Crystal XP2i User manual

C R Y S T A L

engineering corporation

Operation Manual

XP2i

ATEX Digital Test Gauge

Contents

Introduction........................................................1

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Unitsbutton.............................................................3

Zero...................................................................3

Peak detection and Average . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Resetting (clearing) recorded peak values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Automaticshut-off.......................................................4

Backlighting the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

MeasuringVacuum......................................................5

Water Density (Inches of Water). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overpressure Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Filter...................................................................6

Low battery indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Battery replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Reset..................................................................7

Troubleshooting.....................................................7

Noisy or unstable reading when used with uids ..............................7

Non-repeatability of pressure measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Slow return to zero and/or non-repeatability of pressure measurements. . . . . . . . . . 8

Err1displayed..........................................................8

Err2displayed..........................................................8

Display continuously ashes all segments ...................................8

Digital Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

I/OSettings.............................................................9

Communication Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Query Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

MessageStore..........................................................9

Model................................................................10

Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Pressure (one line). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pressure,High..........................................................10

Pressure,Low..........................................................10

Range................................................................10

Return Average Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Return the Average Window Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SerialNumber .........................................................11

Version...............................................................11

WaterDensity..........................................................11

ZeroCheck............................................................11

Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

ClearPeaks...........................................................12

Disable/Enable Peak Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

MessageStore.........................................................12

Next Pressure Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

NoAutoOff............................................................12

Reset.................................................................12

Set the Average Window Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Streaming Data On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

WaterDensity..........................................................13

Zero..................................................................13

Acknowledgment of a Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Troubleshooting the Digital Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Effects of Password Protection on Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Programming Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Calibration........................................................16

XP2i Model & Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Serial Numbering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Model Numbering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Accuracy.............................................................19

Temperature...........................................................19

Humidity..............................................................19

Media Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Pressure Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Connection ...........................................................20

Power ................................................................20

Enclosure .............................................................21

Pressure Ranges, Display Scales & Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Intrinsic Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

ATEX .................................................................23

CSA..................................................................23

IECExScheme.........................................................23

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

C-tick ................................................................23

Software..........................................................23

LabVIEW™ drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

CongXP Conguration Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Accessories.......................................................24

ACadapterkit.........................................................24

Plastic Carrying Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6″Gauge Adapter Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

8½″Gauge Adapter Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

RS-232Cable..........................................................24

Trademarks........................................................24

European Community Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . .25

Warranty..........................................................26

HowtoContactUs:.....................................................26

XP2i ATEX User’s Manual •Page 1

C R Y S T A L

engineering corporation

Introduction

Thank you for choosing the XP2iDigital Test Gauge from Crystal Engineering Corporation.

Your XP2iis a combination of leading edge technology and rugged industrial design.

Accuracy is 0.1 percent of reading - so any XP2ican typically replace several gauges you may

have been using. The XP2iis fully temperature compensated - so there is no change in accu-

racy throughout the entire operating temperature range!

The case, and almost all metal components, are stainless steel. Gaskets seal out dust and water.

Even the RS-232 connector (with or without the cover) is fully sealed. Circuitry is mounted in a

shock absorbing elastomer, and the batteries are easily accessible by removing two screws. But

you won’t need to change batteries often, since 3 AA batteries operate the XP2ifor up to 1500

hours of continuous use. If you are mounting the gauge in a permanent location consider order-

ing the external power supply kit (PN: 2984). With the external power supply the batteries serve as

an automatic backup supply, in case of power failure. Other features include:

•continuous recording of peak and valley pressure readings

•a removable lter (to keep out large particle contaminants)

•all welded 316 stainless steel sensor

•can be cleaned for oxygen service

Your XP2ican be customized, through the use of CongXP™ software available from Crystal Engi-

neering. Your personal computer can disable, enable or modify a variety of features of your XP2i.

Look for the

ConFIGXP PROGRAMMABLE

logo for programmable features, like:

•a user dened pressure scale, and/or disable unused pressure units

•password protection to prevent unauthorized changes

•disable keypad recalibration, peak button, and/or units button

•expand or decrease allowable Zero range

•set the gauge to a dierent density of water factor (4°C, 60°F or 68°F)

•store a 12 digit ID or tag number in non-volatile memory

•adjust calibration values

We hope your

XP2i

meets your expectations, and we're interested in any comments or suggestions you

may have. You can send us a note at: feedback@crystalengineering.net.Many features in this and

our other products are a direct result of your comments!

