CrustBuster 5020 User manual

P.O. Box 526 - Spearville, Kansas 67876 - (620) 227-7106

crustbuster.com

5020

Min-Till Drill

Owner's Manual

(07-98) # 605972

Identification

Your CrustBuster® drill is identified by a Serial Number and Model Number. Record these numbers

in the spaces provided in this manual and refer to them when ordering parts or requesting service.

Serial Number Model Number

Warranty

WARRANTY: In addition to the implied warranties of fitness and of merchantability,

CrustBuster®/Speed King, Inc. warrants new products sold by it to be free from defects in

workmanship and material for a period of 12 months, from the date of delivery to the first user

customer. Warranty on purchased parts (cylinder, blades, bearings, shanks, etc.) will be the

same as that offered by the appropriate manufacturer of these parts.

EXCLUSIONS: No warranty of any kind is made by CrustBuster®/Speed King, Inc. with

regard to new products which have been subject to operation in excess of recommended

capacities, misuse, abuse, negligence, or accident, or have been altered or repaired in any

manner not authorized by CrustBuster®/Speed King, Inc. CrustBuster®/Speed King, Inc. is

constantly striving to improve its products. Changes in design and improvement will be made

whenever CrustBuster®/Speed King, Inc. believes the efficiency of its products will be

improved thereby, but without incurring any obligation to incorporate such improvements in

any products which have been shipped or are in service. No obligation exists for

compensation of unauthorized repairs or modifications without prior approval. And in no event

will CrustBuster®/Speed King, Inc. be liable for consequential damages, such as but not

limited to: downtime, delayed or late tillage or planting, etc.

WARRANTY REGISTRATION: This warranty is not valid unless registered with

CrustBuster®/Speed King, Inc. within 10 days from the date of purchase. It is the sole

responsibility of the selling retail dealer to fill out the registration forms and see that they are

properly filed with CrustBuster®/Speed King, Inc. This can be done at crustbuster.com.

WARRANTY PROCEDURE: Should any part fail to conform with this warranty,

CrustBuster®/Speed King, Inc. will repair or replace the part or parts which do not conform.

If a part is defective, take it to your authorized CrustBuster® Farm Equipment Dealer

immediately, along with your warranty registration, and complete the proper forms requesting

a warranty adjustment. Our representative will pick up the part to be returned to the factory

for examination. If the customer (first user) requests that a new part be substituted for the old

part, a new part will be charged to the dealer who will in turn charge the customer. If the part

is found by us to be defective, a credit for the part will be given to the dealer to be passed on

to the customer. If the dealer or customer wishes to repair the part, this will be done only if

authorized by CrustBuster®/Speed King, Inc. This warranty procedure is in addition to all

remedies authorized by law.

CRUSTBUSTER®/SPEED KING, INC.

Box 1438

Dodge City, KS 67801

Specifications are subject to change without notice. ® is a registered trademark of CrustBuster/Speed King, Inc.

Table of Contents

Identification & Warranty . . . . . . . . . . . . . . . . . . . . . . Inside Cover

Safety........................................... 2-6

OperatingCautions................................... 7

Field Operating Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Setting Down Pressure & Seed Depth . . . . . . . . . . . . . . . . . . . . 8

WobbleSlotSeedCup ................................ 9

Chain Tension on Drive Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Calibration & Seed Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Sprocket Box Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Meter Man Acreage Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Lubrication, Maintenance, and Service . . . . . . . . . . . . . . . . . . . 11

SprocketLocations.................................. 12

OpenerSettings .................................... 13

RowSet-ups.................................... 14-16

SeedRateCharts................................ 17-24

Repair Parts:

Frame............................................ 26

WheelArm ........................................ 27

GrainBox ...................................... 28-29

Drive.......................................... 30-31

Gear Assembly - Left. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32-33

Gear Assembly - Right . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-35

Min-TillOpener.................................. 36-37

Min-Till Opener Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

FeedTubes........................................ 39

CoverShield....................................... 39

Presswheel Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

LightingSystem..................................... 41

BE A SAFE OPERATOR

BY THINKING BEFORE ACTING

AND

BY READING

YOUR OWNER'S MANUAL

Avoid Accidents

Most accidents, whether they occur in

industry, on the farm, at home, or on the

highway, are caused by the failure of some

individual to follow simple and fundamental

safety rules or precautions. For this reason

most accidents can be prevented by recog-

nizing the real cause and doing something

about it before the accident occurs.

———————

Regardless of the care used in the design

and construction of any type of equipment,

there are many conditions that cannot be

completely safeguarded against without

interfering with reasonable accessibility and

efficient operation.

A CAREFUL OPERATOR

is the Best Insurance Against an Accident.

The complete observance of one simple

rule would prevent many thousands

of serious injuries each year.

That rule is:

Never Attempt to

Clean, Oil, or Adjust

A Machine While It Is In Motion.

To Our Customers

The following pages and illustrations are

printed to help supply you with the knowledge

to better operate and service your new

CrustBuster equipment.

We are proud to have you as a customer

and feel you will be proud to be a

CrustBuster owner.

Any piece of equipment needs, and must

have, a certain amount of service and main-

tenance to keep it in top running condition.

We have attempted to cover all the adjust-

ments required to fit most conditions; how-

ever, there may be times when special care

must be taken to fit a condition.

Study this owner's manual carefully and

become acquainted with all the adjustments

and operating procedures before attempting

to operate your new equipment. Remember,

it is a machine and has been designed and

tested to do an efficient job in most operating

conditions and will perform in relation to the

services it receives.

If special attention is required for some

condition, ask your CrustBuster dealer; he

will be glad to help and answer any questions

on operations and service of your new ma-

chine.

TAKE TIME FOR SAFETY

2

Safety

RECOGNIZE SAFETY INFORMATION

UNDERSTAND SIGNAL WORDS

FOLLOW SAFETY INSTRUCTIONS

3

Safety

OPERATE SAFELY

AVOID TIP-OVERS

KEEP RIDERS OFF MACHINE

4

Safety

HANDLE FUEL SAFELY - AVOID FIRES

PREPARE FOR EMERGENCIES

PRACTICE SAFE MAINTENANCE

5

Safety

WEAR PROTECTIVE CLOTHING

USE SAFETY LIGHTS AND DEVICES

TRANSPORT SAFELY

ALWAYS RAISE THE JACK STANDS BEFORE TRANSPORTING.

