Crystal WT Series User manual

C R Y S T A L

engineering corporation

Operation Manual

WTSeries

Digital Pressure Gauge

Contents

Introduction........................................................2

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Unitsbutton.............................................................4

Zero...................................................................4

Peak detection and Average . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Resetting (clearing) recorded peak values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Automaticshut-off.......................................................5

Backlighting the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

MeasuringVacuum......................................................6

Water Density (Inches of Water). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Overpressure Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Low battery indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Battery replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Reset..................................................................7

Troubleshooting.....................................................8

Noisy or unstable reading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Non-repeatability of pressure measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

DisplayedErrors.........................................................8

Display continuously ashes all segments ...................................9

DigitalInterface.....................................................9

Calibration.........................................................9

WT Series Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Model Numbering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Specications......................................................11

Accuracy.............................................................11

Temperature...........................................................11

Humidity..............................................................11

Media Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Pressure Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Connection ...........................................................12

Power ................................................................12

Enclosure .............................................................13

Pressure Ranges, Display Scales & Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Software..........................................................15

LabVIEW™ drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

CongXP Conguration Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Accessories.......................................................15

ACadapterkit.........................................................15

RS-232Cable..........................................................15

Trademarks........................................................15

Warranty..........................................................16

HowtoContactUs:.....................................................16

Page 2 •WT Series

C R Y S T A L

engineering corporation

Introduction

The WTSeries Digital Test Gauge is designed to t in 8” or 10” panel mount applications common-

ly found in portable test sets. The WTSeries is based on the Crystal Engineering Corp. model XP2i

digital pressure gauge (www.xp2i.com). The WTSeries pressure gauge has been repackaged so

that it may be mounted in a portable enclosure, while retaining easy access to batteries and to the

digital (RS-232) interface (both of which would otherwise be on the back of the gauge).

Accuracy is 0.1 percent of reading - so any WTSeries gauge can typically replace several gauges

you may have been using. The gauge is fully temperature compensated - so there is no change

in accuracy throughout the entire operating temperature range! Three AAA batteries provide

up to 500 hours of continuous operation. The batteries are easily replaced by removing the two

screws.

Your WTSeries gauge can be customized, through the use of CongXP software available from

Crystal Engineering. Your personal computer can disable, enable or modify a variety of features of

your WT Series.

Look for the

Con

FIGXP PROGRAMMABLE logo for programmable features that will:

•provide a user-dened pressure scale, and/or disable unused pressure units

•disable keypad recalibration, enable peak button and/or units button

•expand or decrease allowable Zero range

•enable other pressure units (like inches of mercury, kPa, bar, etc.)

•create and enable a user-dened pressure unit

•store a 12 digit ID or tag number in non-volatile memory

•adjust calibration values

We hope the WTSeries gauge meets your expectations, and we're interested in any comments or

suggestions you may have. You can send us a note at: feedback@crystalengineering.net. Many

features in this and our other products are a direct result of your comments!

Crystal Engineering is the company that designs, manufactures, markets and services the XP2i,

30 series pressure calibrators, MultiCal multimeter pressure adapters and a variety of industry spe-

cic pressure measuring equipment. Crystal Engineering pioneered features like full temperature

compensation and “of reading”rated gauges and calibrators. Pressure measuring equipment is the

