Cryo Bio System SYMS I User manual

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 1/ 18]

User manual

SYMS I MANUAL SEALING MACHINE

For CBS™ High Security straws and HSV High Security Vitrification straws

Read this manual carefully before using the SYMS I manual sealing machine

CRYO BIO SYSTEM –www.cryobiosystem.com –tel +33 (0)2 33 34 64 64

Edition: 2021

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 2/ 18]

Contents

1 INTRODUCTION ............................................................................................................................................. 3

1.1 Applications.................................................................................................................... 3

1.2 Mechanical characteristics.......................................................................................... 3

1.3 Electrical characteristics............................................................................................... 3

1.3.1 Equipment nominal value ...................................................................................... 3

1.3.2 Environmental parameters..................................................................................... 4

1.3.3 Electrical safety ....................................................................................................... 4

1.4 Precautions ..................................................................................................................... 4

2HYGIENE AND SAFETY .............................................................................................................................. 5

2.1 Scope of application ..................................................................................................... 5

2.2 Protection, Safety ........................................................................................................... 5

2.2.1 Safety indications .................................................................................................... 5

2.2.2 Installation safety rules ........................................................................................... 6

3SYMS I...................................................................................................................................................... 8

3.1 Overview ......................................................................................................................... 8

3.2 Description of devices................................................................................................... 8

3.2.1 SYMS I manual sealing machine........................................................................... 8

4ASSEMBLY AND ADAPTATION................................................................................................................ 11

5PROCEDURE ........................................................................................................................................... 15

5.1 Operation of the individual straw welder ................................................................. 15

6MAINTENANCE ...................................................................................................................................... 17

6.1 Precautions ................................................................................................................... 17

6.2 Maintenance ................................................................................................................ 17

6.3 Transport and storage.................................................................................................. 17

6.4 Recycling of worn parts............................................................................................... 17

6.5 Non-responsibility clause............................................................................................ 17

7CONTACT ............................................................................................................................................... 18

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 3/ 18]

1 INTRODUCTION

1.1 Applications

The SYMS I sealer is a tabletop device designed to seal CBS™ High Security of a

capacity of 0.3 ml and 0.5 ml and High Security Vitrification straws for applications

such as:

Epidemiology research departments;

Biobanks;

Serum banks;

Cell and gene therapy units;

Vaccine producing, pharmaceutical companies (living cells);

Genetic heritage conservatories (animal, vegetable, microbiological);

Laboratories and medical officers specializing in reproduction biology;

Sperm banks.

1.2 Mechanical characteristics

Size (in mm)

Length 230 mm

Width 220 mm

Height 170 mm

Mass (in kg) 6 kg

1.3 Electrical characteristics

1.3.1 Equipment nominal value

Sealer model

UF 400000 (ref. 016399) removable sealing block

Electric power

Power supply voltage 230 VAC +/- 10%

Power supply frequency 50/60 Hz

Consumed power 120 W max

Control circuit 12 V direct current

Thermal energy

Nature electrical

Power 19 A at 4 VAC

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 4/ 18]

Protection by fuses

2 fuses of 2 A.T / 250 VAC / glass tube

5x20 mm, according to CEI127-2

standards.

1.3.2 Environmental parameters

Indoor use

Operating temperature from 5 to 30°C

Maximum relative humidity 80%

Atmosphere

The equipment must not be used at an altitude higher than 2000 m or in an explosive

or corrosive environment.

1.3.3 Electrical safety

Safety standards

Product in class I, requires installation with suitably protected ground.

Pollution degree 2.

1.4 Precautions

We advise you to read this manual with care. It has been produced to help you

discover our SYMS I manual sealing machine and to help you make the most of it.

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 5/ 18]

2 HYGIENE AND SAFETY

2.1 Scope of application

The SYMS I sealer 230 V –UF400000 –ref. 016399 allows the sealing of CBS™ High

Security straws and High Security vitrification straws used in laboratories.

2.2 Protection, Safety

2.2.1 Safety indications

DANGER!

These indications refer to hazards due to electric voltages

DANGER!

These indications refer to hazards due to risks of burns.

DANGER!

These indications refer to hazards concerning the user and

the machine.

