8) Turn on the main switch on the control box.

9) Set the correct speed by turning the speed dial. (For faster speeds, turn clockwise.)

10) Begin drilling by lowering the up-down handle. Use constant pressure. Occasional up and down strokes

can help clear the hole of glass swarf.

Lighten pressure at the end of cut to reduce backside chipping.

11) When hole is completed, gently lift handle to get a smooth finish.

12) Turn off machine, lift the vacuum cup levers, and remove machine.

13) Verify glass core has been ejected from drill bit.

14) Repeat process as needed.

15) Unplug machine from the power supply and clean off any glass/water residue.

ROUTINE MAINTAINANCE

Your AMZ1 Diamond Drilling Machine is designed and built to give you extended service. Drilling of glass

presents tough operating conditions due to the abrasive nature of ground glass particles and the damp

environment of wet drilling. Great benefits can be received by a quick cleanup with a clean rag after each use.

The fresh damp glass slurry will wipe off easily. Left on the machine to dry, it will build up and harden.

This same problem can occur on your drill bits. When the glass swarf hardens inside the drill bit, the next time

you use it, this hard material inside the drill bit could prevent you from drilling a hole! Take the short time it

takes to rinse, dry, and lightly oil your drill bits after each use. Be sure to include the thread and taper of the

drill in this cleanup process. We recommend CRL Cat. No. 1200 Metal Lube for all lubrication maintenance of

the AMZ1.

A light coat of oil should also be wiped on the female thread and taper of the spindle. This area is subjected to

constant wet use. Failure to clean up will cause rusting, resulting in threading problems and poor seating of

-diamond drills.

Occasionally put a light coating of oil on the twin posts your machine travels on. Lower the handle to have

access to these posts. A clean rag with light oil can be used on the entire machine to prevent corrosion.

Pay special attention to the rubber cups located on the bottom of the machine. Clean these after each use with a

clean cloth to remove the abrasive ground glass. Failure to do this will result in scratched glass or loss of

vacuum pressure and holding strength. Cup life can be extended by occasionally wiping cup surfaces with

Technical Glycerine, CRL Cat. No. GL22.

After extended use, the motor brushes may need to be replaced. These are externally serviceable for

convenience and available as a replacement part. If your machine fails to start, check the 10-amp fuse located

on the rear of the machine.

When not using your machine, store in a clean dry place.

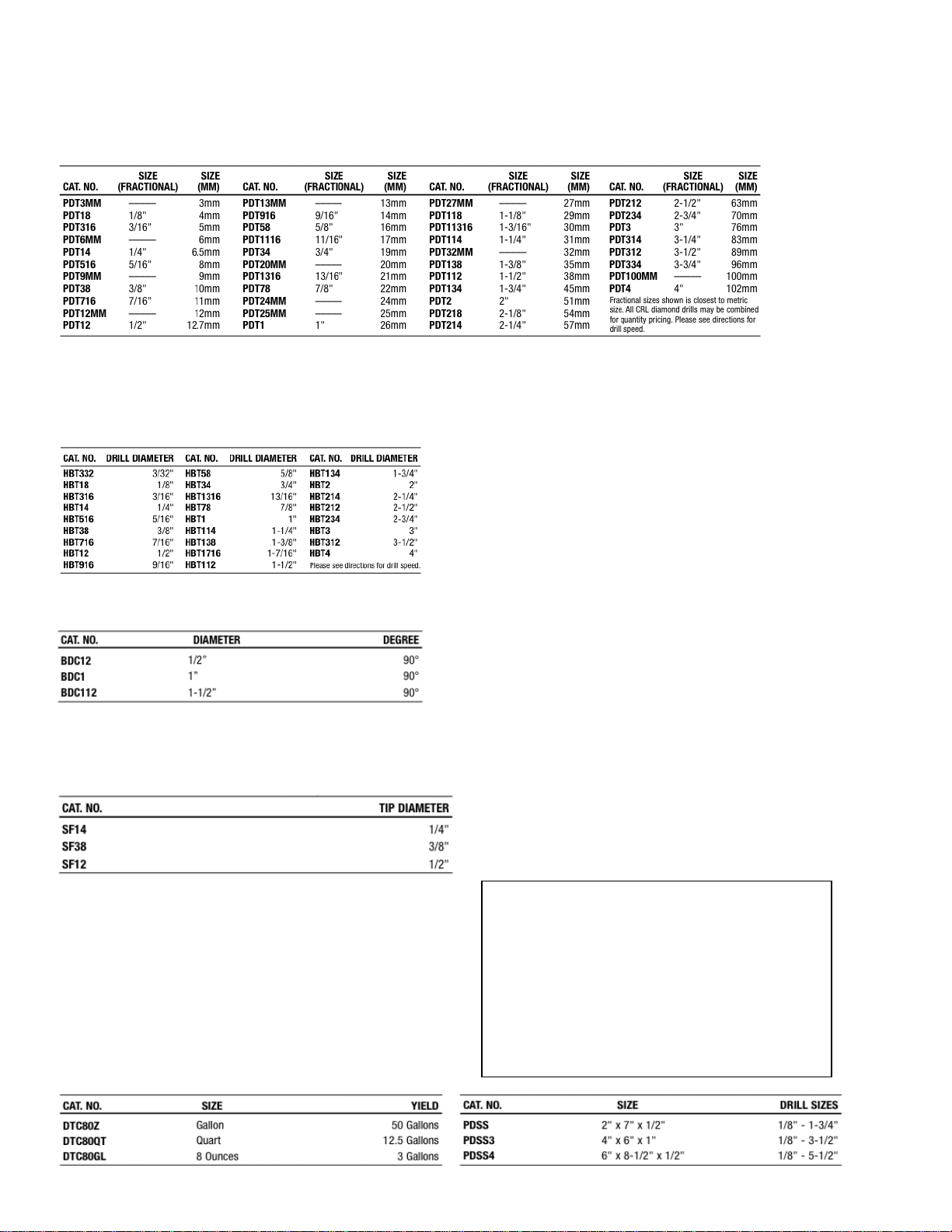

DIAMOND DRILLS

This machine is designed to be used CRL Belgian-threaded Mount Multi-layer Drills. The mount uses a male

thread on the drill bit and female thread on the spindle to pull matching tapers together. This design assures the

tool will be true running. You can use our PDT Series Metal Bond Drills or our HBT Electroformed Drills. The

machine will accept drill sizes from 1/8" to 4" (3mm to 102mm). You may also use CRL Threaded

Countersinks and Spot Facers in this machine.