Secco SUPERCOOL-1000 User manual

M 890-00039 rev.03

SUPERCOOL 1000

Temperature Controller

User’s manual

N/A

N/A

6

5

4

3

2

1

C

7

1 2

1 1

1 0

9

8

MODIFY

WATER USAGE MONIT O RING

PUMP RUN TIME

PUMP MAINTENANCE

INSTALLA T ION

TEST MODE

RH COMPENSATION

& DUST CONTRO L

ALARM

SETTINGS

F A N GROUP 3

F A N GROUP 2

MISTING

TIME & DA T E

CURRENT

CONDITIONS

F A N GROUP 1

MISTING - MANUAL MODE

RUNNING PUMP

MAINTENANCE REQUIRED

MISTING MISTING

DRAINING

MISTING FOR DUST CONTROL

MIST SHUT OFF HIGH RH

MIST SHUT OFF NIGHTIME

RH COMPENSA T ION ACTIVE

ACTIVE FAN GROUP 1

ACTIVE FAN GROUP 2

ACTIVE FAN GROUP 3

ALARMS

TEMPERA T URE

DEFECTIVE PROBE

WA TER SPILL

NO WA TER

LOW WA TER PRESSURE

F A N 1F A N 2F A N 3MISTING P UMP

ALARMS

1000

REV. 00

2SUPERCOOL-1000 rev.03

SUPERCOOL-1000

WARNINGS

The warranty can be void if this product is

used in a manner not specified by the manu-

facturer.

Every effort has been made to ensure that

this manual is complete, accurate and up-

to-date. The information contained in it is

however subject to change without notice

due to further developments.

3

SUPERCOOL-1000 rev.03

SUPERCOOL-1000

TABLE OF CONTENTS

1. INTRODUCTION ............................ 4

1.1. Precautions................................... 4

1.2. Symbols of the Manual................... 4

2. FEATURES.................................... 5

3. LOCATION OF THE CONTROLS....... 6

4. INSTALLATION ............................. 7

4.1. Mounting Instructions .................... 7

4.2. Connections.................................. 7

4.2.1. Probe Inputs ............................ 7

4.2.2. Alarm Connection ..................... 7

5. TIME & DATE ............................... 8

6. MONITORING FUNCTIONS ............. 8

6.1. Current Conditions......................... 8

6.1.1. History .................................... 8

6.1.1.1. Temperature of the Probe Sets used

by the Outputs ....................................8

6.1.2. Individual Probe History ............. 9

6.1.3. Outside T° Probe History........... 9

6.1.4. Humidity Sensor History for the

Outputs................................. 10

6.1.5. Individual Humidity Probe History..

10

6.2. Stress Index................................ 11

6.3. Pump Run Time........................... 11

6.4. Pump Maintenance ...................... 11

6.4.1. Maintenance Done .................. 11

6.4.2. Total Run Time & Reminder Mes-

sage Frequency ...................... 12

6.5. Water Usage............................... 12

7. USER SETUP............................... 13

8. FAN GROUPS ............................. 16

8.1. Principle of Operation................... 16

8.2. Fan Group Parameters.................. 17

8.2.1. Temperature-Based Fans.......... 17

8.2.2. Humidity-Based Fans............... 17

9. MIST ......................................... 18

9.1. Principle of Operation................... 18

9.2. Mist Timers ................................ 18

9.3. Typical Application ...................... 19

9.4. Humidity Compensation ............... 20

9.4.1. Principle of Operation .............. 20

9.4.2. Compensation Adjustments...... 21

9.5. Dust Control .............................. 22

10. MANUAL MODE .......................... 22

11. TEST MODE................................ 23

12. ALARM SETTINGS....................... 24

12.1. Temperature Alarms .................... 24

12.2. Defective Probe Alarm.................. 24

12.3. Water Shortage ........................... 25

12.4. Water Spills ............................... 25

12.5. Low Water Pressure..................... 26

13. TECHNICAL SPECIFICATIONS....... 27

14. MEMORY CARD .......................... 28

15. INSTALLATION REPORT............... 30

16. INDEX........................................ 32

4SUPERCOOL-1000 rev.03

SUPERCOOL-1000

INTRODUCTION1.

Precautions1.1.

WARNING: Read and save these in-

structions!

Safety may be jeopardized if the equipment

is used in a manner not specified by the

manufacturer. Carefully read and keep the

following instructions for future reference.

We strongly recommend installing supple-

mentary ventilation as well as a backup

thermostat on at least one fan stage (refer to

the wiring diagram enclosed with this user's

manual to connect the thermostat).

Although fuses at the input and outputs of

the controller protect its circuits in case of

an overload or over-voltage, we recommend

installing an additional protection device on

the controller’s supply circuit.

The room temperature where the controller

is located must always remain between 32°F

and 104°F (0°C to 40°C). Indoor use only!

To avoid exposing the controller to harmful

gases or excessive humidity, it is preferable

to install it in a corridor.

If the equipment is used in a manner not

specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not spray water on the controller! In

order to clean the control, wipe it with a

damp cloth.

The controller should be opened and inspected

once a year for moisture. Proper care will ex-

tend the life of the control.

Before servicing or cleaning unit, switch

power off at service panel and lock the

switch disconnecting means to prevent

power from being switched accidentally.

When the service disconnecting means

cannot be locked, securely fasten a

prominent warning device, such as a

tag, to the service panel.

1.2. Symbols of the Manual

Warning. Read the following text

carefully; it contains important

information which, if ignored, may

cause the controller to operate

improperly.

High Voltage. Hazard of electrical

shock. Read the message and follow

the instructions carefully.

Pay attention. The following text

contains very useful information.

Both direct and alternating current

(AC/DC).

Direct current (DC).

Alternating current (AC).

Fuse

For Customer Use: Enter below the serial

number located on the side of the alarm

system and keep this information for future

reference.

Model: SUPERCOOL-1000

Serial number:

Date installed:

5

SUPERCOOL-1000 rev.03

SUPERCOOL-1000

FEATURES2.