SHIFT THE TRACTOR INTO A LOWER GEAR WHEN TRANSPORTING DOWN STEEP

SLOPES OR HILLS.

DO NOT TRANSPORT UNLESS THE GRAIN DRILL REFLECTORS, LIGHTS, AND SMV

EMBLEM ARE EASILY VISIBLE FROM THE REAR.

NEVER TRANSPORT THE GRAIN DRILL FASTER THAN 32 KM/H (20 MPH.) REDUCE

SPEED WHEN TRAVELING OVER ROUGH GROUND OR WITH THE BOX FULL.

(CRUSTBUSTER DOES NOT RECOMMEND TRANSPORTING WITH A FULL GRAIN BOX.)

6

Before Operating This Equipment

Read and undertand this owner's manual.

Safety & Set-Up Instructions

FNEVER ALLOW ANYONE TO RIDE THE DRILL!

FCheck lug nuts or bolts. Torque to 100 ft. lbs. after approximately one mile and

periodically after.

FIf your tractor does not already have a lighting receptacle, install one. Always plug

in the drill lighting system to a correctly wired tractor and USE for transport safety.

Field Operating Checklist

____ Inflate tires to recommended air pressure. ( 44 psi)

____ Lubrication as required.

____ Seed shafts turned manually to check for obstructions and improper chain alignment on

drive sprockets.

____ Correct sprocket selection and slot width for seed type and size.

____ Calibration as required for accuracy.

____ Three point center link is adjusted for level drill operation.

____ Drill is hooked secure to tractor.

____ Down pressure set for soil conditions.

____ Acre meter reset.

____ Lower drill while moving forward to avoid plugging openers.

____ Check seed depth and adjust accordingly.

____ Allow no riders.

____ Rotate support stands UP before transporting or operating drill.

____ If transporting drill while box is full, turn drive wheels manually before drilling to assure

packing has not stopped seed flow. (CrustBuster does not recommend transporting with

full grain box.

7

Min-Till Drill

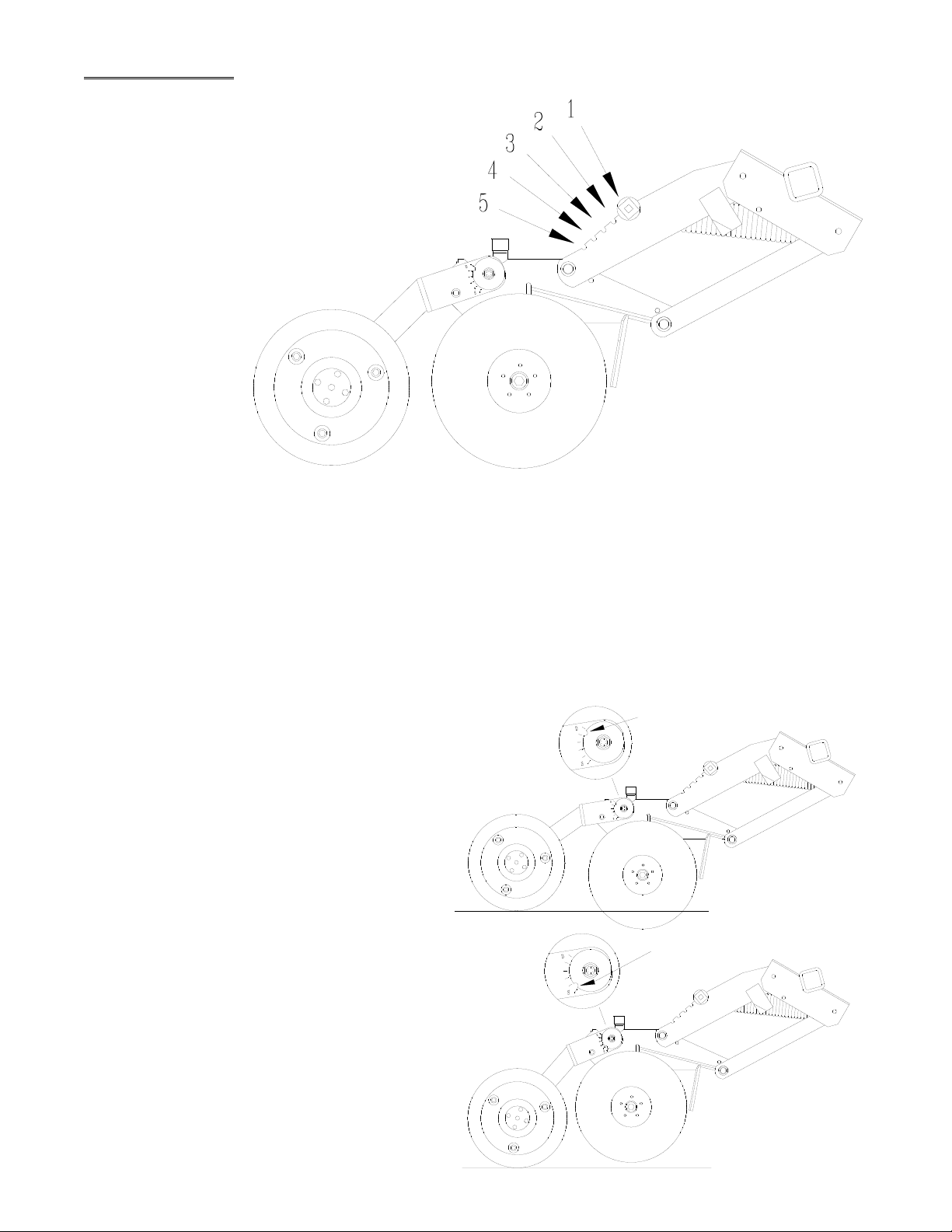

Setting Down Pressure

Opener pressure setting is easy and allows

separate settings for tire compaction areas to

different soil conditions from field to field. Ratchet

mechanism allows you to turn the pressure up or

down. The locking key rolls up or down the notch

gauge and locks to your desired setting from

140# to 250# per opener.

Notch 1 . . 140#

Notch 2 . . . 190#

Notch 3 . . 210#

Notch 4 . . 230#

Notch 5 . . 250#

Down Pressure Spring Adjustment

Row units that run in wheel tracks can be set

with heavier down pressure to assure solid

presswheel action. The following will help in

changing spring pressure.

1. Rotate the tool bar to raise the opener. Fold

up the walkboard to give good access to

the front of the opener.

