crosscontrol CCpilot V700 User manual

Revision: 1.0

2020-09-10

CCpilot V700

Technical Manual

www.crosscontrol.com

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

2

1. Introduction

CCpilot V700 is a freely programmable display computer with 7” high brightness full-colour WVGA

TFT with PCAP touch screen. The strong LED backlight in combination with the optically bonded

PCAP, results in excellent sunlight readability.

The powerful i.MX8X ARM® based main CPU and Linux® operating system constitute an open

platform that facilitates the implementation of premium user-machine interaction, reliable controls

and integrated fleet management solutions. In addition, there is one co-processor responsible for

hardware control and supervision.

This technical manual provides important information regarding the product’s hardware and its

basic usage. For software and operating system specifics, please see additional documentation.

Revision history

Rev

Date

Author

Comments

1.0 2020-09-10 FMG

Release Version

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

3

Contents

1. Introduction................................................................................................................................2

Revision history ...............................................................................................................................2

2. Product models .........................................................................................................................4

2.2. Document conventions .......................................................................................................4

2.3. Identification .........................................................................................................................4

2.4. Environmental resistance .....................................................................................................5

3. Product overview.......................................................................................................................5

3.1. Front side view.......................................................................................................................5

3.2. Rear side view .......................................................................................................................5

3.3. Connector side view ............................................................................................................6

4. Mounting and handling ............................................................................................................6

4.1. Mounting................................................................................................................................6

4.2. Connecting to power supply ..............................................................................................9

4.3. Cable installation ................................................................................................................11

4.4. Special considerations .......................................................................................................11

4.5. Handling and maintenance..............................................................................................12

4.6. Transportation......................................................................................................................13

5. Basic operation........................................................................................................................14

5.1. Turning ON ...........................................................................................................................14

5.2. Turning OFF and suspending .............................................................................................14

5.3. Light sensor ..........................................................................................................................15

5.4. Using the touch screen ......................................................................................................16

5.5. Status notification ...............................................................................................................16

5.6. Error codes ...........................................................................................................................16

6. Interface overview ..................................................................................................................18

6.1. Front panel...........................................................................................................................18

6.2. Buzzer....................................................................................................................................18

6.3. CAN ......................................................................................................................................18

6.4. Ethernet................................................................................................................................18

6.5. USB ........................................................................................................................................19

6.6. Bluetooth..............................................................................................................................19

7. Connectors ..............................................................................................................................20

7.1. M12 connectors, general...................................................................................................20

7.2. Power and CAN M12 pinout .............................................................................................20

7.3. Ethernet M12 pinout ...........................................................................................................21

7.4. USB M12 connector pinout ................................................................................................21

8. Specifications ..........................................................................................................................22

8.1. Technical data....................................................................................................................22

8.2. Environmental specifications.............................................................................................24

8.3. EMC specification...............................................................................................................24

8.4. Weight and dimensions......................................................................................................25

Technical support.........................................................................................................................26

Trademarks and terms of use ......................................................................................................27

