Cryo-con 24C User manual

User's Guide

Model 24C

Cryogenic Temperature Controller

CRYOGENIC CONTROL SYSTEMS, INC.

P.O. Box 7012

Rancho Santa Fe, CA 2067

Tel: (858) 756-3 00

Fax: (858) 75 -3515

www.cryocon.com

Copyright 2010- 2014

Cryogenic Control Systems, Inc.

All Rights Reserved.

Printing History

Edition 3e.

Certification

Cryogenic Control Systems, Inc. (Cryo-con)

certifies that this product met its published

specifications at the time of shipment. Cryo-con

further certifies that its calibration

measurements are traceable to the United

States National Institute of Standards and

Technology (NIST).

Warranty

This product is warranted against defects in

materials and workmanship for a period of one

year from date of shipment. During this period

Cryo-con will, at its option, either repair or

replace products which prove to be defective.

For products returned to Cryo-con for warranty

service, the Buyer shall prepay shipping

charges and Cryo-con shall pay shipping

charges to return the product to the Buyer.

However, the Buyer shall pay all shipping

charges, duties, and taxes for products returned

to Cryo-con from another country.

Warranty Service

For warranty service or repair, this product must

be returned to a service facility designated by

Cryo-con.

Limitation of Warranty

The foregoing warranty shall not apply to

defects resulting from improper or inadequate

maintenance by the Buyer, Buyer supplied

products or interfacing, unauthorized

modification or misuse, operation outside of the

environmental specifications for the product, or

improper site preparation or maintenance.

The design and implementation of any circuit on

this product is the sole responsibility of the

Buyer. Cryo-con does not warrant the Buyer's

circuitry or malfunctions of this product that

result from the Buyer's circuitry.

In addition Cryo-con does not warrant any

damage that occurs as a result of the Buyer's

circuit or any defects that result from Buyer-

supplied products.

Notice

Information contained in this document is

subject to change without notice.

Cryo-con makes no warranty of any kind with

regard to this material, including, but not limited

to, the implied warranties of merchantability and

fitness for a particular purpose.

Cryo-con shall not be liable for errors contained

herein or for incidental or consequential

damages in connection with the furnishing,

performance, or use of this material. No part of

this document may be photocopied,

reproduced, electronically transferred, or

translated to another language without prior

written consent.

Trademark Acknowledgement

CalGen® and Cryo-Con® are registered

trademarks of Cryogenic Control Systems, Inc.

All other product and company names are

trademarks or trade names of their respective

companies.

Safety

The Model 24C does not contain any user

serviceable parts. Do not open the enclosure.

Do not install substitute parts or perform any

unauthorized modification to the product. For

service or repair, return the product to Cryo-con

or an authorized service center.

Cryo-con Model 24C

Table of Contents

Introduction.................................................................................................1

Sensor Inputs.......................................................................................1

Control Loops.......................................................................................2

User Interface......................................................................................2

Remote Control....................................................................................4

Preparing the controller for use..................................................................7

Supplied Items.....................................................................................7

Verify the AC Power Line Voltage Selection.........................................7

Apply Power to the Controller...............................................................8

Installation............................................................................................

Initial Setup and Configuration.............................................................11

A Quick Start Guide to the User Interface...................................................17

Specifications, Features and Functions......................................................21

Specification Summary........................................................................21

Performance Summary........................................................................27

Input Channel Characteristics..............................................................30

Control Loop Outputs...........................................................................34

Remote Interfaces................................................................................36

Rear Panel...........................................................................................37

Mechanical, Form Factors and Environmental.....................................38

Front Panel Operation................................................................................41

The Keypad..........................................................................................41

The Front Panel Display.......................................................................46

Front Panel Menu Operation......................................................................51

Instrument Setup Menus......................................................................51

Basic Setup and Operation.........................................................................73

Configuring a Sensor...........................................................................73

Using NTC Sensors.............................................................................74

Using PTC resistor sensors.................................................................76

Downloading a Sensor Calibration Curve.............................................77

Autotuning............................................................................................80

Temperature Ramping.........................................................................85

Cryocooler Signature Subtraction.........................................................88

Using an external power booster.......................................................... 1

Using CalGen....................................................................................... 1

Using Thermocouple Sensors.............................................................. 5

System Shielding and Grounding Issues....................................................

