Crommelins CC40HP Administrator Guide

1

CROMMELINS™ COMPACTORS

Thank you for your selection of a CROMMELINS™ Compactor.

This Operation Manual explains its use, installation, checking and maintenance.

We highly recommend that you retain this manual for ready reference.

Spare Parts & Service

Phone: 1300 554 524

Freecall Fax: 1800 636 281

spareparts@crommelins.com.au

www.crommelins.com.au

OPERATION & INSTRUCTION MANUAL

2

Thank you very much for purchasing a CROMMELINS™ COMPACTOR.

This manual covers the operation and maintenance of the your compactor. These models

are built to industry best standards, for use in mining, construction, hire industries and

general use.

Please take a moment to familiarise yourself with the proper operation and maintenance

procedures in order to maximise the safe and efficient use of this product.

Keep this owner’s manual at hand, so that you can refer to it at any time.

Due to constant efforts to improve our products, certain procedures and specifications

are subject to change without notice.

When ordering spare parts please have handy your products model number and serial

number. Record these numbers in the boxes below for future reference.

Please fill in the following blanks after checking the production number and serial

number on your product. (The location of these numbers may vary).

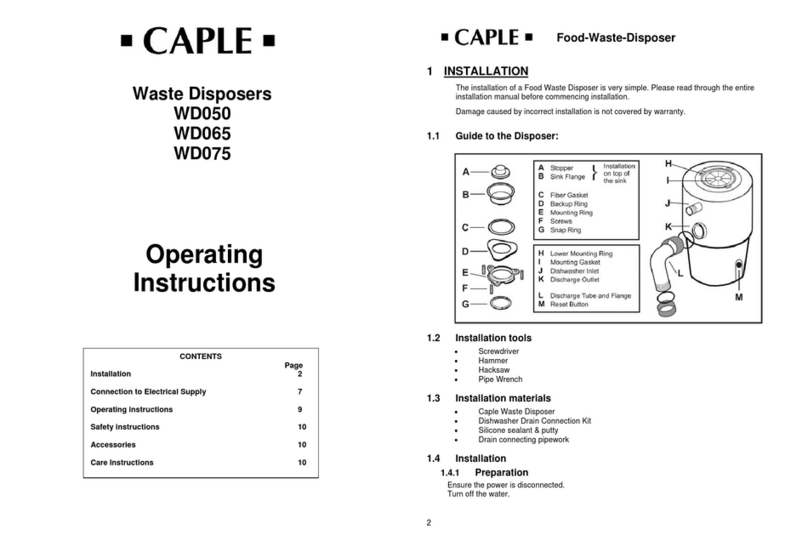

CONTENTS

Introduction & contents ...................................................................................... 2

Warranty ............................................................................................................... 3

Safety .................................................................................................................... 4

Pre-operation checkup ......................................................................................... 5

Starting your compactor …..………………………………………......................................... 5

Hints of operation ................................................................................................. 6

Stopping your compactor ……................................................................................. 6

Maintenance, belt setting & storage .................................................................. 7

Specifications charts .......................................................................................... 8

Trouble shooting ................................................................................................. 9

CC40HP Exploded drawing & parts list .................................................................. 10

CC60 Exploded drawing & parts list ....................................................................... 11

CC70 Exploded drawing & parts list ....................................................................... 12

CC70 Folding handle exploded drawing & parts list .............................................. 13

CC90 Exploded drawing & parts list ...................................................................... 14

SERIAL NO.

MODEL NO.

3

WARRANTY

CROMMELINS™ and CROMTECH™ are a registered trademark of Crommelins Machinery.

Crommelins warrants their goods against defects in materials and workmanship under

normal use and service. Crommelins Machinery warranty does not cover fair wear

commensurate with the age of the product, any damage caused by accident, abuse,

misuse, neglect or failure to observe proper operating instructions or proper machinery

maintenance as described in the instruction manual.

It is the owner’s responsibility to regularly maintain a product in accordance with the

owner’s manual and only use the equipment for its designed purpose.

