CRRCpro GP22R User manual

GP22R MANUAL

GP22R

-1-

Specifications:

War nings!

CRRCpro

WWW.CRRCPRO.COM

Safety Tips!

1. During the break-in period, it is recommended that the engine be installed on the aircraft or a test stand

2. Mount the engine correctly, please make sure all components including the propeller and the engine mount are secure and tight.

3. Keep the surface of the engine clean to ensure proper heat dissipation. Ensure proper cooling/ventilation around the cylinder

with adequate air exhaust.

4. Use an approved propeller and spinner

5. Please ensure that the propeller balanced, as an imbalanced prop robs power.

6. The ignition module can get hot during operation, ensure appropriate cooling.

7. Use the correct battery, Switch and regulator (if applicable) for your ignition

8. Use a fuel tank and fuel line (Tygon) suitable for gasoline operation.

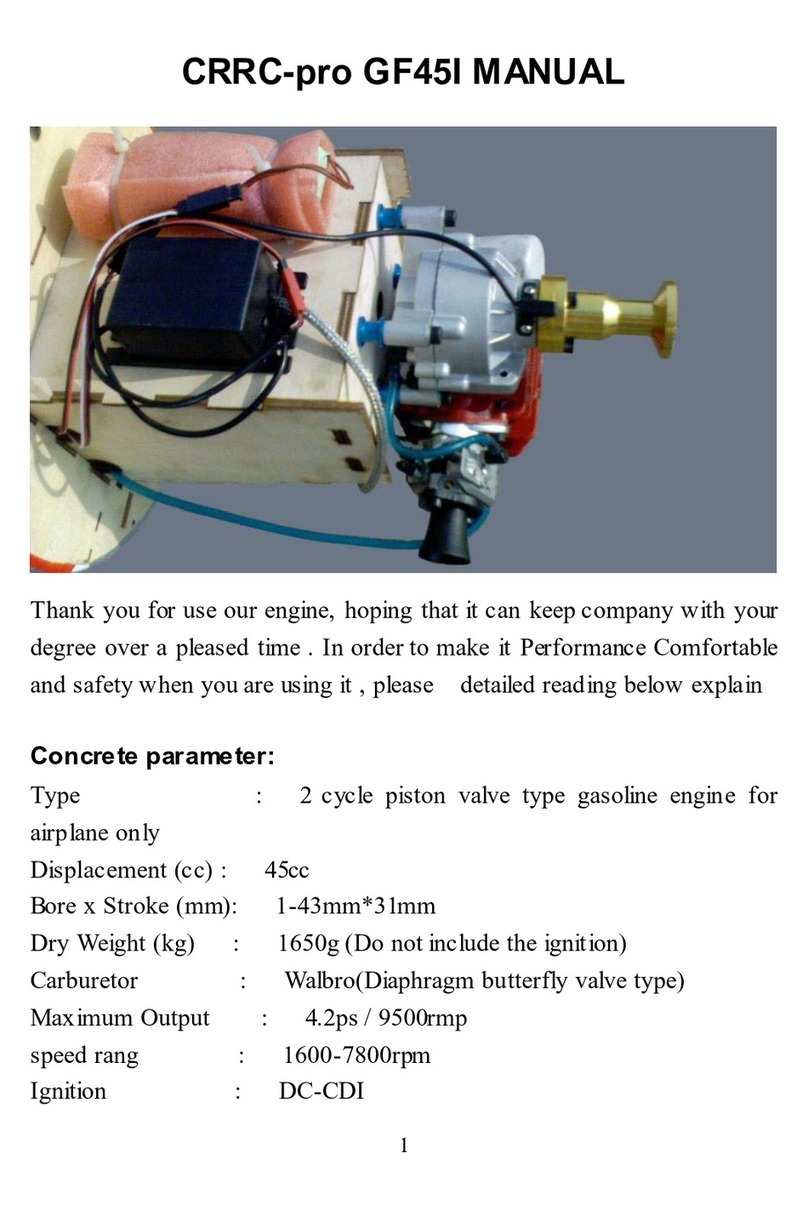

Thank you for using our engine! We hope that you will enjoy it and have many fun and safe flying experiences with its use. In order

to maintain its performance and safety when you are using it, please read the detailed instructions fully before operating this engine.