The SUPERCOOL-1000 is an electronic device

used to control the humidity level and room

temperature in livestock buildings. It allows

the user to cool the building and maintain a

specified humidity level by operating venti-

lation and mist cooling equipment. It can

control one mist cooling zone and three fan

stages. The main features of the SUPER-

COOL-1000 are as follows:

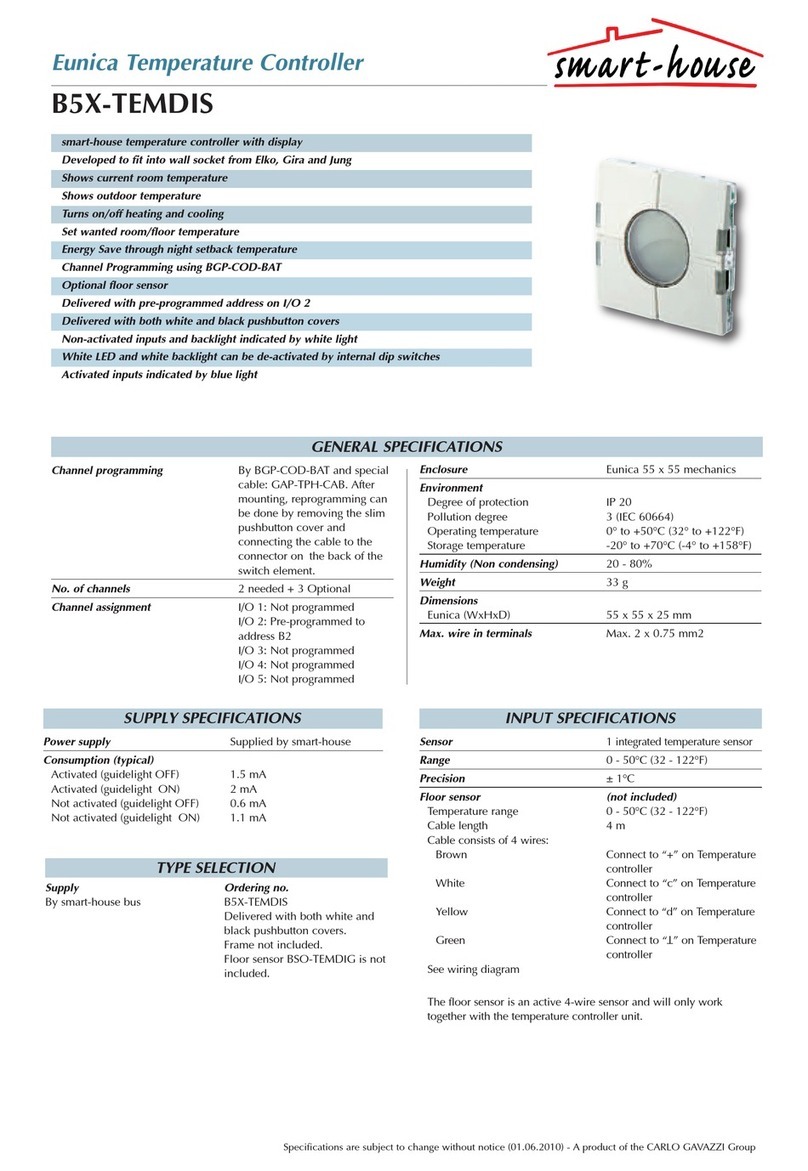

Large LCD Display — The large LCD display

gives the current readings and displays the

parameters. Refer to the next section of this

manual for further information about the pa-

rameters that are shown on this display.

P i lot Li ghts — Pilot lights indicating the state

of outputs allow the user to monitor the

operation of the system without having to

enter the building.

Removable Connectors — The inputs' con-

nection is now made easier by removing the

connectors from the main board.

Manual Control — The mist cooling valve

and pump can be manually activated using a

switch located on the side of the controller.

Dust Control Cycle — When mist units are

not required for reducing room temperature,

they can be operated either continuously or

intermittently to reduce the level of dust in

the room.

Humidity Compensation — Operating times

for mist timers can be automatically adjusted

as a function of humidity levels in the build-

ing.

Probe Inputs — Up to 6 temperature probes,

1 outside temperature probe and 3 humidity

sensors can be connected to the controller

in order to obtain a more accurate reading of

the average room temperature and humidity

level.

Probe Readings Recorded For Past Days —

Minimum and maximum readings from tem-

perature and humidity probes are recorded for

the current day and the past six days.

Monitoring Of Water Consumption — A

pulse input is available to monitor daily wa-

ter consumption for the current day and the

past six days.

Maintenance Reminder Function — A mes-

sage reminding the user to perform pump

maintenance can be signalled after the pump

has been in operation for a specified time.

Alarm Management — Alarms are provided

for defective probes and other system func-

tions. Alarm states are kept in memory until

acknowledged even if an alarm situation has

been rectified.

Password Protection — A password feature

can be enabled to restrict access to the con-

troller setup functions.

Backup Battery — A backup battery allows

the unit to keep time in case of a power

failure.

Overload And Overvoltage Protection — Re-

settable fuses are provided at low-voltage

inputs and outputs of the controller to pro-

tect its circuitry in the case of an overload

or overvoltage.

Computer Control — The controller can be

connected to a computer, thus making it

possible to centralize the management of

information and diversify control strategies.

Test Mode — A test mode allows you to

simulate temperature changes and verify

controller performance.