Crystal Engineering is the company that designs, manufactures, markets and services the XP2i, 30

series pressure calibrators, MultiCal multimeter pressure adapters and a variety of industry spe-

cic pressure measuring equipment. Crystal Engineering pioneered features like full temperature

compensation and “of reading”rated gauges and calibrators. Pressure measuring equipment is the

only thing we do and that’s why we say: PRESSURE is Our BUSINESS™

Page 2 •XP2iATEX User’s Manual

C R Y S T A L

engineering corporation

Operating Instructions

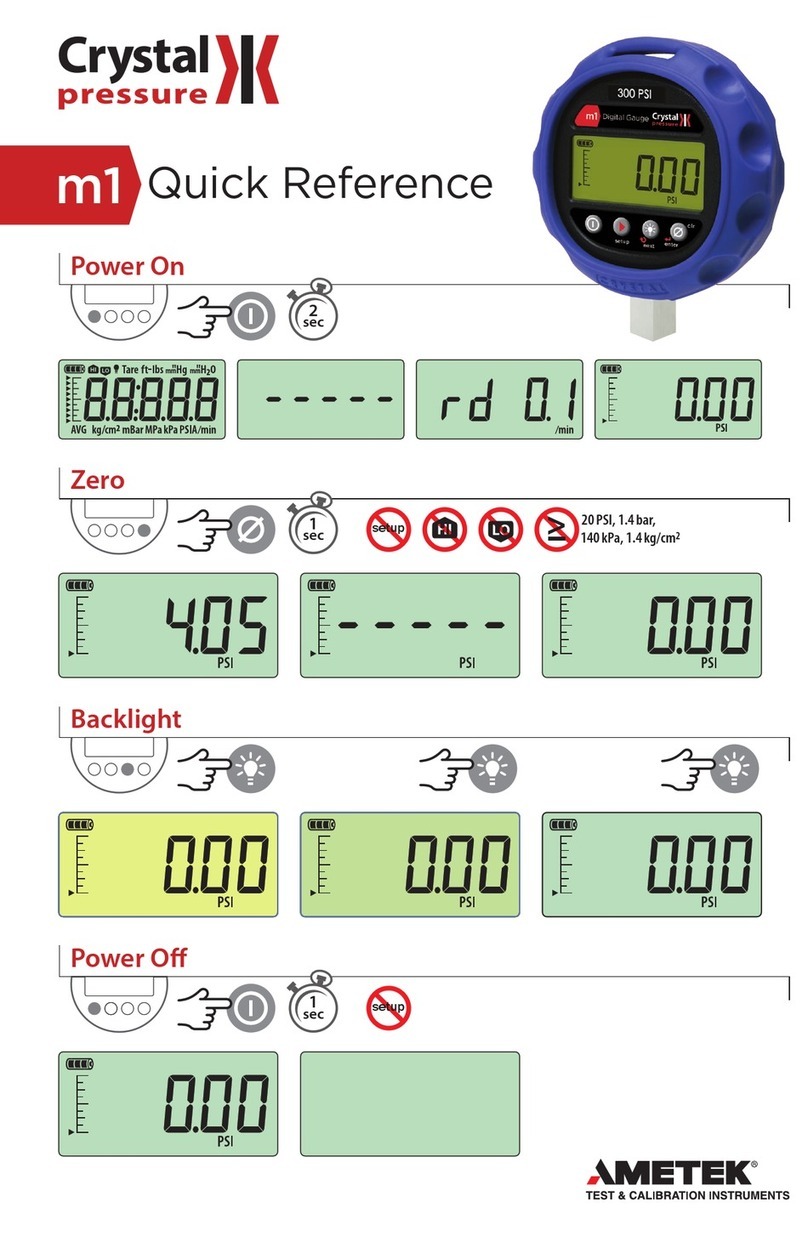

The XP2iis shipped with batteries installed, so it’s ready to use. Press and hold the

(on/off)button. The XP2iwill rst test all LCD segments. Release the but-

ton when the XP2iindicates pressure.

The XP2ialways resumes operation in the mode and the units of the pressure last used, and it

does not automatically rezero when turned on.

Connect the XP2ito your system. Use pipe thread tape or pipe thread sealant on the ¼″NPT t-

ting. Always use a wrench (¾″or 19mm) for installation and removal of

XP2i

!There is a limit to

how much rotational force can be applied to the case, so don’t rely on, or use, the case to screw the

XP2i

into a tting, and don’t use the case to remove the

XP2i

tting, either.

WARNING: Severe injury or damage can occur through improper use of pressure instru-

ments! Do not exceed recommended pressure limits of tubing and ttings. Be certain all pres-

sure connections are secured.