Instrument Calibration................................................................................101

Cryo-con Calibration Services..............................................................101

Calibration Interval...............................................................................101

Remote Operation......................................................................................102

Remote Interface Configuration...........................................................102

Remote Programming Guide......................................................................105

General Overview................................................................................105

An Introduction to the SCPI Language.................................................106

iii

Cryo-con Model 24C

Remote Command Tree.......................................................................115

Remote Command Descriptions..........................................................11

Code snippet in C++............................................................................138

EU Declaration of Conformity.....................................................................13

Appendix A: Installed Sensor Curves..........................................................141

Factory Installed Curves.......................................................................141

User Installed Sensor Curves...............................................................142

Sensor Curves on CD..........................................................................143

User Calibration Curve File Format......................................................143

Appendix B: Updating Instrument Firmware...............................................147

Discussion............................................................................................147

Updating unit firmware.........................................................................148

Appendix C: Troubleshooting Guide...........................................................151

Error Displays.......................................................................................151

Control Loop and Heater Problems......................................................152

Temperature Measurement Errors.......................................................153

Remote I/O problems...........................................................................154

General problems................................................................................156

Appendix D: Tuning Control Loops.............................................................157

Introduction..........................................................................................157

Various methods for obtaining PID coefficients....................................157

Manual Tuning Procedures..................................................................158

Appendix E: Sensor Data...........................................................................15

Cryo-con S700 Silicon Diode................................................................15

Cryo-con S 00 Silicon Diode................................................................160

Cryo-con R500 Ruthenium-Oxide Sensor............................................161

Cryo-con R400 Ruthenium-Oxide Sensor............................................162

Sensor Packages.................................................................................163

Appendix F: Configuration Scripts..............................................................167

Script File Structure .............................................................................167

Script File Example..............................................................................170

Appendix G: Sensor Data Tables................................................................173

Silicon Diode........................................................................................173

Platinum RTD.......................................................................................175

Rhodium-Iron.......................................................................................175

Cryogenic Linear Temperature Sensor (CLTS)....................................175

Cernox™..............................................................................................176

Ruthenium-Oxide.................................................................................178

Appendix H: Rear Panel Connections........................................................181

Sensor Connections.............................................................................181

Control Loop #1 Connections...............................................................183

Control Loop #2 and Relay Connections.............................................183

Ethernet (LAN) Connection..................................................................184

IEEE-488.2 Connections......................................................................184

RS-232 Connections............................................................................184

Index........................................................................................................... 185

iv

Cryo-con Model 24C

Index of igures

Figure 1: 4122-030 Rack Mount Kit............................................................

Figure 2: 4034-032 Rack Mount Kit............................................................10

Figure 3: Model 24C Rear Panel Layout....................................................37

Figure 4: Model 24C Front Panel Layout...................................................41

Figure 5: Thermocouple Module................................................................. 5

Figure 6: Thermocouple Switches.............................................................. 5

Figure 7: Proper Assembly of the Input Connector ....................................181

Figure 8: Diode and Resistor Sensor Connections.....................................182

Figure : RS-232 Null Modem Cable..........................................................184

v

Cryo-con Model 24C

Index of Tables

Table 1: Model 24C Instrument Accessories...............................................14

Table 2: Cryogenic Accessories..................................................................15

Table 3: Loop #1 Output Summary.............................................................18

Table 4: Control Type Summary..................................................................1

Table 5: Supported Sensor Types...............................................................21

Table 6: Accuracy and Resolution for PTC Resistors..................................22

Table 7: Minimum and Maximum Resistance vs. Bias Voltage...................23

Table 8: Resolution for NTC Resistors........................................................24

Table : 10mV Constant-Voltage Accuracy Specifications..........................24

Table 10: Supported Sensor Configurations...............................................30

Table 11: PTC Resistor Sensor Configuration...........................................31

Table 12: Loop 1 Heater output ranges.......................................................34

Table 13: Loop 2 Heater output ranges.......................................................35

Table 14. AC Power Line Fuses..................................................................38

Table 15: Keypad key functions..................................................................45

Table 16: Temperature Units.......................................................................47

Table 17: Input Channel Configuration Menu..............................................52

Table 18: Control Loop Setup Menus..........................................................55

Table 1 : User Configurations Menu..........................................................5

Table 20: System Configuration Menu........................................................60

Table 21: Over Temperature Disconnect Configuration..............................62