only thing we do and that’s why we say: PRESSURE is Our BUSINESS™

WT Series •Page 3

C R Y S T A L

engineering corporation

Operating Instructions

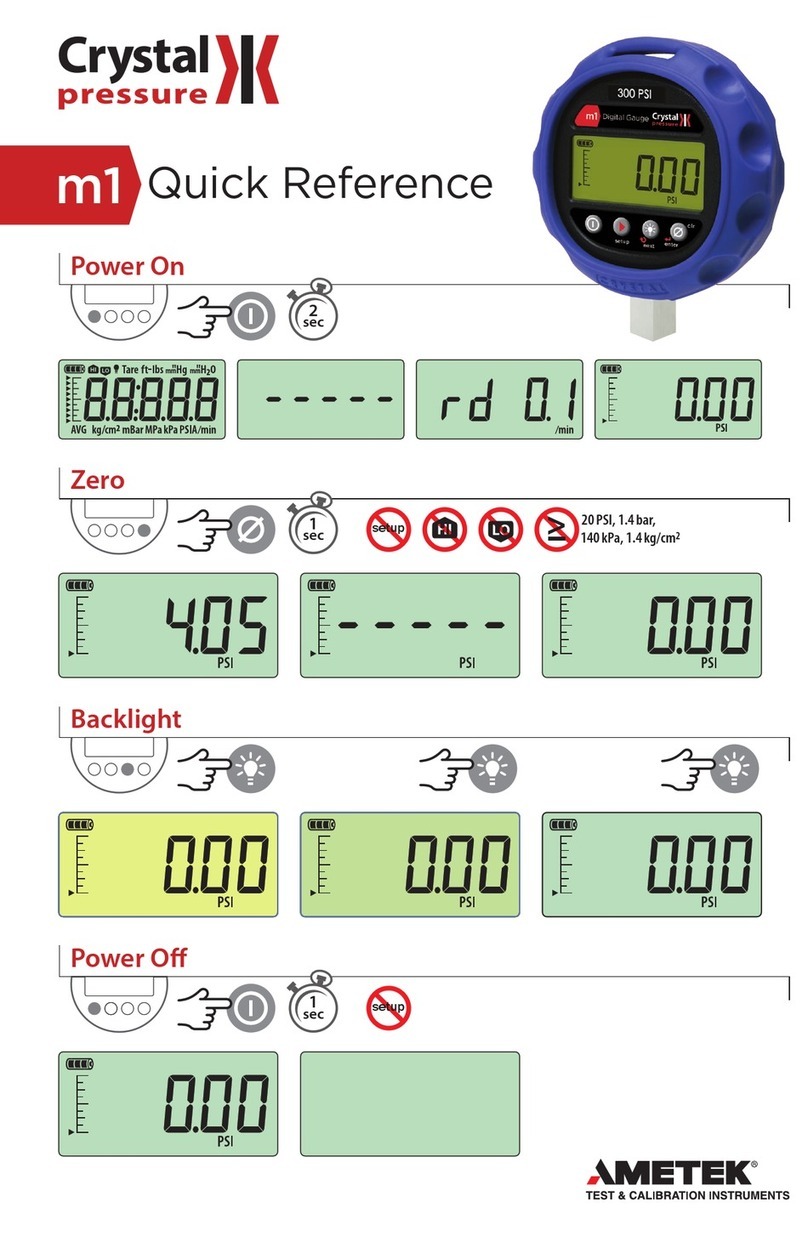

The WTSeries gauge is shipped with batteries installed, so it’s ready to use. Press

and hold the (on/off)button. The gauge will rst test all LCD segments. Re-

lease the button when the gauge indicates pressure.

The WTSeries gauge always resumes operation in the mode and the units of the pressure last

used, and it does not automatically rezero when turned on.

WARNING: Severe injury or damage can occur through improper use of pressure instru-

ments! Do not exceed recommended pressure limits of tubing and ttings. Be certain all pres-

sure connections are secured.

CAUTION: Never insert any object into the pressure connection! The sensor diaphragm is

very thin and can be damaged or destroyed by solid or sharp objects. Cleaning of the sensor

must be done with appropriate solvents only.

The WTSeries is intended for gauge pressure measurement. It indicates the dierence between

applied pressure and ambient barometric pressure. However, the

zero

button can be used to

force the WTSeries to read zero pressure at any applied pressure, up to the full scale rating of the

gauge. The factory default setting limits the maximum zero value to 200 PSI, but this limit can be

changed with

Con

FIGXP .

Some WTSeries gauges are rated for absolute pressure. Absolute gauges indicate the dierence

between applied pressure and an internal vacuum reference. Absolute pressure is always positive.