2. Using ratchet type wrench, roll locking key

up or down notch gauge to desired setting.

Setting Seed Depth

Understanding the tool bar operation and

parallel linkage design will make setting the drill

much easier. Refer to the drawing on the next

page.

Rotating the rockershaft DOWN

sets seed depth more SHALLOW.

Each tool bar is controlled by a hydraulic cylin-

der within each wheel arm. An adjustable depth

stop sets the travel of the cylinder which in turn

determines how much the tool bar rotates.

Set depth stop in middle position as a starting

point. To set deeper seed depth, screw the

depth stop out and lengthen the cylinder travel.

The opener and presswheel relationship con-

trols the depth of seed.

When lowering the openers, be sure the tool

bar is in the full down position and the

cylinder is retracted against the depth stop.

The parallel linkage must be "set" to

achieve the desired down pressure and

depth control.

Individual presswheels may be set to correct for

wheel track compaction. Usually, these will only

need to be adjusted once if the same tractor is

pulling the drill the entire season. At the rear of

the opener, a cam rotation bracket holds the

single presswheel arm. Turn the cam toward

the "D" or "S" to achieve the desired depth

control.

LOWERING the presswheel

will set seed depth more SHALLOW.

DEEP

SHALLOW

8

Wobble Slot Seed Cup Adjustments and Service

The wobble slot seed cups should be checked

against the slot gauge initially and anytime service

has been performed on the seed shaft or individual

seed cups. Refer to the drawing below for proper

adjustment if repairs have been made.

To verify that all seed cups are set the same on

the shaft, start with all cups fully closed. A slight

crack between the cup halves would be considered

normal tolerance. If any individual cup is not

"zeroed out," open the slot width using the adjust-

ing handle, loosen allen set screws and adjust to

equal others on shaft.

To determine if the gauge is reflecting the correct

seed cup slot width, open the seed cups using the

adjusting handle. Notice that wobble slot halves

are positioned differently on the hex shaft. Identify

a cup that will accept a piece of ½" keystock or

other measuring device comfortably and give solid

contact against each half. It may be necessary to

turn the hex shaft slightly to position the particular

seed cup correctly. Close the slot width firmly

against the measuring device. At the cup next to

the wobble slot adjusting handle, position

the gauge to equal the slot width you have just

measured with the keystock by loosening with a

screwdriver and sliding in or out.

Before removing the keystock, make certain the

bearing located on the adjustment lever is securely

running between the shaft bushings. Adjusting

bushings must be set screwed tightly to shaft with

zero to 1/64" tolerance between the bushing and

bearing. Excess tolerance in this area will allow

the seed shaft to float from right to left, thus open-

ing and closing wobble slot and varying the seed

rate.

Small changes in rate can be made by opening or

closing slot width. To close the slot width with

grain in the box, close the slot down a maximum of

1/8" and then rotate the shaft one turn to clear the

slot. Repeat this process until the desired slot

width is selected.

Seeding rate is affected by seed size, seed

treatments, foreign material, and test weight.

Refer to seed rate charts as guidelines for

desired seeding rates.

Chain Tension on Drive Shaft

When making sprocket changes to the seed

shaft, tighten chain to leave approximately 1/2"

of flex. The final sprocket must allow the hex

shaft to slide within the sprocket when the

adjusting lever is moved. If the chain is too

tight, bowing and binding of box end will occur

making seed cup adjustment difficult. Lightly

lubricate the shaft where the sprocket will slide.

DO NOT OVERTIGHTEN CHAIN.

9

Calibration, Seed Rates and Sprocket Box

Calibration/Drilling Rates

Planting the right rate can be frustrating. Some-

times the end result is not what the rate chart

indicates. Seeding rate is affected by seed size,

seed treatments, foreign material, test weight,

and tire air pressure.

1. Always plant clean seed.

2. Check tire air pressure.

3. Seed treatments vary by type and time of

application.

Some seeds are treated at the processor. Drill

box treatments are common methods of applica-

tion. Each of these can "gum" up the wobble slot

cup halves and reduce final seeding rate.

Treated seed often flows differently than non-

treated seed.

A general method for checking quantities drilled

is as follows:

1. Set drill for desired seeding rate.

2. Fill the box level; then pull drill for a short

distance to settle seed. Refill box exactly

level full.

3. Drill a calculated one acre.

4. Carefully weigh the seed required to refill the

box level full.

5. Compare the amount used versus that stated

on the rate chart.

6. Adjust seeding rate by changing the sprocket

combination or wobble slot width.

One method involves catching seed from one or

more seed cups and utilizing a density scale to

determine actual rates. These scales are com-

mercially available, inexpensive and very easy to

use. Information can be obtained from

CrustBuster®/Speed King, Inc.

Sprocket Box Operation

The sprocket box design will enable the operator

to set a wobble slot width once for a given seed

size and change rates by changing the speed of

the seed shaft. Choose a range of seeding rates

that you wish to operate in, set the slot width as

indicated by the chart and simply change knob

position with the slide handle to effect seed rate.

A narrow slot width will produce more even

distribution and spacing in the row.

When changing derailleur, be sure openers

are rotated out of ground.

To change position, move throw-out lever toward

the rear to disengage the chain from the lower

sprocket. Pull the spring loaded collar outward

with two fingers and slide side to side to the

desired gear position. Pull throw-out lever for-

ward to re-engage the chain.

Sprocket Box

10

Spacing 20'

6" .00265

7 ½" .00212

8" .00191

10" .00152

Do Not Attempt To Service

Your Drill While

It Is In Motion!

Meter Man Acreage Counter

(Option)

Calibration

Use the formulas below to determine your imple-

ment calibration factor or refer to the predeter-

mined factors listed when using CrustBuster

drills.

DT = Distance traveled with one counter shaft rotation

(when using two magnets, divide DT by 2).

WW = Working Width of implement (in inches).

WW x DT/2 = Calibration factor

6272640

NOTE: Whenever a gear change is made on the

shaft being monitored, you will need to enter a

new calibration factor.

Entering Calibration Factor

1. Depress ON/C

2. Round off factor to 5 digits

3. Enter factor (remember decimal point)

4. Depress + key

5. Depress = key

6. Depress decimal point (screen display 0)

Meter Man Factors by Model

5020 Drills

Scraper Blade Replacement

Opener blade inside scrapers are spring loaded

and require no adjustment. To replace the

scraper blades, remove rear lock nut and slide

both blades from stem. Assemble with new

blades and replace onto stem being careful not to

overtighten lock nut.