Table 22: Network Configuration Menu.......................................................64

Table 23: PID Table Edit Menu...................................................................66

Table 24: Sensor Setup Menu....................................................................67

Table 25: Calibration Curve Menu...............................................................68

Table 26: Auto Tune Menu..........................................................................6

Table 27: digital output Status Indicators....................................................71

Table 28: Digital Output Modes...................................................................71

Table 2 : Recommended Sensor Configuration Data.................................78

Table 30: Autotune Menu............................................................................83

Table 31: Autotune States...........................................................................84

Table 32: First CalGen Menu, Diode Sensor.............................................. 2

Table 33: CalGen Menu, 2-point Diode Sensor........................................... 3

Table 34: CalGen New Curve Menu........................................................... 4

Table 35: Thermocouple Polarities............................................................. 7

Table 36: GPIB Host Setup Parameters.....................................................103

Table 37: BB Package Specifications.........................................................164

Table 38: Input Connector Pin-out..............................................................181

Table 3 : Sensor Cable Color Codes.........................................................182

Table 40: Loop 1 Connections....................................................................183

Table 41: Loop #2 and Digital Output Connections....................................183

Table 42: RS-232 DB- Connector Pinout.................................................184

vi

Cryo-con Model 24C Introduction

Introduction

The Model 24C is a four-input, four-control loop cryogenic temperature controller

designed for general purpose laboratory and industrial use. Each input is independent

and capable of temperature measurement to <100mK with an appropriate

temperature sensor. The Model 24C supports virtually any cryogenic temperature

sensor produced by any manufacturer.

The four-output control loop circuits feature a primary 50W heater, a secondary

heater of 25W and two 10-Volt non-powered outputs. All control modes are supported

by all outputs.

The 24C front panel incorporates a large high resolution graphics TFT type Liquid

Crystal Display with an exceptionally wide viewing angle. With it's bright white LED

back-light, complete instrument status can be seen at a glance, even from across the

room.

Sensor Inputs

The Model 24C has four identical input channels, each of which implements a

ratiometric AC resistance bridge. This bridge uses separate, balanced circuits to

simultaneously measure both the voltage drop across the temperature sensor and the

current flowing through it. By measuring current with a higher accuracy than it can be

set, precision resistance measurements are obtained, even at low excitation levels.

Negative-Temperature-Coefficient (NTC) resistors are often used as low temperature

thermometers, especially at ultra-low temperature. Examples include Ruthenium-

oxide, Carbon-Glass, Cernox™, Carbon-Ceramic, Germanium and several others.

Their resistance and sensitivity increase dramatically at low temperature but their

sensitivity is usually poor at warmer temperatures.

The Model 24C provides robust support for NTC resistor sensors by using constant-

voltage AC excitation. In the warm region where the sensor has low resistance and

low sensitivity, constant-voltage will apply a high excitation current to improve

measurement accuracy. At low temperature where the sensor has high sensitivity and

high resistance, measurement errors are dominated by sensor self-heating.

Constant-voltage excitation reduces this error by reducing power dissipated in the

sensor as temperature decreases.

A common source of error at ultra-low temperature is sensor self-heating due to DC

offsets in the measurement electronics. The Model 24C resistance bridge measures

the actual current flowing through the sensor to actively cancel DC offsets by using a

feedback loop to offset it's excitation source.

Ultra-low temperature systems can be negatively affected by coarse steps in

excitation current. The Model 24C prevents this by using a step-less, continuously

variable excitation source.

Positive Temperature Coe icient (PTC) resistor sensors including Platinum, CLTS

and Rhodium-Iron RTDs use the resistance bridge in a constant-current, AC mode.

Platinum RTD sensors use a built-in DIN standard calibration curve that has been

extended to 14K for cryogenic use. Lower temperature use is possible with custom

calibrations.

1

Cryo-con Model 24C Introduction

Silicon diode sensors are supported over their full temperature range by using the

bridge in a DC, constant-current mode.

Thermocouple sensors are supported by using an optional thermocouple module

that plugs into any of the Model 24C's input channels. Up to four modules can be

connected to a single instrument.

For all sensor types, conversion of a sensor reading into temperature is performed by

using a Cubic Spline interpolation algorithm. In addition to providing higher accuracy

than conventional linear interpolation, the spline function eliminates discontinuities

during temperature ramps or sweeps by ensuring that the first and second derivatives

are continuous.