6SUPERCOOL-1000 rev.03

SUPERCOOL-1000

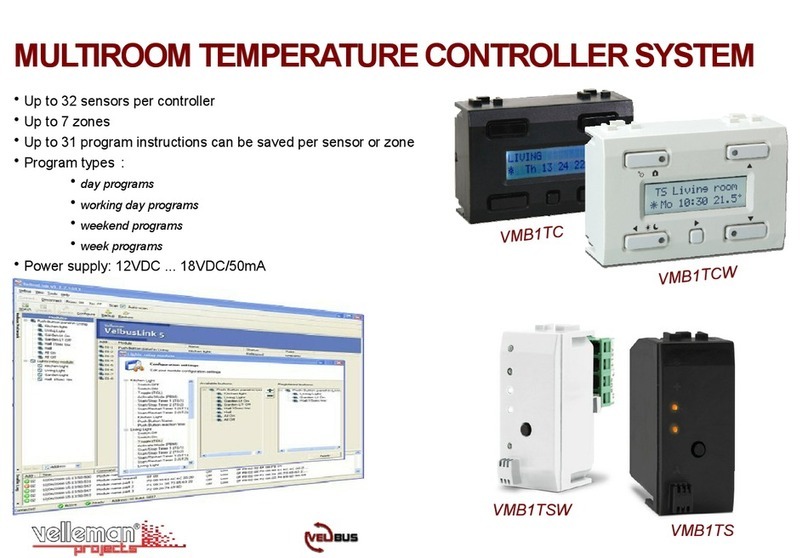

3. LOCATION OF THE

CONTROLS

N/A

N/A

6

5

4

3

2

1

C

7

12

11

10

9

8WATER USAGE MONIT O RING

PUMP RUN TIME

PUMP MAINTENANCE

INSTALLA T ION

TEST MODE

RH COMPENSATION

& DUST CONTROL

ALARM

SETTINGS

F A N GROUP 3

F A N GROUP 2

MISTING

TIME & DA T E

CURRENT

CONDITIONS

F A N GROUP 1

MISTING - MANUAL MODE

RUNNING PUMP

MAINTENANCE REQUIRED

MISTING MISTING

DRAINING

MISTING FOR DUST CONTROL

MIST SHUT OFF HIGH RH

MIST SHUT OFF NIGHTIME

RH COMPENSA T ION ACTIVE

ACTIVE FAN GROUP 1

ACTIVE FAN GROUP 2

ACTIVE FAN GROUP 3

ALARMS

TEMPERA T URE

DEFECTIVE PROBE

WA TER SPILL

NO WA TER

LOW WA TER PRESSURE

F A N 1F A N 2F A N 3MISTING P UMP

ALARMS

LCD Display

Navigation &

Adjustment

Keys

LED display

Output

Status LEDs

Current

Condition

Arrow Keys

MODIFY

Button

LED Display — The display on the top left

corner of the faceplate shows the current

room temperature averaged over all selected

temperature probes. It can also display the

average hu midit y leve l of th e sel ec ted hu mid -

ity sensors. Refer to the User Setup chapter

to select the sensors.

LCD Display — The LCD display on the right

shows the current readings and parameters

to be adjusted when you select a function.

The three keys besides the display are used to

edit parameters and step through the display.

When the parameters for a given function

cannot all be presented at once on the dis-

play, arrows are displayed on the right hand

side to indicate that additional parameters

can be displayed using the arrow keys. After

5 minutes of inactivity, the display returns to

the room's average temperature reading.

Adj us tme nt a n d navi gat io n a rr ow keys — The

arrow keys that are located at the upper right

corner are used to scroll the LCD display

when all parameters cannot be presented all

at once. These keys are also used to change

a parameter's value once the MODIFY key

has been pressed.

Cu rre n t con di tio n but to n — This button gives

a quick access to the current conditions in the

barn (temperature, humidity level, etc.)

Cu rre n t con di tio n ar r ow keys — These arrows

are used to access the sub-menus located in

the CURRENT CONDITION's menu.

Adjusting a Parameter — Press the MODIFY

key to edit a parameter, the parameter then

flashes on the display. This means that it

can now be modified by using the up and

down-arrow keys that are located beside

the display.

Output Status LEDs — LEDs at the left side

of the control panel give the status of each

output. When the LED is turned on, the out-

put is activated; when the LED is turned off,

the output is deactivated. The mist output

pilot light turns on during the ON time of the

misting timer; it flashes during the OFF time

of the misting timer and is turned off when

no timer is active.

7

SUPERCOOL-1000 rev.03

SUPERCOOL-1000

INSTALLATION4.

4.1. Mounting Instructions

Open the latch and lift the cover. Remove

the black caps located on each of the four

mounting holes. Mount the enclosure on

the wall using four screws. Be sure the

electrical knockouts are at the bottom of

the enclosure in order to prevent water from

entering the controller. Insert the screws in

the mounting holes and tighten. Fasten the

four black caps provided with the controller

onto the four mounting holes. The enclosure

must be mounted in a location that will allow

the cover to be completely opened right up

against the wall.

4.2. Connections

Refer to the wiring diagram enclosed with

this user's manual to connect the controller.

Use the electrical knockouts provided at the

bottom of the enclosure. Do not make ad-

ditional holes in the enclosure, particularly

on the side of the enclosure when using a

computer communication module.

All wiring must be done by an autho-

rized electrician and must comply with

applicable codes, laws and regulations.

Be sure power is off before doing any

wiring to avoid electrical shocks and

equipment damage.

Do not install rigid conduit into electrical

knockouts. Only nylon cable glands are

permitted for cable or wire fastening.

The controller has no power-on switch.

An external switch or circuit breaker

shall be included in the building instal-

lation to interrupt power to L and N

electric power lines. It shall be in close

proximity to the equipment and within

easy reach of the operator. It shall be

marked as the disconnecting device for

the equipment.

Note that the input terminals can be

taken off from the main board to make

the connections easier.

4.2.1. Probe Inputs

Probes operate at low voltage and are isolated

from the supply. Make sure that probe cables

remain isolated from all high voltage sources.

In particular, do not route the probe cables

through the same electrical knockout as other

cables. Do not connect the shield from the

probe cable to a terminal or a ground.

Extending a probe: Each probe can be ex-

tended up to 500 feet (150 meters).

To extend a probe: Use a shielded cable of

outside diameter between 0.245 and 0.260

in (6.22 and 6.60 mm) (the cable dimensions

should not be under 18 AWG) to ensure the

cable entry is liquid tight. Do not ground

the shielding.

It is preferable to solder the cable joint to

ensure a proper contact between the two

cables.

Do not run probe cables next to other

power cables. When crossing over other

cables, cross at 90°.

4.2.2. Alarm Connection

There are two types of alarms on the market.

One type activates when current is cut off at

its input, whereas the other activates when

current is supplied at its input. For an alarm

of the first type, use the NC terminal as

shown on the wiring diagram. For an alarm

of the second type, use the NO terminal.

8SUPERCOOL-1000 rev.03

SUPERCOOL-1000

5. TIME & DATE

Press1. 7- TIME & DATE. The current

time and date are displayed.

12:00:00 PM

01/31/200X

Press MODIFY. The hours flash on the2.

display. Use the arrow keys to set the hours.

Press MODIFY. The minutes flash on the dis-

play. Use the arrow keys to set the minutes.

Press MODIFY once again. The seconds flash

on the display. Use the arrow keys to adjust

the seconds to the desired value.

