Crystal AEOLUS IS-18CA User manual

AEOLUS™ Stackable

Incubator Shaker

Note

Please read this manual carefully before installing the equipment. Please follow all

the instructions contained in this manual during operation. Otherwise, the user shall

be responsible for any consequence arising therefrom including potential bodily

harm and/or property damage.

Copyright:

1. No part of this manual may be reproduced, distributed, or transmitted in any form

or by any means, including photocopying, recording, or other electronic or

mechanical methods, without the prior written permission of the publisher, Crystal

Technology & Industries, Inc.

2. Contents contained in this manual, including all technical data, specification, and

performance figures are subject to change without notice.

Preface

Thank you for choosing Crystal Technology & Industries, Inc. AEOLUS™ CO2 Incubator

Shaker. Your trust and support are greatly appreciated.

Our Incubator Shaker Series is designed for shaking and heating samples with optional

CO2 and humidity control to meet the research and experiment needs in modern

biotechnology. Our state-of-the-art embedded microprocessor system utilized in this

machine has powerful data processing ability, outstanding stability, excellent

interference resistance, and high precision control of the temperature and shaking

performance of the instrument. Sophisticated manufacturing processes, aesthetic product

design, and a user-friendly interface are elegantly incorporated into the production of the

instrument.

The Incubator Shaker is widely used in biology, microbiology, medicine, pharmaceutics,

food science, and environmental science, which include various biological and chemical

reactions that require high precision control of temperature and shaking. Applicable

processes include bacteria culture, fermentation, and hybridization, and enzyme and cell

tissue research. It is also applicable to both static and dynamic culture of microbial cells

and strains.

Table of Contents

1. Overview

2. Unpacking Guide

3. Preparation

4. Safety Instructions

5. Installation

6. Structure

7. Control Panel

8. Settings

9. Operating Instructions

10. Maintenance

11. Troubleshooting

12. Method of Use Accessories

13. Optional Accessories

14. Warranty

P9

P13

P14

P18

P19

P20

P31

P32

P33

P35

P43

P45

P7

Note

Please read this manual carefully before installing the equipment. Please follow all

the instructions contained in this manual during operation. Otherwise, the user shall

be responsible for any consequence arising therefrom including potential bodily

harm and/or property damage.

Copyright:

1. No part of this manual may be reproduced, distributed, or transmitted in any form

or by any means, including photocopying, recording, or other electronic or

mechanical methods, without the prior written permission of the publisher, Crystal

Technology & Industries, Inc.

2. Contents contained in this manual, including all technical data, specification, and

performance figures are subject to change without notice.

Preface

Thank you for choosing Crystal Technology & Industries, Inc. AEOLUS™ CO2 Incubator

Shaker. Your trust and support are greatly appreciated.

Our Incubator Shaker Series is designed for shaking and heating samples with optional

CO2 and humidity control to meet the research and experiment needs in modern

biotechnology. Our state-of-the-art embedded microprocessor system utilized in this

machine has powerful data processing ability, outstanding stability, excellent

interference resistance, and high precision control of the temperature and shaking

performance of the instrument. Sophisticated manufacturing processes, aesthetic product

design, and a user-friendly interface are elegantly incorporated into the production of the

instrument.

The Incubator Shaker is widely used in biology, microbiology, medicine, pharmaceutics,

food science, and environmental science, which include various biological and chemical

reactions that require high precision control of temperature and shaking. Applicable

processes include bacteria culture, fermentation, and hybridization, and enzyme and cell

tissue research. It is also applicable to both static and dynamic culture of microbial cells

and strains.

Table of Contents

1. Overview

2. Unpacking Guide

3. Preparation

4. Safety Instructions

5. Installation

6. Structure

7. Control Panel

8. Settings

9. Operating Instructions

10. Maintenance

11. Troubleshooting

12. Method of Use Accessories

13. Optional Accessories

14. Warranty

P9

P13

P14

P18

P19

P20

P31

P32

P33

P35

P43

P45

P7

1.2 Features

12

1.1 Description

1. Overview 1. Overview

The AEOLUS™ CO2 incubator shaker with controlled temperature, shaking, humidity,

and CO2 concentration can be stacked three units high, while occupying the floor space

of only one unit. The combination and innovation of Proportional-Integral-Derivative (PID)

and Fuzzy control technology have allowed for high precision control of the instrument’s

chamber temperature. The three axis eccentric balance mechanism is stable, reliable,

and durable. The speed control system has a speed terminal feedback system, which

ensures high precision oscillation within the instrument. An inverter compressor is used

for refrigeration, thus making cooling a highly efficient process with low energy

consumption. The instrument’s noise reduction design keeps the noise level to only

55dB. The independent modular operation design makes it easy to selectively choose

which functions to run, so it can be used as a CO2 incubator for culturing cells statically,

or as an ordinary open air shaker, or as a biochemical incubator.

This machine can run continuously, but also includes a timer which can be set up to 999

hours. 12 segment functions can be programmed to achieve diverse environment

conditions, and specific running times for each segment can be set to create the required

environments. The rail platform makes it convenient to place and retrieve samples in the

instrument. The 7 inch color touch screen provides easy and streamlined operation.

Additionally, the WiFi monitoring system can be equipped with multiple phones, allowing

multiple users to remotely monitor the same instrument. Remote monitoring also sends

timely alarm information to deal with emergency situations quickly and safely without air

intake to protect cultured cells.

ŸGood thermal insulation, air tightness and waterproof properties: The main box

body, door, and insulation materials of the instrument all use foamed polyurethane

materials, which have the advantages of lightness, sound insulation, shockproof,

electrical insulation, heat resistance, cold resistance, solvent resistance, and aging

resistance.

ŸAutomatic adjustment of PID control: Instrument adjusts itself to the appropriate

parameters according to the different user set conditions and ensures high

precision and stability of temperature.

ŸStrong cooling capacity: Chamber can be cooled to 20°C below the ambient

temperature (Lowest temp is 4℃).

ŸExcellent temperature control performance: When stable at 37°C, the uniformity in

the cavity reaches ≤ ±0.2°C.

ŸPull out rail platform: Operator can easily pull the platform out to load or unload

fixtures and then push it back and lock. Only one locking handle in the middle of the

platform provides fast and convenient operation.

ŸIntuitive visual 7 inch color touch screen: Modular display shows the different

functions.

ŸCapacitive touch screen: The capacitive screen is durable and has no reaction

delay when the screen is pressed.

ŸSimple screen interface: A variety of functions, set values, and actual values are

displayed. At a glance, the user will know all the running parameters as they are

easy to find and operate.

ŸThe display screen has an automatic lock screen, automatic sleep function, and

password protection functions: Prevent mis-operation or allowing non-authorized

personnel to perform non-permissible operations.

ŸThree units can be stacked: Instrument can be purchased as a single unit, double

stack, or triple stack with the option to stack units (up to triple stack) in the future.

ŸBi-directional ultraviolet sterilization: The chamber is equipped with two sets of UV

sterilization light components to enhance the germicidal effect and reach every part

of the chamber.