Control Loops

There are four independent control loop outputs:

1. Loop #1 heater output is a linear, low noise RFI filtered current source that

can provide up to 1.0 Ampere into 50 resistive loads. Three full-scale

ranges are available in decade increments down to 500mW full-scale.

2. Loop #2 is a linear heater with two output ranges of 25-Watts and 2.5-Watt

full-scale into a 50 load.

3. Loop #3 and #4 are a non-powered analog voltage output intended to control

an external booster power supply. Output is selectable at 10 or 5 Volts full

scale.

User Interface

The Model 24C’s user interface consists of a large, bright TFT type Liquid Crystal

Display and a full 21-key keypad. In this user-friendly interface, all features and

functions of the instrument can be accessed via this simple and intuitive menu driven

interface.

The Home screen projects four user configurable zones that allow the real-time

display of all input channel, control loop and instrument status information. From this

screen, accessing any of

the instrument's

configuration menus

requires only the press of

a single key. As always,

convenient names can be

assigned to input

channels.

1A:Sample Holder 2B:First Stage

251.445K 123.845K

300.000K 1-Off- ow 100.000K 2-Off- ow

C:Second Stage D:Rad Shield

15.445K 4.845K

RO-600 RuOx 10mV R500 RuOx 1.0mV

Ä

2

Cryo-con Model 24C Introduction

Cryo-con's innovative instrument configuration menus show real-time status

information so the user can instantly view the results of any changes made.

On the control loop menu,

the controlling source

temperature, heater range

and power output level can

be observed while tuning a

loop.

An essential feature for

debugging system software

is the Network Configuration

Menu's ability to show

remote commands as they

are sent and received to the

instrument.

Sensor Curves: The Model 24C includes built-in curves that support most

industry standard temperature sensors. Additionally, eight user calibration curves

are available for custom or calibrated sensors. Each user curve may have up to 200

entries and are entered from the front panel, or transferred via any of the available

remote interfaces.

New calibration curves may be generated using the CalGen feature to fit any existing

diode, Platinum or NTC resistor calibration curve at up to three user specified

temperature points. This provides an easy and effective method for obtaining higher

accuracy temperature measurements without expensive sensor calibrations.

Data logging is performed by continuously recording to an internal 1,365 entry

circular buffer. Data is time stamped so that the actual time of an event can be

determined. Non-volatile memory is used so that data will survive a power failure.

Input Channel Statistics: The Model 24C continuously tracks temperature

history independently on each input channel and provides a statistical summary that

indicates the channel's minimum, maximum, average and standard deviation. Also

shown are the slope and the offset of the best-fit straight line of temperature history

data.

Alarms: Visual, remote and audible alarms are independently programmed to

assert, or clear based on high or low temperature condition, or a detected sensor

fault. Latched alarms are asserted on an alarm condition and will remain asserted

until cleared by the user.

Network Configuration Menu

Dev: M24C1234

DHCP Ena: On

Msk:255.255.255.0

00:50:C2:6F:40:3C

IP: 192.168.0.198

GWy:192.168.0.1

>input a:temp?;units?;name?;sys:time?

<0.5321;K;Sample Holder;14:37:25.

3

oop 1A:Sample Holder

Set Pt:300.000K

Pgain: 6.000

Igain: 60.00S

Dgain: 7.500/S

Pman: 5.0000%

Type: RampT

Input: ChA

A: 123.456K

Ramp 42% of Mid

Range: MID

PID Table index: 2

Htr oad: 50W

Next2

Cryo-con Model 24C Introduction

Relays: The Model 24C has two 10-Ampere dry-contact relays. These can be used

to control a refrigerator system or other external equipment.

Each relay can be asserted or cleared based on the temperature reading of a

selected input channel. High and low setpoints may be set from the front panel or a

remote interface. Furthermore, the relays can be manually asserted ON or OFF.

Remote Control

Standard Remote Interfaces include Ethernet and RS-232. IEEE-488.2(GPIB) and

USB are optional.

The Model 24C connects directly to any Ethernet Local-Area-Network (LAN) to make

measurements easily and economically. TCP/IP and UDP data port servers brings

fast Ethernet connectivity to all common data acquisition software programs including

LabView. An ASCII text based command language identical to those commonly

used with GPIB or RS-232 interfaces is implemented. This is the primary way that

user software interfaces to the instrument.

