5

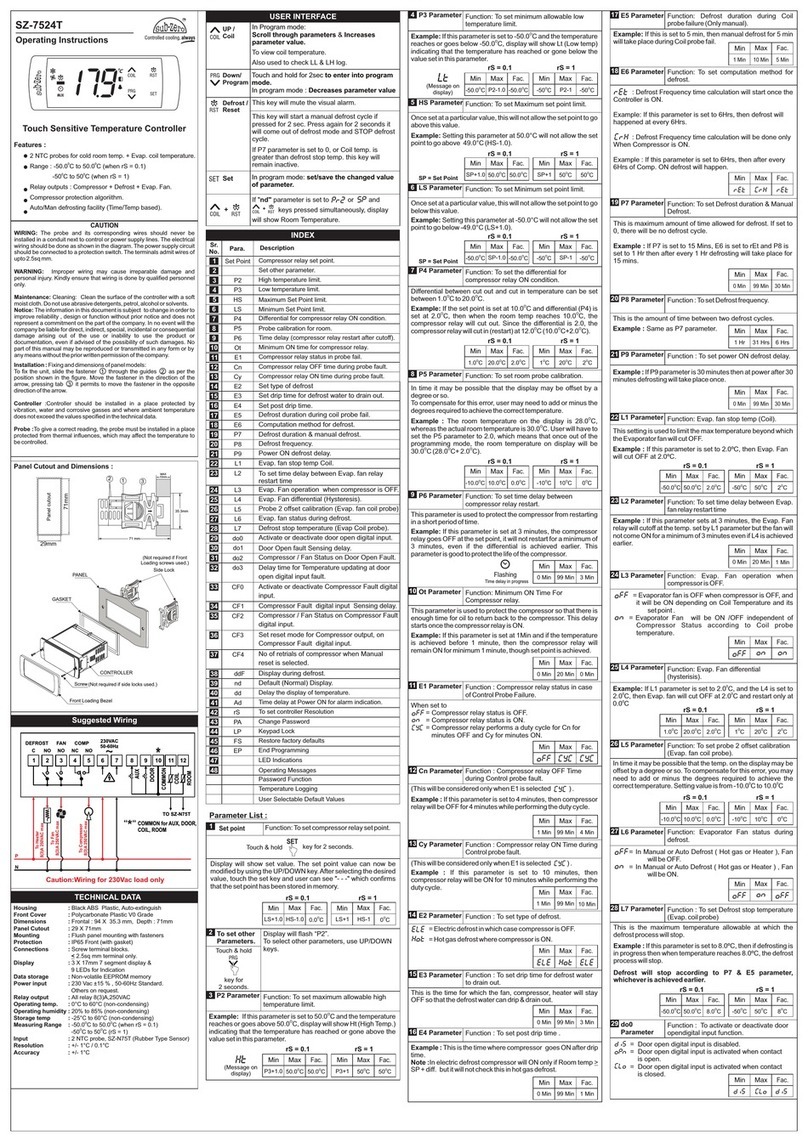

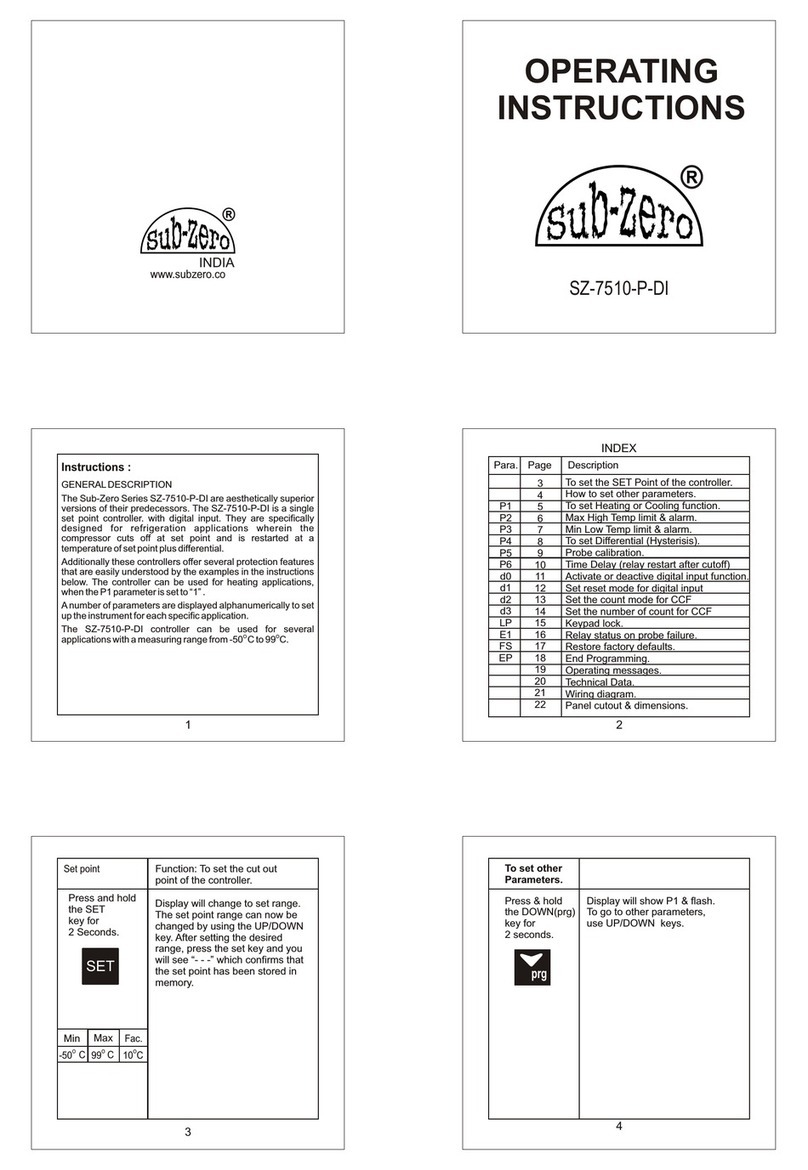

P1 Parameter

Function: To set controller for heating

or cooling.

0 1 0

To change

the P1

parameter,

press the

SET key.

Use UP/DOWN keys to get

desired value & press set

to confirm.

0: Cooling mode and

1: Heating mode.

Min Max

Fac.

6

8

P4 Parameter Function: To set the differential.

To change

the P4

parameter,

press the

SET key.

Use UP/DOWN keys to set

desired value.

Differential between cut out and

cut in temperature can be set

O O

between 1 C to 20 C.

O

1 C

Min Max

Fac.

O

20 C O

2 C

Example (in cooling mode) :

O

If the set point is set at 10 C and

O

differential is set at 2 C, then when

O

the system reaches 10 C, the relay

will cut out. Since the differential is

2, the relay will cut in (restart) at

O O O

12 C (10 C+2 C).

9

P5 Parameter Function: To set probe calibration.

To change

the P5

parameter,

press the

SET key.

To compensate for this error, you

may need to add or minus the

degrees required to achieve the

correct temperature. Setting value

O O

is from -10 C to +10 C.

Use UP/DOWN keys to set desired

value.

In time it may be possible that the

display may be offset by a degree

or so.

O

-10 C

Min Max

Fac.

O

10 C O

0 C

Example : The temperature on

O

the display is 28 C, whereas the

O

actual temperature is 30 C. You will

need to set the P5 mode to 2,

which means that once out of the

programming mode, the

temperature will show

O O O

30 C (28 C + 2 C).

10

P2 Parameter

Function: To set maximum allowable

high temperature limit.

To change

the P2

parameter,

press the

SET key.

Use UP/DOWN keys to set

desired value.

Once set at a particular

value, this will not allow the

set point to go above this