ŸInverter compressor: Noiseless, durable, highly efficient, and energy saving.

ŸUltra quiet design: The whole instrument runs very quietly; the noise level is less

than 55dB, giving the operator a quiet environment.

ŸSlow acceleration and deceleration: Shaking function starts and stops slowly to

prevent large shear forces on the bacteria or cells.

ŸHigh pressure water rinse for the platform and bottom of the chamber: Simple

cleaning that is fast and efficient.

1.2 Features

12

1.1 Description

1. Overview 1. Overview

The AEOLUS™ CO2 incubator shaker with controlled temperature, shaking, humidity,

and CO2 concentration can be stacked three units high, while occupying the floor space

of only one unit. The combination and innovation of Proportional-Integral-Derivative (PID)

and Fuzzy control technology have allowed for high precision control of the instrument’s

chamber temperature. The three axis eccentric balance mechanism is stable, reliable,

and durable. The speed control system has a speed terminal feedback system, which

ensures high precision oscillation within the instrument. An inverter compressor is used

for refrigeration, thus making cooling a highly efficient process with low energy

consumption. The instrument’s noise reduction design keeps the noise level to only

55dB. The independent modular operation design makes it easy to selectively choose

which functions to run, so it can be used as a CO2 incubator for culturing cells statically,

or as an ordinary open air shaker, or as a biochemical incubator.

This machine can run continuously, but also includes a timer which can be set up to 999

hours. 12 segment functions can be programmed to achieve diverse environment

conditions, and specific running times for each segment can be set to create the required

environments. The rail platform makes it convenient to place and retrieve samples in the

instrument. The 7 inch color touch screen provides easy and streamlined operation.

Additionally, the WiFi monitoring system can be equipped with multiple phones, allowing

multiple users to remotely monitor the same instrument. Remote monitoring also sends

timely alarm information to deal with emergency situations quickly and safely without air

intake to protect cultured cells.

ŸGood thermal insulation, air tightness and waterproof properties: The main box

body, door, and insulation materials of the instrument all use foamed polyurethane

materials, which have the advantages of lightness, sound insulation, shockproof,

electrical insulation, heat resistance, cold resistance, solvent resistance, and aging

resistance.

ŸAutomatic adjustment of PID control: Instrument adjusts itself to the appropriate

parameters according to the different user set conditions and ensures high

precision and stability of temperature.

ŸStrong cooling capacity: Chamber can be cooled to 20°C below the ambient

temperature (Lowest temp is 4℃).

ŸExcellent temperature control performance: When stable at 37°C, the uniformity in

the cavity reaches ≤ ±0.2°C.

ŸPull out rail platform: Operator can easily pull the platform out to load or unload

fixtures and then push it back and lock. Only one locking handle in the middle of the

platform provides fast and convenient operation.

ŸIntuitive visual 7 inch color touch screen: Modular display shows the different

functions.

ŸCapacitive touch screen: The capacitive screen is durable and has no reaction

delay when the screen is pressed.

ŸSimple screen interface: A variety of functions, set values, and actual values are

displayed. At a glance, the user will know all the running parameters as they are

easy to find and operate.

ŸThe display screen has an automatic lock screen, automatic sleep function, and

password protection functions: Prevent mis-operation or allowing non-authorized

personnel to perform non-permissible operations.

ŸThree units can be stacked: Instrument can be purchased as a single unit, double

stack, or triple stack with the option to stack units (up to triple stack) in the future.

ŸBi-directional ultraviolet sterilization: The chamber is equipped with two sets of UV

sterilization light components to enhance the germicidal effect and reach every part

of the chamber.

ŸInverter compressor: Noiseless, durable, highly efficient, and energy saving.

ŸUltra quiet design: The whole instrument runs very quietly; the noise level is less

than 55dB, giving the operator a quiet environment.

ŸSlow acceleration and deceleration: Shaking function starts and stops slowly to

prevent large shear forces on the bacteria or cells.

ŸHigh pressure water rinse for the platform and bottom of the chamber: Simple

cleaning that is fast and efficient.

ŸAutomatic defrosting function: The machine automatically defrosts according to its

own needs, no need to enter the prescribed time or any other settings.

ŸEnergy saving control: The advanced Polyurethene material foaming process

improves the insulation performance, reduces energy consumption, and saves more

electrical energy.

ŸDC brushless motor drive: Low noise, high efficiency, no maintenance, long life,

minimal heat, no effect on the chamber temperature.

ŸDouble cross flow fan driving air circulation: Wind pressure is high, large air volume,

low noise, low heating capacity and long life.

Ÿ12 automatic programmable sections control function: User can set 12 different

speeds, temperatures, and times to automatically run the instrument at.

ŸAcousto-optic alarm and protection functions: Over temperature alarm, over speed

alarm, sensor fault alarm, timing alarm, open door alarm, over CO2 concentration

alarm, over humidity alarm, electric leakage protection, no intake alarm (Instrument

with CO2 function)

ŸOpen door protection: When the door opens, the machine stops running to protect the

safety of the operator.

ŸAutomatic recovery run: When the operation stops as a result of power failure, after

the power is supplied again, the instrument automatically resumes operation

according to the original parameters of operation.

ŸLong timing: User can set 0-999 hours and 59 minutes of operation time; the touch

screen displays the remaining time, and when time runs up the instrument prompts

"Program Finish".

ŸPowerful data storage function: Data can be stored for more than 2 years. Data is

recorded in 1 minute intervals.

ŸReal-time data query function: On the display, operator can query the running data

from the latest 7 days. Data is recorded in 1 minute intervals.

ŸU disk export data function: With a USB port, it is easy to export more than 2 years of

running data records to the USB.

ŸAlarm information recording and query function: Alarm information memory is stored

and can be queried.

ŸDisplay has a real-time temperature curve display function: Historical data and real-

time data is displayed on the same diagram display and is easy to check.

ŸDisplay can be switched from English interface to Chinese interface: If user is used to

the Chinese interface, it is easy to switch at any time.

ŸRemote WiFi monitor accessory: Instrument can be remotely controlled through

wireless LAN monitoring or internet mobile phone. Many mobile phones can monitor

the same instrument.

ŸComputer monitoring software accessory: Instrument can be monitored by a LAN

wired computer monitoring, and can remotely send alarm messages to connected

mobile phones.

1. Overview 1. Overview

34

And more on the instrument version with CO2 functions:

ŸCO2 infrared sensor: Accurate control, sensitive response, stable performance and

long life. It is not affected by any changes in temperature or humidity. Match the full

set of CO2 control accessories.

ŸMulti High-Efficiancy-Particulate-Air (HEPA) filters: Prevent gas impurities in the

cylinder or pollution source from contaminating the gas in the chamber.

ŸEasy cleaning inner chamber: It is easy to wipe and disinfect the inner chamber

without dismantling the platform to minimize the growth of bacteria.

ŸDouble hollow glass window: Heating and antifogging design allow the cell culture in

the chamber to be clear at a glance.