Press MODIFY. The month flashes. Use3.

the arrow keys to set the month. Press

MODIFY, the day flashes. Use the arrow

keys to set the day. Press MODIFY once

again, the year flashes. Use the arrow keys

to set the year.

MONITORING FUNCTIONS6.

6.1. Current Conditions

6.1.1. History

Temperature of the Probe6.1.1.1.

Sets used by the Outputs

Press1. C- CURRENT CONDITIONS.

Press the current condition down-arrow2.

key to select the temperature reading of the

desired misting or ventilation output (Mist

T°, Fan #1-3 T°). The output's average tem-

perature is displayed. The output's active

temperature probes flash on the display.

Mist T° 80.0 °F

Pr.Act: 123456

Press on the navigation down-arrow key,3.

today's minimum temperature, as read by the

output's probes, is displayed along with the

time and date.

Mist T° 12/04/XX

Min 79.2 12:06P

Press on the navigation down-arrow key,4.

today's maximum temperature, as read by

the output's probes, is displayed along with

the time and date.

Mist T° 12/04/XX

Max 85.3 5:06P

Press on the navigation down-arrow key5.

to scroll the display. The minimum and maxi-

mum readings of the output's temperature

probes are displayed for the current day and

for the past 6 days.

Press on the navigation down-arrow key6.

again to display the current reading of the

temperature probes.

1: 84.5 2: 84.0

3: 84.0 4: 83.5

9

SUPERCOOL-1000 rev.03

SUPERCOOL-1000

6.1.2. Individual Probe History

Press1. C- CURRENT CONDITIONS.

The room temperature is displayed. The

probes that have been chosen to measure this

average temperature are flashing on screen

(refer to the User Setup chapter to select the

room temperature probes).

Avg.T°: 84.0°F

Pr.Act:123456

Press the current condition down-arrow2.

key. The minimum and maximum temperature

recorded by the room temperature probes

are displayed for the current day and for the

past 6 days.

Avg.T° 12/04/XX

Min 80.6 12:00A

Keep pressing the navigation down-arrow3.

key, the current temperature of each probe

is displayed.

1: 84.5 2: 84.0

3: 84.0 4: 83.5

Keep pressing the navigation down-arrow4.

key, today's minimum temperature, as read

by the first temperature probe, is displayed

along with the time and date.

Probe 1 12/04/XX

Min 79.5 1:51A

Press on the navigation down-arrow key,5.

today's maximum temperature, as read by

the first probe, is displayed along with the

time and date.

Probe 1 12/04/XX

Max 86.0 4:28P

Press on the navigation down-arrow6.

key to scroll the display. The minimum and

maximum readings of all individual probes

are displayed for the current day and for the

past 6 days.

6.1.3. Outside T° Probe History

Press1. C- CURRENT CONDITIONS.

Press the current condition down-arrow2.

key to select the current reading of the out-

side temperature probe.

Out T° 64.2°F

Press the current condition down-arrow3.

key. Today's minimum outside temperatures

is displayed along with the time and date.

Out T° 12/04/XX

Min 58.4°F 12:00A

Press the current condition down-arrow4.

key. Today's maximum outside temperatures

is displayed along with the time and date.

Out T° 12/04/XX

Max 64.4°F 12:00A

Keep pressing the navigation down-arrow5.

key. The minimum and maximum readings of

the outside temperature sensor are displayed

for the past six days.

10 SUPERCOOL-1000 rev.03

SUPERCOOL-1000

6.1.4. Humidity Sensor History for

the Outputs

Press1. C- CURRENT CONDITIONS.

Press the current condition down-arrow2.

key to select the relative humidity reading of

the desired misting or ventilation output (Mist

RH, Fan 1-3 RH). The output's average hu-

midity level, as read by the selected sensors,

is displayed. The output's active humidity

sensors flash on the display.

Mist RH 60%

Pr.Act: 123

Press on the navigation down-arrow key,3.

today's minimum humidity level, as read by

the output's sensors, is displayed along with

the time and date.

Mist RH 12/04/XX

Min 60% 5:22P

Press on the navigation down-arrow key,4.

today's maximum humidity level, as read by

the output's sensors, is displayed along with

the time and date.

Mist RH 16/04/XX

Max 85% 10:18A

Press on the navigation down-arrow5.

key to scroll the display. The minimum and

maximum humidity readings of the output's

sensors for the current day and for the past

6 days are displayed.

Press on the navigation down-arrow key6.

again to display the current readings of the

output's humidity sensors.

1: 50 2: 55

3. 60

6.1.5. Individual Humidity Probe

History

Press1. C- CURRENT CONDITIONS.

Press the current condition down-arrow2.

key to select the average humidity display.

Avg. RH 72%

Pr.Act:123

Press the current condition down-arrow3.

key. The minimum and maximum humidity

levels, as read by the room's RH probes, are

displayed for the current day and for the past

6 days. The sensors that have been chosen

for this purpose flash on the display (refer to

the User Setup chapter to select the room's

humidity sensors).

Avg.RH 12/04/XX

Min 58% 12:00A

Keep pressing the navigation down-arrow4.

key, the current humidity reading of each

probe is displayed.

1: 55 2: 50

3: 54

Keep pressing the navigation down-arrow5.

key, today's minimum humidity level, as read

by the first humidity probe, is displayed along

with the time and date.

RH 1 12/07/XX

Min 40 1:51A

Press on the navigation down-arrow key,6.

today's maximum humidity level, as read by

the first probe, is displayed along with the

time and date.

RH 1 12/07/XX

Max 60 4:28P

Press on the navigation down-arrow7.

key to scroll the display. The minimum and

maximum readings of all individual probes

for the current day and for the past 6 days

are displayed.

11

SUPERCOOL-1000 rev.03

SUPERCOOL-1000

6.2. Stress Index

The stress index is the sum of the tempera-

ture in degre es Fa hrenhe it an d the re lati ve hu-

midity. For example, a temperature of 75°F

and a relative humidity of 63% gives a stress

index of 138. This value is an indication of the

animals' comfort level. The lower the number

is, the higher the comfort level is.

Press1. C- CURRENT CONDITIONS.

Press the current condition down-arrow2.

key to select the stress index of the mist

output (Mist SI).

Mist SI 64

Press on the navigation down-arrow key,3.

today's minimum stress index level is dis-

played along with the time and date.