value.

the display will show Ht (High

Temp.) indicating that the

temperature has gone above the

value in this parameter and at this

point the buzzer will activate.(if AL

parameter is set to 1)

Example : Setting this parameter

O

at 25 C will not allow the

O

set point to go above 25 C. Also,

O

if the temperature reaches 25 C,

O

XX C

Max

Fac.

O

99 C O

99 C

Min

(Message on display)

H

P6 Parameter

0 Min

99 Min

3 Min

Function: To set time delay

between relay restart time.

To change

the P6

parameter,

press the

SET key.

Min Max

Fac.

Use UP/DOWN keys to set desired

value.

This parameter is used to protect

the compressor from restarting in a

short period of time and can be set

between 0 to 99 minutes.

Example : If this parameter is set

at 3 minutes, the relay will cut off at

the set temperature, but will not

restart for a minimum of 3 minutes,

even if the differential is achieved

earlier. This parameter is good to

protect the life of the compressor

when there are power fluctuations

and the compressor is switched off

and on within a few seconds.

Flashing

Time delay in progress

7

Function: To set minimum allowable

low temperature set point.

Use UP/DOWN keys to set desired

value. Once set at a particular

value, this will not allow the set

point to go below this value.

Example : Setting this parameter

O

at -30 C will not allow the set point

O

to go below -30 C. Also, if the

O

temperature reaches -30 C, the

display will show Lt (LowTemp.)

indicating that the temperature has

gone below the value in this

parameter and at this point the

buzzer will activate.

P3 Parameter

O

-50 C

Max

Fac.

O

XX C O

-50 C

To change

the P3

parameter,

press the

SET key.

Min

(Message on display)

XX = Set Point

XX = Set Point