ŸHigh humidity, anti-rust, and anti-condensation design: Prevents the door from rusting

due to high humidity. Prevents rust in the internal chamber. Prevents the micro flow of

water on the door to the ground when the door is open.

ŸAutomatically liquid filled device accessory: The liquid can be automatically filled to

the wet disk when the passive humidifying liquid is evaporated and dried in the

chamber.

ŸActive humidification device accessory: The humidity in the chamber can be

controlled.

Procedure for testing the CO2 control function unit with RH Controller:

In order to ensure the stability of the humidity in the chamber, it is recommended that

flasks be arranged evenly and that circulation and ventilation is ensured in the chamber.

The specific layout method and the number of flasks are as follows:

15

12

80%~85%

70%

Set

RH Value

Max. QTY

of the Flask Place Test conditions

Take 250ml flask as an example:

1. Fill 250ml flask with 100ml pure water

2. Set the temperature of the instrument:

37℃

3. Set the speed of the instrument: 25rpm1

4. Ambient temperature: 20℃~25℃

ŸAutomatic defrosting function: The machine automatically defrosts according to its

own needs, no need to enter the prescribed time or any other settings.

ŸEnergy saving control: The advanced Polyurethene material foaming process

improves the insulation performance, reduces energy consumption, and saves more

electrical energy.

ŸDC brushless motor drive: Low noise, high efficiency, no maintenance, long life,

minimal heat, no effect on the chamber temperature.

ŸDouble cross flow fan driving air circulation: Wind pressure is high, large air volume,

low noise, low heating capacity and long life.

Ÿ12 automatic programmable sections control function: User can set 12 different

speeds, temperatures, and times to automatically run the instrument at.

ŸAcousto-optic alarm and protection functions: Over temperature alarm, over speed

alarm, sensor fault alarm, timing alarm, open door alarm, over CO2 concentration

alarm, over humidity alarm, electric leakage protection, no intake alarm (Instrument

with CO2 function)

ŸOpen door protection: When the door opens, the machine stops running to protect the

safety of the operator.

ŸAutomatic recovery run: When the operation stops as a result of power failure, after

the power is supplied again, the instrument automatically resumes operation

according to the original parameters of operation.

ŸLong timing: User can set 0-999 hours and 59 minutes of operation time; the touch

screen displays the remaining time, and when time runs up the instrument prompts

"Program Finish".

ŸPowerful data storage function: Data can be stored for more than 2 years. Data is

recorded in 1 minute intervals.

ŸReal-time data query function: On the display, operator can query the running data

from the latest 7 days. Data is recorded in 1 minute intervals.

ŸU disk export data function: With a USB port, it is easy to export more than 2 years of

running data records to the USB.

ŸAlarm information recording and query function: Alarm information memory is stored

and can be queried.

ŸDisplay has a real-time temperature curve display function: Historical data and real-

time data is displayed on the same diagram display and is easy to check.

ŸDisplay can be switched from English interface to Chinese interface: If user is used to

the Chinese interface, it is easy to switch at any time.

ŸRemote WiFi monitor accessory: Instrument can be remotely controlled through

wireless LAN monitoring or internet mobile phone. Many mobile phones can monitor

the same instrument.

ŸComputer monitoring software accessory: Instrument can be monitored by a LAN

wired computer monitoring, and can remotely send alarm messages to connected

mobile phones.

1. Overview 1. Overview

34

And more on the instrument version with CO2 functions:

ŸCO2 infrared sensor: Accurate control, sensitive response, stable performance and

long life. It is not affected by any changes in temperature or humidity. Match the full

set of CO2 control accessories.

ŸMulti High-Efficiancy-Particulate-Air (HEPA) filters: Prevent gas impurities in the

cylinder or pollution source from contaminating the gas in the chamber.

ŸEasy cleaning inner chamber: It is easy to wipe and disinfect the inner chamber

without dismantling the platform to minimize the growth of bacteria.

ŸDouble hollow glass window: Heating and antifogging design allow the cell culture in

the chamber to be clear at a glance.

ŸHigh humidity, anti-rust, and anti-condensation design: Prevents the door from rusting

due to high humidity. Prevents rust in the internal chamber. Prevents the micro flow of

water on the door to the ground when the door is open.

ŸAutomatically liquid filled device accessory: The liquid can be automatically filled to

the wet disk when the passive humidifying liquid is evaporated and dried in the

chamber.

ŸActive humidification device accessory: The humidity in the chamber can be

controlled.

Procedure for testing the CO2 control function unit with RH Controller:

In order to ensure the stability of the humidity in the chamber, it is recommended that

flasks be arranged evenly and that circulation and ventilation is ensured in the chamber.

The specific layout method and the number of flasks are as follows:

15

12

80%~85%

70%

Set

RH Value

Max. QTY

of the Flask Place Test conditions

Take 250ml flask as an example:

1. Fill 250ml flask with 100ml pure water

2. Set the temperature of the instrument:

37℃

3. Set the speed of the instrument: 25rpm1

4. Ambient temperature: 20℃~25℃

Model

1.3 Specifications

0 (Stop),30~300 RPM

1. Overview 1. Overview

6

Room Temp. Minus 20℃~60℃ (Lowest Temp. is 4℃)

5

Speed

Speed Accuracy

Max. Load

Platform Dimensions

0~999Hours 59min.

Yes

Yes

Yes

Yes

1 min.

Timer

Automatic Defrost

Heat Power

Cool Power

Max Power

U Disk Download Date

USB Data Export

Date Storage Interval

Most Recent 912 Days of Data

Noise Level

Water Sparge Resistant

Interface Languages English or Chinese

Auto-run after

Power Recovery

≤1000W

IS-18CA IS-18CA

±1rpm

Model

Temp. Range

≤55db (When Compressor is Running)

≤ ±0.2°C (@37°C)

≤300W

≤800W

20kg (44.1lb)

900×550mm (35.4 x 21.6in)

Orbit Diameter

CO2 Sensor

CO2 Control Range 0~20%

Ø26mm (Ø1.02in)

Data Stored

Time, Temp, Speed,

CO2 Concentration,

RH, Instrument Status

Power Supply

Net Weight

AC110V+11V, 60Hz

195kg (430lb)

Mobile Monitoring and

WiFi Control

PC Monitor and Control

by RS485 (Option)

Optional

Optional

Optional

Optional

CO2 Display Accuracy

Temperature Accuracy

Down-Swing (Optional up-swing door for top unit of triple stack)

95%

CO2 Control Accuracy

CO2 Recovery Time

after Door Open for 30s

Max. Humidity

Door Open Direction

Programmable

Segments 12 Segments

Relative Humidity Type Active Humidification

Disinfection UV Lamps on Left and Right Walls

Parameter Protection

Screen Data Display

Password Protected

Displays Most Recent 7 Days of Data

Data Curve Display Temp. Curve, Speed Curve, CO2 Curve, RH Curve

Max. Capacity

±0.1%( @5% )

≤6min (@37℃)

≤6min(@5%)