Mist SI 02/03/XX

Min 25 11:00A

Press on the navigation down-arrow key,4.

today's maximum stress index level is dis-

played along with the time and date.

Mist SI 02/03/XX

Max 72 12:24A

Press on the navigation down-arrow5.

key to scroll the display. The minimum and

maximum readings of the stress index for

the current day and for the past 6 days are

displayed.

6.3. Pump Run Time

A daily history record of pump run times is

available for the current day and the previous

six days. Refer to following section to display

total pump run time.

Press1. 9- PUMP RUN TIME.

The pump run time is displayed. Use the2.

down-arrow key to scroll the display.

12/07/xx 3hr

12/06/xx 3hr

Pump Maintenance6.4.

A message reminding the user that pump

maintenance is required can be signalled after

the pump has operated a specified time. The

user specifies the number of pump operat-

ing hours before maintenance is required.

The “MAINTENANCE REQUIRED” pilot light

flashes when the specified operating time

has been reached.

Maintenance Done6.4.1.

The following procedure indicates to the

controller that pump maintenance has been

performed. The total pump operating time

is then reset.

Press1. 10 - PUMP RUN TIME.

Maintenance

done? No

The message2. “Maintenance done?” is

displayed on screen. Select “Yes” if the

maintenance has been done.

12 SUPERCOOL-1000 rev.03

SUPERCOOL-1000

Total Run Time & Reminder6.4.2.

Message Frequency

Press1. 10 - PUMP RUN TIME.

Press the down-arrow key. The total run2.

time of the pump is displayed.

Pump total

runtime 17h

Press the down-arrow key once again.3.

The frequency for performing pump mainte-

nance is displayed in hours. This is the pump

operating time required before the reminder

message is signalled. Use the adjustment

keys to adjust the value. It ranges from 10

to 30,000 hours (in steps of 10 hours).

Pump maintenance

after: 400hr

6.5. Water Usage

The controller has a pulse input to monitor

the daily water consumption. The daily water

consumption is displayed for the current day

and for the previous six days.

Press1. 8- WATER USAGE MONITORING.

Today's water consumption is displayed.

*Available if a water meter has been enabled in the

Installation menu (see User Setup).

Press the down-arrow key and scroll the2.

display. T he water c ons umpt ion for the previ -

ous six days is displayed.

12/07/xx 27lit

12/06/xx 32lit

13

SUPERCOOL-1000 rev.03

SUPERCOOL-1000

7. USER SETUP

The following section describes how to

customize the controller for your particular

application. Normally, this setup needs to be

done only once. A worksheet is available at

the end of this manual to write down your

parameter settings.

Press1. 11 - INSTALLATION.

The following parameters are presented be-

low in the order they appear on the display.

The installer's password must first be entered

to access these menus. To modify a param-

eter, press MODIFY then use the arrow keys

to change it. When you are finished adjusting

a parameter, press MODIFY to validate the

new value and to return to the display mode.

Press the down-arrow key to move to the

next parameter.

Time Format — AM-PM or 24 hours mode.

Time format

AM-PM

Temperature Units — Fahrenheit (F°) of

Celsius (°C) degrees.

Temp. units

°F

# of Temperature Probes — Select the number

of temperature sensors in use. Adjustable

from 1 to 6 sensors.

# T° probes

6

Relative Humidity (RH) Probe — Select the

number of humidity sensors in use. Adjust-

able from 0 to 3 sensors.

#RH Probes

3

Ou t si de Te m pe rat u re P rob e — Select "Yes" to

enable the outside temperature sensor.

Use Out T°

Probe ? Yes

Mist Temperature probes — The mist output's

activation is based on the average reading of

the selected temperature probes; the probes

that are enabled for this purpose flash on the

display. Press MODIFY then use the adjust-

ment buttons to set the status of each tem-

perature probe for the activation of the mist

output. *Only the probes that are enabled above

are available. Note that at least 1 temperature probe

must be assigned to the mist output. If no selection

is made, the output will operate according to the

temperature reading of the 1st probe.

Mist T° probes

123456

Mist Humidity Probe — The mist output's

relative humidity functions are performed

following the average humidity reading of the

selected sensors; the probes that are enabled

for this purpose flash on the display. Press

MODIFY then use the adjustment buttons to

set the status of each temperature probe for

the activation of the mis t outp ut. *Available if

at least one humidity probe is enabled above.

Mist RH probes

123

Mist Dust Control — Select "Yes" to enable

the dust control option. This feature allows

to acti vate the mis t ou tpu t to maint ain a m ini -

mum humidity level at all time, even when

the mist outputs are not used to cool down

the air. *Available if at least one humidity probe is

assigned to the mist output above.

Use dust con-

trol ? Yes

14 SUPERCOOL-1000 rev.03

SUPERCOOL-1000

Mist Relative Humidity Compensation — Se-

lect "Yes" to enable the humidity compensa-

tion option on the mist output. This feature

allows an automatic control of the mist timer,

based on the humidity level in the room.

*Available if at least one humidity probe is assigned

to the mist output above.

Use RH Compensa-

tion ? Yes

Mist shutoff with RH — Select "Yes" to

enable the mist shutoff option. This feature

allows to stop the mist output when the hu-

midity level in the room is too high. *Available

if at least one humidity probe is assigned to the mist

output above.

Mist shut off

with RH ? Yes

Mist Shutoff Set Point — If the mist shutoff

function is enabled above, select the hu-

midity level above which the mist output is

deactivated.

Mist shut off

RH Setp 80%

Mist Shutdown at Night — Select “Yes"

to disable mist output over a given time

period.

Mist shut off

night? Yes

Day / Night starts at — If the night's shutoff

function is enabled above, define a time

period during which the mist output is dis-

abled.

Night starts at

6:00P

Day starts at

7:00A

# Fan groups — Select the proper number

of fan groups (stages). Adjustable from 1

to 3 groups.

#Fan group

3

Fan Groups 1-3 – Operation mode — Select

the proper operation mode of each fan group:

the fans' activation can either be based on the

temperature (T°) or on the humidity level in

the room (RH). *Available if at least one humidity

probe is enabled above.

Fan group #1

mode : RH

Fan Groups 1-3 Humidity Probes — If a fan

group's activation is based on the humidity

level, the controller uses the average reading

of the selected humidity sensor to operate the

fans. Press MODIFY then use the adjustment

buttons to set the status of each humidity

probe for the activation of the fan group.

