CRKITS CS Series User manual

1

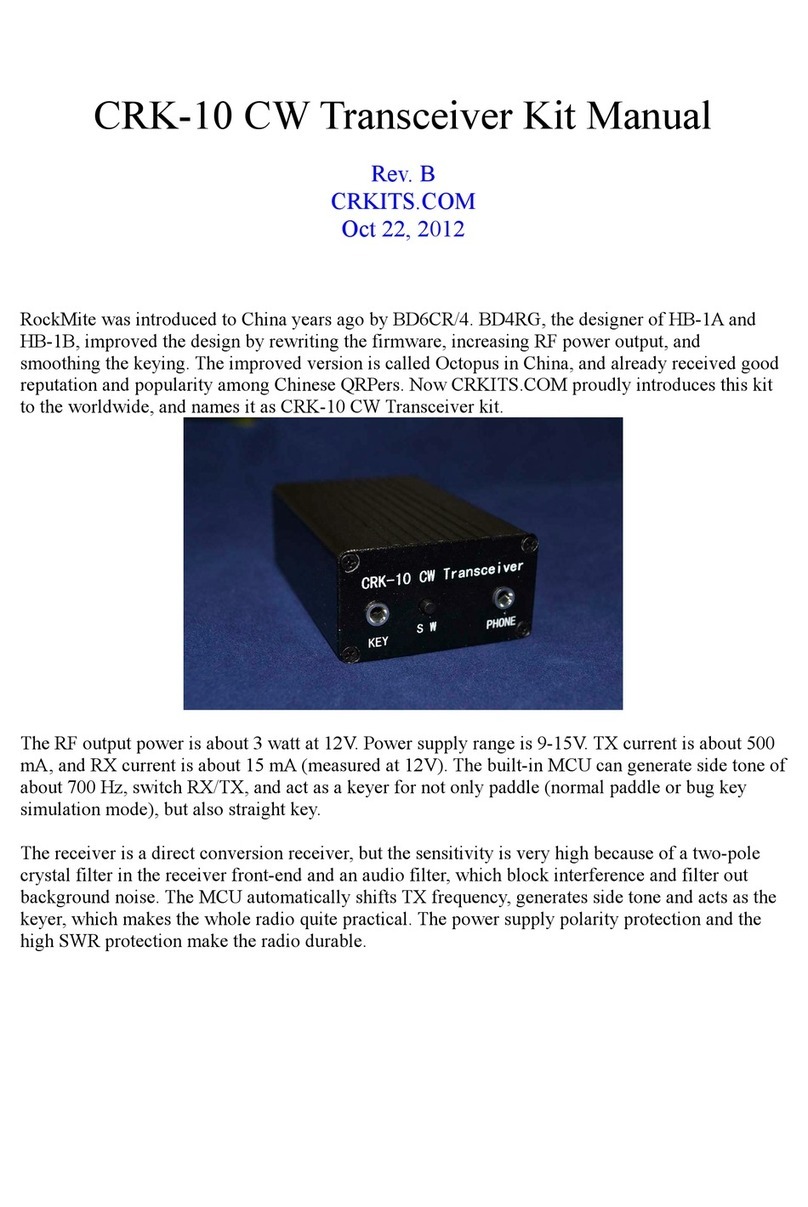

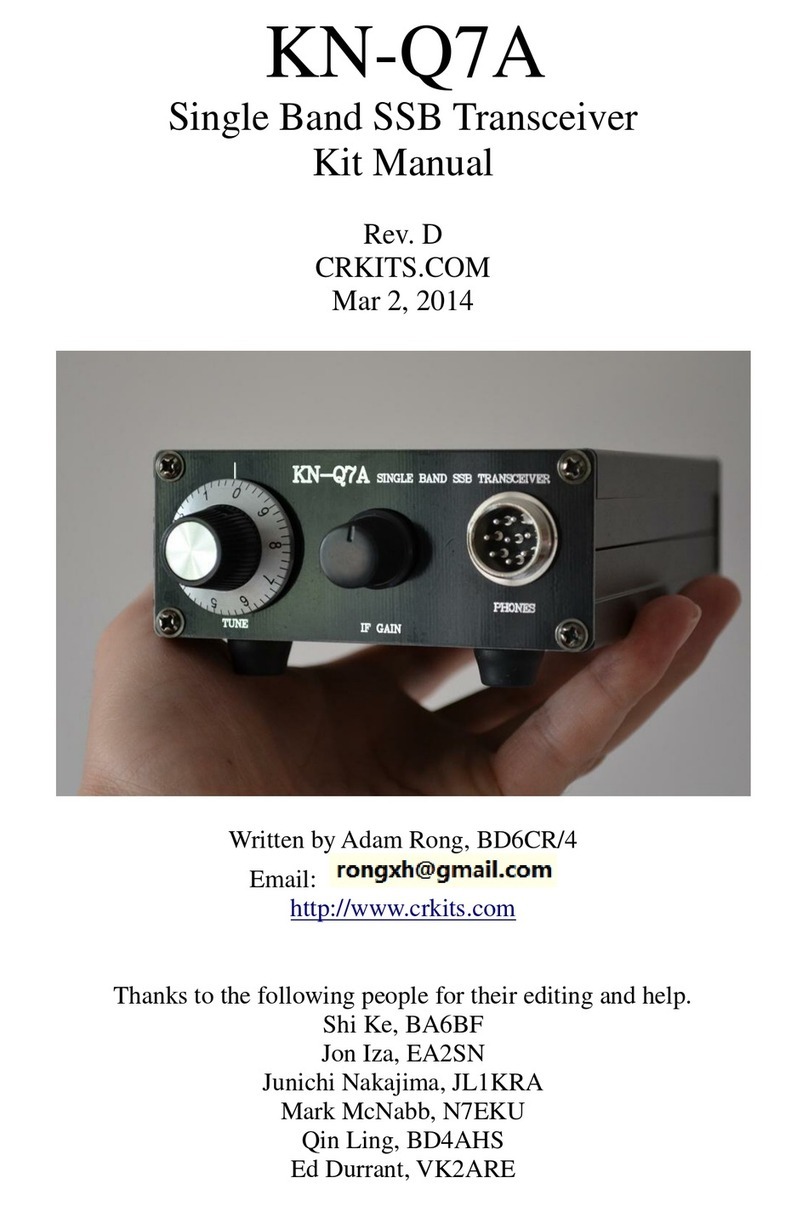

CS Series SSB Transceiver

Single Band SSB Transceiver Kit Manual

Rev. Preliminary Release –CRKITS.COM

April 8, 2017 –Preliminary Release

Original written by Adam Rong, BD6CR/4 Modified by Larry Lovell, N7RGW

Email: http://www.crkits.com

Thanks to the following people for their editing and help.

Shi Ke, BA6BF

Jon Iza, EA2SN

Junichi Nakajima, JL1KRA

Mark McNabb, N7EKU

Larry Lovell, N7RGW

Qin Ling, BD4AHS

Ed Durrant, VK2ARE

Revision History

Modified from KN-Q7A- Mar 4, 2014: Rev. D, rewritten for PCB V2.2 and 20m

version

1 May 2017 –Rev. A CS-Series

2

THANK YOU!

Thank you for purchasing your CS-SERIES Single Band SSB Transceiver Kit. The

kit was designed by BA6BF, and is now supplied by CRKITS.COM and its

worldwide distributors. The CS-SERIES kit is an ideal candidate for field

operation, back pack and emergency use.

In this revision of manual, we have rewritten for PCB CS-Series. 40M and 20 M

version will be also covered.

Specifications

Dimension: 153 mm x 97 mm x 40 mm, not including protruding features

Weight: approximately 12 oz. or 340 g.

Power Supply: 12~13.8 V, 3 A

Current consumption: about 70 mA in RX and about 2 A in TX @ 13.8 V

RF output: up to 10 W PEP @ 13.8 V (5 W PEP for the 20m version)

Spur suppression: better than -43 dBc

Sensitivity: better than 0.5 μV at 10 dB SNR

IF filter: 6 pole crystal ladder filter + 1 pole post IF amplifier crystal filter

IF frequency: 8.467 MHz

Frequency tuning range: 7.000~7.300 MHz or 14.000~14.350 MHz

Connectors:

oSpeaker output: 3.5 mm connector, mono output

oMicrophone input: 8-pin, can be configured to be compatible with

electret microphones or speaker microphones

oDC IN connector: Type 2.1 mm center positive

oAntenna connector: BNC type

Controls:

oIF Gain Control: act as volume control

oTune Control

Disclaimer

We offer the kit as is and do not guarantee the assembled kit by yourself can meet

your local regulatory requirements, including safety, RF, environmental or others.

As some parts used in the kit are obsolete, we cannot guarantee that all the

components in the kit are brand new, but we bear the responsibility of providing

them as good as possible.