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

4

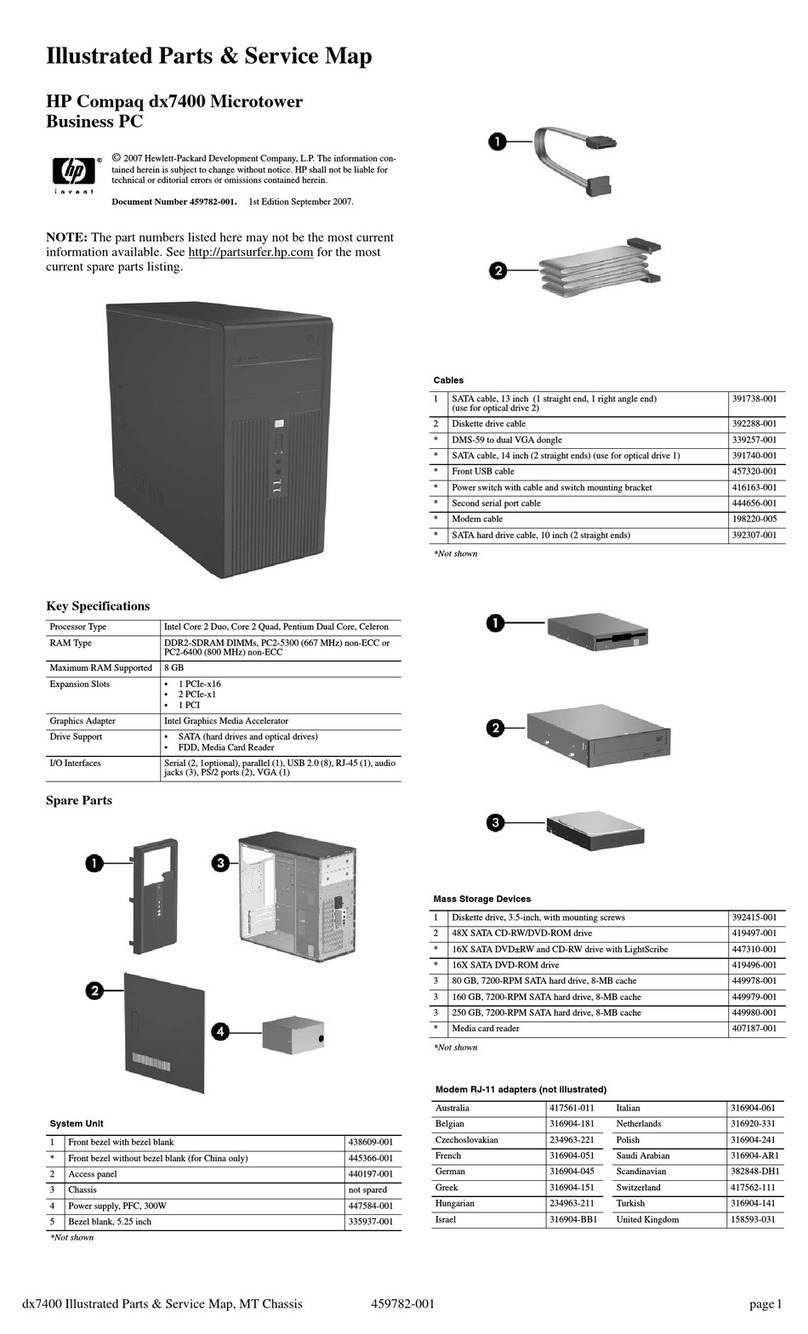

2. Product models

This documentation is applicable for all CCpilot V700 models. These models are:

•CCpilot V700 standard version of product. Part number C000152-04

•CCpilot V700 standard with Bluetooth module. Part number: C000152-01

•CCpilot V700 custom version. Part number C000152-02.

These models share the same level of performance, hardware architecture, TFT, enclosure

and connectors. The PCB is the same for all versions but may be populated differently.

2.1.1. Customized models

The platform enables additional customization of hardware and software. Described herein are

the features included in product models described above. Additional features in customized

models will be documented separately.

Contact CrossControl for customization inquiries.

2.2. Document conventions

This document uses the following conventions:

Description

Appearance

Important information

Differences between product

models

(exclamation symbol)

(observe’ symbol)

Text formats used in this document are described in the table below:

Format

Use

Italics

Names, designations, and references

Bolded

Important information

2.3. Identification

Each device has identification labels with serial number, part number and revision which identifies

your unique device. This information is required when communicating with CrossControl regarding

Technical support and Service/Repair needs.

Figure 1: Identification labels

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

5

2.4. Environmental resistance

The CCpilot V700 product has been designed to manage tough environmental demands. Much

effort has been put into designing and selecting system components to provide a reliable and

robust device.

Thorough testing has been performed in order to ensure compliance to a broad range of

applicable regulatory requirements and to meet user demands of a ruggedized product for

machinery control.

A complete list of standards to which the product has been tested for compliance can be found

in chapters 8.2 and 8.3.

3. Product overview

This chapter contains illustrations of the CCpilot V700 showing the location of external

connectors, indicators etc. Connectors are described in more detail in chapter 7. Additional

mechanical information can be found in chapter 8.4.

3.1. Front side view

At the front side of the device there is a 7” display with projected capacitive touch-sensor

(PCAP). There is also a light sensor and an RGB status LED in the front. The light sensor

enables automatic dimming of display and the RGB status LED shows operation modes or fault

indications.

