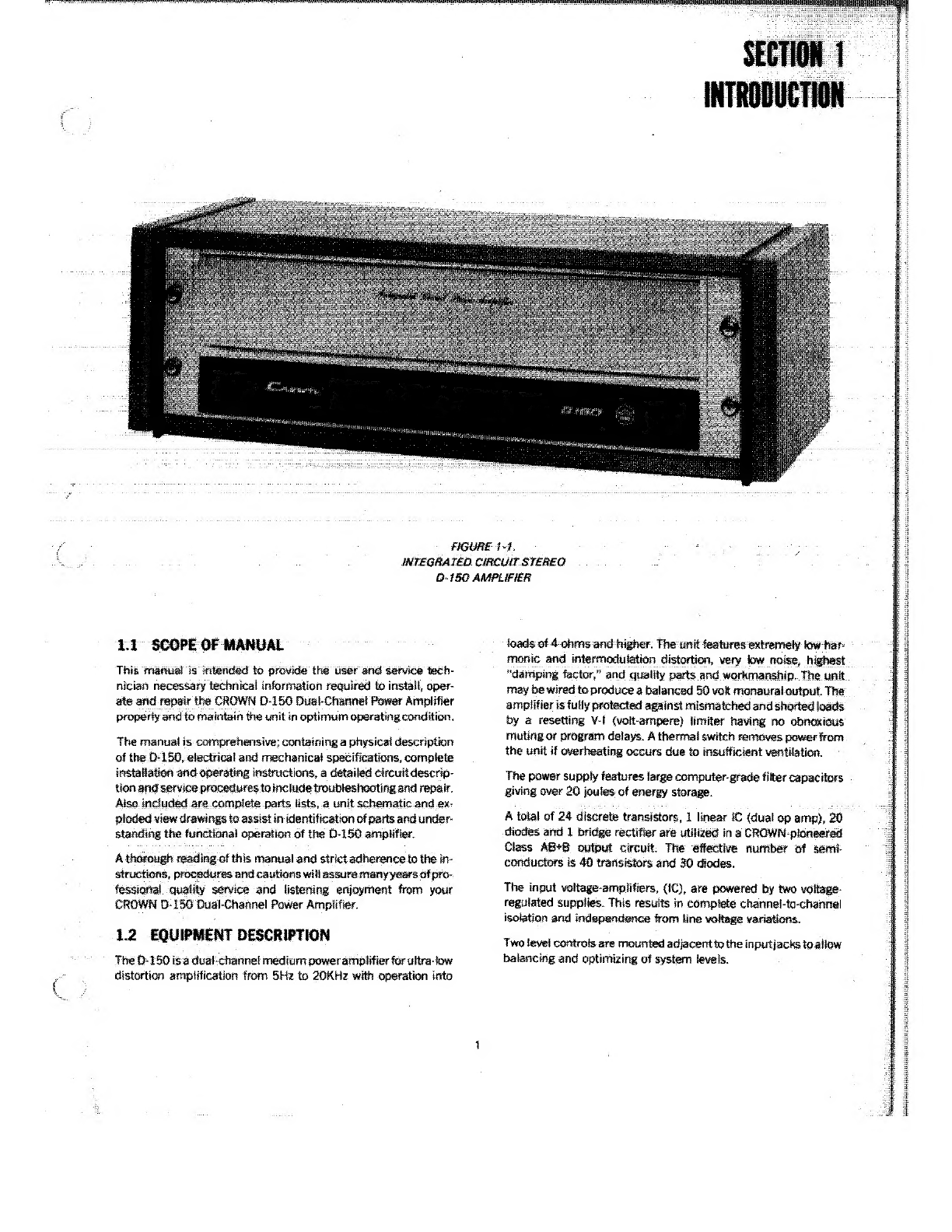

Crown D-150 User manual

Other Crown Amplifier manuals

Crown

Crown D-75 User manual

Crown

Crown 280A User manual

Crown

Crown ComTech DriveCore CT 475 User manual

Crown

Crown Macro-Tech MA-1200 Quick start guide

Crown

Crown 1160MA User manual

Crown

Crown D-150 User manual

Crown

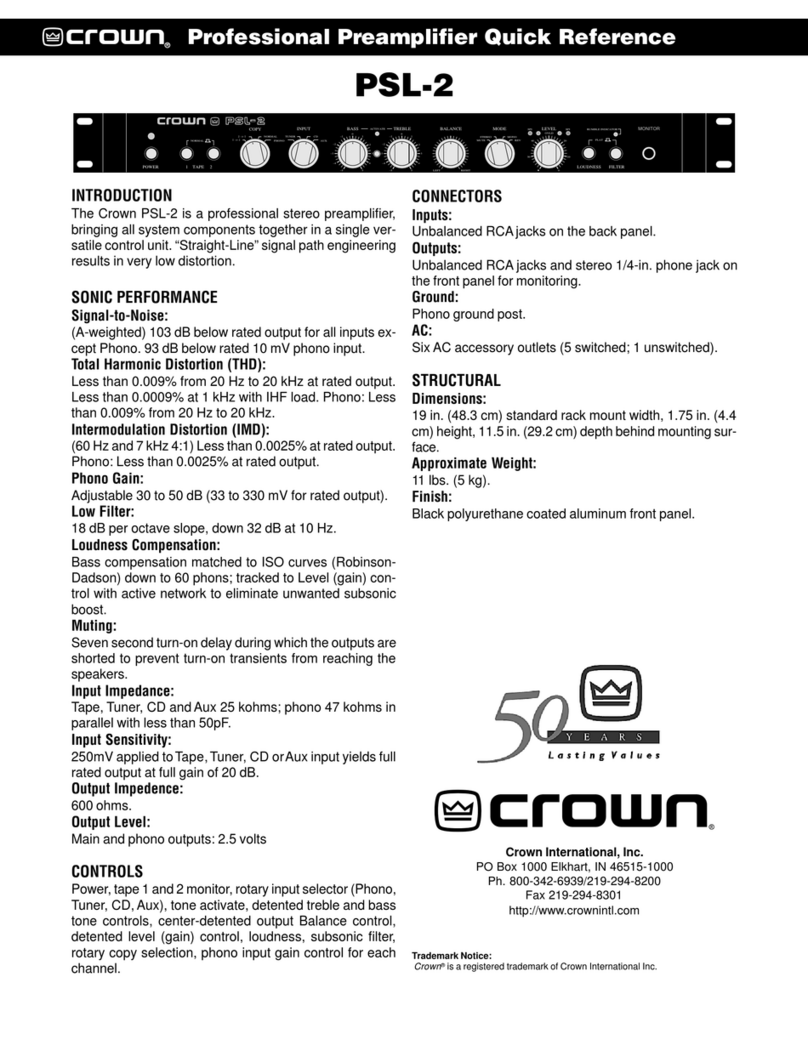

Crown PSL-2 User manual

Crown

Crown VRACK User manual

Crown

Crown I-Tech I-T5000 HD User manual