Tools Preparation

The tools needed for the kit building are solder iron, solder sucker, clipper,

tweezers, pliers, screw drivers including Philips and slotted, and a multi-meter of

3

digital or analog type. Besides, you will need an electric drill and a 3 mm drill bit,

a 50 Ω, 20 W or higher power dummy load, an HF band SWR/Power meter, a 13.8

V/ 3 A power supply, a personal computer running Windows, an amateur radio

transceiver with a general coverage receiver and calibrated frequency display, and

other ancillary instruments. It will be nice if you have access to a frequency

counter, an audio signal generator, a RF signal generator, an oscilloscope and a

spectrum analyzer, but they are not absolutely required.

Parts Inventory

Open the package and read the one-page quick guide thoroughly. Also, some

volunteers have translated some manuals for you. To download your local

language documents, you can search the CHINA_QRP group file section on Yahoo

or go to the document archive section of http://www.crkits.com/. There you will

find a list of all documents (Thanks EA2SN for Spanish translations and JL1KRA

for Japanese translations).

You need to download the complete part list and do the parts inventory carefully.

40 m and 20 m version: http://crkits.com/ cspartlist.pdf

We have put resistors, trimmers, potentiometers and 104 capacitors into one plastic

bag so it will make your work much easier. You may find some extra parts, and it

is fine to keep them as backup.

It is okay to discard the original metal front panel, rear panel and the original 8x

panel screws now, because they have replacements in the kit. If you find problems

or missing parts, please contact your seller directly.

We offer several frequency ranges to meet different requirements (this list is

subject to change without notice):

7.000 MHz to 7.300 MHz for 40 meters

14.000 MHz to 14.350 MHz for 20 meters

Board Assembly

We will do it step by step, finishing one part of assembly at a time, and testing it to

ensure final success. We will provide partial schematic in each step to help you

understand the theory of operation, and make sure you install all the parts required

to do the final testing of the block.

However, the partial schematic might not contain all the parts you should install in

each step, so don't get confused when you are told to install a part not shown on the

4

schematic. Note that PCB version is subject to change without prior notice and it

may look slightly different from yours.

A. Preset this trimmer fully counterclockwise before you apply power supply.

When you adjust the bias voltage for the final PA, turn it clockwise very

very slowly, or the final PA is easily damaged.

NOTE: With this initial revision of the Assembly Manual, it is

recommended that you first begin with the assembly of the Digital

Sandwich: See: Detailed manual with photos located at

http://www.crkits.com/

5

Step 0: Sandwich Digital VFO

Let's start with the Sandwich Digital VFO. It is an Arduino and Silicon-Labs si5351a

based open-source design by CRKITS.COM to offer stable and wider range

frequency coverage. A dual-color LED offers frequency reading capability. It has

three outputs: One for VFO, another for BFO and the last one for crystal

calibration.

Unlike KN-Q7A, CS-series uses common 8.467 MHz IF, so the IF settings will be

different.

6

The table below shows the CS-series setting based on the sketches for CS-40, CS-

20 and later on available bands.

JP10

80-meter

40-meter

20-meter

OPEN

band high limit =

3800 kHz

default frequency =

3700 kHz

BFO = around 8467.2

kHz

band high limit =

7200 kHz

default frequency =

7100 kHz

BFO = around 8467.2

kHz

band high limit = 14350

kHz

default frequency =

14300 kHz

BFO = around 8467.2

kHz

SHORT

band high limit =

3900 kHz

default frequency =

3700 kHz

BFO = around

8467.2kHz

band high limit =

7300 kHz

default frequency =

7200 kHz

BFO = around 8467.2

kHz

band high limit = 14350

kHz

default frequency =

14200 kHz

BFO = around 8467.2

kHz

Other than the above setting difference, for CS-series kit building, please refer to

the kit building manual at http://crkits.com/sandwichkitassemblymanual.pdf

We will assemble the Sandwich Kit first, but not install it with the main PC Board

at this time.

DO NOT attach Sandwich Kit to faceplate at this time.

DO NOT connect the Sandwich Kit to the main PCB at this time.

The Sandwich will be installed to the PCB in Step 6.

7

Step 1: Power Supply Circuit

Let's start with the power supply circuit. Should you want to study the whole

schematic prior to the building to have better understanding, you may find a copy

of the circuit at the end of this manual.

Please study the partial schematic before soldering.