Using the Ethernet SMTP protocol, the controller will send e-mail based on selected

alarm conditions. E-mail is configured by using the web page interface.

Using the Ethernet HTTP protocol, the instrument’s embedded web server allows the

instrument to be viewed and configured from any web browser.

4

Cryo-con Model 24C Introduction

5

Cryo-con Model 24C Introduction

In order to eliminate ground-loop and noise pickup problems commonly associated

with IEEE-488 systems, the Model 24C moves the internal IEEE-488 circuitry to an

optional external module that interfaces directly to the electrically isolated and low

noise Ethernet interface. This compact module is completely transparent to the IEEE-

488 system and does not require changes to customer software or LabView drivers.

Remote Command Language: The Model 24C's remote command language

is SCPI compliant according to the IEEE-488.2 specification. SCPI establishes a

common language and syntax across various types of instruments. It is easy to learn

and easy to read.

The SCPI command language is identical across all Cryo-con products so that the

user's investment in system software is always protected.

Command Scripts can be used to completely configure an instrument including

setting custom sensor calibration curves and PID tables. Further, scripts can query

and test data. They are commonly used in a manufacturing environment to set a

baseline state and test a target product. In the laboratory, scripts can be used to save

and restore configurations for various experiments.

XML (Extensible Markup Language) is used for the structure and format of script files.

XML can be generated and edited with a standard text editor. Further, it is easy to

read and understand.

Firmware updates: Instrument firmware updates may be installed by using the

Ethernet connection. Cryo-con provides firmware updates, on request, via e-mail.

They are free of charge and generally include enhancements and new features as

well as problem fixes. Send e-mail to cctechsupport@cryocon.com

Ethernet API: An Applications Program Interface (API) package is supplied that

facilitates communication with the instrument using the TCP/IP and UDP protocols. It

is supplied as a Microsoft Windows DLL that is easily linked with C, C++ or Basic

programs.

6

Cryo-con Model 24C Preparing the controller for use

Preparing the controller for use

The following steps help you verify that the controller is ready for use.

Supplied Items

Confirm that you have received the following items with your controller. If anything is

missing, contact Cryogenic Control Systems, Inc. directly.

Model 24C Cryogenic Temperature Controller.

This User’s Manual.

Cryo-con software CD.

Input connector kit (4024-016) consisting of four screw-in DIN-6 input

connectors (PN 04-0414).

Output connector kit (4124-018) consisting of a 10-pin detachable

terminal block (04-0007) and a dual banana plug(04-0433).

Detachable 120VAC USA Line Cord (04-0310), or universal Euro cord.

Certificate of Calibration.

Verify the AC Power Line Voltage Selection

The AC power line voltage is set to the proper value for your country when the

controller is shipped from the factory. Change the voltage setting if it is not correct.

The settings are: 100, 120 220, or 240 VAC. For 230 VAC operation, use the 240 VAC

setting.

On the rear panel of the instrument, the AC voltage selection is on the power entry

module. If the setting is incorrect, please refer to section Fuse Replacement and

Voltage Selection to change it.

7

Cryo-con Model 24C Preparing the controller for use

Apply Power to the Controller

Connect the power cord and turn the controller on by pressing the Power key for a

minimum of 2 Seconds. The front panel will show a Power Up display with the model

number and firmware

revision.

While the Power Up display

is shown, the controller is

performing a self-test

procedure that verifies the

proper function of internal

data and program

memories, remote interfaces and input/output channels. If an error is detected during

this process, the controller will freeze operation with an error message display. In this

case, turn the unit off and refer to Appendix C: Troubleshooting Guide.

Caution: Do not remove the instrument’s cover or attempt to repair

the controller. There are no user serviceable parts, jumpers or

switches inside the unit. Further, there are no software ROM chips,

trim pots, batteries or battery-backed memories.

All firmware installation and instrument calibration functions are

performed externally via the remote interfaces.

After about fifteen seconds, the self-test will complete and the controller will begin

normal operation.

8

Cryogenic Control Systems, Inc.

Model 24C SN:209999 Rev: 1.23B

IP:192.168.1.5 Static Port: 5000

MAC: 00:50:c2:6f:40:3E

Calibration: Testing NVRAM: Testing

Device Name: NewCryocon Connecting

GPIB Adrs: 012 RS232: 9600

Status: Self Test

Cryo-con Model 24C Preparing the controller for use

Installation

General

The Model 24C can be used as a bench top instrument, or mounted in an equipment

rack. In either case, it is important to ensure that adequate ventilation is provided.