Clamp Capacity: 25mlx134/ 50ml×134/ 100ml×60/ 150ml×60/ 200ml×60/

250ml×60/ 500ml×32/ 1000ml×22/ 2000ml×15/ 3000ml×12/ 5000ml×6

Sticky Mat: 25mlx187/ 50ml×187/ 100ml×112/ 150ml×104/ 200ml×84/

250ml×76/ 500ml×40/ 1000ml×28/ 2000ml×15/ 3000ml×12/ 5000ml×6

5~60℃

Temp Recovery after

Door Open for 30s

Display 7” Color Capacitance Touch Screen

Touch Screen Type Capacitance

Screen Auto-Lock Screen Requires Password After Set Screen Inactivity Time

Screen Auto-Sleep Screen Sleeps After Set Screen Inactivity Time

±0.1%

IR

Temperature Uniformity

Temperature Stability

RH Control

Passive Humidifier

Automatic Water

Application range of

CO2 temperature

1380×875×530(+80 w/ feet)mm (54.33×34.45×20.87(+3.15 w/ feet)in)

Internal Dimensions

External Dimensions

985×775×410mm (38.78×30.51×16.14in)

≤ ±0.2°C (@37°C)

≤ ±0.1°C (@37°C)

IS-18A

NA

NA

NA

NA

NA

NA

NA

NA

IS-18A

Time, Temp, Speed,

Instrument Status

Illumination LED Lamps on Left and Right Walls

Model

1.3 Specifications

0 (Stop),30~300 RPM

1. Overview 1. Overview

6

Room Temp. Minus 20℃~60℃ (Lowest Temp. is 4℃)

5

Speed

Speed Accuracy

Max. Load

Platform Dimensions

0~999Hours 59min.

Yes

Yes

Yes

Yes

1 min.

Timer

Automatic Defrost

Heat Power

Cool Power

Max Power

U Disk Download Date

USB Data Export

Date Storage Interval

Most Recent 912 Days of Data

Noise Level

Water Sparge Resistant

Interface Languages English or Chinese

Auto-run after

Power Recovery

≤1000W

IS-18CA IS-18CA

±1rpm

Model

Temp. Range

≤55db (When Compressor is Running)

≤ ±0.2°C (@37°C)

≤300W

≤800W

20kg (44.1lb)

900×550mm (35.4 x 21.6in)

Orbit Diameter

CO2 Sensor

CO2 Control Range 0~20%

Ø26mm (Ø1.02in)

Data Stored

Time, Temp, Speed,

CO2 Concentration,

RH, Instrument Status

Power Supply

Net Weight

AC110V+11V, 60Hz

195kg (430lb)

Mobile Monitoring and

WiFi Control

PC Monitor and Control

by RS485 (Option)

Optional

Optional

Optional

Optional

CO2 Display Accuracy

Temperature Accuracy

Down-Swing (Optional up-swing door for top unit of triple stack)

95%

CO2 Control Accuracy

CO2 Recovery Time

after Door Open for 30s

Max. Humidity

Door Open Direction

Programmable

Segments 12 Segments

Relative Humidity Type Active Humidification

Disinfection UV Lamps on Left and Right Walls

Parameter Protection

Screen Data Display

Password Protected

Displays Most Recent 7 Days of Data

Data Curve Display Temp. Curve, Speed Curve, CO2 Curve, RH Curve

Max. Capacity

±0.1%( @5% )

≤6min (@37℃)

≤6min(@5%)

Clamp Capacity: 25mlx134/ 50ml×134/ 100ml×60/ 150ml×60/ 200ml×60/

250ml×60/ 500ml×32/ 1000ml×22/ 2000ml×15/ 3000ml×12/ 5000ml×6

Sticky Mat: 25mlx187/ 50ml×187/ 100ml×112/ 150ml×104/ 200ml×84/

250ml×76/ 500ml×40/ 1000ml×28/ 2000ml×15/ 3000ml×12/ 5000ml×6

5~60℃

Temp Recovery after

Door Open for 30s

Display 7” Color Capacitance Touch Screen

Touch Screen Type Capacitance

Screen Auto-Lock Screen Requires Password After Set Screen Inactivity Time

Screen Auto-Sleep Screen Sleeps After Set Screen Inactivity Time

±0.1%

IR

Temperature Uniformity

Temperature Stability

RH Control

Passive Humidifier

Automatic Water

Application range of

CO2 temperature

1380×875×530(+80 w/ feet)mm (54.33×34.45×20.87(+3.15 w/ feet)in)

Internal Dimensions

External Dimensions

985×775×410mm (38.78×30.51×16.14in)

≤ ±0.2°C (@37°C)

≤ ±0.1°C (@37°C)

IS-18A

NA

NA

NA

NA

NA

NA

NA

NA

IS-18A

Time, Temp, Speed,

Instrument Status

Illumination LED Lamps on Left and Right Walls

78

Unpacking Procedure

Warning

ŸDue to its weight, please use a lift or a forklift or other lifting apparatus to transport or

move the instrument. DO NOT TRANSPORT OR MOVE THE INSTRUMENT WITHOUT

HELPERS.

ŸInspect contents upon receiving the instrument, if the instrument is upside down,

contact the manufacturer immediately.

ŸMake sure the power is disconnected and the instrument is not loaded when moving

the instrument. Please move instrument individually before stacking them.

2. Unpacking Guide 2. Unpacking Guide

Equipped in type of CO2 Model only

Equipped in type of CO2 Model only

Equipped in type of CO2 Model only

Equipped in type of CO2 Model only

Power Cord

Liquid Collection Tray

Fuse

Cross Screwdriver 2#

Single open-end Wrench 24

Wrench S10

User Manual

Filter

Filter Protection Package

Hood

PU Pipe (5 m)

Silicone Tube 12×2Ø

T-Connectors 14Ø

Two-way Connectors 14Ø

Three-way Connectors

1

1

1

1

1

1

1

1

1

1

4

1

1m

1

1

2

Packing List

Accessories

Platform handle backup

Name Qty Remark

Stackable Incubator Shaker

AC250V/10A

Equipped in type of CO2 Model only

1. Lift the instrument with a lift or forklift and place the instrument on a level surface with

caution.

2. Remove the protective packing material and inspect if the instrument is damaged.

3. Please find the packing list, in the user manual, in the plastic documents pouch inside

the shipment box.

3. Check the packing list in the manual to make sure there are no missing accessories;

if there are please contact Crystal Technology immediately.

78

Unpacking Procedure

Warning

ŸDue to its weight, please use a lift or a forklift or other lifting apparatus to transport or

move the instrument. DO NOT TRANSPORT OR MOVE THE INSTRUMENT WITHOUT

HELPERS.

ŸInspect contents upon receiving the instrument, if the instrument is upside down,

contact the manufacturer immediately.

ŸMake sure the power is disconnected and the instrument is not loaded when moving

the instrument. Please move instrument individually before stacking them.