Solder 1x DC IN socket, and trim the pins flush to avoid shorts with chassis

foot screws

Solder 1x speaker connector near the DC IN power connector; make sure

you install it in place

Bend the pins of 1x 1N5820 diode as shown, and solder. For other diodes,

always bend the pins like this.

Solder 1x 1000 μF capacitors; check polarity

Solder 1x 0.1 μF (104) monolithic capacitor near 7808. Remember that all

capacitors without marking are 104 ones.

8

Solder 1x 7808 as shown for test purposes now. If your kit comes with

LM2940-8.0, it is an upgrade for lower dropout voltage.

Plug in a 12~13.8 V power supply to the DC IN connector (center positive)

and measure the voltage on pin 3 of 7808 near to the 104 capacitor to see if

it is within +/-5 % of 8 V; if not, check power supply polarity and your

soldering

Disconnect the power supply and proceed to the next step.

9

Step 2: Audio Amplifier

The core component of the audio amplifier is a TDA2822M. It is a dual channel

amplifier but we only use one channel here. Please study the schematic before

soldering.

Place 1x 8 pin IC socket, paying close attention to the notch, and solder, then

insert a TDA2822M with correct orientation as shown on the photo

Solder 1x 1000 μF capacitors; check polarity

Solder 2x 100 μF electrolytic capacitor; check polarity

Solder 1x 10 μF electrolytic capacitor; check polarity

Solder 1x 8050 transistor; check PCB outline

Solder the remaining capacitors and resistors; when finished, it will look

much like the photo below

10

Plug in a 12~13.8 V power supply and connect an external speaker of 8 Ω or

higher impedance to the speaker connector.

Touch pin 5 of the nearby NE602A using tweezers to inject some noise, and

note if the audio amplifier works. If not, please check your soldering, and

check the pin 2 of the TDA2822M for the presence of 8V.

If all is okay, disconnect the power supply and the external speaker to

proceed to the next step.

WARNING: It is not a good choice to plug in a headphone to the speaker

connector, as the radio does not have an AGC circuit and an abrupt strong signal or

noise may cause damage to your ear.

11

Step 3: Detector/ Double Sided Band Modulator

The core component is a double-balanced mixer and oscillator NE602A. It acts as

the detector in the RX path and also as a DSB modulator in TX. Please study the

schematic before soldering.

Place 1x 8 pin IC socket, paying close attention to the notch, and solder, then

insert a NE602A with correct orientation as shown on the photo

Solder 1x SIP5 socket as on-board microphone connector as shown on the

photo

Solder 1x relay. This relay is controlled by the PTT and switches 8 V RX/

TX power

Solder 1x 104 monolithic capacitor near 1000 μF capacitor. Remember that

all capacitors without marking are 104

Solder 1x 1N4148 near the relay. Remember that all diodes without marking

are 1N4148 and bend the pin near the bar marking on the body

Solder the remaining inductors, resistors, diodes and capacitors. When

finished, it will look like the photo below.

Plug in a 12~13.8 V power supply. Short the PTT pin to GND to see if the

relay works.

Check your soldering and the presence of 8 V on pin 8 of NE602A if it is not

normal. If all is okay,

Disconnect the power supply and the external speaker to proceed to the next

step.

1

2

3

4

5

6

7

8

NE602A

104

103

103

1.5K

104

104

104

100uH

+8V

104

4148

1.5K

+8VR

10k +8V

1

2

3

4

5

MICROPHONE

PTT

MIC

+8VT

104

1

2

UNBAL*

104

Sandwich BFO

DETECTOR

12

13

Step 4: RX IF Amplifier

The core component is an MC1350. There is no AGC circuit designed, and the IF

gain is controlled by a potentiometer (IF GAIN) and also used as volume control.

A crystal filter is added after the output network of the MC1350. Please study the

schematic before soldering. Xa is a marking for IF crystals.

Always check PCB marking for the difference between 20m and 40m versions.

Place 1x 8 pin IC socket, paying close attention to the notch, and solder, then

insert a MC1350 with correct orientation as shown on the photo

Pick 1 –8.4762 MHz IF crystal and solder. You don't have to place an

insulator under the crystal or ground the crystal case

14

Pick the potentiometer marked B10K and solder it as IF GAIN control,

making sure that the shaft is vertical to the PCB side

Solder the remaining inductors, resistors and capacitors. When finished, it

will look like the photo below.

Plug in a 12~13.8 V power supply and connect an external speaker to the

speaker connector.