Figure 2: CCpilot V700 front side view

3.2. Rear side view

The rear side contains the mounting holes for either a fastener in accordance with 1.5” RAM®

ball mount (RAM-202U) or custom bracket for panel mounting and a GORE-TEX®membrane

for ventilation.

Light

RGB status

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

6

Figure 3: CCpilot V700 rear side view

3.3. Connector side view

At the side of the device there are external interface connectors, i.e. 3 x M12 for Power, CAN,

Ethernet and USB.

4. Mounting and handling

This chapter contains recommendations for installation, handling and maintenance of the

product.

4.1. Mounting

CCpilot V700 supports two different mounting methods, a RAM mount or a panel mount. These

two mounting methods are described separately below.

For both fastening methods, use the appropriate 3 pc. M5 x 0.8 button head screw of type MRT

(Torx) The recommended torque for the screws is 1.5-2.0 Nm. Using fluid locker or locking

washers (split ring, toothed lock, etc.) is required for proper mounting. Ensure that the M5

mounting screws are clean and dry before mounting.

GORE-TEX

membrane, under

mount for added

protection

Figure 4: CCpilot V700 connector side

Ethernet

Power and CAN

USB

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

7

Note that the depth of the threaded holes is 8 mm. Be careful not to use too long screws which

may damage the device when tightened. It is also very important to use a fastening plate with

holes that are not larger in diameter than 6 mm to avoid pulling out the threaded inserts from

the unit.

4.1.1. RAM mount

CCpilot V700 can be mounted using a RAM mount, i.e. RAM-202U, a round base 1.5” ball

mount which allows adjustment of the display’s position and angle. Screw length should be

12mm.

Figure 5: 3 hole ram mount

4.1.2. Panel mount

Alternatively, the device can be mounted in a panel-cutout using a panel mounting bracket

(article number C000152-48), Screw length should be 10mm.

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

8

Figure 6: Mounting bracket

The mounting bracket is designed for a panel thickness of 1.5 - 3.0 mm. Panel cut out

dimensions are shown in the figure below. A drawing in DXF-format for precision cutting of

panels is available upon request. Screw length should be 10mm.

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

9

Ensure that CCpilot V700 is mounted to a smooth, flat surface. Fastening the unit to an uneven

surface may stress the enclosure, damage the outer flange or possibly even flex the circuit

board inside, leading to a premature failure.

4.2. Connecting to power supply

This chapter describes how the CCpilot V700 is preferably connected to the power supply of

the equipment it is installed in. The principle is the same for vehicular and stationary

installations.

Carefully read through the following sub-chapters. They are critical for designing and adapting

the electrical system of the equipment in which the CCpilot V700 is installed. Connector

pinouts are found in chapter 7.

4.2.1. Wire gauge

Wire gauge for the power supply should be dimensioned with respect to the total load current,

the cable length required, and the worst-case voltage drop allowed, considering the minimum

operational voltage of the device.

•Current consumption of the CCpilot V700 device is found in chapter 8.1.

•The wire gauge for the power supply is recommended to be at least 0.75 mm2/AWG 18 for

“normal” loads.

4.2.2. External fuse

To prevent cable fire in case of short circuit, an external fuse must always be used when

powering the device from a high current capable power source, for example a vehicle battery.

•The fuse shall be located as close to the battery/power source as practically possible. A

recommendation is to place the fuse at a maximum distance of 15 cm (6 inches) from the

(+) terminal of the source.

•Fuse rating shall be dimensioned with respect to wire gauge, maximum current

consumption and the inrush current of the device. Refer to chapter 8.1 for fuse rating

details.

•As a guideline, a slow acting fuse with 2-3 A current rating should be used.

•Remember to also apply fusing for the on/off control wiring, see chapter 4.2.4.

4.2.3. External key switch signal

The device’s key switch signal should be connected to the positive supply line via the vehicle’s

ignition key switch.

•The wire gauge for the key switch signal shall be dimensioned to handle the total switch

current and the fuse type and rating shall be selected to prevent cable fire in case of

cabling short circuit.