2. Unpacking Guide 2. Unpacking Guide

Equipped in type of CO2 Model only

Equipped in type of CO2 Model only

Equipped in type of CO2 Model only

Equipped in type of CO2 Model only

Power Cord

Liquid Collection Tray

Fuse

Cross Screwdriver 2#

Single open-end Wrench 24

Wrench S10

User Manual

Filter

Filter Protection Package

Hood

PU Pipe (5 m)

Silicone Tube 12×2Ø

T-Connectors 14Ø

Two-way Connectors 14Ø

Three-way Connectors

1

1

1

1

1

1

1

1

1

1

4

1

1m

1

1

2

Packing List

Accessories

Platform handle backup

Name Qty Remark

Stackable Incubator Shaker

AC250V/10A

Equipped in type of CO2 Model only

1. Lift the instrument with a lift or forklift and place the instrument on a level surface with

caution.

2. Remove the protective packing material and inspect if the instrument is damaged.

3. Please find the packing list, in the user manual, in the plastic documents pouch inside

the shipment box.

3. Check the packing list in the manual to make sure there are no missing accessories;

if there are please contact Crystal Technology immediately.

9

ŸPay attention to avoid any risk of body injuries from disassembling, lifting, or

moving the instrument.

ŸThe CO2 concentration may increase and can be harmful to your health if

operating the instrument in a small and airtight room.

ŸPlease keep the room ventilated when the CO2 function is on. Additionally, please

avoid direct inhalation of the gas when opening the door.

ŸKeep the vent of the instrument away from heat sources or other vents, otherwise

the compressor cannot be started or started frequently during refrigeration.

ŸWhen the instruments are stacked, make sure the floor loading capacity is at

least 1.5 times of the instruments weight. Stack them up near the wall or on the

floor with a reinforced beam to ensure good loading capacity.

The instrument must be placed on a firm and level surface. The total weight of the

instrument when fully loaded (474 lb/unit) must be taken into consideration. There

must be sufficient space left around the instrument. There should be at least 20 cm

between the instrument and any wall or any two adjacent instruments.

3.1 Placement Conditions

Warning

3.2 Ambient Conditions

a. F or indoor use only

b. A mbient Temperature: 10℃-35℃

c. R elative Humidity: 20%-80% RH

d.Atmospheric Pressure: 75kPa-106kPa

e. Use a dedicated power outlet with a capacity no less than 1.3 kW and AC 110 V

f. The fluctuations of power supply voltage is less than 10% of rated voltage

3. Preparation3. Preparation

3.3 Space Conditions

10

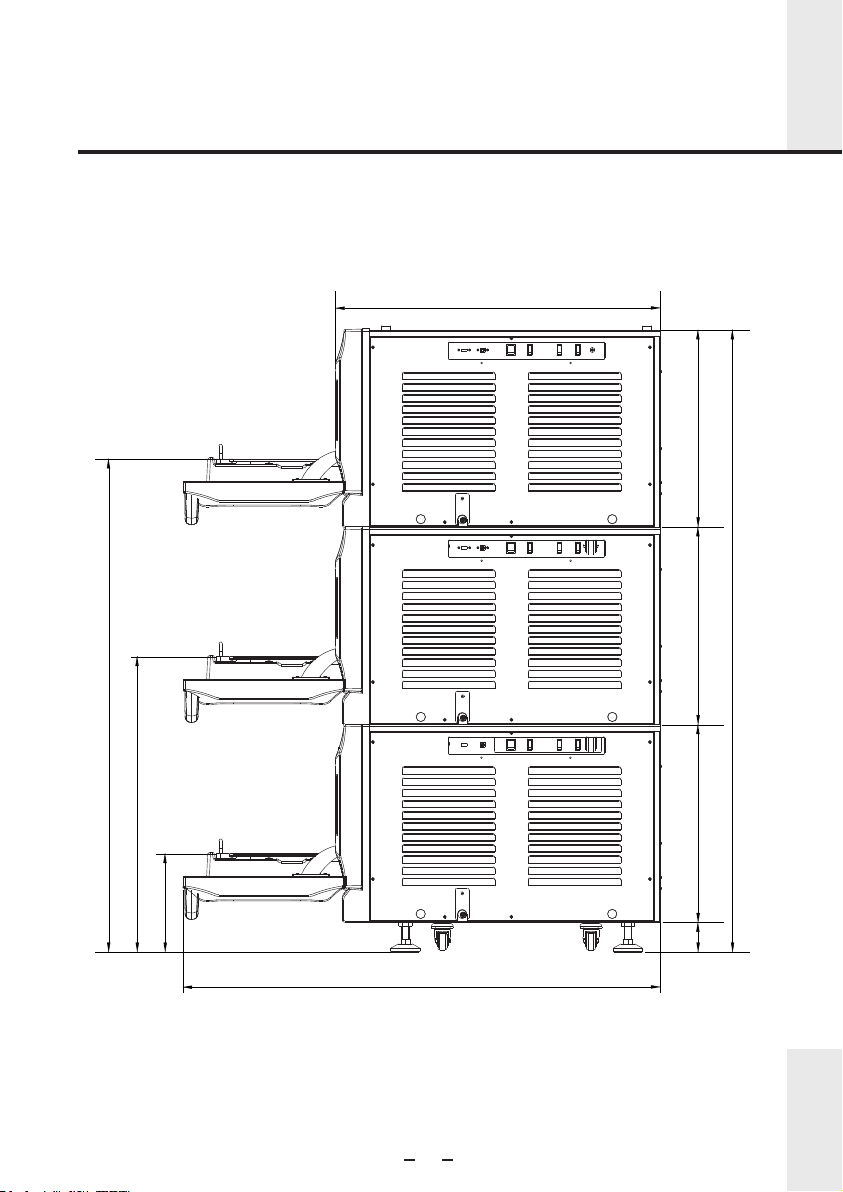

●3 Down-swing-door instruments are stacked as below:

1290mm

270mm

800mm

880mm

80 530mm 530mm 530mm

1670mm

mm

1330mm

Note: When double and triple stacked, it is recommended that the second and third

instruments are not used at speeds exceeding 250 RPM.

9

ŸPay attention to avoid any risk of body injuries from disassembling, lifting, or

moving the instrument.

ŸThe CO2 concentration may increase and can be harmful to your health if

operating the instrument in a small and airtight room.

ŸPlease keep the room ventilated when the CO2 function is on. Additionally, please

avoid direct inhalation of the gas when opening the door.

ŸKeep the vent of the instrument away from heat sources or other vents, otherwise

the compressor cannot be started or started frequently during refrigeration.

ŸWhen the instruments are stacked, make sure the floor loading capacity is at

least 1.5 times of the instruments weight. Stack them up near the wall or on the

floor with a reinforced beam to ensure good loading capacity.

The instrument must be placed on a firm and level surface. The total weight of the

instrument when fully loaded (474 lb/unit) must be taken into consideration. There

must be sufficient space left around the instrument. There should be at least 20 cm

between the instrument and any wall or any two adjacent instruments.