CAUTION: Never insert any object (other than the ⁄” NPT metal lter) into the pressure

connection! The sensor diaphragm is very thin and can be damaged or destroyed by solid or

sharp objects. Cleaning of the sensor must be done with appropriate solvents only.

Most XP2is are intended for gauge pressure measurement. That is, they indicate the dierence

between applied pressure and ambient barometric pressure. However, the

zero

button can be

used to force an XP2ito read zero pressure at any applied pressure, up to the full scale rating of

the gauge. The factory default setting limits the maximum zero value to 200 PSI, but this limit can

be changed with

ConFIGXP

.

Some XP2is are rated for absolute pressure. Absolute gauges indicate the dierence between

applied pressure and an internal vacuum reference. Absolute pressure is always positive. For

instance barometric pressure at sea level is on average about 14.7 PSI (approximately 100 kPA or

1 Bar), so at sea level this is the lowest expected pressure indication. However, absolute gauges

can be “zeroed”(unless prevented by CongXP). After zeroing an absolute gauge it is possible to

indicate a negative pressure.

WARNING: This gauge can display zero pressure when connected to a source of pressure! Do

not rely on the display indication before disconnecting - it may not be indicating true pres-

sure. Never disconnect pressure instrumentation without rst relieving system pressure!

XP2i ATEX User’s Manual •Page 3

C R Y S T A L

engineering corporation

Units button

Pressing this button causes the XP2ito select the next available unit of pressure

measurement. See “Pressure Ranges, Display Scales & Resolution” for the list of

pressure units available for your model.

ConFIGXP PROGRAMMABLE

Units that you don’t need or never use can be

turned o. You can also dene a special unit for your XP2i with CongXP. That way you can use the

XP2i to display directly in a unit not otherwise available, such as feet of seawater, or foot-pounds

of torque. When your custom unit is selected and displayed on the XP2i, all pressure unit icons will

be o.

Zero

To zero the

XP2i

, you must turn o peak indication, then press the

zero

button

for at least ½ second. The display will then briey ash all dashed lines (- - - - -),

indicating that it has been re-zeroed. If you attempt to zero the gauge while more

than 200 PSI is applied (or the pressure limit set with CongXP), the command will

be ignored, and “- -HI-” will be displayed.

WARNING: This gauge can display zero pressure when connected to a source of pressure! Do

not rely on the display indication before disconnecting - it may not be indicating true pres-

sure. Never disconnect pressure instrumentation without rst relieving system pressure!

You can clear the zero value: Turn o peak indication then press and hold the

zero

button until

the display changes from (- - - - -) to (- - -). This is especially useful for absolute gauges that have

been zeroed while measuring barometric pressure.

Zeroed Clear Zero (Unzero)

ConFIGXP PROGRAMMABLE

You can change the point at which the Zero button will display

“- -HI-”. For instance, you could set the maximum zero to 3000 PSI, if you need to mix high pres-

sure gases. You can also disable the zero button entirely, by setting the Zero value to a large nega-

tive number.

The

zero

button changes its function when the peak high (

HI

) or the peak low (

LO

) icon is

displayed. While a peak icon is displayed the

zero

button becomes the

clear

button.

PSI inH2O inHg kpa

mmHg mmH2O mbar kgf/cm2

LO

HI

PSI inH2O inHg kpa

mmHg mmH2O mbar kgf/cm2

LO

HI

Page 4 •XP2iATEX User’s Manual

C R Y S T A L

engineering corporation

Peak detection and Average

Pressing the Peak button causes the display to cycle through the following:

HI

. . . . . . . . . . Recorded maximum pressure

LO

. . . . . . . . . . Minimum recorded pressure

HI

LO

. . . . Average pressure*

<No Icon> . . . . Live pressure display

Peak high and low values are not saved when the gauge shuts o; they will reset to the current

reading when the XP2iis turned on or reset.

* From the factory this Average Pressure is disabled. Use CongXP to enable.

ConFIGXP PROGRAMMABLE

In some cases the ability to display a peak value may not be

needed, or may even be dangerous. CongXP allows you to disable this button.

XP2is can average 1 to 10 readings, recalculated every time pressure is measured (3 times per

second). Enable and set the number of readings to be averaged with CongXP.

Resetting (clearing) recorded peak values

Peak values can only be cleared when displaying either a high or low recorded

pressure. Press the

clear

button for at least ½ second. Dashed lines will then

briey appear across the display and both

HI

and

LO

icons will ash briey,

indicating that both peak values have been cleared. Both peak high and low values

will then display the current applied pressure. Pressing the

clear

button while either peak hi or

peak lo icon is displayed will not aect the zero value. If you need to rezero the gauge, you must

turn o both peak icons by pressing the

peak

button.