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 6/ 18]

2.2.2 Installation safety rules

Installation

- To be safe, this equipment must be connected to an installation that is in conformity

(in France NFC 15-100), equipped with a ground connection, suitably protected

against ground faults.

- Operation on alternating current. The voltage and frequency must comply with the

indications given on the nameplate.

- In the event of damage to the mains cable, turn of the welder power supply

immediately. "Mortal danger!" Have the cable replaced by a specialist or contact

the after sales service at Cryo Bio System.

Warning

- If the equipment is used in a way that is not specified in the manual, this may have

an effect on the protection offered by the equipment.

- All modifications and repairs of an electrical nature must only be carried out by

qualified personnel, operating under the authority of the after-sales service

technician representing Cryo Bio System.

Descriptions

The SYMS I system consists of:

the SYMS I sealer,

a main power cable,

a set of spare parts

New: a control pedal is available as an option, under the reference 017171.

Energizing is carried out using the switch marked “U0”on the back panel and is

displayed by a green indicator light “D1”on the front panel.

The control pushbuttons or pedal will start the welding cycle.

Notes:

welding time (in seconds), factory setting: 2 s

press time (in seconds), factory setting: 4 s

The protection trap provides total safety against burns when the sealer is operating.

Similarly, the opening of the protection trap will cause the cycle to stop and block

the controls. However, the equipment will remain energized (indicated by the green

power indicator light).

A fuse protection covers any fault current that might be generated.

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 7/ 18]

Recommendations

The CBS™ straw is guaranteed to be tight, because of the temperature, the pressure

and the thermal impulse time, adapted to the raw material.

The user must not change any of the sealing and press times.

The sealing area must be clean and dry.

Guaranteed tightness depends on the systematic use of suitable filling end fittings.

The SYMS sealer must never be used for sealing conventional PVC or PETG straws.

Never operate the sealer for more than 10 consecutive cycles. Allow at least 5

minutes between each series of 10 cycles.

Never operate the sealer empty (without any straws in place).

Comply with the protection indications given on the nameplate.

Pay attention to the stability of the sealer.

Never place the apparatus in such a way that it is difficult to operate the isolating

switch.

2.3 Standardization

We the undersigned, Cryo Bio System - ZI n°1 Est - 61300 SAINT OUEN SUR ITON, certify

that:

The SYMS I sealer, as per model ref.: 016399

- complies with the European directives in force:

Basse-Tension N° 73/23 CEE,

CEM 89/336 CEE,

and to the standards:

EN 61010-1

EN 61326-1

EN 61326/A1

- complies with the Canadian requirements: CAN/CSA C22.2 No. 1010.1-92

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 8/ 18]

3 SYMS I

3.1 Overview

3.2 Description of devices

3.2.1 SYMS I manual sealing machine

View of front panel Pic-DE

C.S.C

D3

TRA

D2

D1

Pic-HT

Bu S1

View of rear panel

U0

C-COF

J0

F1, F2

PI C-P1

B-P1

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 10 / 18]