*This option is only available if the fan group's

activation is based on the humidity level.

Fan #1 RH probes

123

Fan Groups 1-3 Temperature Probes

If the fan group's activation is based on the

Temperature — The controller uses the aver-

age reading of the chosen temperature probes

to activate the selected fan output.

Fan #1 T° probes

123456

If the fan group's activation is based on the hu-

midity level — The controller uses the average

temperature of these probes either to start

the selected fan group when the temperature

is too high (critical T°) or to stop it when the

temperature is too low (minimum T°), without

considering the humidity level.

15

SUPERCOOL-1000 rev.03

SUPERCOOL-1000

• Press MODIFY then use the adjustment

buttons to set the status of each temperature

probe. *Only the probes that are enabled above

are available.

Water meter — Select "Yes" to enable a

water meter.

Use Water meter?

Yes

Water's measurement unit — Se le ct th e mea -

surement units of the water consumption:

liters or gallons. *This option is available if the

water meter is enabled above.

Water meter unit

lit

Water Meter's Calibration — Amount of water

per pulse. *This option is available if the water

meter is enabled above.

Water unit/pulse

3

Water pressure switch — Select "Yes" to

enable a water pressure switch.

Use water press.

switch? Yes

Pr ess ure swi tch co nta c t — Select which type

of contact is used by the pressure switch

when the water pressure is at an accept-

able level: Normally open (NO) or Normally

closed (NC).

Type of press.

switch NC

Dr ai n Va l ve De l ay — Adjust the delay required

to drain water from supply lines when the

drain valve is opened. Adjustable from 0 to

60 seconds.

Draining time

15sec

Room temperature display — The red digital

display at the left handside of the controller

shows the average temperature of selected

temperature probes. Press MODIFY then use

the a djustm ent b ut ton s to sel ect the tem pe ra -

ture probes that are used for the display of the

average room temperature. *Only the probes

that are enabled above are available.

T° Probe display

123456

Humidity level display — The red digital

display at the left handside of the controller

can display the average reading of selected

humidity sensors. Press MODIFY then use

the adjustment buttons to select the humidity

sensors that are used to display the average

humidity level. *Only the humidity sensors that

are enabled above are available.

RH Probe display

123

Change Password — The user can define a

password to restrict access to certain func-

tions (INSTALLATION and TEST MODE). The

password must be entered each time one of

these functions is selected. When the correct

password is entered, it does not need to be

reentered until the display times out (i.e. after

15 minutes of inactivity). The password is a

sequence of three numbers from 0 to 99. To

disable the password feature, set the pass-

word to 0, 0, 0. By default, the password is

set to 0, 0, 0.

New password ?

** ** **

• Press MODIFY. The first two digits of the

password flash on the display.

The new password must be entered, one

number at a time. Use the arrow keys to enter

the first number. Press MODIFY to step to

the next number. Use the arrow keys to enter

the second number, etc.

Program Version Number — The program

version of your controller is displayed.

16 SUPERCOOL-1000 rev.03

SUPERCOOL-1000

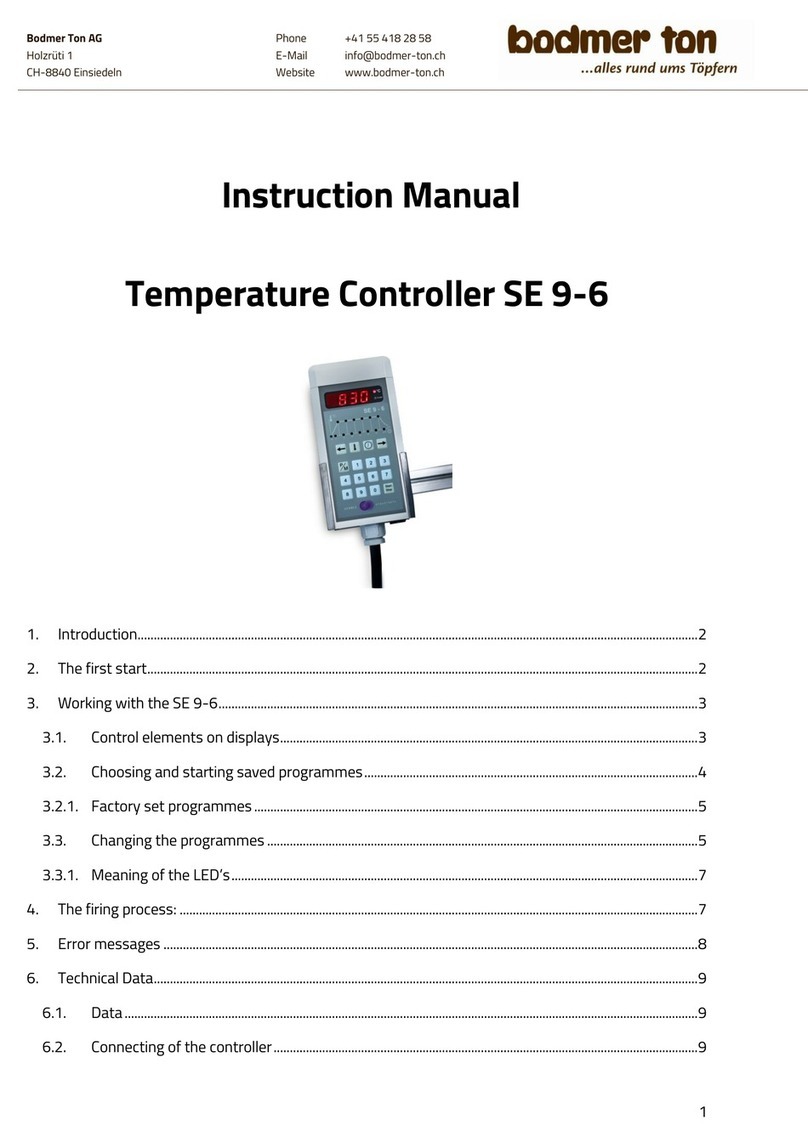

8. FAN GROUPS

Principle of Operation8.1.

The controller can control three groups (or

stages) of On/Off fans. The activation of these

fans can either be based on room tempera-

ture or on the relative humidity level in the

building.