Our goods come with guarantees that cannot be excluded under the Australian Consumer

Law. You are entitled to a replacement or refund for a major failure and for compensation

for any other reasonably foreseeable loss or damage. You are also entitled to have goods

repaired or replaced if the goods fail to be of acceptable quality and the failure does not

amount to a major failure.

CONSUMER ADVICE

Any claim under these warranties must be made in the warranty period from the date of

purchase of the product.

To make a claim under the warranty, you must return the product (with proof of purchase)

to the closest warranty agent or to the place of purchase.

There are over 185 national authorised service/repair agents available, visit

www.crommelins.com.au for their details and locations.

Where a failure does not amount to a major failure, Crommelins Machinery is entitled to

choose between providing you with a repair, replacement or refund. To obtain

compensation, you would need to provide documentary evidence of the loss or damage

suffered, and documentary evidence that such loss or damage was a reasonably

foreseeable consequence of a failure by Crommelins Machinery to comply with a consumer

guarantee under the Australian Consumer Law.

Crommelins Operations Pty Ltd trading as Crommelins Machinery and Crommelins

Australia.

CROMMELINS MACHINERY:

Ph: (08) 9350 5588 Fax: (08) 9451 6381

reception@crommelins.com.au

www.crommelins.com.au

PO Box 352, BENTLEY WA 6982

ABN 11 008 889 656

4

SAFETY

This manual contains important information on how to use the Crommelins compactor

models properly and safely. Please read through this manual before you attempt to

operate this product.

Ensure safe operation, this compactor is designed to give safe and dependable service if

operated according to the instructions.

•Always make a pre-operation inspection before starting the engine. (For more

information read engine operational manual)

•Stay AWAY from base plate during operation.

•Do not place flammable objects near the unit.

•Children and pets must always keep away from the area of operation.

•Never allow anyone to operate the unit without proper instructions.

•Must know how to stop the engine quickly and understand the operation of all controls.

•Be careful with the operating place and ventilation, avoid operating the machine in a

closed room, tunnel or other badly ventilated places, as its exhaust fumes contain

deadly poisonous carbon monoxide. If the machine is unavoidably operated in such a

place, discharge the exhaust fumes outside the room by a suitable means.

•Mufflers and other hot parts are dangerous. Do not touch them with hands or any other

body parts.

•Observe the following cautions when transporting. Close fuel tank cap securely and

close fuel tap tightly during transportation. Drain petrol or diesel from fuel tank before

transporting over a long distance or on rough roads.

•Stop engine without fail before replenishing fuel tank. Never replenish fuel while the

engine is running or remains hot otherwise spilled or evaporated fuel is liable to catch

fire from the engine spark or muffler heat. Wipe off spilled fuel before starting engine.

To prevent injury, wear the following protective clothing: Gloves, hard hat, work boots, ear

plugs, safety goggles and any other protective items required by job conditions.

5

PRE-OPERATION

•Consult engine manual for detailed starting information.

•Check all bolts and screws for tightness. Loose bolts and screws may cause damage to

the unit.

•Make sure that all dirt, mud, etc., are thoroughly removed from areas such as cooling air

inlet of engine, carburettor, and air cleaner.

•Check V-belt tightness. The normal slack should be approximately 10-15mm (1/2”) when

the belts are forcibly depressed in the middle position between two pulleys. To set belt

tightness; refer to Belt Setting at page 3.

•Check fuel level and refill as required.

•Check engine oil level. If engine oil level is low, refill it with the correct engine oil as

stated in the engine manual.

CAUTION! – Make sure nobody is in the vicinity of the compactor when starting the engine;

it might move suddenly with force.

STARTING PETROL COMPACTOR

STEP 1 – Turn fuel tap to ON position.

STEP 2 – Set throttle lever to LOW (starting position).

STEP 3 – For cold engine starting, close choke lever.

STEP 4– Set engine switch to ON.

STEP 5 – Pull recoil start handle to point of resistance, carefully return handle, then pull

smoothly and swiftly to START.

DO NOT pull recoil starter rope to the end as it may cause damage. When the rope is pulled

out, carefully return the rope slowly. Do not let the rope snap back.