3.1 Placement Conditions

Warning

3.2 Ambient Conditions

a. F or indoor use only

b. A mbient Temperature: 10℃-35℃

c. R elative Humidity: 20%-80% RH

d.Atmospheric Pressure: 75kPa-106kPa

e. Use a dedicated power outlet with a capacity no less than 1.3 kW and AC 110 V

f. The fluctuations of power supply voltage is less than 10% of rated voltage

3. Preparation3. Preparation

3.3 Space Conditions

10

●3 Down-swing-door instruments are stacked as below:

1290mm

270mm

800mm

880mm

80 530mm 530mm 530mm

1670mm

mm

1330mm

Note: When double and triple stacked, it is recommended that the second and third

instruments are not used at speeds exceeding 250 RPM.

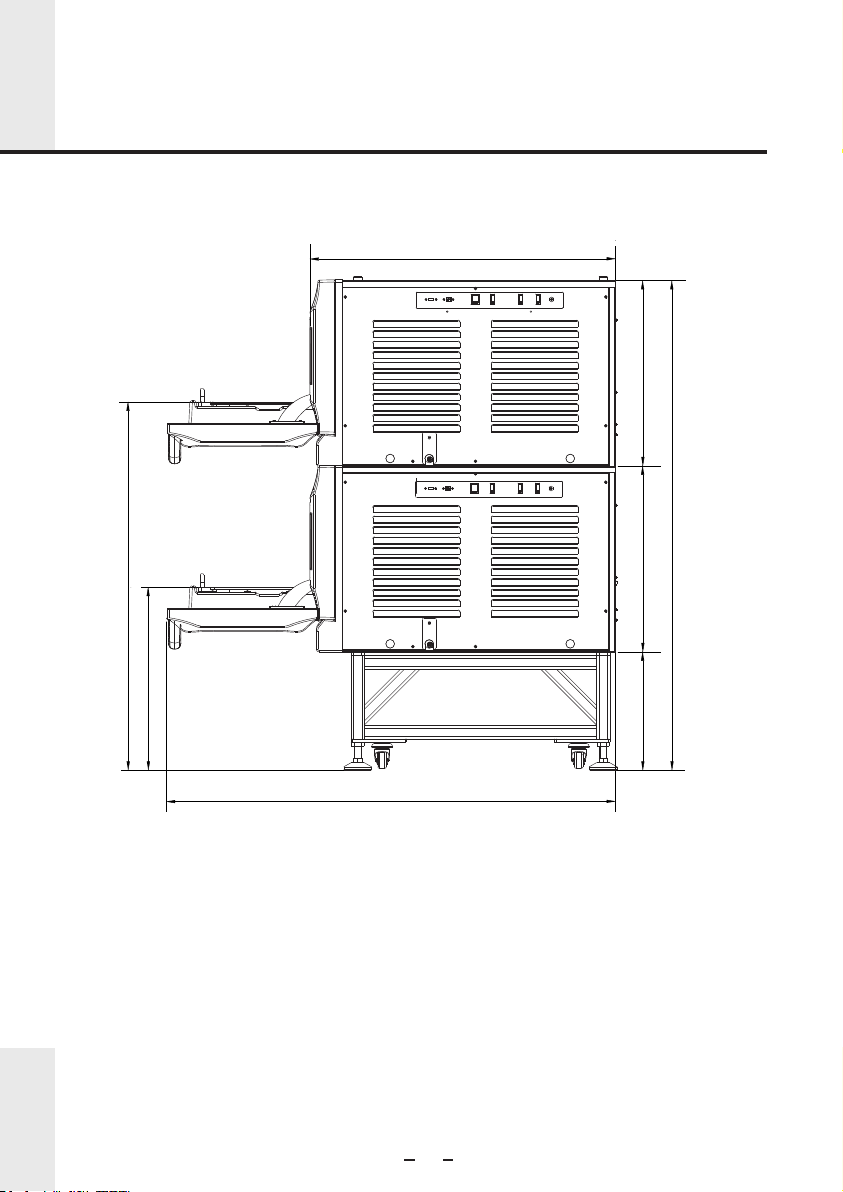

●Stacking Rack (IS-A118) and 2 Down-swing-door instruments are stacked as

below:

●2 Down-swing-door instruments and 1 Up-swing-door instrument are stacked as

below:

12

11

3. Preparation3. Preparation

1060mm

530mm

1290mm

880mm

340mm 530mm 530mm

1400mm

1290mm

530mm 530mm 530mm

1332mm

800mm

270mm

2055mm

80

mm

Note: When double and triple stacked, it is recommended that the second and third

instruments are not used at speeds exceeding 250 RPM.

Note: When double and triple stacked, it is recommended that the second and third

instruments are not used at speeds exceeding 250 RPM.

●Stacking Rack (IS-A118) and 2 Down-swing-door instruments are stacked as

below:

●2 Down-swing-door instruments and 1 Up-swing-door instrument are stacked as

below:

12

11

3. Preparation3. Preparation

1060mm

530mm

1290mm

880mm

340mm 530mm 530mm

1400mm

1290mm

530mm 530mm 530mm

1332mm

800mm

270mm

2055mm

80

mm

Note: When double and triple stacked, it is recommended that the second and third

instruments are not used at speeds exceeding 250 RPM.

Note: When double and triple stacked, it is recommended that the second and third

instruments are not used at speeds exceeding 250 RPM.

: This instrument contains flammable refrigerant. Be careful when installing and

operating to prevent the risks of combustion or explosion.

: Risk of burns may be created when operating or maintaining.

: Risk of hand injuries due to improper operation or accidents when opening the

door.

Please make sure to follow the safety instructions!

● Please use a lift or a forklift or other lifting apparatus to raise or move the instrument.

● Make sure the power supply voltage matches the voltage of the instrument before it is

connected.

● The instrument must be properly placed.

● Use a grounded power socket.

● Do not drag the power cord when unplugging.

● Do not use a damaged or non-designated power cord.

● Only qualified personnel are allowed to open the control box.

● Keep the handle on the platform screwed when the instrument is running.

● Keep the room ventilated.

Disconnect the power supply in any of the situations below:

● Moving or transporting the instrument

● Opening the power box

● Changing the fuse

● Malfunctioning of the instrument

● Instrument is out of use for a long period of time

4. Safety Instructions 5. Installation

Lifting the instrument by hand should be prohibited. Please use a lift or a forklift or other

lifting apparatus to raise or move the instrument.

Note

5.1 Tool Requirements

a. H ex wrench S10. Cross screwdriver #2. Single open-end wrench 24

b. A lift or forklift or other lifting apparatus with a minimum loading capacity

of 350 kg (772 lb).

5.2 Installation

a. Ensure the installation site meets the requirement as instructed in Section 3.1.

b. First unit installation: Raise adjustable feet away from the ground.

c. Slowly and smoothly move the instrument on its wheels to its designated location.

d. Loosen the four adjustable feet with a wrench to touch the ground, keep it level, then

tighten the four adjustable feet with a wrench. The instrument needs to be stable and

cannot be moved.