Automatic shut-off

The XP2ihas a shuto timer and will turn o automatically after 20 minutes of operation. Pressing

any button or sending any command via the RS-232 connection resets the shuto timer for an-

other 20 minutes of operation.

The shuto feature can be defeated, if desired, when turning the XP2ion. Pressing the

(on/off) and

zero

buttons simultaneously will prevent the XP2ifrom automatically turning o.

The XP2iwill briey display the words “No Auto O” to indicate that it will not turn o.

This procedure is required each time the XP2iis turned on, if you want to defeat the auto-shuto.

XP2i ATEX User’s Manual •Page 5

C R Y S T A L

engineering corporation

Backlighting the Display

Pressing the (backlight) button instantly lights the display at maximum brightness,

but to keep it on you need to hold down the button for 2 seconds. The display will ash

briey, indicating that it will stay on for 1 minute. If you press the button again, the

backlight will go into a lower brightness setting to extend battery life, the display will again ash

briey, and remain on for 2 minutes. Press the button once more and the light will go out.

If you start the XP2iin the“No Auto O” mode, you select the brightness level the same way, but

the light will never time out and turn o; you will have to either turn o the XP2ior press the

backlight again until the light goes out.

Measuring Vacuum

All versions of the XP2ican be used to measure moderate vacuum, though only ranges of 300 PSI

(and 20 bar or 2000 kPa) and lower are actually tested and certied for vacuum operation.

When measuring pressure less than ambient barometric conditions, a minus (-) sign will appear.

XP2is are not recommended for continuous use at high vacuum.

Absolute gauges (models with a “B” in front of “XP2I” in the part number) will NOT indicate a

negative sign when vacuum is applied, unless the zero button has been pressed while a pressure

greater than full vacuum is applied to the gauge. If your absolute gauge does indicate a nega-

tive pressure, you can clear the zero value (“unzero”) by pressing the zero button until the display

changes from ----- (5 dashes) to - - - (dash, space, dash, space, dash). See “Zero” for details.

Water Density (Inches of Water)

The following applies only to models where inches of water are available. As shipped from the

factory, the XP2iis set to display inches of water corresponding to the density of water at 4°C

(39.2°F). You may require a dierent water density for your application, so the XP2ican be set to

use the density of water at 20°C (68°F) or 15.6°C (60°F), instead.

To check and or change the water density setting from the keypad, turn on the XP2iby pressing

the (on/off) button and the

units

button simultaneously. The display will indicate either

“4C” or “60F” or “68F”.

Press the

units

button until the display cycles to the desired water density, then press the

zero

button to store the selection (this will not zero the gauge).

ConFIGXP PROGRAMMABLE

Select and set the desired density of water. If the XP2iis pass-

word protected, you will not be able to view or change the water density from the keypad.

Page 6 •XP2iATEX User’s Manual

C R Y S T A L

engineering corporation

Overpressure Conditions

The XP2iwill read pressure up to approximately 110% of the rated pressure range. Above 110%

percent of the range the display will start ashing and the readings will not be reliable. The zero

function does not aect the point at which the display starts ashing to indicate overpressure,

so depending on the zero value it is possible that the display can start ashing without the maxi-

mum pressure being displayed.

For instance, if a 100 PSI XP2iis zeroed when 30 PSI is being applied, it will indicate that the over-

pressure condition has been reached at 80 PSI (i.e., 110% x 100 PSI – 30 PSI = 80 PSI).

Overpressure can aect accuracy, but the eect is only temporary unless the sensor has been

destroyed. See Specications for maximum overpressure.

Filter

The XP2ihas a removable, stainless steel mesh lter, installed in the bottom of the pressure con-

nection. This lter is designed to keep large particles from becoming entrapped in the sensor

cavity.

If the XP2ifails to return to zero, or returns to zero or new applied pres-

sures slowly, the lter may be obstructed. The lter can be removed and

cleaned if necessary, by unscrewing it with a 5⁄32”(4 mm) hex key, and

using solvents and/or compressed air to clean it out. Or, you can pur-

chase a replacement lter, PN:3002.

Low battery indication

The battery icon ( ) is the rst indication of a low battery. The

XP2iwill continue to operate accurately while the icon is visible.

When the batteries are exhausted, the letters“batt” will appear

across the display. After“batt” appears, no pressure measurements

will be possible until the batteries are replaced.