•As a guideline, a slow acting fuse in the range of 100-5000 mA for the key switch signal

should be sufficient for most practically usable wire gauge.

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

10

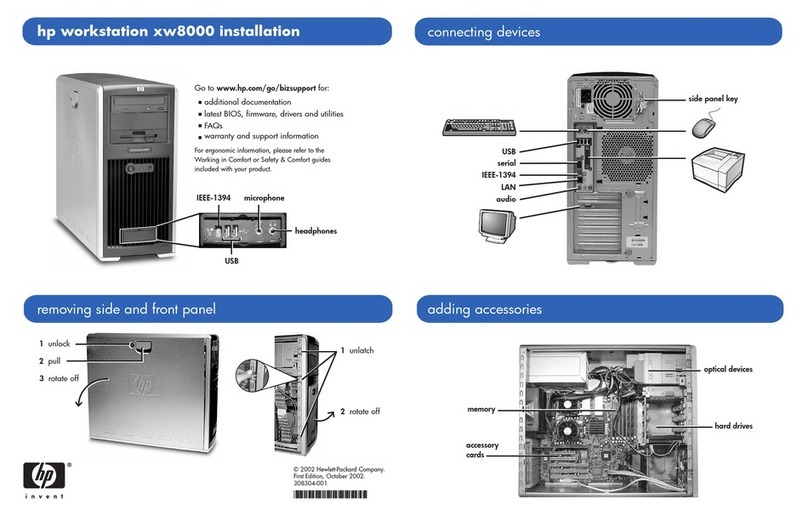

4.2.4. Application example

Below is an application example schematic of the CCpilot V700 power supply connection.

If the system has a main switch for completely disconnecting the battery (S1 in schematic

below), the device’s power supply and key switch signal shall be connected after the main

switch.

It is not recommended to disconnect the battery without shutting down the device first - since

doing so will immediately switch off all internal voltages, regardless of ongoing operations. Any

information which was not saved to flash memory will be lost when disconnecting the battery.

However, no physical damage will be caused to the device by disconnecting the battery.

Figure 7: Schematic example for power supply installation of a CCpilot V700 device in a

vehicle. The ignition switch (S2) can be shared by several devices (Device X, Y, …)

By connecting the power supply according to the example above, the CCpilot V700 device will

automatically start up when the key switch (S2) is closed and shut down when the switch is

opened.

Note that the on/off behaviour of the CCpilot V700 described here is the default configuration.

Its response to the on/off signal may be altered using the CCAux API, see chapter 5.1 for more

details.

Be advised that the device consumes a small amount of power from the main supply also when

shutdown (123 µA at 12V, 0.38mA at 24V) or suspended (37mA at 12V, 22mA at 24V).

Therefore, if the device has been attached for a long period of time without the vehicle motor

GND

1

2

4

F1

2-3 A

GND

BATTERY

S2

(Turnkey

switch)

M12

connector 1

:

:

F2

0.1-0.5 A

Device B

GND

Device C

GND

IMAX: 2.5 mA

Min 0.75 mm2/AWG 18

S1

(Main switch)

(on/off control)

Min 0.75 mm2/AWG18

Device A

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

11

running, the battery may be drained, resulting in inability to start up the vehicle. A main switch

for disconnecting the device’s main supply is highly recommended in such situations.

4.3. Cable installation

Cables shall be installed in such a way that they do not run any risk of being damaged, pinched

or worn.

•Avoid excessive bending and twisting of cables.

•Use strain-relief on cables near the device to minimize stress on cables and connectors.

•Properly snap the connectors to give reliable contact and sealing and to avoid unnecessary

strain.

•Shielded cables are recommended and, in some cases, necessary to ensure reliable

communication and appliance with agricultural EMC standards.

4.3.1. Recommendations for cable shields

To achieve electromagnetic compliance and stable operation of the system, shielded cables

are required for Ethernet and USB interfaces.

4.4. Special considerations

To ensure proper and reliable operation and to retain IP-classification of the device, below

recommendations must be followed:

•The device should be placed in a way that prevents direct and continuous exposure to

water or close proximity to hot-air vents.

•To enable sufficient cooling, the device must be installed in a way that allows ambient air to

circulate around it. A clearance of at least 50 mm around the device is recommended.

