal operation setpoint is 36°F.

5. The temperature control will cycle the compressor,

evaporator fan motor and condenser fan motor to

maintain box temperature at the control setting. For more

information see Evaporator Fan Operation on page 9.

Defrost

The temperature control also monitors the evaporator

temperature and will turn off the compressor and condenser

fan motor when needed to allow accumulated frost on the

evaporator to clear. During this defrost cycle, the digital

temperature display will read dEF. After the defrost cycle is

complete, the temperature control will return to a normal

cooling cycle, but the display will continue to read dEF until

the evaporator returns to normal cooling temperatures (up

to 30 minutes).

The electronic temperature controller monitors evaporator

temperature and compressor run time to determine the

proper time for a positive defrost cycle. A defrost cycle can

occur as often as every 2 hours under extremely heavy

usage. It can last a minimum of 2 minutes. When the

controller enters the defrost mode the compressor is shut

off and will remain off until the evaporator coil temperature

exceeds:

• 41°F (5°C) or the controller reaches a time limit of 100

minutes on a refrigerated unit.

ERC112 TEMPERATURE CONTROL

Status Displayed Comments

Normal (°C) Temp. [°C] Unit depends on setting

(parameters in control)

Normal (°F) Temp. [°F]

Show set-point Temp.

Set to Defrost dEF / Temp Depends on setting

(parameters in control

or as chosen by upper

left button)

Sensor 1 defect E01 X Air sensor

Sensor 2 defect E02 X Coil sensor

Sensor 3 defect E03 X Open

Sensor 4 defect E04 X Open

High temperature alarm Hi X Automatically switching

at 2 sec rate

Low temperature alarm Lo X

Line voltage too high,

above 140 volts

uHi X

Line voltage too low,

below 96 volts

uLi X

Control calls for cooling

for more than 24 hours

straight

LEA X Time includes defrost.

Error will go away if the

control cycles off the

compressor or if the

power is shut off. If error

is on a cold pan it could

be related to a high

ambient temperature or

not shutting the rail off

nightly.

All alarms sound for approximately 10 seconds and then