STEP 6 – As the engine warms up return the choke to the open position. The warmup

procedure should particularly be followed during cold weather.

STARTING DIESEL COMPACTOR (REFER TO ENGINE MANUAL)

STEP 1 – Turn fuel tap to ON position.

STEP 2 – Set throttle lever to LOW (starting position).

STEP 3 – Engine is fitted with automatic decompression.

STEP 4– Set engine switch to ON.

STEP 5- Pull recoil start handle to point of resistance, carefully return handle, then pull

smoothly and swiftly to START.

DO NOT pull recoil starter rope to the end as it may cause damage. When the rope is pulled

out, carefully return the rope slowly. Do not let the rope snap back.

6

HINTS OF OPERATION

•During uphill compaction, it may be necessary to swing the handle over and pull the

machine slightly.

•When compacting on a sloping terrain, the machine may tend to slide sideways. The

operator must steer toward the rise causing the machine to travel at an angle. DO

NOT operate on inclines of more than 20 degrees.

•When operating the machine in wet or damp soil, it may occasionally be required to

clean the bottom of the base plate. Mud accumulation on the base plate will slow the

machine down and prevent efficient soil compaction.

•When operating this compactor on asphalt surface, it is recommended that light oil or

kerosene be applied to the bottom of the base plate to prevent asphalt sticking and/or

accumulation.

•Operating the machine on a fully compacted, hard, or non-yielding surface will cause it

to bounce and damage exciter bearings and will greatly reduce the life of the machine.

Reduce engine speed to eliminate bounce.

•When transporting the unit ensure the fuel tap is turned OFF to prevent flooding.

STOPPING PETROL COMPACTOR

STEP 1 – Set throttle lever to LOW (starting position). Allow engine to run for 2-3

minutes.

STEP 2 – Set engine switch to OFF position. Ensure the engine stops completely.

STEP 3 – Turn fuel tap to OFF position.

STEP 4– Cover the machine after the muffler has cooled off and keep the

compactor in a dry place.

EMERGENCY SHUTDOWN: Move throttle lever to LOW and set engine switch to

OFF position.

STOPPING DIESEL COMPACTOR

STEP 1 – Set throttle lever to LOW (starting position). Allow engine to run for 2-3

minutes.

STEP 2 – Set engine switch to OFF position. Ensure the engine stops completely.

STEP 3 – Turn fuel tap to OFF position.

STEP 4– Cover the machine after the muffler has cooled off and keep the

compactor in a dry place.

7

MAINTENANCE

CAUTION - FLAMMABLE LIQUID. When performing maintenance, stop engine and do not

smoke in adjacent area.

CAUTION - HIGH TEMPERATURE. Allow machine and engine to cool down before

performing maintenance. Contact with hot components can cause serious injury.

CAUTION - MOVING PARTS. Make sure engine is shut down before maintenance. Contact

with moving parts can cause serious injury.

DAILY SERVICE

•Check air cleaner element and clean as necessary.

•Check engine oil levels.

•Check for any loose fasteners.

•Check belt tension.

WEEKLY SERVICE (every 50 hours of operation)

•Refer to engine service manual.

•Check engine mounts and all bolts and screws for tightness. Loose bolts and

screws may cause damage to the unit.

BELT SETTING

STEP 1 – Loosen engine base bolt (underneath engine) to allow engine-base movement.

STEP 2 – Insert V-belt into clutch pulley and reducer pulley one at a time.

STEP 3 – Adjust the engine position by moving engine-base to ensure v-belts are tight

enough.

IMPORTANT: Normal slack should be approximately 10-15mm (1/2”) when the belts are

forcibly depressed in the middle position between rotor pulley and clutch pulley.

Tighten all engine bolts and cover V-belt and pulley with belt cover, tighten cover bolts.

STORAGE

•Ensure fuel tap is turned OFF position.

•Make sure that the engine is completely cool before storage.

•Clean up oil and dust accumulation on rubber parts.

•Clean the base plate and wipe on a light coat of oil to prevent rust formation.

•Cover the machine and store it in a dry place.