Type

Displacement (cc)

Bore

Stroke

Total Weight

Carburetor

Maximum Output

Typical RPM Range

Ignition

Ignition Power

Gasoline/Oil Mix

Recommended Propellers

2 Cycle Gasoline Engine for airplane use only

22 cc

1.26in (32mm)

1.06in (27mm)

697g (exclude Ignition and muffler)

Walbro (Diaphragm & Butterfly Valve)

2.6HP @ 8800 RPM

1700RPM ~8800RPM

Auto advanced DC-CDI

DC4.8V-8.4V NiMH, LiPo or LiFe pack

25~40:1

16x6, 16x8, 17x6 ,17x8 2-Blades propeller

1. Warning! This gasoline engine is strictly intended for model aircraft usage only, please do not use in the other untested

applications.

2. Warning! This engine is not a toy! Serious injury and/or death can occur from its misuse! READ and become familiar with this

entire instruction manual. Learn the Engine's applications, limitations ,and possible hazards.

3. Please place your safety and the safety of others paramount while operating. CRRCPRO will not be held responsible for any

safety issues or accidents involving this engine.

Carburetor settings:

-2-

Disclaimer:

CRRCpro

GP22R

WWW.CRRCPRO.COM

9. Use the correct fuel mix for break in (25:1) (gas and oil)

10. After engine break, the recommended mix is (40:1) (gas and oil)

11. Adequate filtering of your fuel ensures reliable operation

12.Use a pre-flight check list before flying your model. See section on recommended pilot's check list

13. Secure your model properly when starting

14. Do not use your fingers or hand to start your engine, recommended to use a starter

15. Adjust your carburetor correctly (Please do not adjust the carburetor needle position if you're a beginner)

16. Ensure that your spark plug is in good condition and is correctly tightened, Ensure that your ignition cap is securely mounted.

Make sure that your ignition wires are not frayed and appropriately secured

17. Remember that when the engine is running every one must stay behind the line of the rotating propeller; never to the side or

the front!

18. Do not allow any part of your body to come in contact with rotating propeller.

19. Do not wear loose clothing and watch your radio neck straps. These can get caught in the moving propeller

20. Do not operate this engine if you are under the influence of any drugs, alcohol or medication that could affect your ability to

use the engine properly.

We cannot control the safe operation of our products. We do not accept responsibility from injuries or damage to property

resulting from the misuse and abuse of our products.

1. Choke Control

(the choke control should be used when the engine is cold)

2. Throttle Control

3. Idle Adjustment

Screw ( adjust the idle speed)

4. (L) Low-speed

Needle (adjusts the fuel/air mixture at low speeds)

5. (H) High-speed

Needle(adjusts the fuel/air mixture at high speeds)

Each CRRCPRO Engine has been factory preset. However, higher elevations will influence the performance of the carburetor.

To obtain optimum output of the engine, slight adjustment of the carburetor maybe necessary. For safety reasons do not make

adjustment to the carburetor while the engine is running.

Idle Adjustment

Turning the Idle Adjustment Screw (No.3) clockwise will increase the idle speed. Turning the Idle Screw counter-clockwise will

decrease the idle speed.

Low Speed Needle Adjustment

Turning the Low-speed Needle (No.4) clockwise will lean the fuel/air mixture at low speeds. Turning the Low-speed Needle

(No.4) counterclockwise will richen the fuel/air mixture at low speeds. The default or factory setting of the Low-speed Needle

is as follows: turn the needle clockwise to the fully stop/closed position and then turn back 1.5 turns

High Speed Needle Adjustment

Turning the High-speed Needle (No.5) clockwise will lean the fuel/air mixture at high speeds. Turning the Low-speed Needle

(No.5)counter-clockwise will richen the fuel/air mixture at high speeds. The default or factory setting of the High-speed Needle is

as follows:

turn the needle clockwise to the fully stop/closed position and then turn back 1.5 turns. It is recommended that the High-speed

DC-CDI details:

Engine Break In

-3-

CRRCpro

GP22R

WWW.CRRCPRO.COM

Needle be adjusted by the use of a tachometer to obtain maximum speed. Smooth acceleration and deceleration is an indicator

of proper engine performance.