For instance barometric pressure at sea level is on average about 14.7 PSI (approximately 100 kPA

or 1 Bar), so at sea level this is the lowest expected pressure indication. However, absolute gauges

can be “zeroed”(unless prevented by CongXP). After zeroing an absolute gauge it is possible to

indicate a negative pressure.

WARNING: This gauge can display zero pressure when connected to a source of pressure! Do

not rely on the display indication before disconnecting—it may not be indicating true pres-

sure. Never disconnect pressure instrumentation without rst relieving system pressure!

Page 4 •WT Series

C R Y S T A L

engineering corporation

Units button

Pressing this button causes the WTSeries gauge to select the next available unit of

pressure measurement. See “Pressure Ranges, Display Scales & Resolution” for

the list of pressure units available for your model.

Con

FIGXP PROGRAMMABLE Units that you don’t need or never use can be

turned o. You can also dene a special unit for your WTSeries gauge with CongXP. That way

you can use the WTSeries gauge to display directly in a unit not otherwise available, such as feet

of seawater, or foot-pounds of torque. When your custom unit is selected and displayed on the

WTSeries gauge, all pressure unit icons will be o.

Zero

To zero the WTSeries gauge, you must turn o peak indication, then press the

zero button for at least ½ second. The display will then briey ash all dashed

lines (- - - - -), indicating that it has been re-zeroed. If you attempt to zero the gauge

while more than 200 PSI is applied (or the pressure limit set with CongXP), the

command will be ignored, and “- -HI-” will be displayed.

WARNING: This gauge can display zero pressure when connected to a source of pressure! Do

not rely on the display indication before disconnecting—it may not be indicating true pres-

sure. Never disconnect pressure instrumentation without rst relieving system pressure!

You can clear the zero value: Turn o peak indication then press and hold the

zero

button until

the display changes from (- - - - -) to (- - -). This is especially useful for absolute gauges that have

been zeroed while measuring barometric pressure.

Zeroed Clear Zero (Unzero)

Con

FIGXP PROGRAMMABLE You can change the point at which the Zero button will display

“- -HI-”. For instance, you could set the maximum zero to 1 PSI. You can also disable the zero but-

ton entirely, by setting the Zero value to a large negative number.

The

zero

button changes its function when the peak high (

HI

) or the peak low ( LO ) icon is

displayed. While a peak icon is displayed the

zero

button becomes the clear button.

PSI inH2O inHg kpa

mmHg mmH2O mbar kgf/cm2

LO

HI PSI inH2O inHg kpa

mmHg mmH2O mbar kgf/cm2

LO

HI

WT Series •Page 5

C R Y S T A L

engineering corporation

Peak detection and Average

Pressing the Peak button causes the display to cycle through the following:

HI

. . . . . . . . . . Recorded maximum pressure

LO . . . . . . . . . . Minimum recorded pressure

HI

LO . . . . Average pressure*

<No Icon> . . . . Live pressure display

Peak high and low values are not saved when the gauge shuts o; they will reset to the current

reading when the WTSeries gauge is turned on or reset.

* From the factory this Average Pressure is disabled. Use CongXP to enable.

Con

FIGXP PROGRAMMABLE In some cases the ability to display a peak value may not be

needed, or may even be dangerous. CongXP allows you to disable this button.

WTSeries gauges can average 1 to 10 readings, recalculated every time pressure is measured (3

times per second). Enable and set the number of readings to be averaged with CongXP.

Resetting (clearing) recorded peak values

Peak values (if enabled) can only be cleared when displaying either a high or low

recorded pressure. Press the clear button for at least ½ second. Dashed lines

will then briey appear across the display and both

HI

and

LO

icons will ash

briey, indicating that both peak values have been cleared. Both peak high and

low values will then display the current applied pressure. Pressing the clear button while

either peak hi or peak lo icon is displayed will not aect the zero value. If you need to rezero the

gauge, you must turn o both peak icons by pressing the peak button.

Automatic shut-off

The WTSeries gauge has a shuto timer and will turn o automatically after 20 minutes of non-

operation. Pressing any button or sending any command via the RS-232 connection resets the

shuto timer.