Turn the potentiometer to fully clockwise, touch pin 6 of MC1350 using

tweezers and note if the noise coming out of the speaker increases. Turn the

potentiometer counter clockwise to note if the noise decreases. If it is not

normal, please check your soldering, and check the pin 1, 2 and 8 of the

MC1350 for the presence of 8 V.

If all is okay, turn the potentiometer fully clockwise again, and disconnect

the power supply and the external speaker to proceed to the next step.

15

Step 5: IF Crystal Filter

This part includes 6 each 8.4762 MHz IF crystals, 7x capacitors and 2x relays.

Please study the schematic before soldering. Xa is a marking for IF crystals.

Always check PCB marking for the difference between 20m and 40m versions.

Pick 6 each 8.4762 MHz IF crystals and solder. You don't need to place

insulators under the crystals or ground the crystal cases

Solder 7 each 47 pF capacitors

Solder 2 each relays. When finished, it will look like the photo below

Plug in a 12~13.8 V power supply and connect an external speaker to the

speaker connector.

Touch pin 5 of the uninstalled NE602A using tweezers to note a little noise

from the speaker. If it is not normal, please check your soldering.

If it is okay, disconnect the power supply and the external speaker to

proceed to the next step.

16

Step 6: Mixer and VXO Local Oscillator

The core component is another double-balanced mixer and oscillator NE602A. It

acts as the RX/TX mixer.

The Digital Sandwich will replace the VXO crystals and the BFO oscillator.

DO NOT install: VXO crystal(s).

Do not install parts with marking ended with #.

Place 1x 8 pin IC socket, paying close attention to the notch, and solder, then

insert a NE602A with correct orientation as shown on the photo

Solder the remaining parts. When finished, it will look like the photo below.

1

2

3

4

5

6

7

8

NE602A+8V

100uH

104

104

104

4148

1.5K

104

+8VT

PAIN

104

Sandwich VFO

MIXER

17

Connecting the Sandwich to the PC Board

Solder on the main board as

shown to get regulated 8V power.

Mount

assembled

sandwich to the

front panel as

shown

Solder the two

104 capacitors as

shown.

Connect the

ground pin as

shown

18

Plug in a 12~13.8 V power supply and connect an external speaker to the

speaker connector.

Touch pin 1 of the NE602A using tweezers or even with an antenna cable tip

to note if strong band noise comes out of the speaker.

Turn the TUNE control to check if VFO frequency changes thus the noise

tone changes. The VFO frequency change can be detected by a general

coverage SSB/CW receiver nearby.

Check soldering and the presence of 8 V on pin 8 of the NE602A if it is not

normal.

If all is okay, disconnect the power supply and the external speaker to

proceed to the next step.

19

Step 7: RX Front End

This part of circuit includes an antenna connector, a relay, two 1N4148 diodes as a

level limiter for protection purposes and two DIY7-xx IFT's (DIY-3.8 for 80m,

DIY7-7 for the 40m or DIY-14 for 20m) as RX band-pass filters (BPF). By

completing this step, you will have a fully working receiver, so you will be able to

align it and hear some signals. Please study the schematic before soldering. Always

check PCB marking for the difference between 20m, 40m or 80m versions.

Solder 2x IFT's DIY7-xx (DIY-3.8 for 80m, DIY7-7 for the 40m or DIY-14

for 20m).

Solder 3x 1N4148 diodes; check polarity

Solder 1x relay

Solder the remaining capacitors. When finished, it will look like the photo

below. And it also completes the RX part

DIY7-7/14

DIY7-7/14

2p

27p/15p

27p/15p

4148

4148

TORX

RXBPF

NOTE: X/Y for 40m/20m value

20

Now let's do a brief alignment and enjoy receiving on-air signals. Plug in a

12~13.8V power supply and connect an external speaker to the speaker

connector.

Touch ANT pin using an antenna cable tip to note strong band noises or

signals coming out of the speaker.

Turn the TUNE control slowly to see if you can hear any on-going QSO.

Check your soldering if it is not normal. If all is okay, disconnect the power

supply and the external speaker to proceed to the next step.

Alternate Method for pre-alignment:

Power need not be applied for this adjustment.

Place a signal generator at the antenna input of an appropriate frequency

(example: 7.200 MHz for 40 Meter).

Place an oscilloscope on the final pin of the 27p or 15p capacitor or Pin 1 of

the NE602.

Adjust the coils for maximum amplitude.