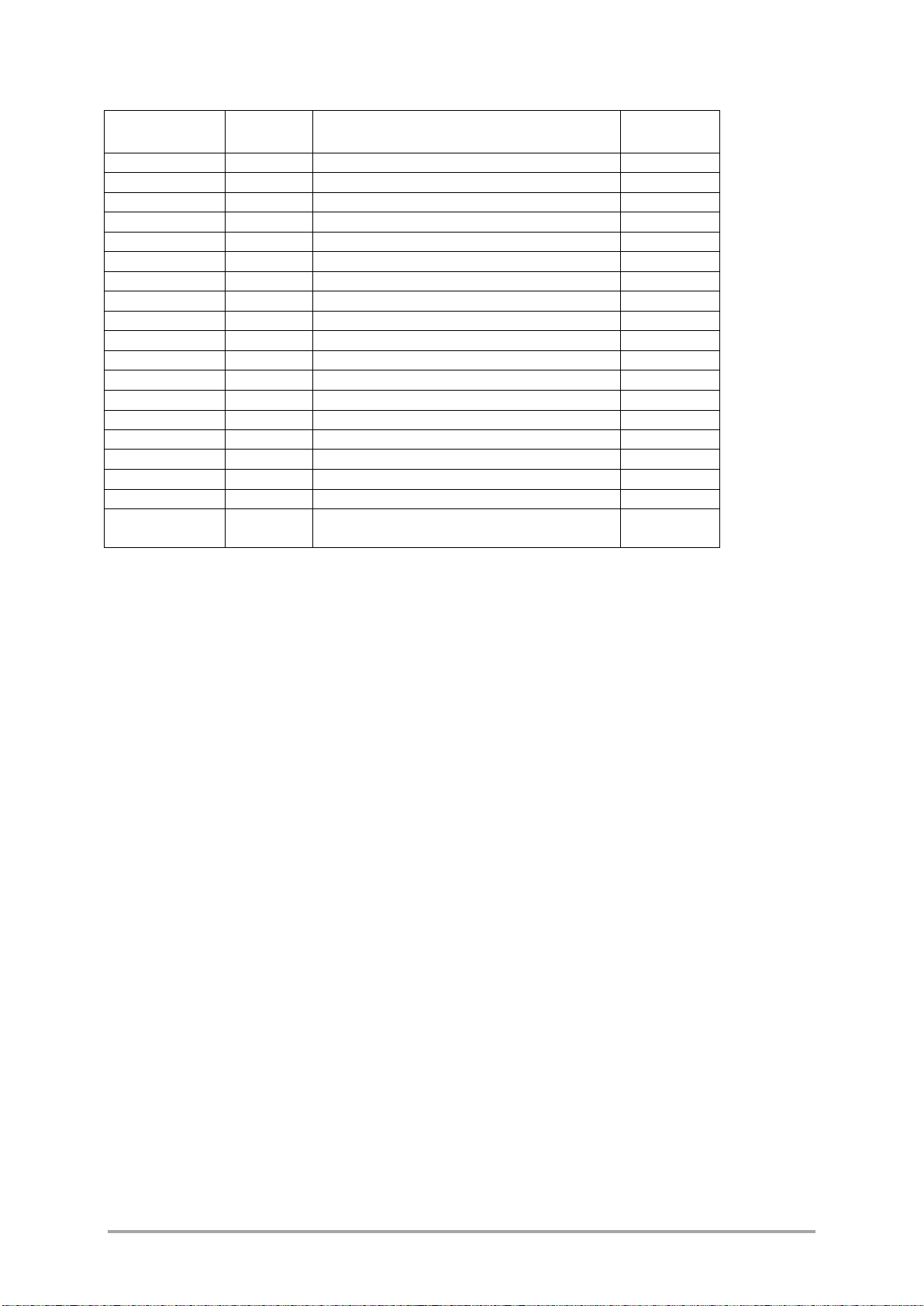

Mark

Quantity

Description

Article

reference

C.S.C

1

Complete Upper casing

017179

Bu

4

Black rubber screw stop

016416

C-COF

1

Case frame with inserts

017178

TRA

1

Trap ¼ turn

009844

U2

1

Control pedal

017171

COMP-230v

1

Kit version 230V

017184

C-P1

1

Potentiometer cover

017328

U0

1

Wired mains socket

017168

S1

1

White NO push button

001593

J0

1

Female socket, 3-pin

001394

B-p1

1

Rev counter knob, P/N:90-87742C/ 1rev

001550

Cb1-230V

1

Mains power cord

000939

F1, F2 - 230V

2

Fuse 5x20 2A.T

017173

D1

1

Green LED T1 ¾ 4V

004815

D2

1

Yellow LED T1 ¾ 4V

004814

D3

1

Orange LED T1 ¾ 4V

004813

Pic-DE

2

Electrical Hazard Pictogram

001970

Pic-HT

1

High Temperature Pictogram

001967

F1, F2, PTFE G9

et G22, A19

Spare parts

009848

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 11 / 18]

4 ASSEMBLY AND ADAPTATION

Recommendation: On exit from the factory, the SYMS I sealer is configured for use

with 0.3 and 0.5 ml CBSTM High Security straws and High Security Vitrification straws.