Battery replacement

The XP2iuses 3 AA batteries*. Batteries must only be changed in a non-hazardous area! With the

hex key wrench (5⁄64”[2mm], provided with the gauge), unscrew the two rear panel screws to gain

access to the battery compartment. After replacing the batteries, the XP2iwill start operating

immediately (without having to press the button). This indicates that a complete reset has oc-

curred, and is normal.

XP2i ATEX User’s Manual •Page 7

C R Y S T A L

engineering corporation

WARNING: The XP2i is Intrinsically Safe only if powered by one of the following battery

types: Rayovac Maximum Plus, Energizer® E91, Energizer® EN91, or Duracell MN1500.

Reset

If for some reason the XP2ineeds to be reset,

remove any battery for at least one minute, then

reinstall the battery. If the reset is successful, the

XP2iwill start operating without pressing the

(on/off) button. Reset will clear the zero, peak

values will be reset to the current reading, and the

XP2iwill be set to the default engineering units.

Troubleshooting

The XP2iis a very high performance gauge. Due to the high resolution of this product, you may

observe conditions that appear to be defects in the product, but are in fact a result of being able

to resolve and measure pressure to a degree not possible with other instruments.

Noisy or unstable reading when used with uids

When calibrating or comparing the indicated pressure from an XP2iagainst a hydraulic dead-

weight tester or piston gauge, the reading on the XP2imay appear unstable - the least signicant

digit jumps up and down several counts.

Reason: Gas (usually air) is trapped in the line between the gauge and the deadweight tester.

What is actually happening is the mass is oscillating up and down, and the combination

of gas and uid is acting like a spring. At higher pressures (above 2000 PSI, typically) this

may eventually diminish, as the gas dissolves into the uid.

Solution: Evacuate all tubing with a vacuum pump, before introducing uid into the system.

Page 8 •XP2iATEX User’s Manual

C R Y S T A L

engineering corporation

Non-repeatability of pressure measurements

When checking the gauge against a hydraulic deadweight, increasing pressure measurements do

not match decreasing pressure measurements.

Reason: As in the previous note, gas has dissolved into the hydraulic uid. When decreasing the

pressure, the dissolved gas then leaves the uid, but at an uneven rate, so small pressure

dierential (due to uid head pressure) may exist between the reference deadweight

and the gauge being tested.

Solution: Evacuate all tubing with a vacuum pump, before introducing uid into the system.

Slow return to zero and/or non-repeatability of pressure measurements

Reason: Filter is obstructed.

Solution: Clean lter - see “Filter”section for instructions.

Err 1 displayed

Reason: The XP2ichecks the integrity of internal calibration coecients every time it’s turned

on. If any coecients have been corrupted in any way, “Err 1” is displayed.

Solution: Contact factory for instructions on how to restore the memory to the original factory

settings.

Err 2 displayed

Reason: The XP2ihas tried to display a number too large for the display (i.e., more than 5 digits).

May be due to an electrical malfunction or numerical error.

Solution: Contact factory for further instructions.

Display continuously ashes all segments

Reason: After a reset, and after replacing batteries, the XP2ichecks the integrity of program

memory. If for some reason it has been modied or corrupted, it ashes all segments,

and prevents normal operation.

Solution: Contact factory for instructions on how to restore the memory to the original factory

settings.

Digital Interface

The XP2ican be connected to a personal computer via RS-232, using an ordinary DB9 exten-

sion cable (male DB9 for the XP2iconnection, female DB9 for the PC side). The interface lets you

record displayed readings and recorded peaks. The data string always includes the pressure units.

XP2i ATEX User’s Manual •Page 9

C R Y S T A L

engineering corporation

And the XP2ican be operated remotely, as if you were pressing the buttons. You can use a simple

terminal program to send the commands, or, you can incorporate them into your own software

program.

A special command, Streaming Data, initiates data transmission of displayed pressure at the rate

of approximately 3 times per second.

I/O Settings

The serial interface settings are:

BAUD RATE PARITY DATA BITS STOP BITS FLOW CONTROL

9600 NONE 8 1 NONE

Communication Format

Input is case-sensitive; all instructions should be sent in UPPERCASE. Instructions must be termi-

nated with a single carriage return (CR) character followed by an optional linefeed (LF) character.

Note that while the XP2iexpects either CR or CR/LF as command termination on its input, it

always appends a CR/LF pair to its output. For reference, CR is ASCII value 13 decimal, while LF is

ASCII character 10 decimal.