Cooling airflow enters through the side holes and exhausts out the fan on the rear

panel. It is important to allow at least ½" of clearance on the left and right sides and to

ensure that the exhaust path of the fan is not blocked.

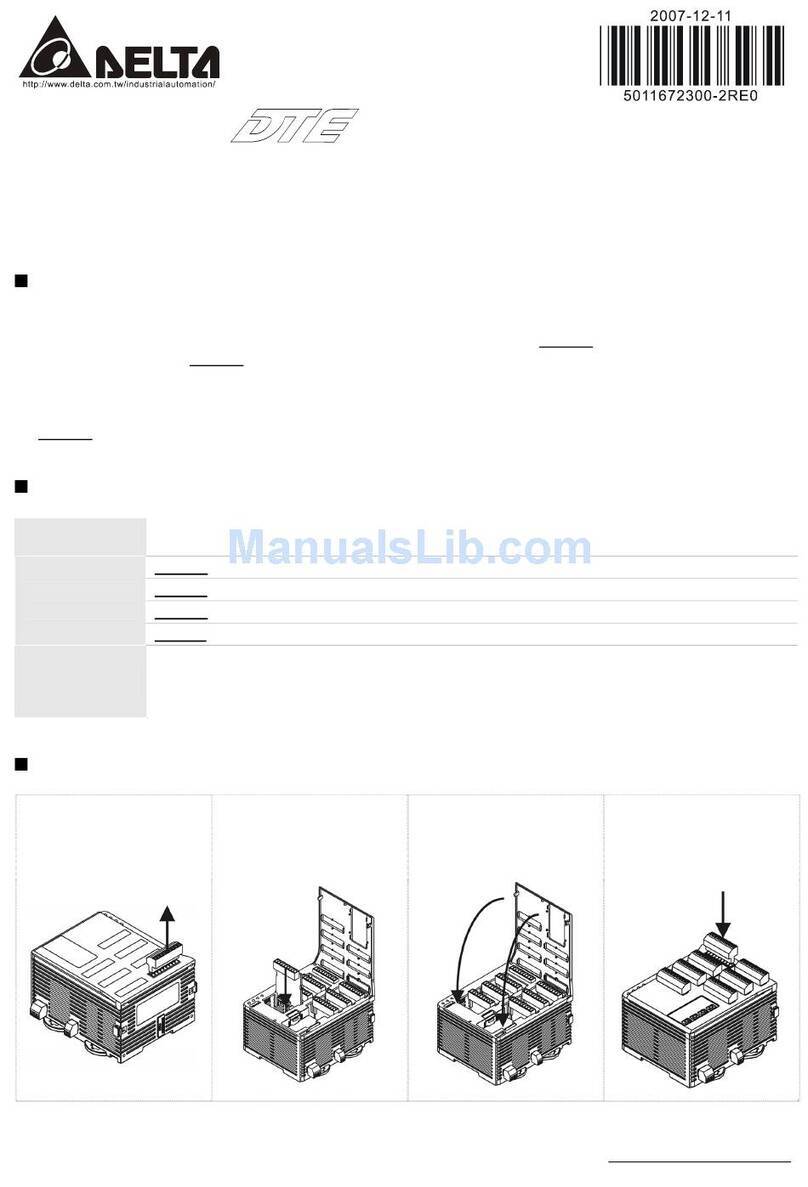

Rack Mounting

You can rack mount the controller in a standard 1 -inch rack cabinet using the

optional rack mount kit. Instructions and mounting hardware are included with the kit.

4122-030 Single instrument 2U rack mount kit.

4034-032 Single instrument shelf rack mount kit.

4034-031 Dual instrument shelf rack mount kit.

Figure 1: 4122-030 Rack Mount Kit

Cryo-con Model 24C Preparing the controller for use

Using the one- or two-instrument shelf rack mount kit, additional equipment may be

mounted on the shelf space next to the controller. Note that these rack mount kits

extends the height of the controller from 2U (3½") to 3U (5¼").

Since the controller is an industry standard size, it is possible to mount any similar

size instrument next to it in the rack.