NOTE: Do not over tighten lock nut. Be sure

scapers move freely. Failure to do so

will result in damage to scrapers and

proper operation of scrapers.

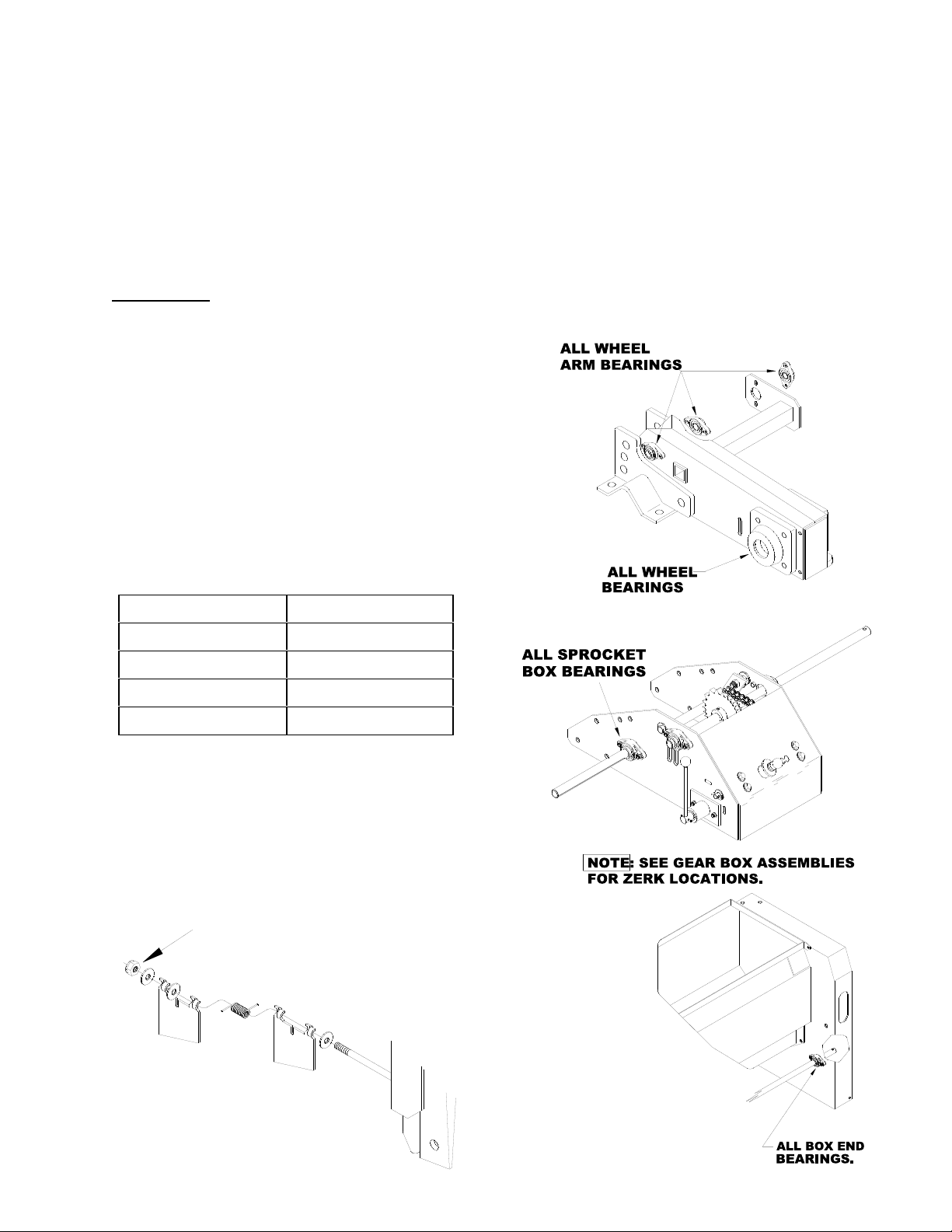

Lubrication, Maintenance,

and Service

Proper maintenance will extend the life of your

drill and give you years of excellent performance.

Refer to the repair part drawings and the illustra-

tions below for lubrication requirements. Use a

high quality grease in pivot points and bearings.

On greaseable sealed bearings, be careful not to

over-grease and destroy the dirt seal. Pay atten-

tion to recommended intervals. Oil chains with a

chain lube. A light penetrating oil or liquid graph-

ite should be used on seed cups initially and at

the end of each season. Clean cups with air

pressure or vacuum before applying penetrating

oil.

