2

NivoGuide® 8100 • Two-wire 4 … 20 mA/HART

Contents

58878-EN-190215

Contents

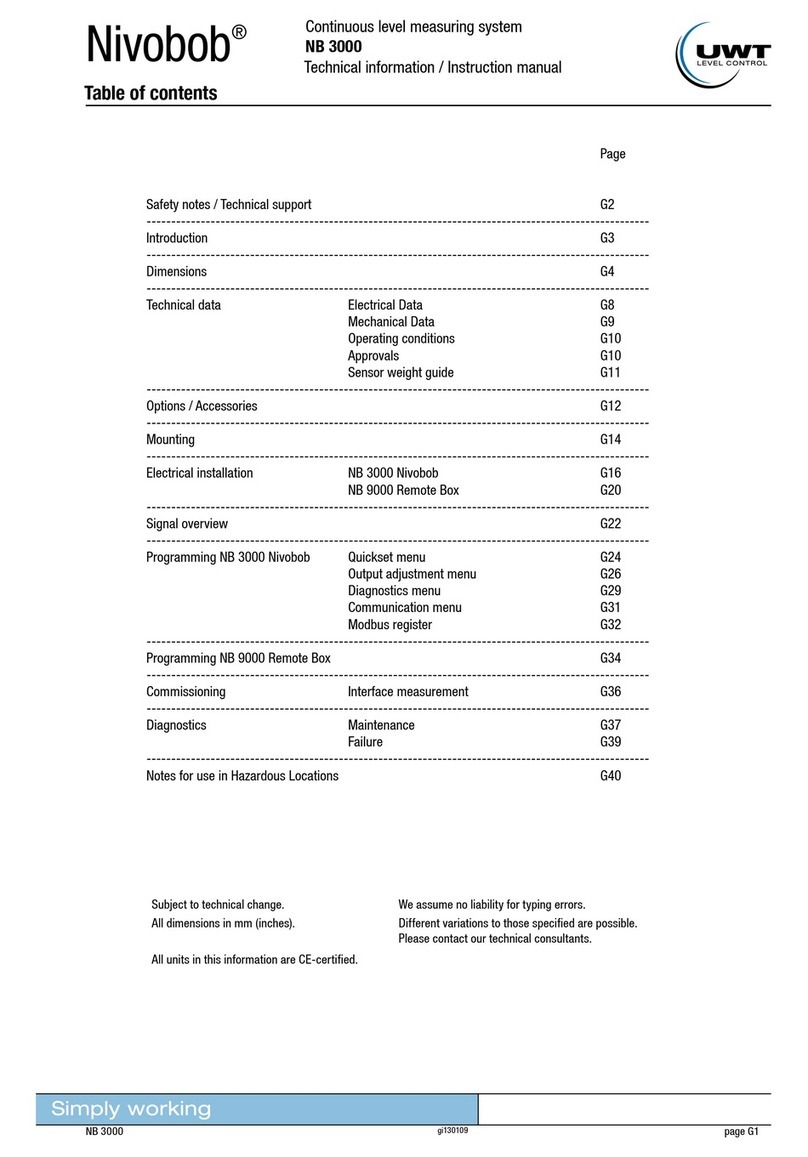

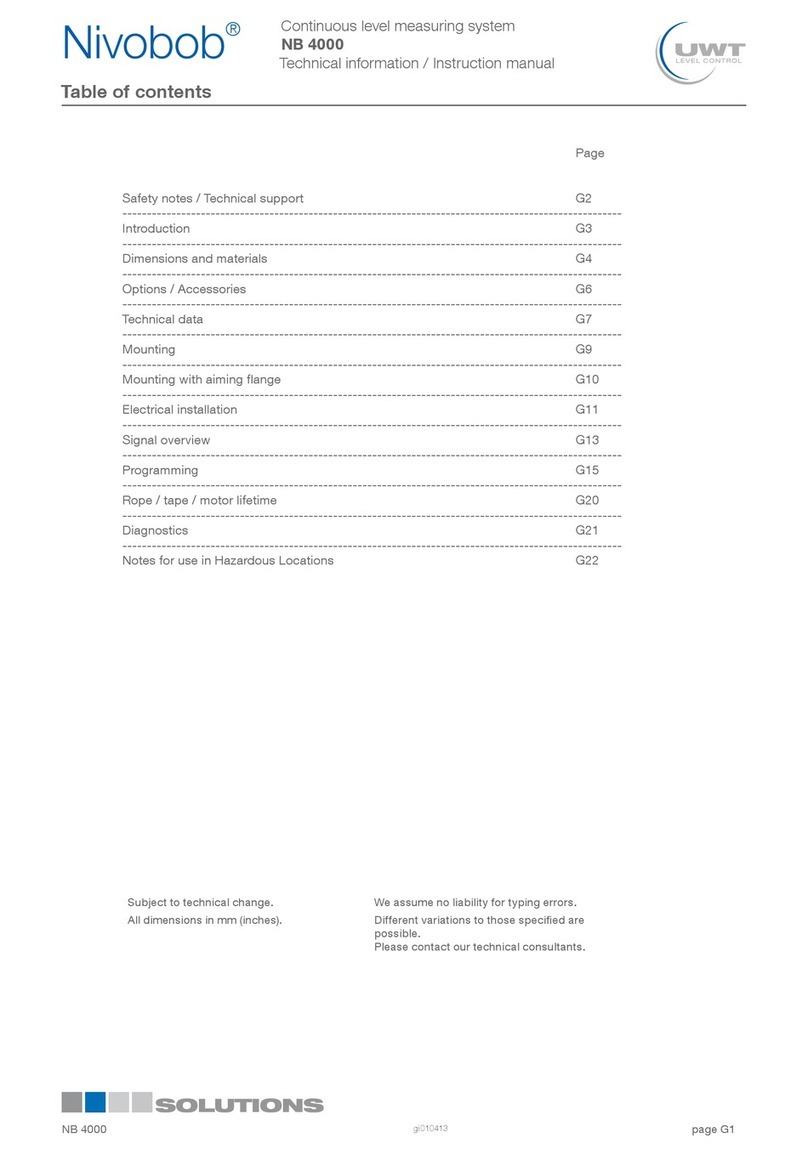

1 About this document ............................................................................................................... 4

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety ......................................................................................................................... 5

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 EU conformity................................................................................................................... 6

2.6 NAMUR recommendations .............................................................................................. 6

2.7 Installation and operation in the USA and Canada ........................................................... 6

3 Product description ................................................................................................................. 7

3.1 Conguration.................................................................................................................... 7

3.2 Principle of operation........................................................................................................ 8

3.3 Packaging, transport and storage................................................................................... 10

3.4 Accessories and replacement parts ............................................................................... 10

4 Mounting................................................................................................................................. 12

4.1 General instructions ....................................................................................................... 12

4.2 Mounting instructions ..................................................................................................... 13

5 Connecting to power supply................................................................................................. 17

5.1 Preparing the connection ............................................................................................... 17

5.2 Connecting..................................................................................................................... 18

5.3 Wiring plan, single chamber housing.............................................................................. 19

5.4 Wiring plan, double chamber housing ............................................................................ 20

5.5 Switch-on phase............................................................................................................. 21

6 Set up with the display and adjustment module ................................................................ 22

6.1 Insert display and adjustment module............................................................................ 22

6.2 Adjustment system......................................................................................................... 23

6.3 Parameter adjustment - Quick setup .............................................................................. 25

6.4 Parameter adjustment - Extended adjustment................................................................ 25

6.5 Saving the parameterisation data................................................................................... 43

7 Diagnostics and servicing .................................................................................................... 44

7.1 Maintenance .................................................................................................................. 44

7.2 Status messages............................................................................................................ 44

7.3 Rectify faults................................................................................................................... 47

7.4 Exchanging the electronics module................................................................................ 50

7.5 Exchanging the cable/rod............................................................................................... 51

7.6 How to proceed if a repair is necessary.......................................................................... 52

8 Dismount................................................................................................................................. 53

8.1 Dismounting steps.......................................................................................................... 53

8.2 Disposal ......................................................................................................................... 53

9 Supplement ............................................................................................................................ 54

9.1 Technical data ................................................................................................................ 54

9.2 Dimensions .................................................................................................................... 66