You have 30 seconds to complete an instruction. After 30 seconds, the XP2iwill evaluate whatever

it has received and try to match it to its table of commands. Since the command is incomplete, it

will fail to match and the XP2iwill return: N,Ø. (Negative acknowledgment with no reception er-

rors, so syntax is wrong.)

Query Instructions

All queries start with a question mark (?). Any pressure values returned are split across two lines;

the rst contains a oating-point value, and the second contains the name of the measurement

unit. Each line is right-justied in a xed width 10 character eld. (Since each line is terminated

with a CR-LF pair, this means the total length of the response to a measurement query is 24

bytes.) A decimal point will always be included with the pressure value (for clarity) even if it is not

displayed on the XP2i. For example, a pressure query of a 300 PSI XP2ion the mbar scale could

return a reading like this:

2478.

mbar

If the batteries are low enough to trip the low battery message, then any pressure query will re-

place the pressure value with the letters “BATT”.

Message Store

?MSG Retrieve the data (usually tag# or ID) from the message store.

Page 10 •XP2iATEX User’s Manual

C R Y S T A L

engineering corporation

Model

?MOD Return the model name, up to 20 characters long. For example, an ATEX 100 PSI XP2i,

would return the following:

AX100PSIXP2I

Pressure

?P,U Pressure returns the pressure value, followed by the pressure unit on the second line.

Example:

-7.89

mmH2O

Pressure (one line)

?PRE Returns data and units on one line, and separates the reading and units with a comma.

Example:

2.01,PSI

Pressure, High

?P,H Pressure, High returns the stored peak pressure value, in whatever pressure units are cur-

rently being displayed.

91.3

mmH2O

Pressure, Low

?P,L Pressure, Low returns the peak low, or “valley” measurement, in the pressure units currently

being displayed.

-10.7

mmH2O

Range

?RNG Range, returns the pressure range of the gauge. It is returned in two, 10 character lines. The

rst line is the value, the second line is the engineering unit. For example, a 100 PSI XP2i

would return

100.00

PSI

XP2i ATEX User’s Manual •Page 11

C R Y S T A L

engineering corporation

Return Average Pressure

?P,A Using the same format as the“?P,U” command, the average pressure is returned. If averaging

is disabled, “X,0”is returned. Enable averaging through Cong XP.

Return the Average Window Size

?AVS The average sample size is returned. If averaging is disabled,“X,0” is returned. Enable averag-

ing through Cong XP.

Serial Number

?SN# The serial number is returned in two strings. A typical example is shown below:

3

12659

Version

?VER Version returns the XP2i’s rmware version as a 4 digit number preceded by the letter“R”.

This number is for factory use, only.

Example Version Number:

R0101

Water Density

?H2O Applies only to models with that include inches of water. Water density returns the current

density of water in terms of temperature with one of three values possible:

_4C

60F

68F

Zero Check

?Z,U Zero Check reveals how much was subtracted from the reading to zero the gauge, in the

pressure units currently being displayed. When batteries are installed or the XP2iis reset, the

zero is cleared, and equals zero.

32.7

kPa

Page 12 •XP2iATEX User’s Manual

C R Y S T A L

engineering corporation

Commands

The following are commands. All commands start with an exclamation mark (!).

Clear Peaks

!CLR Clear high and peak low values by setting them to the current live reading (which might not

be zero). For instance, if the current live reading were 253 PSI, then both high and low peak

registers would contain 253.

Disable/Enable Peak Display

ConFIGXP PROGRAMMABLE

Prevent peak pressure readings from being displayed.

!NPK Prevents peaks from being displayed.

!PKS Enables peak button operation (default).

Message Store

ConFIGXP PROGRAMMABLE

!MSGx Up to 12 characters (usually tag# or ID) can be stored in EEPROM. Set the message with

“!MSGx”where “x” is the message.

Next Pressure Unit

!I,P This command is acknowledged with a simple “A,Ø”. To check which units were selected,

send the command “?P,U” to return the pressure value and the current pressure units.

No Auto Off

!NAO Prevents automatic shutdown. Every time an XP2iis turned on, it defaults to a shutdown

schedule of 20 minutes after the last button push or the last RS-232 command. This com-

mand will return:

NO

AUTO

OFF

To re-enable automatic shutdown, send the reset (“!RST”) command. (Read the Reset sec-

tion rst to be sure you understand all eects of performing a reset.)