11

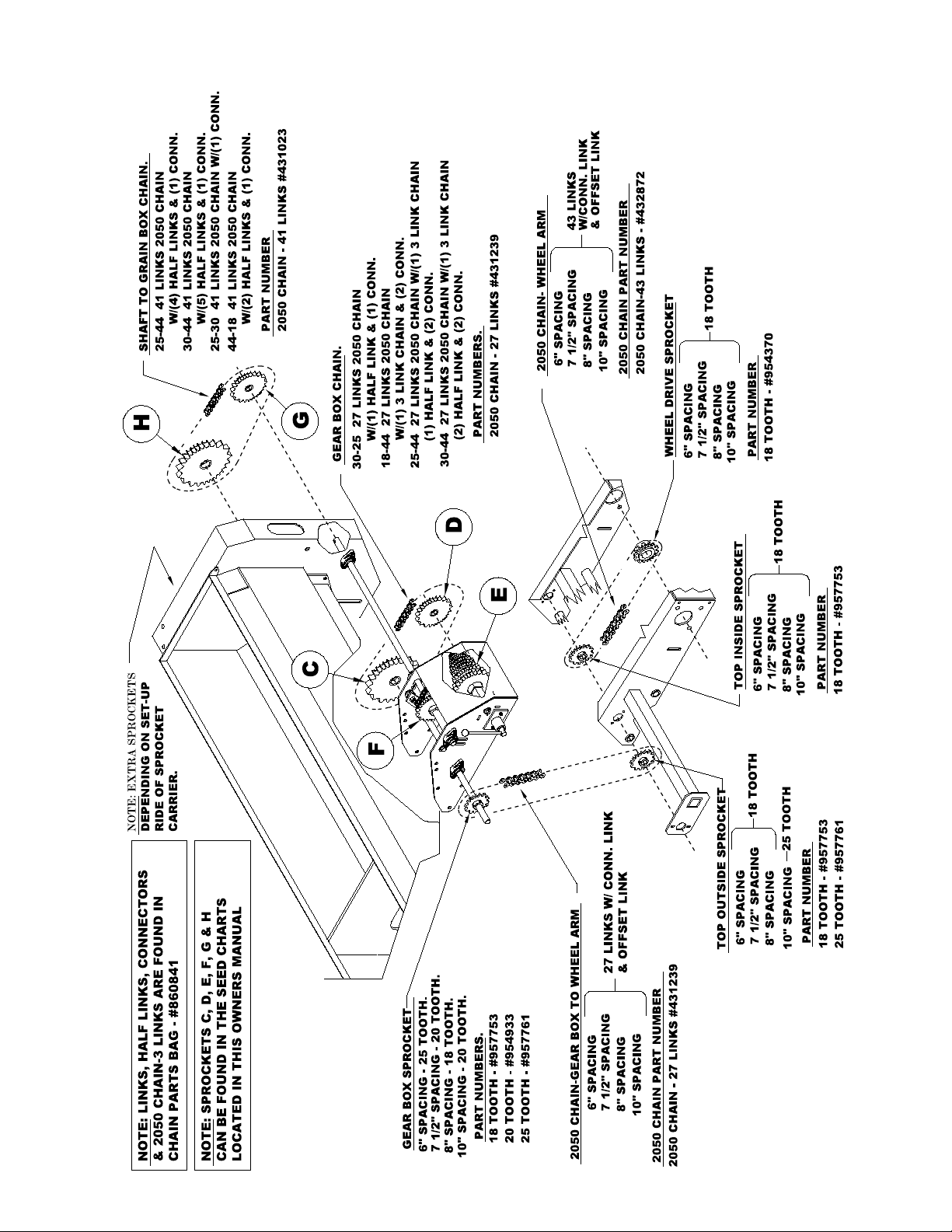

5020 Sprocket Locations

12

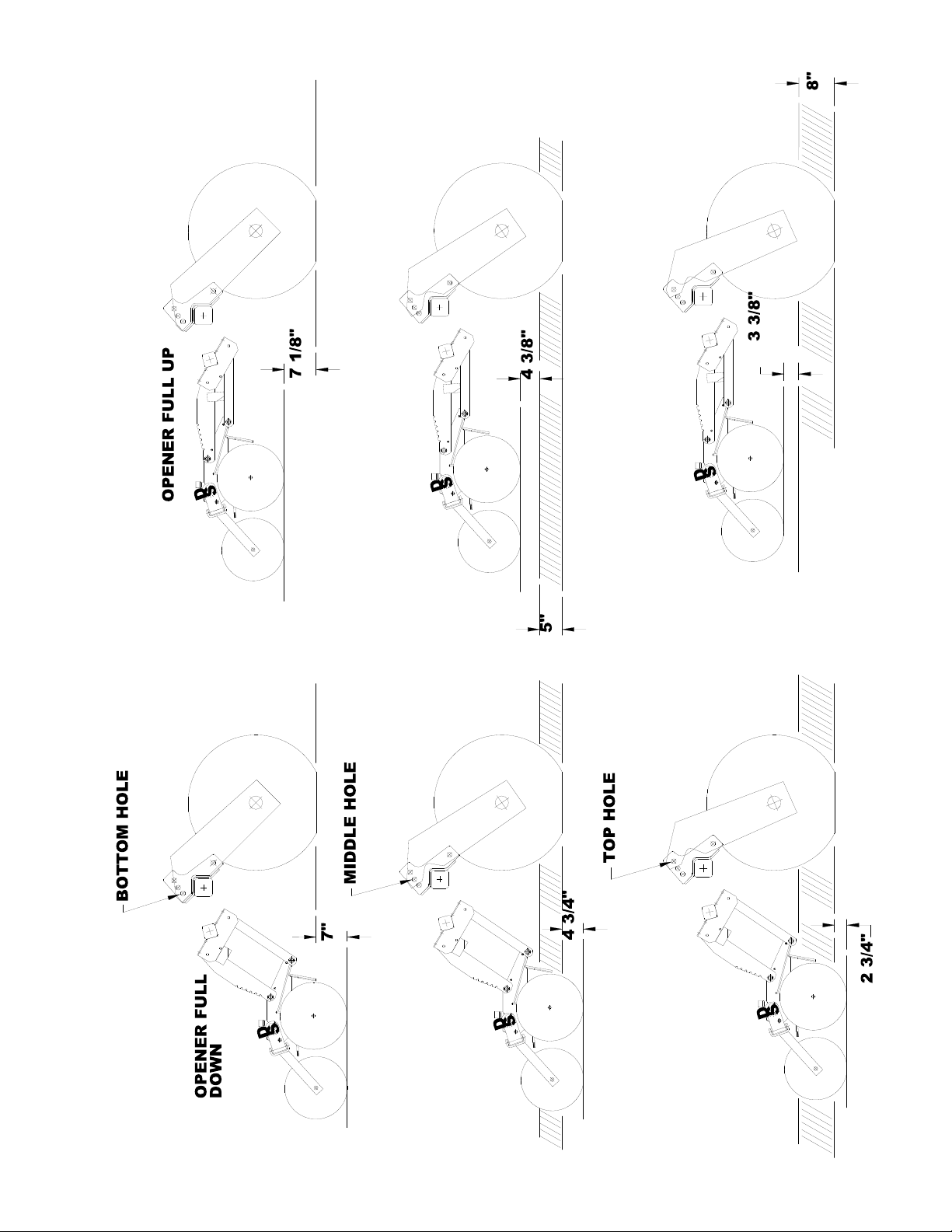

Conventional

Setting Low Ridge

Setting High Ridge

Setting

Opener Settings

13

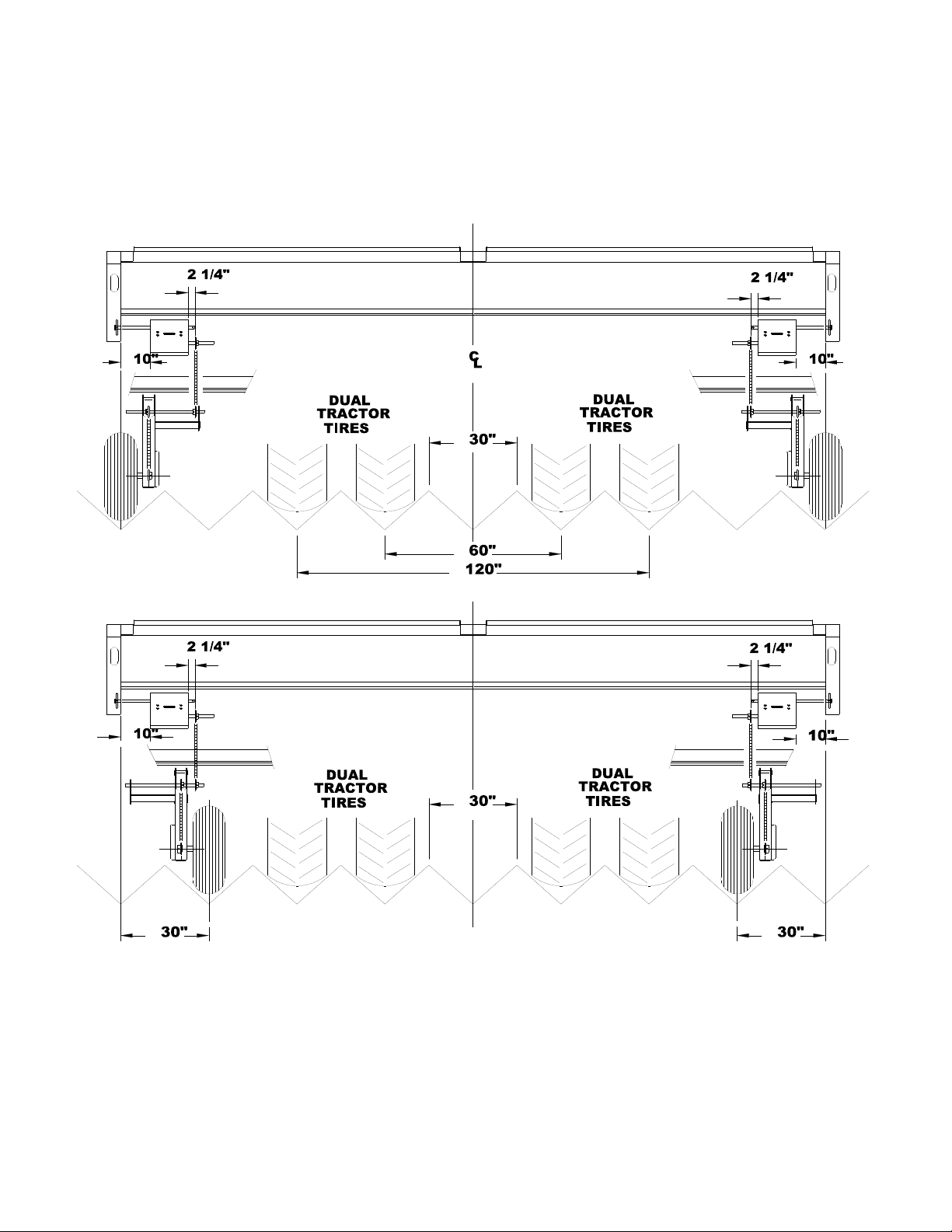

30" Row Set-ups

Top view is set-up for dual tires or single tires.