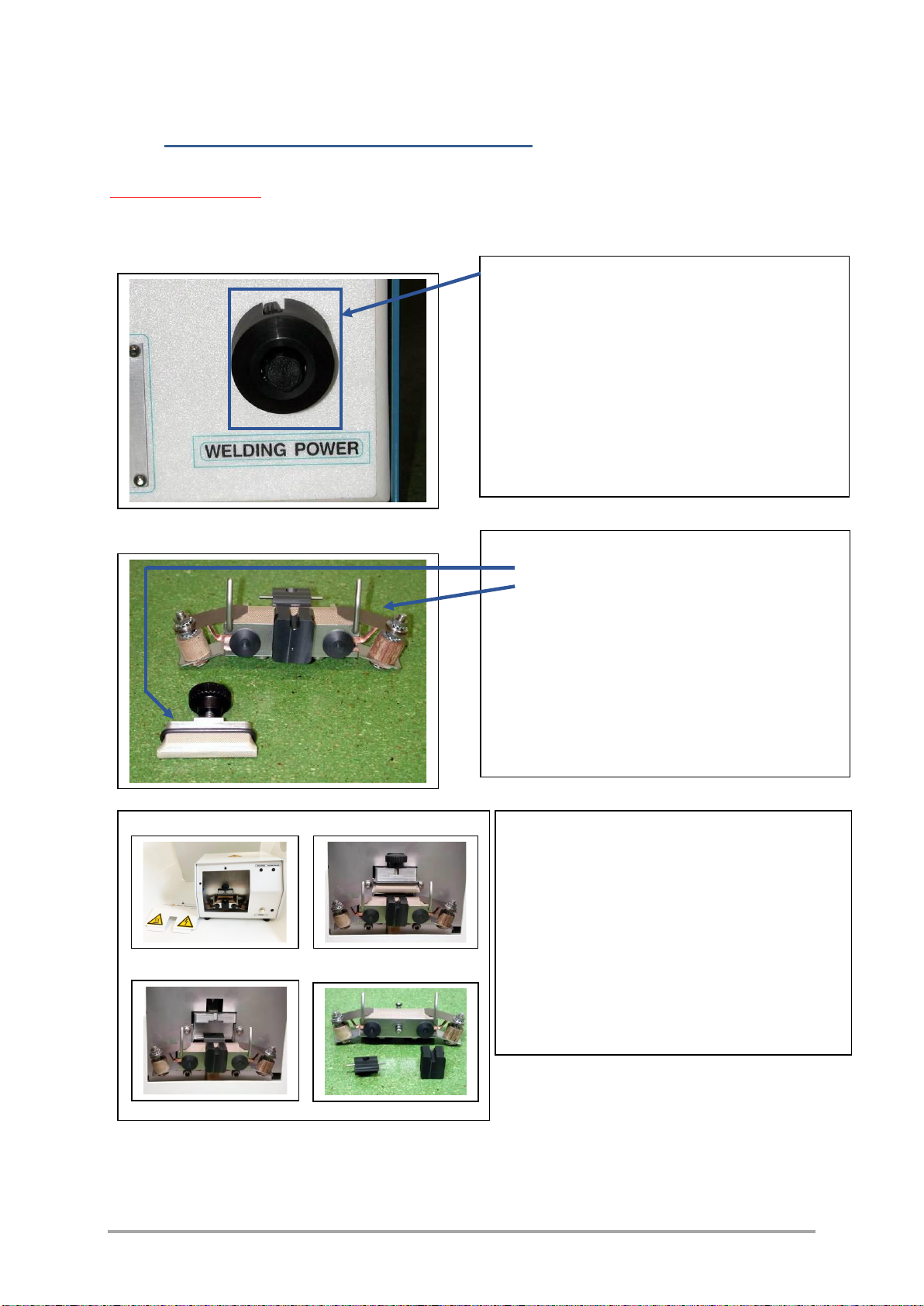

Sealing power

Cleaning

The welding power is pre-set in the factory

and is accessible on the potentiometer on

the rear face.

This setting is specific to the machine.

It is strongly advised not to modify this

setting.

However, and only on the advice of a

maintenance technician, the user may be

called upon to modify this setting if the

sealing is judged inadequate.

The removable parts are:

the cooling jig,

the welding electrode assembly.