Warning: When using the shelf type rack mount kits, do not use

screws that protrude into the bottom of instrument more than ¼".

Otherwise, they can touch internal circuitry and damage it.

10

Figure 2: 4034-032 Rack Mount Kit

Cryo-con Model 24C Preparing the controller for use

Initial Setup and Configuration

Before attempting to control temperature, the following instrument parameters should

be checked:

1. The Loop #1Heater resistance setting should match the actual heater

resistance that you are going to use. Choices are 50 and 25. A heater

resistance of less than 25 should use the 25 setting. Using the 50

setting with a heater resistance much less than 50 may cause the

instrument to overheat and disengage the control loops.

Set the heater resistance by pressing the Loop 1 key and refer to the Loop

Configuration Menu section.

2. The Loop #1 heater range should be set to a range where the maximum

output power will not damage the equipment. To set this parameter, press the

Loop 1 key and refer to the Loop Configuration Menu section.

3. The controller has an over-temperature disconnect feature that monitors a

selected input and will disconnect both control loops if the specified

temperature is exceeded. This feature should be enabled in order to protect

your equipment from being over heated. To enable, press the System key

and refer to the System Functions Menu section.

i NOTE: Factory defaults may be restored at any time by use of

the following sequence: 1) Turn AC power OFF. 2) Press and hold

the Enter key while turning power back ON. This sequence will

restore factory defaults including resetting user supplied sensor

calibration curves and saved user configurations. However, it will

NOT erase the instrument’s internal calibration data.

11

Cryo-con Model 24C Preparing the controller for use

Model Identification

The model number of all Cryo-con controllers is identified on the front and rear panel

of the instrument as well as in various instrument displays.

Ordering Information

Standard Description

Model 24C Controller with four standard multi-function sensor input channels.

Controller includes: User's Manual, Cryo-con software CD, four

input connectors, heater connector, terminal block plug, detachable

power cord and a certificate of calibration.

Specify AC Line Voltage when ordering:

-100 Configured for 0 - 100VAC with detachable USA power

cord.

-110 Configured for 110 - 120VAC with detachable USA power

cord.

-220 Configured for 220VAC with detachable universal Euro

(Shuko) line cord.

-240 Configured for 240VAC with detachable universal Euro

(Shuko) line cord.

Options Description

4039-004 Thermocouple Input Module. Field installable. Supports all

thermocouple types. Controller supports up to 4 modules.

4001-002 IEEE-488.2 (GPIB) Option. Field installable.

4001-001 USB Option. Serial Port Emulation. Field installable.

12

Cryo-con Model 24C Preparing the controller for use

Technical Assistance

Troubleshooting guides and user’s manuals are available on our web page at

http://www.cryocon.com.

Technical assistance may be also be obtained by contacting Cryo-con as follows:

Cryogenic Control Systems, Inc.

PO Box 7012

Rancho Santa Fe, CA 2067-7012

Telephone: (858) 756-3 00x100 FAX: (858) 75 -3515

e-mail: cctechsupport@cryocon.com

For updates to LabView™ drivers, Cryo-con utility software and product

documentation, go to our web site and select the Download area.

Current Firmware Revision Level

As of July, 2014 the firmware

revision level for the Model 24C

series is 2.52. Instrument firmware

can be updated in the field via the

LAN port. Updates are available on

the Internet.

Current Hardware Revision Level

As of July, 2014, the hardware

revision level for the Model 24C

series is C.

Returning Equipment

If an instrument must be returned to Cryo-con for repair or recalibration, a Return

Material Authorization (RMA) number must first be obtained from the factory. This

may be done by Telephone, FAX or e-mail.

When requesting an RMA, please provide the following information:

1. Instrument model and serial number.

2. User contact information.

3. Return shipping address.

4. If the return is for service, please provide a description of the malfunction.

If possible, the original packing material should be retained for reshipment. If not

available, consult factory for packing assistance.

Cryo-con’s shipping address is:

Cryogenic Control Systems, Inc.

1727 La Brisa

Rancho Santa Fe, CA 2067-7012

13

Hardware

Revision A B, C

Relay contact

rating 2.0A, 30W 10.0A, 150W

Non-powered

outputs 10.0V Selectable 10V or 5V

full scale.