The shuto feature can be defeated, if desired, when turning the gauge on. Pressing the

(on/off) and

zero

buttons simultaneously will prevent the WTSeries gauge from automatically

turning o. The gauge will briey display the words“No Auto O” to indicate that it will not turn o.

This procedure is required each time the gauge is turned on, if you want to defeat the auto-shuto.

Page 6 •WT Series

C R Y S T A L

engineering corporation

Backlighting the Display

Pressing the (backlight) button instantly lights the display at maximum brightness,

but to keep it on you need to hold down the button for 2 seconds. The display will ash

briey, indicating that it will stay on for 1 minute. If you press the button again, the

backlight will go into a lower brightness setting to extend battery life, the display will again ash

briey, and remain on for 2 minutes. Press the button once more and the light will go out.

If you start the WTSeries gauge in the “No Auto O” mode, you select the brightness level the

same way, but the light will never time out and turn o; you will have to either turn o the gauge

or press the backlight again until the light goes out.

Measuring Vacuum

All versions of the WTSeries gauge can be used to measure moderate vacuum, though only

ranges of 300 PSI (and 20 bar or 2000 kPa) and lower are actually tested and certied for vacuum

operation.

When measuring pressure less than ambient barometric conditions, a minus (-) sign will appear.

WTSeries gauges are not recommended for continuous use at high vacuum (pressures lower than

-14.5 PSI, at sea level).

Absolute gauges (models with a “B” following the pressure range designation in the part num-

ber) will NOT indicate a negative sign when vacuum is applied, unless the zero button has been

pressed while a pressure greater than full vacuum is applied to the gauge. If your absolute gauge

does indicate a negative pressure, you can clear the zero value (“unzero”) by pressing the zero but-

ton until the display changes from ----- (5 dashes) to - - - (dash, space, dash, space, dash).

See “Zero” for details.

Water Density (Inches of Water)

The following applies only to models where inches of water are available. As shipped from the fac-

tory, the WTSeries gauge is set to display inches of water corresponding to the density of water at

4°C (39.2°F). You may require a dierent water density for your application, so the WTSeries can

be set to use the density of water at 20°C (68°F) or 15.6°C (60°F), instead.

To check and or change the water density setting from the keypad, turn on the WTSeries gauge

by pressing the (on/off) button and the units button simultaneously. The display will indi-

cate either “4C” or “60F” or “68F”.

Press the units button until the display cycles to the desired water density, then press the

zero

button to store the selection (this will not zero the gauge).

Con

FIGXP PROGRAMMABLE Select and set the desired density of water.

WT Series •Page 7

C R Y S T A L

engineering corporation

Overpressure Conditions

The WTSeries gauge will read pressure up to approximately 110% of the rated pressure range.

Above 110% percent of the range the display will start ashing and the readings will not be reli-

able. The zero function does not aect the point at which the display starts ashing to indicate

overpressure, so depending on the zero value it is possible that the display can start ashing with-

out the maximum pressure being displayed.

For instance, if a 100 PSI WTSeries gauge is zeroed when 30 PSI is being applied, it will indicate

that the overpressure condition has been reached at 80 PSI (i.e., 110% x 100 PSI – 30 PSI = 80 PSI).

Overpressure can aect accuracy, but the eect is only temporary unless the sensor has been

destroyed. See Specications for maximum overpressure.

Low battery indication

The battery icon ( ) is the rst indication of a low battery. The WTSeries gauge will continue

to operate accurately while the icon is visible. When the batteries are exhausted, the letters “batt”

will appear across the display. After “batt” appears, no pressure measurements will be possible

until the batteries are replaced.

Battery replacement

The WTSeries gauge uses 3 AAA alka-

line batteries. The batteries are located

above the gauge behind a metal pan-

el. With a small at blade screwdriver,

unscrew the two panel screws to gain

access to the battery compartment.

Remove the battery holder and slide the

cover o. After replacing the batteries,

the gauge will start operating imme-

diately (without having to press the

button). This indicates that a complete

reset has occurred, and is normal.