Bottom view can be set-up for single or dual tires. To get the 30 inch dimension to the

center of the wheel, the right wheel arm is mounted on the left, and the left wheel arm

is mounted on the right.

14

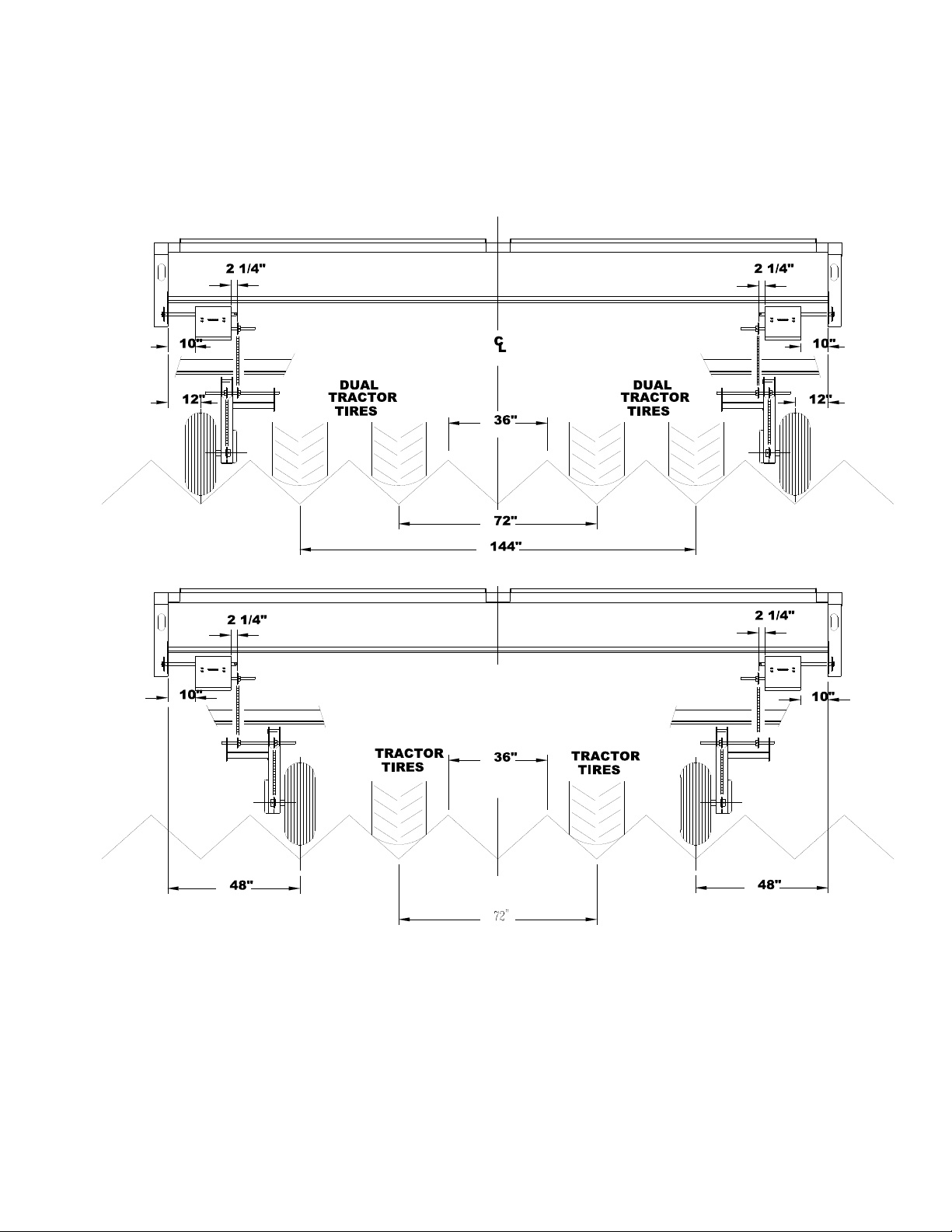

36" Row Set-ups

Top view is set-up for dual tires or single tires.