•To maintain IP classification, all M12 connectors must have a mating external connector

attached. Protective caps shall be used on all non-mated connectors. Please note that the

protective caps mounted on the M12 connectors are for transportation protection only.

•The device has a ventilation membrane, refer to Figure 3 for the location. For proper

ventilation of the device, dirt and water must be prevented from accumulating and covering

the membrane. Be cautious not to insert objects which may puncture the membrane. Doing

so will violate the IP-classification and void the warranty of the device.

•Install the device and any cables attached in a way that they are not subject to excess

vibrations or other potentially harmful stress.

•Loose fasteners are a common cause for excessive vibration. Fasteners may come loose

due to improper mounting techniques such as omitting thread lockers (fluid locker or

locking washers) or by over/under-tightening. Proper tightening requires dry, clean

fasteners and a torque wrench.

•If the device is exposed to chemicals, water, dirt or other pollutants, it is recommended to

have it cleaned off as soon as possible. See chapter 4.5.1 for cleaning instructions.

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

12

4.5. Handling and maintenance

Handle the device with care and pay attention to the following handling instructions:

•Disconnect all cables to the device during welding or when performing other service to the

machine imposing a risk of damaging electronic devices.

•Service and repair to the device shall only be made by authorized personnel. If the device

is opened by unauthorized personnel, its warranty will be void.

•Scratches or other damages may occur to the display surface if it is exposed to sharp

objects, abrasives or heavy impacts. This must be avoided to increase the longevity of the

screen.

•The internal eMMC flash storage has a limited number of write cycles. Therefore it is

recommended that the amount of writing to flash is limited within software applications.1

•Always consider personal safety when installing and operating the product. For example,

in vehicle installations, CrossControl does not recommend that the product is being

actively operated by the driver when a risk of injury to people or damage to property is

present.

4.5.1. Cleaning

To ensure proper and reliable functionality over time, pay attention to the following cleaning

instructions and precautions:

•Wipe the device clean from dirt using a soft damp cloth, preferably of microfiber type.

Larger amount of dry dust may be swept off using a soft brush before wiping clean.

•Avoid using alkaline, alcoholic or other potentially adverse chemicals for cleaning as doing

so may damage the device. However, small amount isopropyl alcohol may be used for

removing harsh stains.

•Avoid spraying or by other means applying larger amount of water or alcohol directly to the

device. Instead, lightly dampen a cloth before using it for cleaning the device.

•After cleaning, make sure that the device surface is left dry.

•Never use high-pressure air, vacuum, water or steam to clean the device.

4.5.2. Real time clock battery

Time and date information is stored in a memory sustained by an internal back-up battery. The

battery is a 3V 1000mAh high operating temperature Poly-carbonmonofluoride Lithium battery.

The expected life time of the battery is approximately 20 years. The battery is not replaceable.

1The eMMC is used in pseudo SLC mode and implements both static and dynamic wear levelling to reach the

best reliability. The number of program/erase cycles is between 20k to 60k depending on the manufacturer and

temperature. Our recommendation for the application software is to temporary cache in RAM and to write larger

chunks of data to the eMMC. This recommendation is not specific to eMMC but is applicable to all flash

memories.

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

13

4.6. Transportation

When transporting the device it is recommended to use the original packaging. Make sure that

protective caps are used on all non-mated connectors. The storage temperature interval [-40°C

to +80°C] must be met.

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

14

5. Basic operation

This section covers basic operation of the product such as start-up, shut-down, suspend,

resume, display operation and status notification.

Observe that the behaviour of the external on/off control is user configurable in terms of:

•Enabling/disabling functionality

•Configurable timing parameters

•Edge or level triggered

Notifications during start-up are indicated by the status LED or beeping with the buzzer in

different patterns. The buzzer is used for audible alerts as well as for various error notifications,

see chapter 5.6 for error code details.

The status notification behaviour in the operational state of the device is configurable by user

applications. Described herein are the factory default behaviours of the on/off controls and the

status notification.

5.1. Turning ON

The CCpilot V700 product can be started in different ways:

1. Connecting the external on/off control signal to a positive supply input (at or above

approximately 6V).

oWhen started this way, the on/off signal must remain asserted. De-assertion of this

signal will shut down the device unless configured otherwise.