Engine Start (Recommend to use starter)

If this is the first time of you to start the engine, please fill a little lubrication to the spark plug hole and turn the propeller

assembly lightly to make the piston lubricated enough.If you start by right hand, please stand left front of the engine, contrariwise,

please stand right front of engine.

Note: When hand starting the GP22R, use a thick glove or heavy duty starter stick to protect your hand.

1. The propeller should be installed on the drive washer so that it is at the one o’clock position and at the beginning of the

compression stroke so that it is comfortable to flip it through compression.

2. Have someone help you hold the airplane while you start the engine.

3. Close the choke on the carburetor and open the throttle slightly from the idle position.

4. Switch on, or power your radio system and make sure you have control of the throttle visually at the carburetor. Also make sure

that the reversing position of the servo is correct at the transmitter and that the throttle is at the minimum position.

5. Switch the ignition to ON. If you installed the optional TX activated gas engine kill switch properly between the manual on/off

switch and the ignition, make sure that the TX switch assigned is in the on position. The LED should be illuminated red to indicate

that the ignition is armed.

6. Flip the propeller counter clockwise several times briskly.

7. After you hear some initial fi ring sounds, move the choke lever to the OPEN position.

8. Set the throttle to a high idle. Set the propeller so that it’s at the beginning of the compression stroke

9. Flip the propeller through compression rapidly. If this is done properly, the engine will start after several brisk fl ips of the

propeller.

10. After starting, let the engine idle for 30 to 45 seconds. Open and close the throttle slowly until the engine runs smoothly at

idle and at full throttle. Acceleration should also be smooth. If acceleration is not smooth adjustments to the carburetor may be

necessary. (See Carburetor settings )

11. If your engine does not start, repeat steps 6 through 10.

Use a good quality 2 cycle engine oil

Use a fuel mixture of 20:1 or 25:1 (Bench running)

Use this fuel mixture for approximately 2-3 hours of run time, we suggest that you bench run the engine to become

familiar with it operation. A high Octane unleaded fuel (98 Octane is ideal) is recommended. Do not run the engine at full

throttle for more than ten seconds during this test stand break in as the engine will not be getting the normal cooling

effect that you would get if the engine was in a model that was flying. The GP22R engine requires approximately 12-20

hours running time to complete the break in process. We recommend using a smaller propeller during the engine break in

period.

Engine Cooling

A proper cooling system is vital for any engine. An air cooled engine requires an appropriately sized air intake. Also to keep

this air cooling process working the incoming air must be exhausted. Further, the exhaust air outlet should be four times (4X) the

size of the cool air intake.

Example:

. 10 square inches of air intake area would require

. 40 square inches of exhaust air outlet area

It is up to you to insure that the air flows freely to, over, and away from, the hot cylinder(s) and muffler(s).

The DC-CDI module is a Micro Controller Type Electronic Ignition Module with Auto Advanced Timing. Please observe the

following operational requirements:

-4-

CRRCpro

GP22R

WWW.CRRCPRO.COM

Pilots check list

We strongly recommend checking the following items regularly for your own safety before starting!

1. Check the propeller bolts for tightness

2. Check that the spinner is firmly attached

3. Check the propeller for possible damage

4. Check to be sure you have the throttle position at idle

5. Check all batteries

6. Check servo functions

7. Check to see that the ignition switch is OFF

8. Check pressure (6-8 bar) system of retract (if applicable)

9. Check all linkages for play

10. Check your wheels for possible damage and easy running

11. Check the wing mounting for tight fit and proper attachment

12. Check the canopy for tight fit and proper attachment

13. When starting the engine one person (minimum) has to hold the airplane

SolutionProblem

Trouble Shooting

The engine is flooded (the crankshaft

housing is filled with fuel).