Bottom view can be set-up for single tires only by moving the right wheel arm to the left,

and the left wheel arm to the right.

15

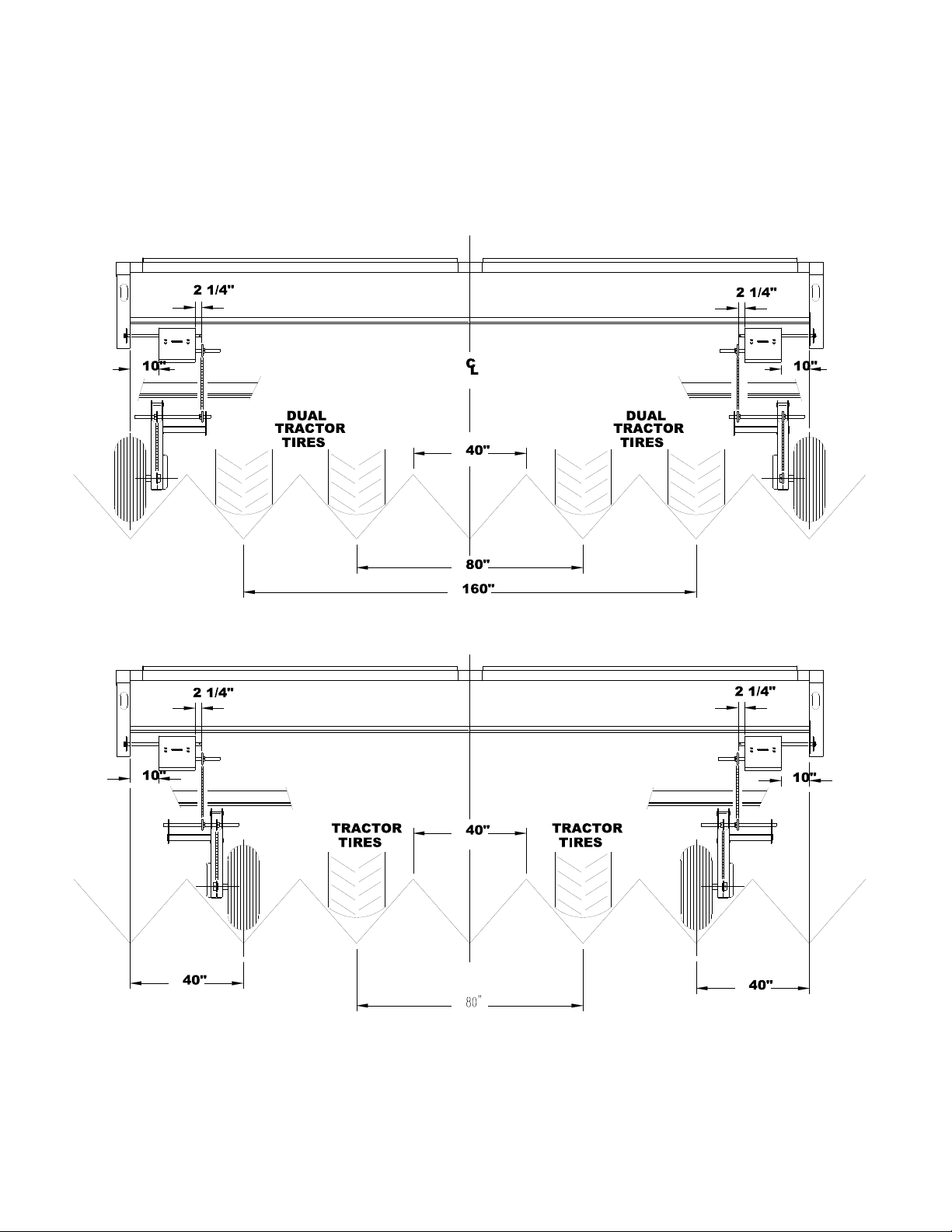

40" Row Set-ups

Top view is set-up for dual tires or single tires.

Bottom view can be set-up for single tires only by moving the right wheel arm to the left,

and the left wheel arm to the right.Row Set-ups

16

Seed Rate Charts

ALFALFA BARLEY

Sprockets Slot Width Sprockets Slot Width

Derailleur Box End Pounds/Acre Derailleur Box End Pounds/Acre

C D E F G H 1/8" 1/4" C D E F G H 1/2" 5/8" 3/4"