Reset

!RST This command schedules a reset. There will be a three second pause before the XP2iresets;

during this time, no commands or queries should be sent to the unit. When the unit resets, a

product identication string, called the Boot Signature, is sent. (See the Programming Tips

section for more information.) Some communications noise, including a serial framing error,

is possible on reset. Resetting the XP2iclears the zero value, clears the peak high and peak

XP2i ATEX User’s Manual •Page 13

C R Y S T A L

engineering corporation

low values, enables automatic shutdown after 20 minutes of inactivity (resetting that timer

to 20 minutes on reset), and selects the rst pressure unit on the XP2i(which can vary with

product type, but will be consistent for each reset operation). After a reset, you should query

and/or select appropriate measurement units using the“?P,U” and “!I,P” commands. If

the reset command fails to operate properly, or appears to “lock up” the device, contact tech-

nical support.

Set the Average Window Size

ConFIGXP PROGRAMMABLE

!AVS x Sets the number of pressure reading to be averaged. The valid rang is from 1 through 10,

i.e. !AVS 5<CR> or !AVS 10<CR>. If an invalid size is entered, or averaging is disabled, “X,0” is

returned. Averaging is enabled with CongXP, only.

Streaming Data On/Off

!SP1 Displayed pressure is sent out the serial port after each new reading, at a rate of approxi-

mately 3 readings per second. Returns data in the same format as the ?PRE query.

!SP0 Cancels streaming data output.

Water Density

ConFIGXP PROGRAMMABLE

!_4C Set the density of water to 4°C (39.2°F)

!60F Set the density of water to 15.6°C (60°F)

!68F Set the density of water to 20°C (68°F)

Zero

!ZER Zeroes the pressure readings by setting a zero value equal to the current applied pressure.

The zero cannot be cancelled, but it can be reloaded by calling this command again. To

check the zero value, send the Zero Check command (“?Z,U”). If you want to disable the

zero after enabling it, send the reset (“!RST”) command. (Read the Reset section rst to be

sure you understand all eects of performing a reset.)

Acknowledgment of a Command

The XP2ialways returns some indication to let you know a command or query was received and

acted on. For queries, the return of the measurement data is the acknowledgment. For commands,

possible acknowledgments are “A”, “N” or “X”, followed by a comma then a single digit. The digit

indicates whether there were any reception errors. The combination is left justied.

AThe XP2iunderstood the command and acted on it.

NThe XP2idid not understand the command, due to either syntax or reception errors.

XThe command was understood, but is not implemented at this time.

Page 14 •XP2iATEX User’s Manual

C R Y S T A L

engineering corporation

Following an “A”, “N” or “X”, the single digits mean the following:

ØThere were no reception errors.

2Buer overow.

4Framing error.

6There were both buer overow and framing errors.

Example acknowledgment:

A,Ø Understood the command and acted on it. No reception errors.

N,4 Could not understand the command because there was a framing error.

N,Ø Could not understand the command, even though it was received without errors, so syntax

must have been wrong.

Troubleshooting the Digital Interface

The following section gives possible reasons for various error codes.

N,Ø The “Ø” indicates there were no overrun or framing errors, so the command was properly

received. However, the “N” means the XP2icould not match it to any allowed command. This

means the syntax must have been wrong. The command is rejected and nothing is done.

Possible reasons:

Instruction sent without a comma between “P” and “U” of the “?P,U” query.

More than 30 seconds passed to nish a command.

Line termination is incorrect; send carriage returns (CR) only, do not send line feeds (LF).

N,2 XP2ibuer overow, no action. In an overrun, bytes are lost, consequently the XP2iwill not be

able to match the command string. If it can’t nd a match, it returns “N”.

Possible reasons:

Not enough time allowed between commands. Check the communication parameters.

N,4 Framing error: Bytes were lost. Therefore, the command could not be matched. A framing er-

ror can sometimes occur after power-on, after reset, or when the batteries are changed; see

the Programming Tips section for suggestions on handling this.

Possible reasons:

Noise on the line either created a false start bit or obscured the stop bit.

Multiple, but infrequent, framing errors are probably due to noise on the connection.

Frequent framing errors likely mean the XP2ior the PC is not operating at precisely 9600 Baud.

Occasionally, plugging the RS-232 connection into the XP2iwill create a single framing error.

XP2i ATEX User’s Manual •Page 15

C R Y S T A L

engineering corporation

N,6 Both buer overrun (N,2) and framing errors (N,2) occurred during this command. The “6”

represents the binary OR masking of the two bits used to indicate a buer overrun (bit 1)

and a framing error (bit 2).

Possible reasons:

Look at“Possible reasons” for troubleshooting the N,2 and N,4 error codes, above.

ERR 1 After sending a command or query, the XP2ireturns (and displays) “ERR 1”.

Reason:

The XP2ihas detected a CRC EEPROM error.