Crown

Crown CNi 4000 User manual

Crown

Crown XTI2 SERIES XTI 4002 User manual

Crown

Crown XTi 1002A User manual

Crown

Crown Macro-Tech MA-3600VZ User manual

Crown

Crown Macro-Tech MA-600 Quick start guide

Crown

Crown XTi Series User manual

Crown

Crown I-Tech I-T4000 User manual

Crown

Crown 1400 CSL Guide

Crown

Crown DC-300A II User manual

Crown

Crown D-45 User manual

Crown

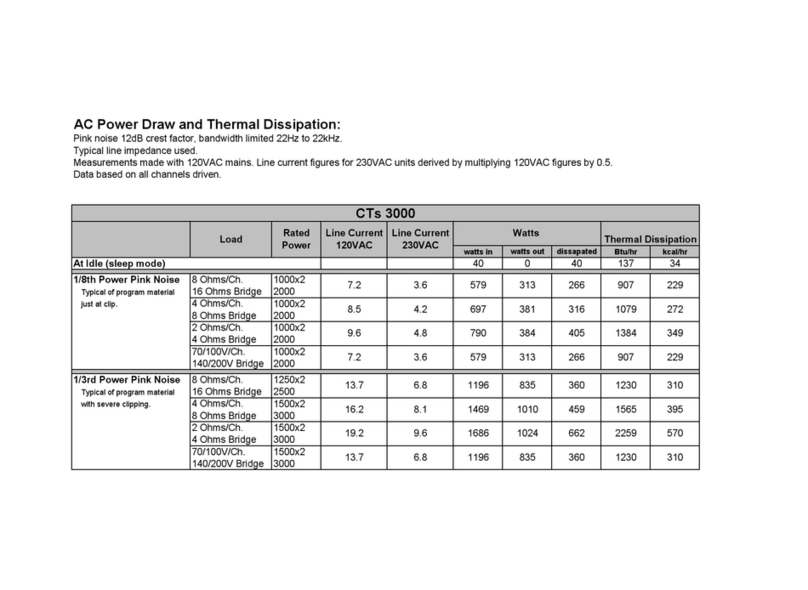

Crown CTS SERIES CTS 3000 Parts list manual