Reset

If for some reason the WTSeries gauge needs to be reset, remove any battery for at least one

minute, then reinstall the battery. If the reset is successful, the gauge will start operating without

pressing the (on/off) button. Reset will clear the zero, peak values will be reset to the current

reading, and the gauge will be set to the default unit of pressure (PSI).

Page 8 •WT Series

C R Y S T A L

engineering corporation

Troubleshooting

The WTSeries gauge is a very high performance gauge. Due to the high resolution of this prod-

uct, you may observe conditions that appear to be defects in the product, but are in fact a result of

being able to resolve and measure pressure to a degree not possible with other instruments.

Noisy or unstable reading

When calibrating or comparing the indicated pressure from a WTSeries gauge against a hydraulic

deadweight tester or piston gauge, the reading on the WTSeries may appear unstable - the least

signicant digit jumps up and down several counts.

Reason: Gas (usually air) is trapped in the line between the gauge and the deadweight tester.

What is actually happening is the mass is oscillating up and down, and the combination

of gas and uid is acting like a spring. At higher pressures (above 2000 PSI, typically) this

may eventually diminish, as the gas dissolves into the uid.

Solution: Evacuate all tubing with a vacuum pump, before introducing uid into the system.

Non-repeatability of pressure measurements

When checking the gauge against a hydraulic deadweight, increasing pressure measurements do

not match decreasing pressure measurements.

Reason: As in the previous note, gas has dissolved into the hydraulic uid. When decreasing the

pressure, the dissolved gas then leaves the uid, but at an uneven rate, so small pressure

dierential (due to uid head pressure) may exist between the reference deadweight

and the gauge being tested.

Solution: Evacuate all tubing with a vacuum pump, before introducing uid into the system.

Err 1 displayed

Reason: The WTSeries gauge checks the integrity of internal calibration coecients every time

it’s turned on. If any coecients have been corrupted in any way, “Err 1” is displayed.

Solution: Contact factory for instructions on how to restore the memory to the original factory

settings.

Err 2 displayed

Reason: The WTSeries gauge has tried to display a number too large for the display (i.e., more

than 5 digits). May be due to an electrical malfunction or numerical error.

Solution: Contact factory for further instructions.

Err 5 or Err 6 displayed

Reason: The WTSeries pressure sensor is exhibiting out of normal operating condition behavior.

Solution: Contact factory for sensor replacement.

WT Series •Page 9

C R Y S T A L

engineering corporation

Display continuously ashes all segments

Reason: After a reset, and after replacing batteries, the WTSeries gauge checks the integrity of

program memory. If for some reason it has been modied or corrupted, it ashes all seg-

ments, and prevents normal operation.

Solution: Contact factory for instructions on how to restore the memory to the original factory

settings.

Digital Interface

The WTSeries gauge can be connected to a personal computer via RS-232, using an ordinary DB9

extension cable (male DB9 for the gauge connection, female DB9 for the PC side). The interface

lets you record displayed readings and recorded peaks. The data string always includes the pres-

sure units. And the WTSeries gauge can be operated remotely, as if you were pressing the but-

tons. You can use a simple terminal program to send the commands, or, you can incorporate them

into your own software program. Refer to the XP2i Programming Instructions manual for details—

available from our website at: www.xp2i.com.

Calibration

If adjustment is required, we recommend returning the unit to the factory. Factory service oers

benets you won’t nd anywhere else. We have the facilities to test your gauge at a variety of

temperatures utilizing NIST traceable standards, resulting in calibration certicates that provide

performance data over temperature. Furthermore, upgrades may be available to add or enhance

operating features. We designed the product to last, and we support it so that you can get the

most from your investment.

Under normal operating conditions, we recommend the WTSeries gauge be calibrated on an

annual basis. Your quality system may require more or less frequent calibration, or your experience

with the gauge, or operating environment may suggest longer or shorter intervals.