2. It is possible to configure the device to automatically start up whenever external power is

applied (i.e. without using any on/off control).

a. Note that this function is disabled as factory default.

For resuming the device from suspend mode, see chapter 5.2.

While starting up the device, it will give a short beep and the status LED will flash with 2 Hz.

When the device enters operational state the status LED will stop flashing and be turned on.

5.2. Turning OFF and suspending

There are several ways to turn off the CCpilot V700 device and also alternatives to enter

suspend mode instead of completely shutting down the device.

5.2.1. Shutting Down

There are a two ways to shut down the device, provided that it is in normal operational state

when the action occurs:

1. By disconnecting the external on/off control for more than a specified time, i.e. using the

turn-key functionality.

oThe time-out is user configurable and defaults to 4 seconds.

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

15

oIf the on/off signal is brought back high again while the device is shutting down, it

won’t restart automatically. A low-to-high transition must occur after the device has

fully shut down to make a restart.

2. By operating system shutdown requests.

To ensure that data is not lost nor the flash memory corrupted, it is recommended that all

necessary data be saved and all programs closed before the device is shut down.

Note that the device won’t shut down from Suspend mode by these actions. See chapter 5.2.2

for details of Suspend mode and wakeup.

When performing any of the above, the CCpilot V700 device will shut down.

5.2.2. Suspending/resuming

Suspending and resuming are faster alternative to shutting down and starting up the device. In

suspend mode, the data remains in RAM memory and the device must be connected to

external power supply to maintain its state.

Suspend mode can be entered in two ways:

1. By disconnecting the external on/off control, i.e. using the turn key functionality.

oBy factory default, disconnecting the external on/off control is configured to shut-

down the device.

2. By selecting the operating systems suspend alternative.

Observe that the product current consumption in suspend mode is higher than in shut-down

mode.

To prevent a vehicles or machines battery from draining when the device is suspended, a user

configurable time-out can be set for how long the unit shall stay in suspend mode before it

automatically shuts down. The default suspend time-out is set to 60 minutes.

Resuming from suspend mode can be done by the following event:

1. By a low-to-high transition of the external on/off control, i.e. using the turn-key functionality.

Configuration of suspend and resume is done through the CCSettingsConsole application or

using the CCAux API. See the software guide for details.

5.3. Light sensor

The CCpilot V700 contains a light sensor that can be used to automatically adjust the display

brightness, depending on the ambient light conditions. As depicted in Figure 2, the light sensor

is located in the lower right corner of the front surface. When automated dimming is enabled,

the level of sensitivity can be adjusted.

The screen brightness can also be manually controlled directly from user applications through

APIs.

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

16

For proper operation it is important to keep the light sensor opening clean and with free

visibility.

5.4. Using the touch screen

To reduce the amount of reflections when operating under sunny conditions, the touch screen’s

protective glass is covered with an anti-glare film. Do not use any sharp or abrasive objects

when interacting with the touch screen.

Basic usage of the capacitive touch screen should be intuitive for most users. Note that the

touch screen is capable of handling two simultaneous touches.

5.5. Status notification

The CCpilot V700 contains a status LED in the front used for notification while starting up,

shutting down or in other operational states. The buzzer may also be used for user

notifications. See Table 1 for a description of the status notification behavior for different

operational states.

Table 1: LED and buzzer indication for different operational states

Operational state

LED indication

Buzzer notification

Device off

OFF

-

Power applied, device off

OFF

-

Starting up

Yellow flashing, 2 Hz

Short beep

Operating (started up)

Static green

-

Suspended

Yellow flashing, 0.2 Hz

-

Shutting down

Static green

-

Rescue mode, starting

Static orange

Short beep

Rescue mode, running

Green flashing, 2 Hz

-

Serial download mode (OS update)

Yellow flashing, 0.5 Hz

-

Forced update mode (OS update)

Orange flashing, 0.5 Hz

-

SS firmware update mode

Static yellow

-

Observe that the status notification behaviour in both the start-up and operating states is

configurable by user applications running on the device.