• Fan Groups Based on the Humidity Level —

The fan groups are activated or deactivated

as a function of the humidity level. They can

either run when the humidity level gets too

low or when it gets too high. To use the fan

groups on low humidity conditions, set the

Start % to a lower value than the Stop %;

to use the fans on high humidity conditions,

do the opposite.

Each fan group refers to the average humidity

reading of its respective humidity sensors.

Refer to the Installation menu to assign these

sensors.

Critical & Minimum Temperatures:

As a protection, a high and a low temperature

limits can be defined to activate or deactivate

all fan outputs in case the room temperature

gets out of range. This protection feature

does not take into account the humidity level

in the room.

Temperature-based

Fan Groups

Fan Group

Status

Room T°Stop T°

Off

On

Start T°

Humidity-based

Fan Groups

Fans on High RH levels

(Start RH% > Stop RH%)

Fans on Low RH Levels

(Start RH% < Stop RH%)

Fan Group

Status

Fan Group

Status

RH Level (%)

RH Level (%)

Stop %

Start %

Off

Off

On

On

Start %

Stop %

Refer to the Installation menu to select

the proper operating mode.

• Fan Groups Based on the Room Tempera-

ture — The fan groups are activated or de-

activated as a function of temperature. Each

fan group refers to the average temperature

reading of its respective humidity sensors: it

starts running when the temperature reaches

the Start T° and stop when the temperature

falls to the Stop temperature. Refer to the

Installation menu to assign temperature sen-

sors to the fan groups.

The start temperatures are defined with re-

spect to each other. This means that when

one of these values is adjusted, the start

temperatures of all consecutive fan groups

are adjusted by the same amount.

17

SUPERCOOL-1000 rev.03

SUPERCOOL-1000

8.2. Fan Group Parameters

Fan parameters vary according to the fan

group operating mode. Refer to the User

Setup chapter to select the appropriate mode:

cooling based on temperature readings or

cooling based on humidity readings.

Temperature-Based Fans8.2.1.

Press1. 1- FAN GROUP 1

2- FAN GROUP 2

or

3- FAN GROUP 3

Start 75.0°F

Stop 74.0°F

Set the output's start and stop tempera-2.

tures using the adjustment buttons. They

can be adjusted from -40 °F to 120 °F (-40

to 48.9 °C). The output's start temperature

must be at least 0.3 °F (0.2 °C) higher than

the output's stop temperature. *Accessible

if the fan group's activation is based on the tem-

perature.

Humidity-Based Fans8.2.2.

Press1. 1- FAN GROUP 1

2- FAN GROUP 2

or

3- FAN GROUP 3

Start 60%

Stop 50%

Set the output's start and stop humidity2.

levels using the adjustment buttons. Adjust-

able from 0 to 100%.

Press the down-arrow key. The minimum3.

allowable temperature for the output's activa-

tion is displayed. Set it to the desired value

using the adjustment buttons. Adjustable

from -40 °F to 120 °F (-40 to 48.9 °C).

*Accessible if the fan group's activation is based on

the humidity level.

Minimum T°

60.0°F

Press the down-arrow key. The critical4.

temperature is displayed: the output is ac-

tivated if the room temperature is higher

than this value; the humidity level is not

taken into account. Adjustable from 0.5 °F

(0.3 °C) above the minimum temperature to

120 °F (48.9 °C).

Critical T°

80.0°F

18 SUPERCOOL-1000 rev.03

SUPERCOOL-1000

9. MIST

Principle of Operation9.1.

The controller has one output for mist cool-

ing. This output is activated using a timer

(time on/time off). During the ON time, the

main valve on the mist output opens and the

pump is started. During the OFF time, the

pump is turned off, the mist valve is closed

and the drain valve is opened during a short

delay to drain the water remaining in the

supply lines. This prevents the nozzles from

dripping. The figure on the following page

shows a typical application.

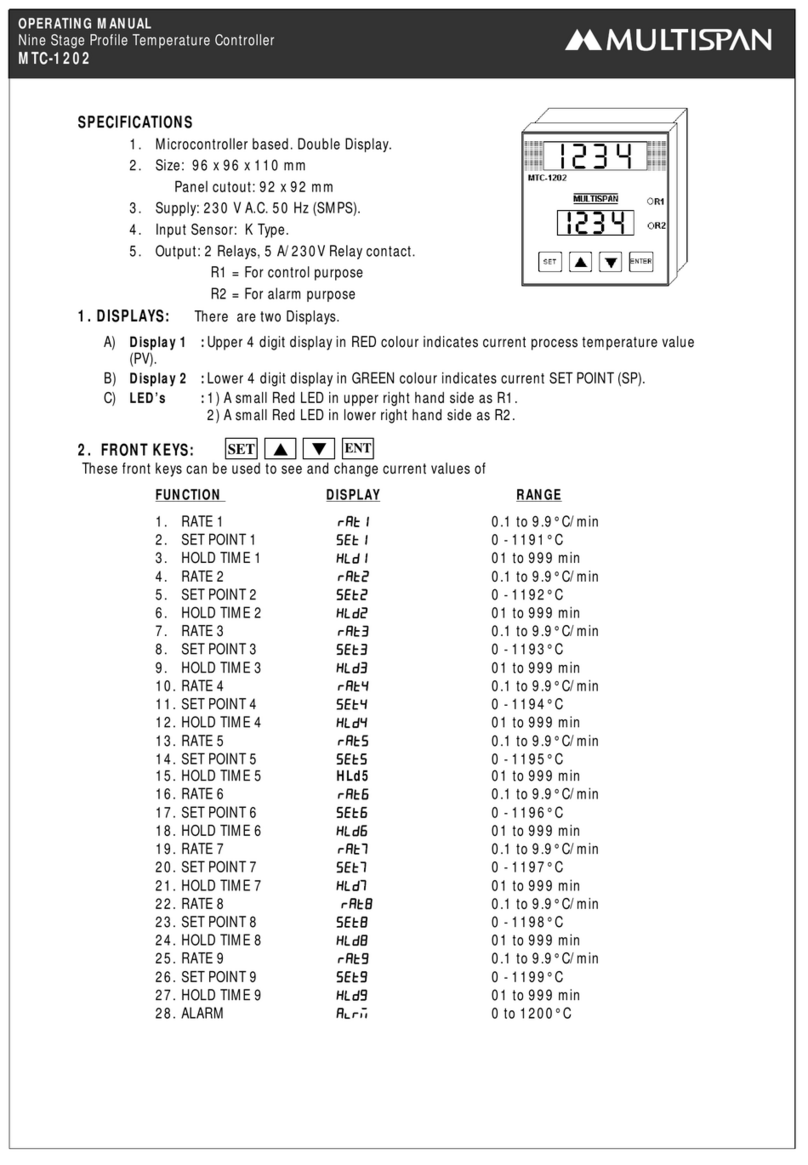

9.2. Mist Timers

The mist output has 4 separate timers: the

timer selection is based on the average tem-

perature reading from probes assigned to

the output, as shown in the following graph

(refer to the User setup chapter to perform

probe assignments).