14

13

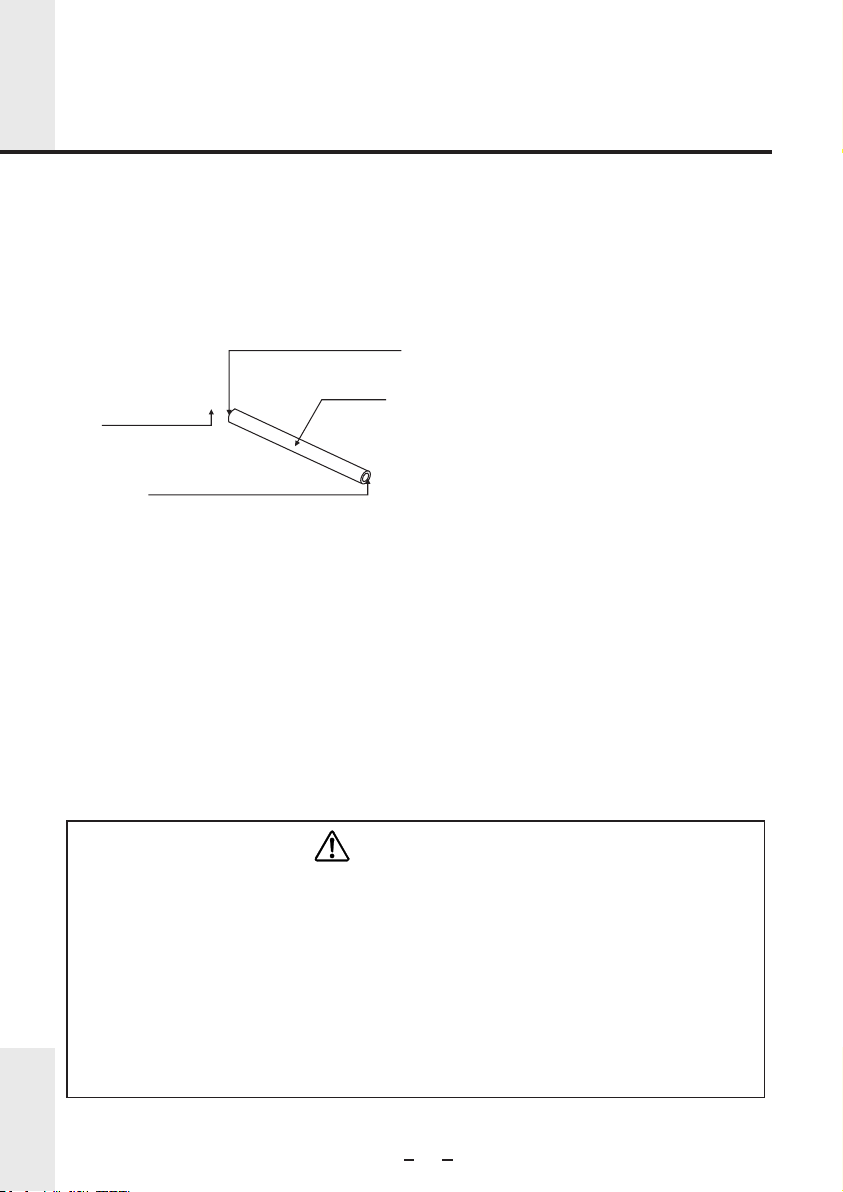

Adjust the height of the feet to allow the instrument to move or be set:

Adjust all feet up to off the

ground so the instrument can

move on its wheels.

Adjust the feet down to the

ground, the instrument will be

fixed.

: This instrument contains flammable refrigerant. Be careful when installing and

operating to prevent the risks of combustion or explosion.

: Risk of burns may be created when operating or maintaining.

: Risk of hand injuries due to improper operation or accidents when opening the

door.

Please make sure to follow the safety instructions!

● Please use a lift or a forklift or other lifting apparatus to raise or move the instrument.

● Make sure the power supply voltage matches the voltage of the instrument before it is

connected.

● The instrument must be properly placed.

● Use a grounded power socket.

● Do not drag the power cord when unplugging.

● Do not use a damaged or non-designated power cord.

● Only qualified personnel are allowed to open the control box.

● Keep the handle on the platform screwed when the instrument is running.

● Keep the room ventilated.

Disconnect the power supply in any of the situations below:

● Moving or transporting the instrument

● Opening the power box

● Changing the fuse

● Malfunctioning of the instrument

● Instrument is out of use for a long period of time

4. Safety Instructions 5. Installation

Lifting the instrument by hand should be prohibited. Please use a lift or a forklift or other

lifting apparatus to raise or move the instrument.

Note

5.1 Tool Requirements

a. H ex wrench S10. Cross screwdriver #2. Single open-end wrench 24

b. A lift or forklift or other lifting apparatus with a minimum loading capacity

of 350 kg (772 lb).

5.2 Installation

a. Ensure the installation site meets the requirement as instructed in Section 3.1.

b. First unit installation: Raise adjustable feet away from the ground.

c. Slowly and smoothly move the instrument on its wheels to its designated location.

d. Loosen the four adjustable feet with a wrench to touch the ground, keep it level, then

tighten the four adjustable feet with a wrench. The instrument needs to be stable and

cannot be moved.

14

13

Adjust the height of the feet to allow the instrument to move or be set:

Adjust all feet up to off the

ground so the instrument can

move on its wheels.

Adjust the feet down to the

ground, the instrument will be

fixed.