Although we prefer that you return the WTSeries gauge to Crystal Engineering for calibration,

ordinary recertication and/or adjustments may be performed by any qualied personnel with ap-

propriate training and equipment. The following instructions are ONLY intended for such qualied

personnel with appropriate test equipment. We recommend that the calibration standards used

have a minimum rated accuracy of 0.025%. This level of accuracy may require the use of piston

(deadweight) gauges or very high performance pressure controllers, such as those manufactured

by DH Instruments (www.dhinstruments.com).

There are no internal potentiometers. The WTSeries gauge contains a “span”factor: “Userspan”,

set to approximately 1 (as shipped from the factory). As components age this may need to be

changed to a value slightly higher or lower, to slightly increase or decrease all readings. This ad-

justment can be made with or without a computer (see: CongXP Conguration Software).

Page 10 •WT Series

C R Y S T A L

engineering corporation

“Zero” the gauge, then record displayed pressure for two or more pressure points. Determine if the

WTSeries gauge would benet from an overall increase or decrease of the indicated pressures.

To change the userspan factor from the keypad, turn o the gauge, then press the (on/off),

units and peak buttons simultaneously. The rmware version will be briey displayed,

followed by the word “cal”, followed by the actual userspan value. The userspan factor may be

adjusted by pressing either the units or peak button to increase or decrease the value, re-

spectively. The value changes in 0.0001 increments. Press the zero button to store the new value

in memory, or the (on/off) button to cancel the change.

For absolute WTSeries gauges, it is possible to correct for long term drift using a second calibra-

tion factor, zero value o set. CongXP and a barometric reference with accuracy of 0.1 PSI or bet-

ter is required to perform the calibration. To calibrate the zero o set, clear the zero as described

earlier in this manual by pressing and holding the zero button until “- - -” appears. Once cleared,

subtract the displayed pressure from barometric pressure, add this dierence to any existing zero

value o set in CongXP, and update the gauge (new value = barometric – displayed + existing).

For example, if the displayed value is 14.5 PSI, barometric pressure is 14.7 PSI, and the existing zero

value o set in CongXP is 0.1 PSI, the new zero value o set would be 0.3 PSI (14.7 - 14.5 + 0.1 = 0.3).

Con

FIGXP PROGRAMMABLE The userspan level can be viewed, set directly, and disabled

by CongXP.

WT Series Serial Number

The serial number of your WTSeries is located

on the front panel directly below the zero but-

ton. It is also stored digitally within the gauge.

Model Numbering System

WT(prex)(type)-(options)

Prex: Pressure range and units - see table on page 14

Type: (none) . . .standard gauge

B . . . . . . . . (Barometric) Absolute pressure indication

Note: Absolute version available only on WTSeries gauges with ranges of 2000 PSI

and higher.

Options: -1000 . . . .Panel Mount Flange for 8.7”bolt center mounting

-1500 . . . . Panel Mount Flange for 10.125”bolt center mounting

WT Series •Page 11

C R Y S T A L

engineering corporation

Specifications

Accuracy specications are for one year, and include all eects of linearity, hysteresis, repeatability,

and temperature within the specied operating temperature range.

The gauge must be exercised and re-zeroed whenever exposed to signicant changes in environ-

mental conditions to achieve these specications. To exercise the gauge, cycle the gauge between

zero and the pressure of interest. A properly exercised gauge will return to a perfect zero reading.

Exposure to environmental extremes of temperature, shock and/or vibration may warrant a more

frequent recertication period.

Accuracy

20 to 100% of Full Scale: . . . . ±0.1% of reading

0 to 20% of Full Scale: . . . . . . . ±0.02% of Full Scale

Vacuum*, 300 PSI and lower pressure gauges:

0 to -14.5 PSIG : . . . . . . . . . . . . . ±0.25% of Full Scale,

where F.S. = . . . . . . . . . . . . . . . . -14.5 PSI

*Not specied for 500 PSI models and higher, although all models can be safely connected to

vacuum.