LONG TERM STORAGE

Remove fuel from the fuel tank. Also remove fuel remaining in the fuel line and chamber of

the carburettor. To drain fuel from the chamber of the carburettor, remove the drain plug

provided at the chamber and remove fuel.

8

PLATE COMPACTOR SPECIFICATION CHART

MODEL CC40HP CC60RP CC70RP CC70RD CC70YD CC90RP

Weight (kg) 48kg 68kg 82kg 98kg 95kg 84kg

Frequency(vpm) 5400 5800 6500 6500 6500 6000

Centrifugal Force

(kn) - 12kn 18kn 18kn 18kn 16.5kn

Plate/Shoe Size

(LxW mm)

480x280

mm

520x

360mm

610x

460mm

610 x

460mm

610x

460mm

540x

500mm

Features

Folding

handle &

wheels

Folding

handle &

wheels

Central

exciter Diesel Diesel

Front

clamps

for

isolation

mat.

Engine Make Honda Robin Robin Robin Yanmar Robin

Engine GX100

6.0hp

EX17

6.0hp

EX17

4.8hp

DY23

4.7hp

L48N

6.0hp

EX17

Engine Features

Side

Valve,

Recoil

Start

OHC

Side

Valve,

Recoil

Start

Fuel Type Petrol Petrol Petrol Diesel Diesel Petrol

Fuel Tank 0.77L 3.6L 3.6L 3.2L 2.4L 3.6L

Noise Level

db@7m - 67db 66db 74db

94db at

1m 69db

Manufacturer’s

Warranty 2 years 2 years 2 years 2 years 2 years 2 years

Engine Warranty

See

manual 3 years 3 years 3 years

See

manual 3 years

9

TROUBLE SHOOTING GUIDE

If the compactor malfunctions immediately shut the machine down. Following are some

simple trouble shooting tips:

PROBLEM

CAUSE

SOLUTION

Engine won’t start, or

stops suddenly

1. No fuel in engine

2. Engine switch being

set to “OFF”

3. Spark plug carbonised

4. Fuel strainer clogged

5. Carburettor blocked

1. Refill Fuel

2. Turn the engine switch to

“ON”

3. Clean spark plug or replace it

with a new one

4. Clean fuel strainer

5. Dismantle and clean

carburettor

Engine runs but the

machine does not

produce any vibration

1. Air cleaner element

clogged

2. Lake of engine power

3. Centrifugal clutch is

slipping

4. Improper v-belt

tension, or excessive

wear of v-belt

1. Dismantle the cleaner

element and clean the

element with proper solvent

(see engine manual)

2. Refer to engine manual

3. Dismantle the clutch

assembly and clean the shoe

and drum with proper solvent

4. Adjust the tension or replace

the belt with new one

Slow or irregular

vibration

1. Centrifugal clutch is

slipping

2. Improper v-belt

tension, or excessive

wear of v-belt.

1. Dismantle the clutch

assembly, and clean the

shoe and drum with proper

solvent

2. Adjust the v-belt tension or

replace the belt with a new

one.

IF THE FAULT PERSISTS, CONTACT YOUR LOCAL DEALER.

10

CC40HP EXPLODED DRAWING & SPARE PARTS LIST

11

CC60 EXPLODED DRAWING & SPARE PARTS LIST

12

CC70 EXPLODED DRAWING & SPARE PARTS LIST

13

CC70 - FOLDING HANDLE - EXPLODED DRAWING & SPARE PARTS LIST

14

CC90 EXPLODED DRAWING & SPARE PARTS LIST

15

This manual suits for next models

5

Table of contents

Popular Garbage Disposal manuals by other brands

Teral

Teral DSP-100H-AWV User manual and warranty

Whirlpool

Whirlpool GC1000XE Installation care and use guide

Weber Maschinentechnik GmbH

Weber Maschinentechnik GmbH CR 4 Operating and maintenance instructions

Electrolux

Electrolux COMPACT Series Installation, Operating and Maintenance Instruction

Meiko

Meiko Green BioMaster Slim Standard Operating instruction

Step 2

Step 2 Lakewood owner's manual