Table of contents

Other CRKITS Transceiver manuals

Popular Transceiver manuals by other brands

Phottix

Phottix Strato TTL instruction manual

Kirisun

Kirisun PT 3800(1) instruction manual

Keysight Technologies

Keysight Technologies S9101A Startup guide

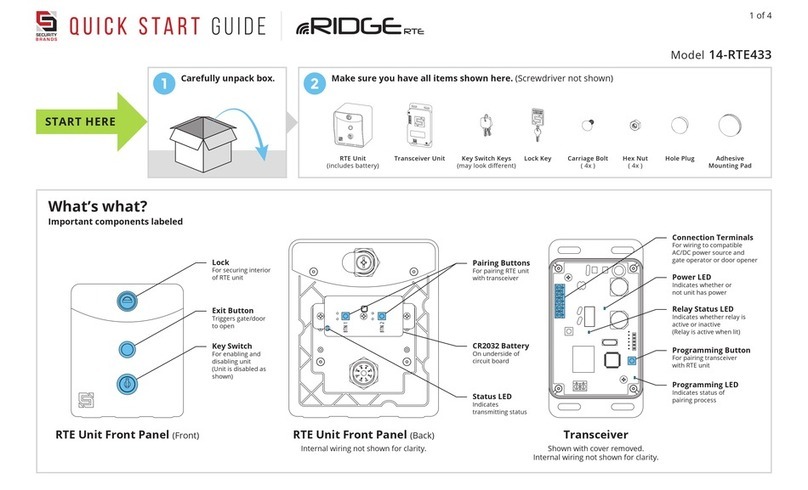

Security Brands

Security Brands RIDGE RTE 14-RTE433 quick start guide

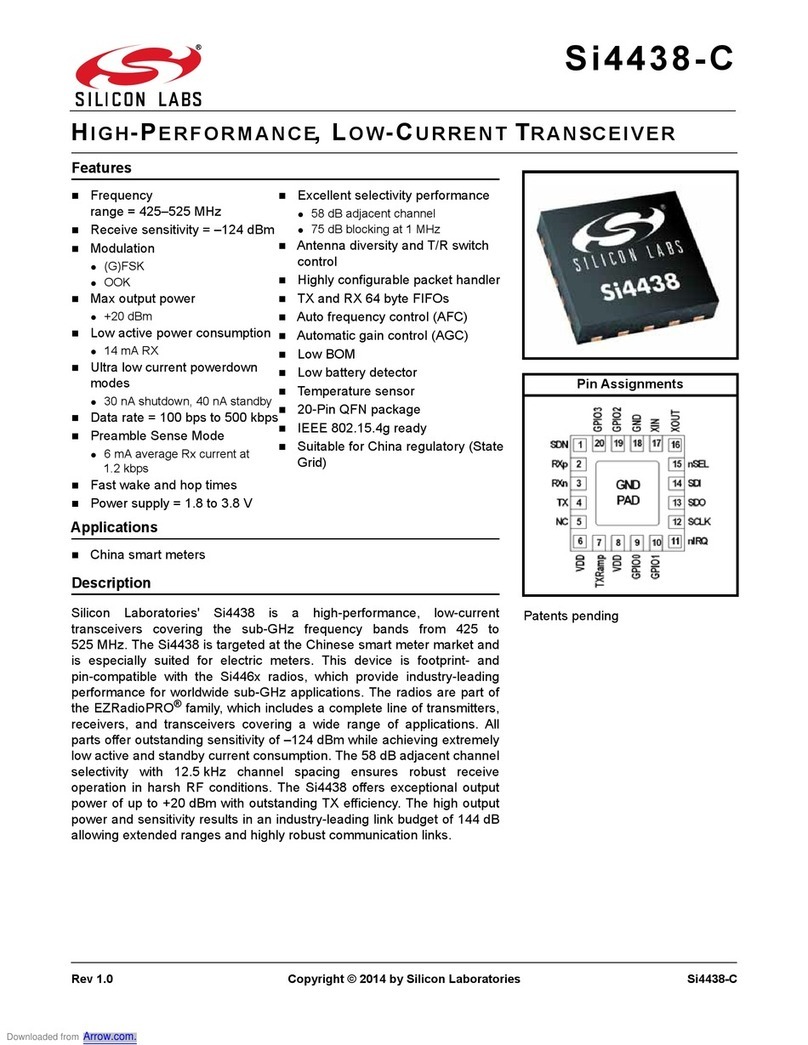

Silicon Laboratories

Silicon Laboratories Si4438-C manual

Yaesu

Yaesu FT-847 Modification