Temperature

Operating & Compensated Range: . . . -10°C to 50°C (14°F to 122°F)

Storage Range: . . . . . . . . . . . . . . . . . . . . . . -40°C to +75°C (-40°F to +167°F)

Humidity

Temperature Range Humidity

-10 to 10°C . . . . . . . . . . . . . . . . . Uncontrolled

10 to 30°C . . . . . . . . . . . . . . . . . . 0 to 95% Relative

30 to 40°C . . . . . . . . . . . . . . . . . . 0 to 75% Relative

40 to 50°C . . . . . . . . . . . . . . . . . . 0 to 45% Relative

Media Compatibility

Liquids and gases compatible with PTFE (Polytetrauoroethylene) penetrated, anodized alumi-

num sensor manifold, 316 stainless steel (sensor), and PTFE tape.

Page 12 •WT Series

C R Y S T A L

engineering corporation

Pressure Conversions

1 PSI = 27.6806 inches of water column (water at 4°C [39.2°F])

27.7070 inches of water column (water at 15.6°C [60°F])

27.7292 inches of water column (water at 20°C [68°F])

2.03602 inches of mercury (mercury at 0°C [32°F])

6.8948 kilopascals

51.7149 millimeters of mercury (mercury at 0°C [32°F])

703.087 millimeters of water column (water at 4°C [39.2°F])

0.068948 bar

68.948 millibar

0.070307 kilograms per square centimeter

Connection

Pressure Fitting: 1/8” female NPT.

Power

Batteries: 3 x AAA, alkaline recommended

Battery Life: 500 hours continuous operation

Low Battery Indicator: Battery Icon ( )

Dead Battery Indication: “batt”

WT Series •Page 13

C R Y S T A L

engineering corporation

Enclosure

Aluminum and stainless steel.

Weight: 1.25 kg (2.7 lbs), including batteries.

All dimensions in inches.

Dimensions in blue are for the 1500 Panel Mount Flange option.

°021

LP3

00.8

REVOCRAER

RETEMAID

08.3

07.8

ELCRICTLOB

50.1

LIATEDTROPLAIRES

1NIP

T

ROPERUSSERP

NOITISOP

AAAX3

)REVOCHTIW(

SSECCAYRETTAB

LAIRES

TROP

LEBALN/S

52.9

04.4

LLAURHT82.0X3

LEBALNOITACIFITNEDI

LEBALEGNAR

)YLNOECNEREFERROFNWOHS(

REVOCSBA

RAER

TROPERUSSERP

TPNF72-"8/1 REVOCRAER

SWERCSGNITNUOM

SECALP4

60.0

LENAP

SSENKCIHT

04.2

55.0

521.01

ELCRICTLOB

66.01

Page 14 •WT Series

C R Y S T A L

engineering corporation

Pressure Ranges, Display Scales & Resolution

1Unneeded pressure units may be disabled via the RS-232 connector using CongXP software.

2kPa models can display pressure in kPa and bar (or mbar) only. PSI and bar models can display all available units.

3WT Series gauges will indicate pressure up to 10% above Range Pressure. Above 110%, the XP2idisplay will ash,

indicating that the applied pressure exceeds the calibrated pressure range. If the calibrated pressure range is exceeded,

the pressure displayed may not be accurate.

4An Absolute pressure version is available only on XP2is and XP2i-DDs with ranges of 2000 PSI and higher.