18 44 16 30 25 44 5 8 30 25 16 30 25 44 31 38 45

18 44 17 30 25 44 5 9 30 25 17 30 25 44 33 40 48

18 44 18 30 25 44 5 9 30 25 18 30 25 44 34 43 51

18 44 19 30 25 44 6 10 30 25 19 30 25 44 36 45 54

18 44 20 30 25 44 6 11 30 25 20 30 25 44 38 47 57

18 44 21 30 25 44 6 11 30 25 21 30 25 44 40 50 60

18 44 22 30 25 44 7 12 30 25 22 30 25 44 42 52 63

18 44 23 30 25 44 7 12 30 25 23 30 25 44 44 54 65

25 44 16 30 25 44 7 12 30 25 16 30 25 30 45 56 67

25 44 17 30 25 44 7 12 30 25 17 30 25 30 48 59 71

25 44 18 30 25 44 8 13 30 25 18 30 25 30 51 63 75

25 44 19 30 25 44 8 14 30 25 19 30 25 30 53 66 79

25 44 20 30 25 44 8 15 30 25 20 30 25 30 56 69 83

25 44 21 30 25 44 9 15 30 25 21 30 25 30 59 73 88

25 44 22 30 25 44 9 16 30 25 22 30 25 30 62 76 92

25 44 23 30 25 44 10 17 30 25 23 30 25 30 65 80 96

30 44 16 30 30 44 10 17 30 25 16 30 30 25 65 80 96

30 44 17 30 30 44 10 18 30 25 17 30 30 25 69 85 102

30 44 18 30 30 44 11 19 30 25 18 30 30 25 73 90 108

30 44 19 30 30 44 12 20 30 25 19 30 30 25 77 95 114

30 44 20 30 30 44 12 21 30 25 20 30 30 25 81 100 120

30 44 21 30 30 44 13 22 30 25 21 30 30 25 85 105 126

30 44 22 30 30 44 13 23 30 25 22 30 30 25 89 110 132

30 44 23 30 30 44 14 24 30 25 23 30 30 25 93 115 138

30 25 16 30 25 44 14 25 25 30 16 30 44 18 92 113 136

30 25 17 30 25 44 15 26 25 30 17 30 44 18 97 120 144

30 25 18 30 25 44 16 28 25 30 18 30 44 18 103 127 153

30 25 19 30 25 44 17 29 25 30 19 30 44 18 109 134 161

30 25 20 30 25 44 18 31 25 30 20 30 44 18 114 141 170

30 25 21 30 25 44 19 32 25 30 21 30 44 18 120 149 178

30 25 22 30 25 44 20 34 25 30 22 30 44 18 126 156 187

30 25 23 30 25 44 21 35 25 30 23 30 44 18 132 163 195

30 25 16 30 25 30 21 36

30 25 17 30 25 30 22 38

30 25 18 30 25 30 24 41

30 25 19 30 25 30 25 43

30 25 20 30 25 30 26 45

30 25 21 30 25 30 28 48

30 25 22 30 25 30 29 50

30 25 23 30 25 30 30 52

17

Seed Rate Charts

CANOLA CORN

Sprockets Slot Width Sprockets Slot Width

Derailleur Box End Pounds/Acre Derailleur Box End Pounds/Acre

C D E F G H 3/16" 1/4" 3/8" C D E F G H 1/2" 5/8" 3/4"

18 44 16 30 25 44 5 7 10 18 44 16 30 25 44 6 8 10

18 44 17 30 25 44 5 8 11 18 44 17 30 25 44 6 8 10

18 44 18 30 25 44 5 8 11 18 44 18 30 25 44 6 9 11

18 44 19 30 25 44 6 8 12 18 44 19 30 25 44 7 9 11

18 44 20 30 25 44 6 9 13 18 44 20 30 25 44 7 10 12

18 44 21 30 25 44 6 9 13 18 44 21 30 25 44 7 10 13

18 44 22 30 25 44 7 10 14 18 44 22 30 25 44 8 11 13

18 44 23 30 25 44 7 10 14 18 44 23 30 25 44 8 11 14

25 44 16 30 25 44 7 10 14 25 44 16 30 25 44 8 11 13

25 44 17 30 25 44 7 10 15 25 44 17 30 25 44 8 12 14

25 44 18 30 25 44 8 11 16 25 44 18 30 25 44 9 12 15

25 44 19 30 25 44 8 12 17 25 44 19 30 25 44 9 13 16

25 44 20 30 25 44 8 12 17 25 44 20 30 25 44 10 14 17

25 44 21 30 25 44 9 13 18 25 44 21 30 25 44 10 14 18

25 44 22 30 25 44 9 13 19 25 44 22 30 25 44 11 15 18

25 44 23 30 25 44 10 14 20 25 44 23 30 25 44 11 16 19

30 44 16 30 30 44 10 14 20 30 44 16 30 30 44 11 16 19

30 44 17 30 30 44 10 15 21 30 44 17 30 30 44 12 17 20

30 44 18 30 30 44 11 16 23 30 44 18 30 30 44 13 18 22

30 44 19 30 30 44 12 17 24 30 44 19 30 30 44 13 19 23

30 44 20 30 30 44 12 18 25 30 44 20 30 30 44 14 20 24

30 44 21 30 30 44 13 19 26 30 44 21 30 30 44 15 21 25

30 44 22 30 30 44 13 19 28 30 44 22 30 30 44 15 22 26

30 44 23 30 30 44 14 20 29 30 44 23 30 30 44 16 23 28

30 25 16 30 25 44 14 21 29 30 25 16 30 25 44 17 23 28

30 25 17 30 25 44 15 22 31 30 25 17 30 25 44 18 25 30

30 25 18 30 25 44 16 23 33 30 25 18 30 25 44 19 26 32

30 25 19 30 25 44 17 25 35 30 25 19 30 25 44 20 27 34

30 25 20 30 25 44 18 26 37 30 25 20 30 25 44 21 29 35

30 25 21 30 25 44 19 27 39 30 25 21 30 25 44 22 30 37

30 25 22 30 25 44 20 28 41 30 25 22 30 25 44 23 32 39

30 25 23 30 25 44 21 30 42 30 25 23 30 25 44 24 33 41

30 25 16 30 25 30 21 30 43 30 25 16 30 25 30 26 34 42

30 25 17 30 25 30 22 32 46 30 25 17 30 25 30 27 36 44

30 25 18 30 25 30 24 34 49 30 25 18 30 25 30 28 38 47

30 25 19 30 25 30 25 36 51 30 25 19 30 25 30 29 40 50

30 25 20 30 25 30 26 38 54 30 25 20 30 25 30 31 42 52

30 25 21 30 25 30 28 40 57 30 25 21 30 25 30 32 44 55

30 25 22 30 25 30 29 42 59 30 25 22 30 25 30 34 46 58

30 25 23 30 25 30 30 44 62 30 25 23 30 25 30 35 48 60

30 25 16 30 30 25 30 44 62 30 25 16 30 30 25 35 48 60

30 25 17 30 30 25 32 46 66 30 25 17 30 30 25 37 52 64

30 25 18 30 30 25 34 49 70 30 25 18 30 30 25 40 55 68

30 25 19 30 30 25 36 52 74 30 25 19 30 30 25 42 58 72

30 25 20 30 30 25 38 55 78 30 25 20 30 30 25 44 61 75

30 25 21 30 30 25 40 57 82 30 25 21 30 30 25 46 64 79

30 25 22 30 30 25 42 60 86 30 25 22 30 30 25 48 67 83

30 25 23 30 30 25 44 63 89 30 25 23 30 30 25 51 70 87

18

Table of contents

Other CrustBuster Drill manuals