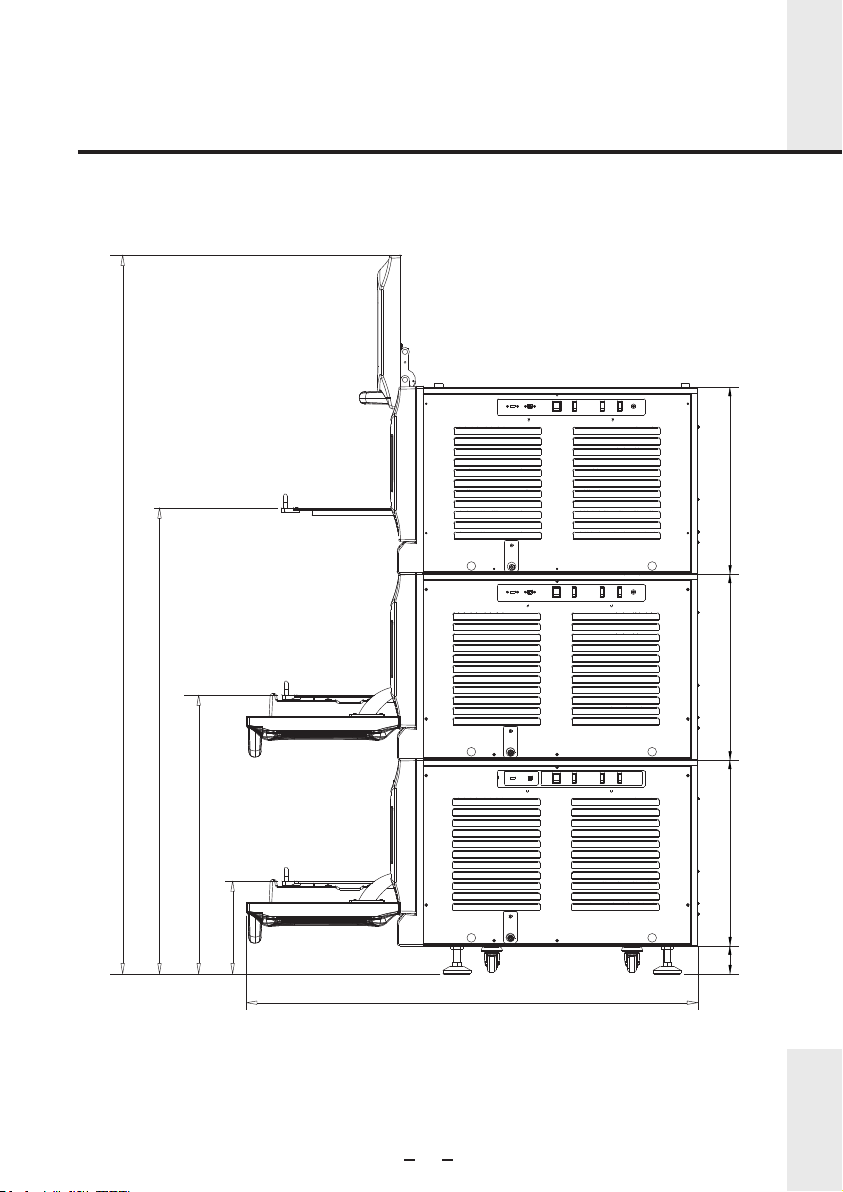

e. To stack the 2nd or 3rd unit, fix it with four screws at the designated locations below

on both sides.

16

5. Installation 5. Installation

Please make sure each instrument is placed level, stable and still. Do not exceed the

maximum load of 20kg and the maximum stacked shaker speed of 250 RPM on the

second and third units.

Note

a. When stacked up to 3 units, units will need a Two-way Connector and 2 T-connectors.

b. When stacked up to 2 units, units will need a Two-way Connector and a T-connector.

5.3 Drain connection

2. Using the polyurethane tube provided,

connect the regulator to a CO2 inlet HEPA

filter first, and then to the CO2 inlet located

on the right side of the shaker. (See Figure 1)

3. Set the CO2 secondary flow control valve to 0.08~ 0.1MPa

(11.6~14.5psi).

(WARNING: Excessive pressure may cause disconnection

of internal pipes inside the CO2 incubator which will result

in leakage of CO2 gas into the surrounding environment.

High CO2 concentration can cause harm to your

health and may cause asphyxia or death. Maintenance

is required if the inline tube falls off.)

5.4 CO2 Connection

1. Install a regulator with flow control valve onto the CO2 Cylinder. Please use a

2 2

regulator with a primary preset pressure of 25MPa (250kg/cm , 3500l b/in ), and a

secondary preset pressure of 0.6MPa (2.0kg/cm, 30psiG).

Gas Inlet

PU Pipe

Filter

Protection Cover

Figure 1

Figure 2

Two-way

Connector

T-connector

15

e. To stack the 2nd or 3rd unit, fix it with four screws at the designated locations below

on both sides.

16

5. Installation 5. Installation

Please make sure each instrument is placed level, stable and still. Do not exceed the

maximum load of 20kg and the maximum stacked shaker speed of 250 RPM on the

second and third units.

Note

a. When stacked up to 3 units, units will need a Two-way Connector and 2 T-connectors.

b. When stacked up to 2 units, units will need a Two-way Connector and a T-connector.

5.3 Drain connection

2. Using the polyurethane tube provided,

connect the regulator to a CO2 inlet HEPA

filter first, and then to the CO2 inlet located

on the right side of the shaker. (See Figure 1)

3. Set the CO2 secondary flow control valve to 0.08~ 0.1MPa

(11.6~14.5psi).

(WARNING: Excessive pressure may cause disconnection

of internal pipes inside the CO2 incubator which will result

in leakage of CO2 gas into the surrounding environment.

High CO2 concentration can cause harm to your

health and may cause asphyxia or death. Maintenance

is required if the inline tube falls off.)

5.4 CO2 Connection

1. Install a regulator with flow control valve onto the CO2 Cylinder. Please use a

2 2

regulator with a primary preset pressure of 25MPa (250kg/cm , 3500l b/in ), and a

secondary preset pressure of 0.6MPa (2.0kg/cm, 30psiG).

Gas Inlet

PU Pipe

Filter

Protection Cover

Figure 1

Figure 2

Two-way

Connector

T-connector

15

1. Do not move the pressure adjustment rod on the regulator when changing the CO2

cylinder. It will affect the secondary pressure and will result in needing to reset the

valve. The inline tube might fall off if the pressure is too high and maintenance will be

required.

2. Check tube regularly to ensure it is safely connected. Change the tube if it is

damaged or aged.

3. Use the stainless steel hoop to tighten the connection point of the Polyurethane tube

and the filter to prevent the pipe from falling off and leaking gas.

4. Use more than 99.99% pure CO2. Low purity may cause blocking of the filter or

damage of the electromagnetic valve.

5.Connection components

A. Schematic diagram B. Actual picture

4. Check the tube connections for possible leakage (the connections between tube and

regulator, tube and access port, and tube and filter).

Note:

5. Installation

17 18

Polyurethane Pipe

(Inner dia.7mm,

outer dia. 10mm)

To the filter

Stainless steel hoop

To the CO2 regulator

6. Structure

●Down-swing-door

●Up-swing-door

Ventilation

Ventilation

Adjustable feet

Adjustable feet

Handle

Handle

Touchscreen Control Interface

WIFI

Interface

USB

Data Out

UV lamp switch

Power switch

Remote wifi monitor interface

(optional)

Co2 Gas Inlet

I

O

I

O

USB port

Warnings

- Make sure the gas supply meets the specified requirements.

- Make sure all the pipes are properly connected.

- Make sure the gas pressure settings are correct.

- Wrong pipe connection or pressure settings may cause CO2 leakage.

- High Co2 concentration will do harm to your health and may cause

suffocation or death.

- Alternative methods should be taken if there is no sufficient ventilation in the

room to guarantee safety. These methods include gas monitoring and alarming

system.

- Maintaining correct gas pressures can prevent gas leakage.

Touchscreen Control Interface

This manual suits for next models

1

Table of contents

Popular Paint Sprayer manuals by other brands

Gröne

Gröne HVLP Turbo 6014 operating instructions

Lafferty

Lafferty 931108FPS Installation & operation instructions

KRAUSE & BECKER

KRAUSE & BECKER 62915 Owner's manual & safety instructions

Homeright

Homeright FINISH MAX C900076 instruction manual

Homeright

Homeright Super Finish Max C800971 instruction manual

Carlisle

Carlisle DeVilbiss DV1 Service manual