ERR 2 The XP2ireturns (and displays)“ERR 2”.

Possible reasons:

The XP2ihas tried to display a number too large for the display (i.e., more than 5 digits), or

may be due to an electrical malfunction or numerical error.

Effects of Password Protection on Commands

If the XP2i is password protected, the following commands will have no eect and return “X,O”:

!_4C, !60F, !68F, !NPK, !PKS, !MSG, !RAS, and !AVS.

Programming Tips

The XP2iis a very straightforward device to communicate with, provided you follow these tips.

This advice is derived from our own experiences automating systems based on the XP2i, as well as

the experiences of our users; following it will probably save you some time.

Anytime you establish (or re-establish) communications with the unit, you should use the

following initialization sequence, which will help you deal with possible noise due to reset, etc.:

1Reset the unit (unless you must preserve zero, peak values, etc.) by sending the“!RST”command.

2Wait 15 seconds.

3Read the Bootloader Signature, even if you ignore it, to clear it from the PC’s input buer; see

below for more details.

4Send a carriage return to clear any noise in the XP2i’s input buer.

5An error code, either “N,Ø” or “N,4” will be returned; this is normal (you have sent an empty

command); read it to clear it. The buers are now reset.

6Use the “?P,U” and “!I,P” commands to select the pressure unit you want to use.

7IF APPROPRIATE, zero the XP2iby sending the “!ZER” command, since the zero value will be

clear.

Page 16 •XP2iATEX User’s Manual

C R Y S T A L

engineering corporation

8IF APPROPRIATE, clear the high and low peak values to the current pressure (zero, if you fol-

lowed step 6) by sending the “!CLR” command.

9If you are logging data, you should log the serial number of the unit for traceability purposes

by using the “?SN#” command. You should also log the product code, hardware revision and

rmware version with the “?VER” command.

10 Disable automatic shutdown with the “!NAO” command.

A quick note about the Bootloader Signature: This string contains a 19 character, product-spe-

cic string (whose contents may vary with product revision), followed by a carriage return (CR),

making the total string length 20 bytes. However, a reset turns the RS-232 interface on and o,

so it may be subject to noise; a NULL may be received before the signature is sent, and the rst

character or so of the Bootloader Signature may be corrupted. A framing error is also possible. The

procedure above will deal with this situation properly. Should you want to parse the bootloader

signature, it has the following format:“=xxxxxxxxxxxxxxxxx=” where xwill vary with

product revision. The bootloader signature is used by the rmware upgrade tool, but should NOT

be used to identify the rmware version; use the“?VER” command for that purpose. If you have a

system that may have Crystal DTG or XP2iunits attached, you can use this signature to determine

which device is in use.

NOTE: Any time you detect the Bootloader Signature, the unit has been reset, or discon-

nected from and reconnected to power; turning the unit on and o with the button will not

send the Bootloader Signature. You can use this behavior to detect a battery change, or a

problem with the XP2i.

Some commands may take up to 500 milliseconds to return a reply. You should always wait at

least 50 milliseconds after each reply is received before sending the next command. After a reset

command it may take up to 15 seconds before the gauge resumes normal operation.

Data transmitted from the XP2iwill always be 7-bit ASCII. Any high-ASCII characters indicate a

line-noise problem, or a problem with the XP2ior PC.

The XP2ihas very thorough integrity checks to catch corruption of program or calibration data

memory. Should the data memory integrity check fail, the unit displays“ERR 1” on the display as

the value line of the serial output. It is important to check for this, or you may mis-parse that line

as “1 PSI”, depending on your program. Should the program memory integrity check fail, the unit

will continuously reset, blinking the LCD on and o, and the serial output will alternate between

the bootloader signature and a line reading “CRC FAIL”. This condition can be recovered from,

in the eld, by reloading the unit’s rmware; contact technical support for details.

Calibration

If adjustment is required, we recommend returning the unit to the factory. Factory service oers

benets you won’t nd anywhere else. We have the facilities to test your gauge at a variety of

Other manuals for XP2i

1

Table of contents

Other Crystal Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Dwyer Instruments

Dwyer Instruments 477-000-FM Installation and operating instructions

Fox Thermal

Fox Thermal FT1 instruction manual

AXIOMA METERING UAB

AXIOMA METERING UAB QALCOSONIC E4 Technical operation guide

PCB Piezotronics

PCB Piezotronics IMI SENSORS 601A21 Installation and operating manual

SKF

SKF SSV Series Assembly instructions

Emerson

Emerson Rosemount 1057 instruction manual