ENGINE MECHANICAL -, Description EM-3

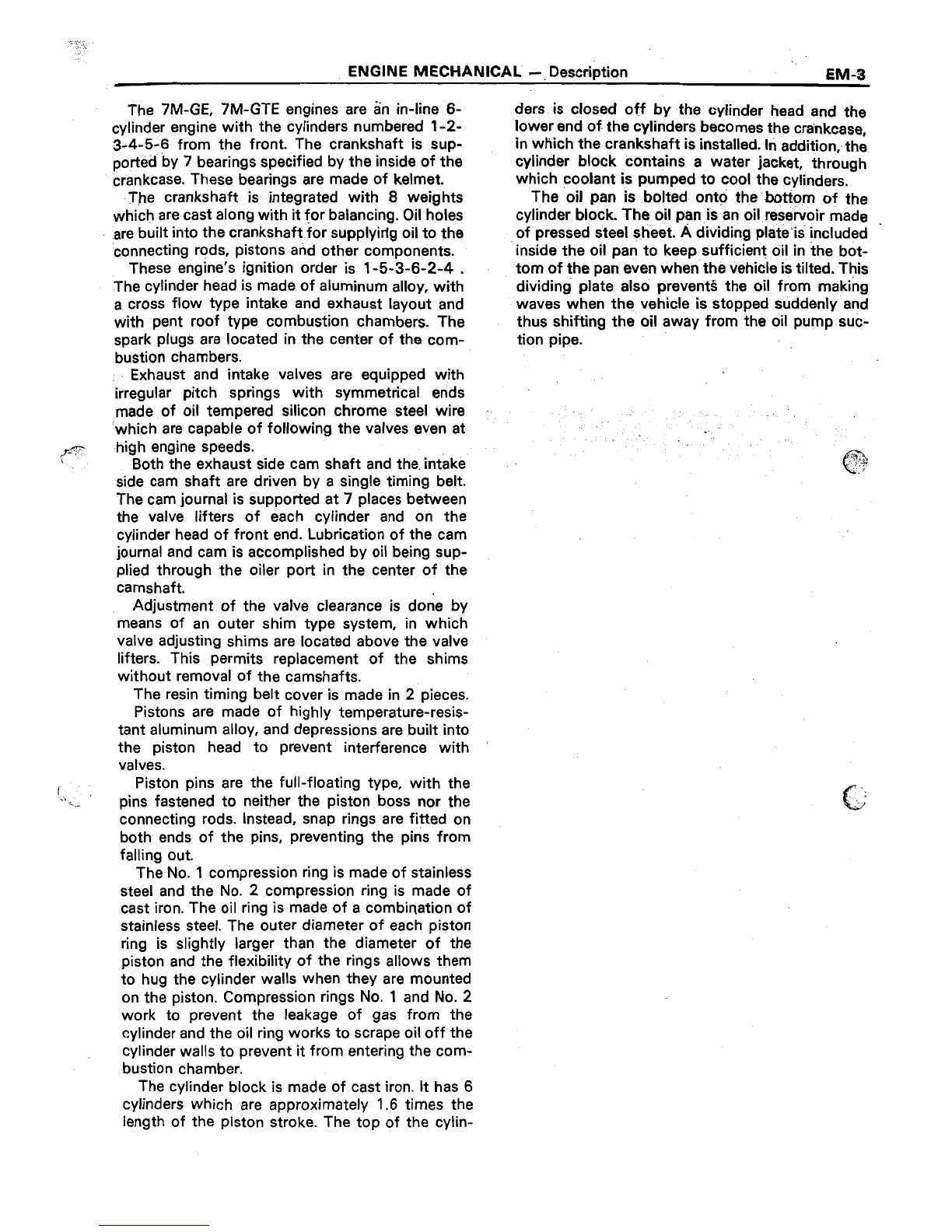

The 7M-GE, 7M-GTE engines are an in-line 6-

cylinder engine with the cylinders numbered l-2-

3-4-5-6 from the front. The crankshaft is sup-

ported by 7 bearings specified by the inside of the

crankcase. These bearings are made of kelmet.

.The crankshaft is integrated with 8 weights

which are cast along with it for balancing. Oil holes

‘are built into the crankshaft for supplying oil to the

connecting rods, pistons and other components.

These ignition order is l-5-3-6-2-4 .

The cylinder head is made of aluminum alloy, with

a cross flow type intake and exhaust layout and

with pent roof type combustion chambers. The

spark plugs are located in the center of the com-

bustion chambers.

Exhaust and intake valves are equipped with

irregular pitch springs with symmetrical ends

made of oil tempered silicon chrome steel wire

which are capable of following the valves even at

,high engine speeds.

Both the exhaust side cam shaft and the. intake

side cam shaft are driven by a single timing belt.

The cam journal is supported at 7 places between

the valve lifters of each cylinder and on the

cylinder head of front end. Lubrication of the cam

journal and cam is accomplished by oil being sup-

plied through the oiler port in the center of the

camshaft.

Adjustment of the valve clearance is done by

means of an outer shim type system, in which

valve adjusting shims are located above the valve

lifters. This permits replacement of the shims

without removal of the camshafts.

The resin timing belt cover is made in 2 pieces.

Pistons are made of highly temperature-resis-

tant aluminum alloy, and depressions are built into

the piston head to prevent interference with

valves.

Piston pins are the full-floating type, with the

pins fastened to neither the piston boss nor the

connecting rods. Instead, snap rings are fitted on

both ends of the pins, preventing the pins from

falling out.

The No. 1 compression ring is made of stainless

steel and the No. 2 compression ring is made of

cast iron. The oil ring is made of a combination of

stainless steel. The outer diameter of each piston

ring is slightly larger than the diameter of the

piston

and

the flexibility of the rings allows them

to hug the cylinder walls when they are mounted

on the piston. Compression rings No. 1 and No. 2

work to prevent the leakage of gas from the

cylinder and the oil ring works to scrape oil off the

cylinder walls to prevent it from entering the com-

bustion chamber.

The cylinder block is made of cast iron. It has 6

cylinders which are approximately 1.6 times the

length of the piston stroke. The top of the cylin-

ders is closed off by the cylinder head and the

lower end of the cylinders becomes the crankcase,

in which the crankshaft is installed. In addition,- the

cylinder block contains a water jacket, through

which coolant is pumped to cool the cylinders.

The .oil pan is bolted onto the botiom of the

cylinder block. The oil pan is an oil reservoir made .

of pressed steel sheet. A dividing included

-inside the oil pan to keep sufficient oil in the bot-

tom of the pan even when the vehicle is tilted. This

dividing plate also prevent5 the oil from making

waves when the vehicle is stopped suddenly and

thus shifting the oil away from the oil pump suc-

tion pipe.