They may be removed without difficulty and

decontaminated, provided that there is:

- no immersion.

Decontamination can be carried out with:

- Sanytex diluted to 5% or another equivalent

product,

- a phase of rinsing with distilled water,

- drying with alcohol.

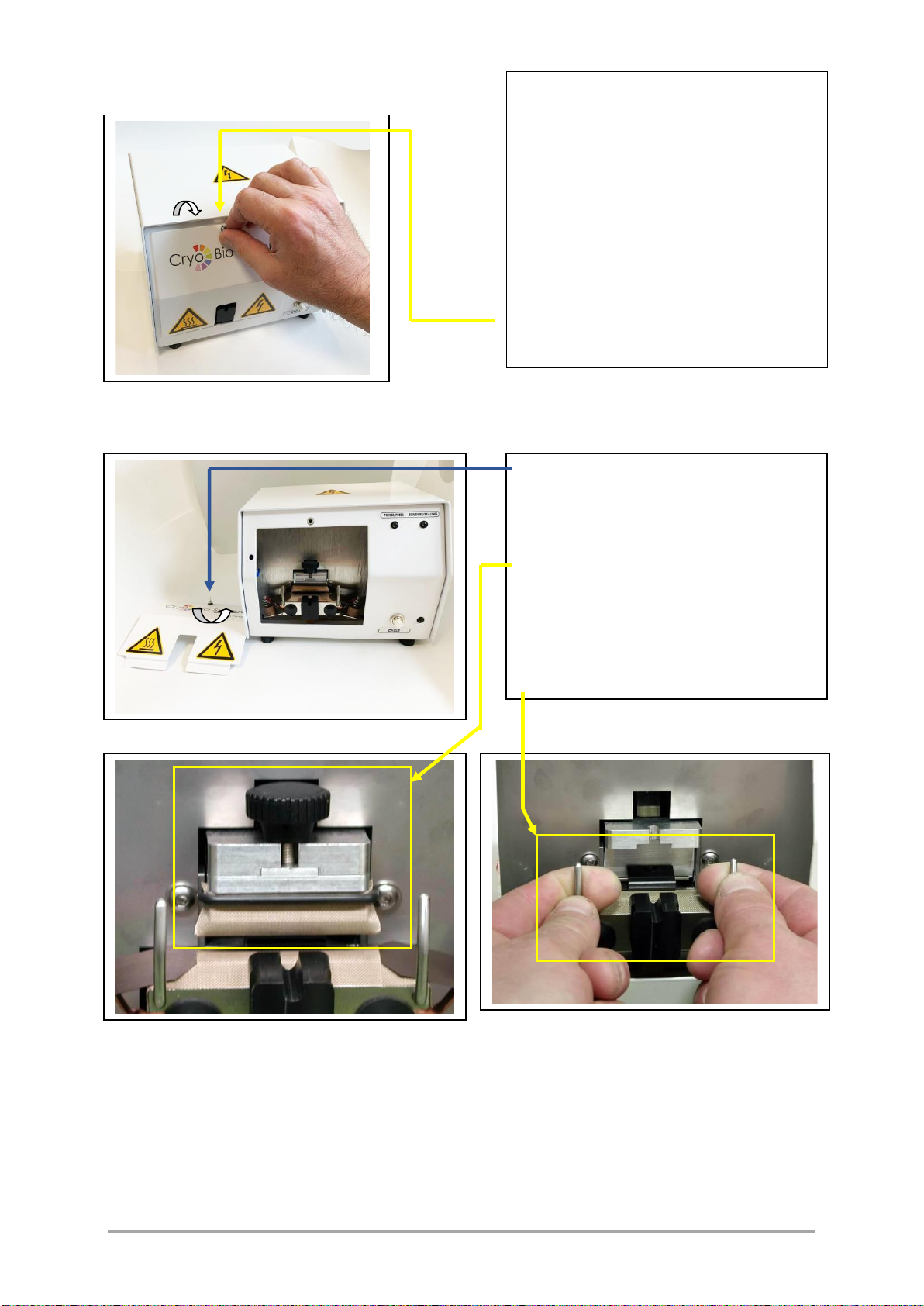

Open the protective flap using rapid nut,

turning it anti-clockwise.