5.6. Error codes

The status LED in the front is also used for indicating error codes by emitting a blue blinking

pattern after shutdown of the device. The device may be started again when in this mode, by

the key switch signal. Depending on the nature of the error, the device may start or go back

into error indication.

When an error occurs, the device is immediately shut down and the error is reported by

blinking a specific number of times corresponding to an error code (see table of error codes).

The blinks will be in a continuous sequence of 1 Hz blinks, with a longer pause of two seconds

after the specific number of blinks, allowing the end user to count the number of blinks. Refer

to Figure 1 below for an example.

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

17

Figure 8: Example of the blinking pattern for error code 3

When an error occurs, an error code is also immediately saved to persistent storage (FRAM). If

several errors occur before the device it is shut down, only the code of the first error is saved

and reported. The error code in persistent storage can be read and cleared from a user

application.

Refer to Table 2: CCpilot V700 error codes for a complete listing of the error codes.

The number of blinks is important information if the unit is sent in for service/repair.

Table 2: CCpilot V700 error codes

Error code

Error code name

Likely problem cause

1 errCodeReadErrEEPROM

Corrupted FRAM. Invalid values. FRAM

may need to be manually

reprogrammed or replaced.

2 errCodeWriteErrEEPROM

Corrupted FRAM. Invalid values. FRAM

may need to be manually

reprogrammed or replaced.

3 errCodeDriverInit

Failed to initialize one or several low

level drivers.

4

-

-

5 errCodeMPDoneTimeoutErr

Timeout waiting for the MP_DONE

signal – MP error. Boot loader missing.

Faulty or unprogrammed eMMC.

6

-

-

7 errCodeTEMPOutOfLimits

Temperature sensor malfunction or

extreme operating conditions.

8

-

-

9

-

-

10

errCodeRCCInit

SS circuit malfunction (clocks).

11

errCodeSSState

Programming bug or faulty processor.

12 errCodeManageDiagnostics

Failed to save diagnostic data to

FRAM.

13

errCodeManageActDeAct

HAL_IO errors (SS internal).

14

errCodeTickTimeOutTimer

HAL_IO errors (SS internal).

15

errCodeOperateModeStateError

SS internal.

16

errCodeHALIOReadErr

HAL_IO errors (SS internal).

17

errCodeHALIOWriteErr

HAL_IO errors (SS internal).

18

-

-

19

-

-

20

-

-

21

errCodeVMAINOutOfLimits

External supply voltage out of limits.

22

-

-

23

-

-

24

errCodeVREFOutOfLimits

Internal reference voltage out of limits.

25

-

-

26

errCode5VOutOfLimits

Internal 5V voltage out of limits.

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

18

6. Interface overview

This section describes the various interfaces of the product. Main part of these interfaces can

be accessed via software APIs. These are described in the CCpilot V700 Software Guide.

6.1. Front panel

6.1.1. Touch screen

The front panel contains a projective capacitive (PCAP) touch screen, which is capable of

handling two simultaneous touches.

6.1.2. Light sensor

There is a light sensor in the front panel used by user applications or used with the built-in

automated function for dimming of the display brightness.

For light sensor location, see Figure 2. Refer to the CCpilot V700 Software guide for details

about accessing the light sensor data from user applications.

6.1.3. RGB status LED

The CCpilot V700 contains a status LED in the front used for notification while starting up, shutting

down or in other operational states.

6.2. Buzzer

The CCpilot V700 has a built-in buzzer that can be used for audible notifications. The buzzer is

software controllable with configurable volume and frequency.

For buzzer location see Figure 3. See chapter 5.5 for buzzer notification events. Refer to the

CCpilot V700 Software guide for details about controlling the buzzer from user applications.

6.3. CAN

The CCpilot V700 has two CAN ports that meets CAN ISO 11898 2.0B (29-bit extended

identifier) and supports bit rates up to 1 Mbps.

Note that Internal EMI filters on CAN High/Low signals have a capacitance of 100 pF (typ)

which deviates from the ISO 11898 standard and implies some limitations on the CAN bus

topology (maximum bus length, number of CAN nodes etc.) when running at high bit-rates, i.e.

above 250 kbps.