Loop 2 output 10W or 1.0W-

Volt full-scale

25W or 2.5W-Volt full-

scale

Cryo-con Model 24C Preparing the controller for use

Instrument Accessories

Cryo-con Part # Description

4034-031 Two instrument shelf rack mount kit

4034-032 One instrument shelf rack mount kit

4034-035 Shielded IEEE-488.2 Interface Bus Cable, 6'6"

04-0310 AC Power Cord

04-0317 AC Power Cord, Cont. European (Shuko)

04-0414 Din-6 Sensor Input Connector, Amphenol T3400 001

04-0007 Ten-pin detachable terminal block for Loop 2 and relay connections.

04-0433 Dual banana plug for Loop 1 connection.

4042-040 8' Sensor cable, four wire, wired to DIN-6 connector.

3124-029 Additional User’s Manual/CD

Table 1: Model 24C Instrument Accessories

14

Table of contents

Popular Temperature Controllers manuals by other brands

Delta Electronics

Delta Electronics DTE20C instruction sheet

Solo

Solo SL4824 Series quick start guide

EnOcean

EnOcean Trio2Sys O2LINE 10020057 Series Installation and operating manual

THORLABS

THORLABS TED350 Operation manual

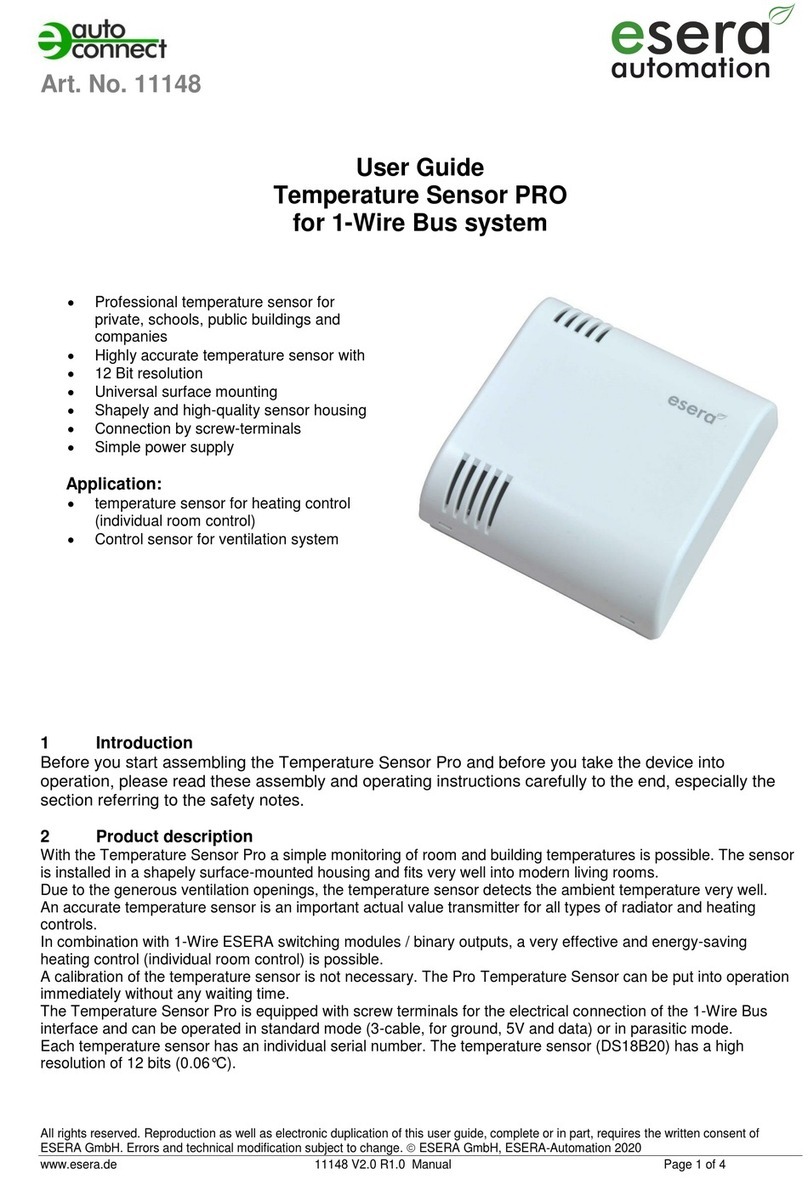

esera automation

esera automation PRO 11148 user guide

Novus

Novus N1020 instruction manual