Loosen the knurled nut and remove the

cooling jig.

Remove the welding electrode assembly

- Remove the stop and straw guide by

pulling them out of the electrode assembly.

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 12 / 18]

Replacing the bands

Carry out your decontamination

procedure.

Recommendation: Dry the

decontaminated elements before

reassembly.

Reassemble the equipment and

check manually that the cooling jig

comes into contact with the welding

band, otherwise, check the positioning

of the end-stop and adjust the cooling

jig with the help of the knurled nut.

Close the protective flap using the

rapid nut, turning it clockwise.

Open the protective flap using the

rapid nut, turning it anti-clockwise.

Loosen the knurled nut and remove

the cooling jig.

Remove the welding electrode

assembly by pulling it by the levers.

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 13 / 18]

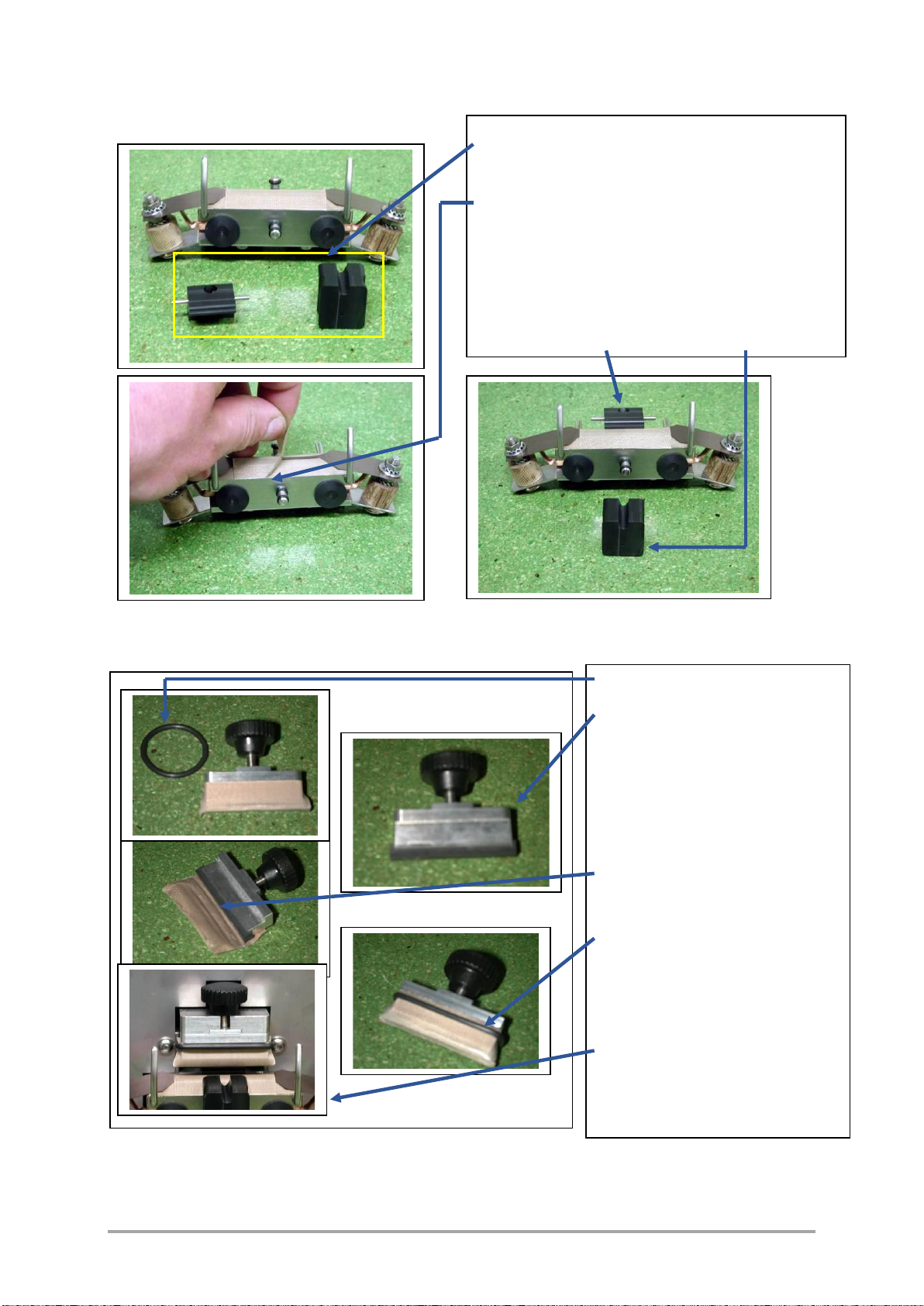

Changing the welding tape band

Changing the cooling jig band

Remove the stop and straw guide by pulling

them out of the electrode assembly.

Remove the adhesive PTFE band covering

the sealing tape.

Cover the sealing tape with the PTFE

adhesive “G9” supplied in the composition.

Make sure that the adhesive is correctly

applied.

Reinstall the end-stop and the straw guide.

Remove the ‘O’ ring weld.

Remove the adhesive PTFE

band covering the cooling jig.

Cover the cooling jig with the

“G22”adhesive PTFE band size

45mm x 30mm supplied in the

composition.

Make sure that the adhesive is

correctly applied.

Reinstall the ‘O’ ring weld.

Reassemble the equipment

and check manually that the

cooling jig comes into contact

to the welding band, otherwise

check the positioning of the

end stop and adjust the cooling

jig with the help of the knurled

nut.

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 14 / 18]

Replacing the elastomer mat

Open the protective flap using the

rapid nut, turning it anti-clockwise.

Loosen the knurled nut and

remove the cooling jig.

Remove the ‘O’ ring weld.

Remove the adhesive PTFE

band covering the cooling jig.

Change the elastomer mat

supplied in the composition by

inserting it in the grove of the

cooling jig.

Cover the cooling jig and the

elastomer mat with the “G22”

adhesive PTFE band of size 45

mm x 30 mm supplied in the

composition (apply the adhesive

correctly).

Reinstall the ‘O’ ring weld.

Reinstall the cooling jig, then