P/N Prex

15PSI

30PSI

100PSI

300PSI

500PSI

1KPSI

2KPSI

3KPSI

5KPSI

10KPSI

PSI bar

P/N Prex

1BAR

2BAR

7BAR

20BAR

30BAR

70BAR

140BAR

200BAR

300BAR

700BAR

kPa

P/N Prex

100KPA

200KPA

700KPA

2KKPA

3KKPA

7KKPA

14KKPA

20KKPA

30KKPA

70KKPA

Pressure Units and Resolution

0.001

0.001

0.01

0.01

0.01

0.1

0.1

0.1

0.1

1

PSI

0.01

0.01

0.01

0.1

0.1

0.1

1

1

1

1

kPa

0.0001

0.0001

0.0001

0.001

0.001

0.001

0.01

0.01

0.01

0.01

kg/cm2

0.0001

0.0001

0.0001

0.001

0.001

0.001

0.01

0.01

0.01

0.01

bar

0.001

0.001

0.01

0.01

0.1

0.1

0.1

0.1

1

0.01

0.01

0.1

0.1

1

inch Hg inch H2O

1

1

1

mm H2O

0.01

0.1

0.1

1

1

mm Hg

0.1

0.1

0.1

1

1

mbar

Over-

pressure

6.5 x

3.0 x

2.0 x

2.0 x

2.0 x

2.0 x

2.0 x

1.5 x

1.5 x

1.5 x

WT Series •Page 15

C R Y S T A L

engineering corporation

Software

LabVIEW™ drivers

Control and communicate with the WTSeries gauge using National Instrument’s LabVIEW.

CongXP Conguration Software

Con

FIGXP Disable unwanted pressure units, set default pressure units, change water density,

adjust calibration, and more via the RS-232 interface.

Replacement Parts

The only user-replaceable parts are the batteries.

Accessories

AC adapter kit

P/N 2984: Permits operation of a WTSeries gauge from an AC supply of 90 - 264 VAC and 47 - 63

Hz. Includes interchangeable international plugs (for USA, Europe, U.K., and Australia). The adapter

will not charge batteries, but in the event of AC power loss, the gauge will automatically revert to

battery operation.

RS-232 Cable

P/N 2400: DB-9 male to DB-9 female straight pass-through cable.

Trademarks

This manual contains the following third-party trademarks, both registered and unregistered. All

marks are the property of their respective companies.

LabVIEW™ . . . . . . . . . . . . . . . . . . . . . . . . . . National Instruments

“Pressure is Our Business™” is a registered trademark of Crystal Engineering Corp.

Page 16 •WT Series

C R Y S T A L

engineering corporation

Warranty

Crystal Engineering Corporation warrants the WTSeries gauge Digital Pressure

Gauge to be free from defects in material and workmanship under normal use and

service for one (1) year from date of purchase to the original purchaser. It does not

apply to batteries or when the product has been misused, altered or damaged by

accident or abnormal conditions of operation.

Crystal Engineering will, at our option, repair or replace the defective device free of charge

and the device will be returned, transportation prepaid. However, if we determine the failure

was caused by misuse, alteration, accident or abnormal condition of operation, you will be

billed for the repair.

CRYSTAL ENGINEERING CORPORATION MAKES NOWARRANTYOTHERTHANTHELIMITEDWAR-

RANTY STATED ABOVE. ALL WARRANTIES, INCLUDING IMPLIED WARRANTIES OF MERCHANT-

ABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE, ARE LIMITED TO A PERIOD OF ONE (1)

YEAR FROM THE DATE OF PURCHASE. CRYSTAL ENGINEERING SHALL NOT BE LIABLE FOR ANY

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, WHETHER IN CONTRACT, TORT OR

OTHERWISE.

Note (USA only): Some states do not allow limitations of implied warranties or the exclusion

of incidental or consequential damages, so the above limitations or exclusions may not apply

to you. This warranty gives you specic legal rights and you may have other rights which vary

from state to state.

How to Contact Us:

Phone (805) 595-5477

Toll-Free (800) 444-1850

Fax (805) 595-5466

Email service@crystalengineering.net

Web www.crystalengineering.net

If calling, have ready the model number, serial number, date of purchase and reason for return.

You will receive instructions for returning the device to Crystal Engineering.

Send your comments to: feedback@crystalengineering.net

Table of contents

Other Crystal Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

BEHA

BEHA Unitest TELARIS 0100 plus instruction manual

Quest Technologies

Quest Technologies VI-100 instructions

CCi

CCi PiMPro Smart Series user guide

Measurement Systems International

Measurement Systems International MSI9850 Operator's manual

Benstone

Benstone Fieldpaq II user manual

Opale-Paramodels

Opale-Paramodels JUMPBOX user manual