The engine starts after being

choked but then stops soon after.

The engine runs rough and is

vibrating strongly.

The engine doesn't reach a

normal RPM at full throttle.

Remove the spark plug; turn the engine to a

position where the fuel runs out.

The low needle on the carburetor is probably too lean. Go back to the

recommended settings and adjust your carburetor from there. This

problem may also indicate a dirty carburetor or faulty ignition.

Balance the propeller. Check the ignition timing. Check your plumbing

for air/fuel leaks. Check your spark plug for carbon and check the spark

plug gap. Check the motor mount to be sure it is rigid. Check to make

sure the engine is mounted on a level surface so that the crankcase is

free of tension. Check the engine and propeller bolts.

Check the carburetor settings. Check to see if the propeller is too large.

Verify that you have the correct muffler system. Check to see if the

engine is overheating. Check the ignition timing. Check the spark plug

for defect. Verify you have the correct gasoline, oil, and have mixed

them with the correct ratio.

You can order any spare parts under the direction of this form easily from our distributor or local hobby shop.

Name

Spark Plug

Cylinder

Piston Ring

Piston

Piston Pin+Piston Pin Retainer

Needle Bearing

Crankshaft

Propeller Washer+Propeller Drive Hub

Bearing+Bearing spacer set

Hall Sensor

Ignition

Crankcase Front

Carburetor Heat Block+Reed Valve Assembly

Gasket

Carburetor Complete

Muffler

Muffler gasket

Engine Mount Stand Offs

Woodruff Key

Part NO.

CM6

22030+M4120X4

22050

22060

22250+22090X2

22080

22070

22150+22130+M8010

22110+22120+22140

22160+M3045*2

22170+22180+M4150X4

22200

22040+22190+22230+22210

22240+M5500*2

22010

22020+M4150X2

22260X4+M5200X8+M5 washer

22100

We hope that you enjoy using your GP22R engine. Please check the website for updates to this instruction manual. Thank you

for purchasing CRRCpro Engine

-6-

CRRCpro

GP22R

WWW.CRRCPRO.COM

GP22R

CM6

22010

22020

M4150X2

22030

22040

M4120X4

22050

22060

22070

22080

22090X2

22250

22100

M8010 22130 22150

22140

22120

22160

M3045X2

22170

22180

M4150X4

22190 22200

22210

22220

22230

22240

M5500X2

22260X4

22270X4

M5140X8

22110

WWW.CRRCPRO.COM

WWW.CRRCPRO.COM

WWW.CRRCPRO .COM

WWW.CRRCPRO.COM

WWW.CRRCPRO. COM

WWW.CRRCPRO.COM

WWW.CRRCPRO.COM

WWW.CRRCPRO.COM

WWW.CRRCPRO.COM

WWW.CRRCPRO.COM

WWW.CRRCPRO .COM

WWW.CRRCPRO.COM

WWW.CRRCPRO.COM

WWW.CRRCPRO.COM

WWW.CRRC PRO.C OM

WWW.CRRCPRO.COM

WWW.CRRCPRO .COM

WWW.CRRCPRO.COM

WWW.CRRCPRO.COM

WWW.CRRCPRO.COM

WWW.CRRCPRO.C OM

WWW.CRRCPRO.COM

WWW. CRRCPRO .COM

WWW.CRRCPRO.COM

Table of contents

Other CRRCpro Engine manuals

Popular Engine manuals by other brands

Sonny's

Sonny's Parker TE0230AS Maintenance manual

Kohler

Kohler Command PRO EFI ECV850 owner's manual

Rotax

Rotax 125 MAX DD2 Repair manual

Scania

Scania DI09 installation manual

Dongfeng Chaoyang Diesel engine Co

Dongfeng Chaoyang Diesel engine Co CYQD 32 Series CYQD32 Service manual

panthera

panthera PM07-18 owner's manual