check manually that the cooling

jig comes into contact with the

welding band, otherwise, check

the positioning of the end-stop

and adjust the cooling jig with

the help of the knurled nut.

Close the protective flap.

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 15 / 18]

5 PROCEDURE

5.1 Operation of the individual straw sealer

The sealer does not require any heating up time. It can be used without any problem

in a laminar flow hood or a controlled temperature environment, because the

thermal pulse welding principle limits the release of calories.

However, after a series of 10 seals, it is recommended to comply with a rest time

of five minutes in order to obtain optimum operation.

Connection

Sélection chauffe

Connect the mains power cable “Cb1”to

the socket in the input filter “U0” identified by:

POWER SUPPLY

For use with the control pedal (available as

an option), connect the cable of the control

pedal to the socket “J0” identified by:

FOOT SWITCH

–Set the “U0”main switch to the ‘ON’ position.

–Check that the green “D1”Power On indicator is lit.

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 16 / 18]

Starting the cycle

Remark: Each pressing of the pushbutton or the control pedal causes a welding

cycle.

Opening the flap

Pressing the white “S1”pushbutton or

the “U2”control pedal (available as an

option) activates a welding cycle.

The opening of the protective flap

causes:

the stopping of the cycle,

the clocking of the controls.

The equipment remains switched on.

This is indicated by the presence of the

green Power On indicator

The welding cycle lasts 4 seconds

and is indicated by the yellow

indicator.

The orange indicator corresponds to

the thermal pulse.

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 17 / 18]

6 MAINTENANCE

6.1 Precautions

Maintenance on the individual straw welding machine must be carried once the

machine has been powered down. In case of an accident, Cryo Bio System cannot

be held responsible.

6.2 Maintenance

The main mechanical and electrical parts of the welding machine do not require

any particular maintenance.

Repairs must be carried by a specialist, approved by Cryo Bio System.

However, it is recommended to regularly clean the welding jaws, particularly if they

got accidentally dirty when welding the straws.

If burn marks show on the PTFE bands, they need to be replaced (see composition).

6.3 Transport and storage

Disconnect the equipment from the mains.