The ports feature highly protected CAN transceivers which are tolerant for bus short-circuits to

main supply voltage and ground.

CAN shield connections are according to J1939-11 with capacitive coupling to ground. There is

no device-internal CAN bus termination, therefore bus termination must be applied externally.

6.4. Ethernet

CCpilot V700 has one Ethernet interface supporting 10BASE-T/100-BASE-TX/FX and Auto-

MDIX.

The Ethernet interface is galvanic isolated with 1.0 kVAC insulation voltage.

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

19

Shielded cables shall be used to ensure reliable communication and electromagnetic

compliance.

As with all Ethernet enabled devices, connecting the device to a public network environment

may impose an IT security threat.

6.5. USB

The CCpilot V700 has one (1) USB port. This port supports an USB OTG interface, i.e. acting

as both host and device. Using the port in USB device mode is only for OS updates through a

connected PC with appropriate tool installed.

In USB host mode, it can be used for application data transfer or the connection of a peripheral

such as a mouse or keyboard.

Due to the M12 connector specification, USB data signal integrity cannot be guaranteed with

higher speeds than full-speed USB (12 Mbps). However, hi-speed operation is supported by

the USB host controller.

The USB port can supply up to 500 mA. The USB port is internally over current and short

circuit to ground protected. Shielded cable shall be used to ensure reliable communication and

electromagnetic compliance.

6.6. Bluetooth

The CCpilot V700 models with P/N C000152-01 have a Bluetooth module to facilitate wireless

communication to and from the device. The Linux based operating system in the CCpilot V700

includes a software Bluetooth stack for easy application development including Bluetooth

functionality.

Refer to the CCpilot V700 Programmers manual guide for details about implementing

Bluetooth functionality in user applications.

Bluetooth chip and communication specification:

Items

Specification

Radio certificates

FCC/IC/CE/RCM/Giteki

Antenna Type

Internal

Wireless specification

802.11 b/g

Bluetooth version

V5.0 Dual Mode – BR / EDR / LE

Frequency range

2.402 –2.480 GHz

Temperature range

The Bluetooth module is operational in the CCpilot V700’s

full temperature range

Range

Circa 100 meters

Max Transmit Power

Class 1 +8dBm from antenna

CCpilot V700

Revision: 1.0

Technical Manual

2020-09-10

www.crosscontrol.com

20

7. Connectors

There are three M12 connectors, marked with 1, 2 and 3 accessible from the side of the

device. Refer to 9 for an overview of the connectors.

7.1. M12 connectors, general

Pay close attention to the coding; violence or excessive force should not be used when mating

the connectors.

Figure 5: M12 connector pinout, 8-pin A-coded, 4-pin D-coded and 5-pin A-coded.

The M12 connector pins/receptacles are made of gold-plated copper-zinc alloy. It is

recommended to use gold-plated pins/receptacles in the mating connectors. Using different

plating in the cable connectors might cause galvanic corrosion. The M12 contact body is made

of polyamide and the sleeve around it is made of nickel-plated zinc.

Note that all three M12 connectors must be mated with its corresponding cable connector or a

proper blind plug to maintain the IP-classification.

7.2. Power and CAN M12 pinout

Ethernet M12 Connector

Matching plug: Female, 8-pin, A-coded with shield

Pin

Signal

1

Power supply

2

Ground

3

*Force pin for USB serial download mode of the i.MX 8X

4

Key switch signal

5

CAN1 high

6

CAN1 low

7

CAN2 high

8

CAN2 low

Table 3: Power and CAN M12 connector pinout

*Pin for forcing the USB serial download mode of the i.MX 8X for flashing of boot and/or image.

Active high. Leave floating or grounded for normal operation.

Table of contents

Other crosscontrol Desktop manuals

Popular Desktop manuals by other brands

HP

HP Workstation xw8000 Installation

HP

HP RP9 G1 9015 Disassembly instructions

Lenovo

Lenovo 821532U - ThinkCentre M52 - 8215 Hardware Maintenance Manual

Panasonic

Panasonic CF-M34 Series Reference manual

Lenovo

Lenovo IdeaCentre A310 Quick reference guide

HP

HP Compaq Pro 6300 Series Microtower Maintenance and service guide