Mist Timers

Timer

Status

Average

T°

Timer 1 On

Timer 1 Stop T°

Timer 2 Stop T°

Timer 3 Stop T°

Timer 4 Stop T°

Timer 2 On

Timer 1 Off

Timer 1 Start T°

Timer 2 Start T°

Timer 3 Start T°

Timer 4 Start T°

Timer 2 Off

Timer 3 Off

Timer 3 On

Timer 4 Off

Timer 4 On

The timers operate using On time and OFF

time values. These values can be automati-

cally adjusted according to the humidity level

in the building. Refer to the chapter “Humidity

Compensation” for more information on this

feature.

Press1. 1- MISTING.

Adjust the start and stop temperatures2.

of the first timer using the adjustment keys.

These temperatures range from -40.0 to

120.0°F (-40.0 to 48.9°C). The stop tem-

perature must be at least 0.3°F (0.2°C) less

than the start temperature.

Start 1 75.0°F

Stop 1 74.0°F

Press the down-arrow key. The time3.

on and time off values of the first timer are

displayed.

ON 1: 0:30m:s

OFF1: 1:00m:s

Adjust the on and off times of the first4.

timer using the adjustment keys. The On

Time value s ranges fro m 5 sec onds to 15 min-

utes; the Off Time value ranges from 0 to

15 minutes, in increments of 15 seconds.

Press the down-arrow key and adjust the5.

temperatures and timer values for timers 2,

3 and 4.

Start 2 77.0°F

Stop 2 76.0°F

19

SUPERCOOL-1000 rev.03

SUPERCOOL-1000

9.3. Typical Application

0012069

99411056

Pump Pressure

Switch

Filters

Water

Meter

Mist

Valve

Drain

Valve

Manual

Drain

Valve

Nozzles

Water's

entry

point

20 SUPERCOOL-1000 rev.03

SUPERCOOL-1000

9.4. Humidity Compensation

The timer's running time value can be au-

tomatically adjusted based on the humidity

level in the building. Refer to the User Setup

chapter to enable this feature.

Principle of Operation9.4.1.

Dry Weather Compensation:

When the humidity level is low, the timer's

stop time values are decreased to increase

the frequency of mist cycles.

The user specifies a percentage decrease to

apply to the time off value during mist cycles.

This decrease is spread over a humidity inter-

val defined by the user. The following graph

illustrates this:

Note: The compensated time off cannot be

less than 15 seconds. If the compensation

requires that the time off value be less than

15 seconds, time off is set to 0 seconds and

the mist units operate continuously.

Wet Weather Compensation:

When the humidity level exceeds the high

humidity compensation set point, the timer's

running time value is decreased. This de-

creases the duration of misting while main-

taining the frequency of the mist cycles.

The user specifies a percentage decrease to

apply to the running time (On Time) value

during mist cycles. This decrease is spread

over a humidity interval defined by the user.

The following graph illustrates this:

Note: The compensated time on value cannot

be less than 5 seconds. If the compensation

requires that the On Time value be less than

5 seconds, the On Time is set to 0 seconds

and the mist units come to a stop.

Dry Weather

Compensation

RH Level

(%)

Compensation

to 50% RH

Compensation

from 60% RH

Compen-

sated

Regular

Stop

Time

% of

decrease

The Stop Time portion

of the timer cha nges a c-

cording to the humidity

level in the room.

Wet Weather

Compensation

RH Level

(%)

Compensation

from 80% RH

Compensation

to 90% RH

Compen-

sated

Regular

Run

Time

% of

decrease

The Run Time portion

of the timer cha nges a c-

cording to the humidity

level in the room.

Table of contents

Popular Temperature Controllers manuals by other brands

Chauvin Arnoux

Chauvin Arnoux C.A 801 user manual

Daikin McQuay

Daikin McQuay IOM 1177 Installation operation & maintenance data

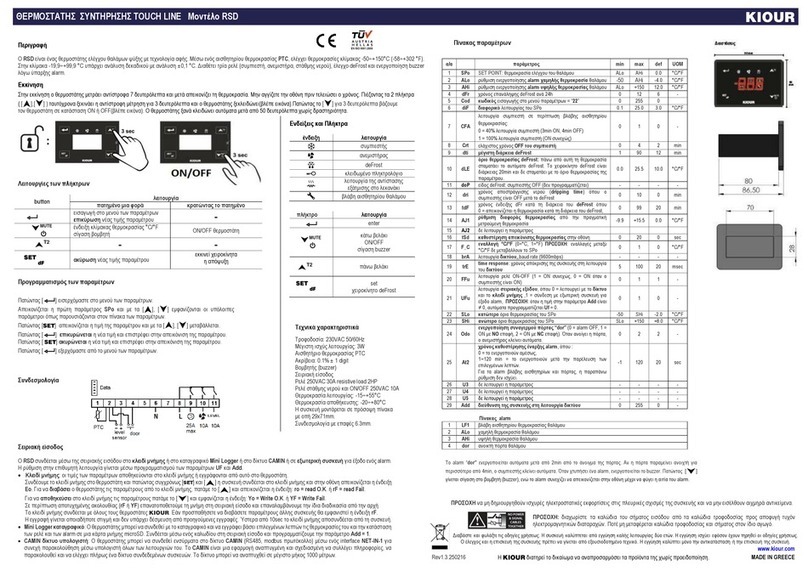

KIOUR

KIOUR TOUCH LINE RSD manual

oventrop

oventrop Unibox TQ vario operating instructions

La Crosse Technology

La Crosse Technology CA85169 Quick setup guide

netvox

netvox R711A user manual