To prevent damage, always store and transport the equipment and related parts

in their original packaging.

Store the equipment in a dry place.

When transporting the SYMS I, avoid shocks or brisk movements.

6.4 Recycling of worn parts

Please dispose of old equipment (transformer, electromagnet) at a

specialized center.

Separate the old pieces of equipment as per their composition: metal, plastic,

etc…

6.5 Non-responsibility clause

The Cryo Bio System company cannot be held responsible for any damage

due to external effects or to inappropriate handling or usage.

See the paragraphs on scope of application and electrical specifications on page 2

of these instructions for use.

This document may not be reproduced, copied, transmitted or given to a party other than the end-user without the explicit

written authorization of Cryo Bio System.

IFU-000100 [Indice C] [SYMS I] [P. 18 / 18]

7 Contact

Cryo Bio System

ZI n°1 Est

61300 SAINT OUEN SUR ITON

02.33.34.64.44

support@imv-technologies.com

Table of contents

Popular Food Saver manuals by other brands

BonsenKitchen

BonsenKitchen VS3906 Operation instructions

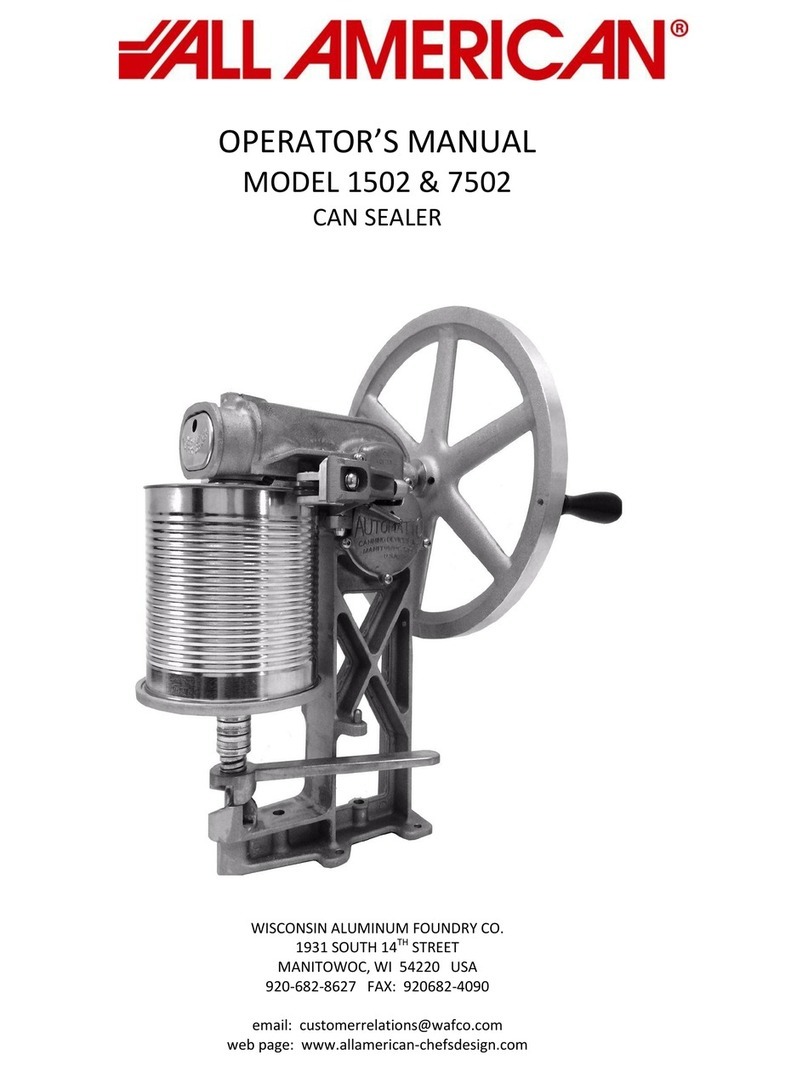

All American

All American 1502 Operator's manual

Silvercrest

Silvercrest 277100 operating instructions

Silvercrest

Silvercrest 397059 2110 operating instructions

Proficook

Proficook PC-VK 1146 instruction manual

Silvercrest

Silvercrest 71770 operating instructions