1644526G (406807) 2020-SEP-2121644526G (406807) 2020-SEP-213

DATE PURCHASED __________________________________________________________________

HOIST SERIAL NUMBER ____________________________________________________________

CYLINDER SERIAL NUMBER ______________________________________________________

DEALER __________________________________________________________________

ADDRESS __________________________________________________________________

PHONE __________________________________________________________________

FOREWORD

Crysteel’s LoBoy hoists have been designed for use on single-axle trucks with cab-to-axle dimensions of

60 to 150 inches for use with bodies of 8 through 18 feet in length and on tandem axle trucks with cab-to-

tandem center dimensions of 102 to 126 inches for use with bodies from 14 to 18 feet in length. Bodies

normally used with these hoists are grain bodies and platforms. This manual contains the information

needed for the proper installation and operation of these hoists.

These instructions are for installing and maintaining all models of LoBoy hoists. With proper installation,

use, and regular maintenance, Crysteel’s LoBoy truck hoists will give many years of trouble free service.

When ordering parts, be sure to give serial number of hoist and cylinder. The serial number of the hoist

is stamped into the hoist frame near the base end of the cylinder. The serial number of the cylinder is

stamped on the barrel of the cylinder near the base. For future reference, copy these numbers NOW in the

space provided above. Order parts by number and description as given in the parts listing in this manual.

1. Engage PTO from cab and adjust engine speed to fast idle.

OPERATIONANDUSE

SOMEDO’SANDDON’TSFORSAFEANDLONGSERVICE

1. Usetheproperhydraulicuid.KEEPITCLEAN.Remembertochangeitregularly.

2. ALWAYS operate the hoist from inside the cab of the truck.

3. If the hydraulic hose connections are correct, the hoist should raise when the hoist control

lever is pulled back, hold when the lever is in the center detent, and lower when the lever

is pushed forward.

4. To raise the hoist, pull the control lever back. To hold the body in a raised position, place

the control lever in its center detent position. To lower the hoist, push the control lever

forward.

5. ALWAYS return the hoist control lever to its center detent position after each use.

6. Whenthehoistcylinderreachestheendofthestroke,oilwillowthroughtheautomatic

bypass valve built into the piston inside the cylinder and return to the reservoir.

7. It is advisable to run the PTO to “power down” or lower the hoist because this will act as

an hydraulic lock to hold the hoist in the lowered position. It is not necessary to do this,

however,becausethereservoirhassucientcapacitywhetherornotthehoistispowered

down.Youwillbenetfromtheadvantagesofthedoubleactinghoistonlyifyoupower

down.

8. To make use of the hydraulic lock feature, place the hoist control lever in the center hold

position after the hoist is powered down. This places the pressure on the valve, where it

belongs, not on the pump.

9. DO NOT LEAVE THE PTO IN GEAR WHILE TRANSPORTING. THIS CAN CAUSE

SEVERE DAMAGE TO THE PTO OR HYDRAULIC PUMP.

10.Thehydraulicsystemshouldbedrained,ushedandrelledwithproperhydraulicuid

atregularintervals.CAUTION:NEVERusehydraulicBRAKEFLUIDinthehydraulic

system.

11.Afteraddingorreplacingthehydraulicuid,cyclethehoistseveraltimestoremoveair

from the cylinders and hydraulic hoses.

2. Lubricateallgreasettingsevery100cyclesoreverytwomonths.Infrequentorinsu-

cient lubrication will cause hoist failure and possibly injury or death.

3. ALWAYS carefully block up the body, using the body prop, before working under it.

4. Do not “race” the engine when unloading.

5. Do not load the hoist beyond its capacity.

6. DO NOT tamper with the hydraulic relief valve. This will void the warranty. It can cause

severe damage to the hoist and cylinder.

7. Never leave the PTO in gear while transporting. It could ruin the hydraulic pump, the PTO

or the transmission.

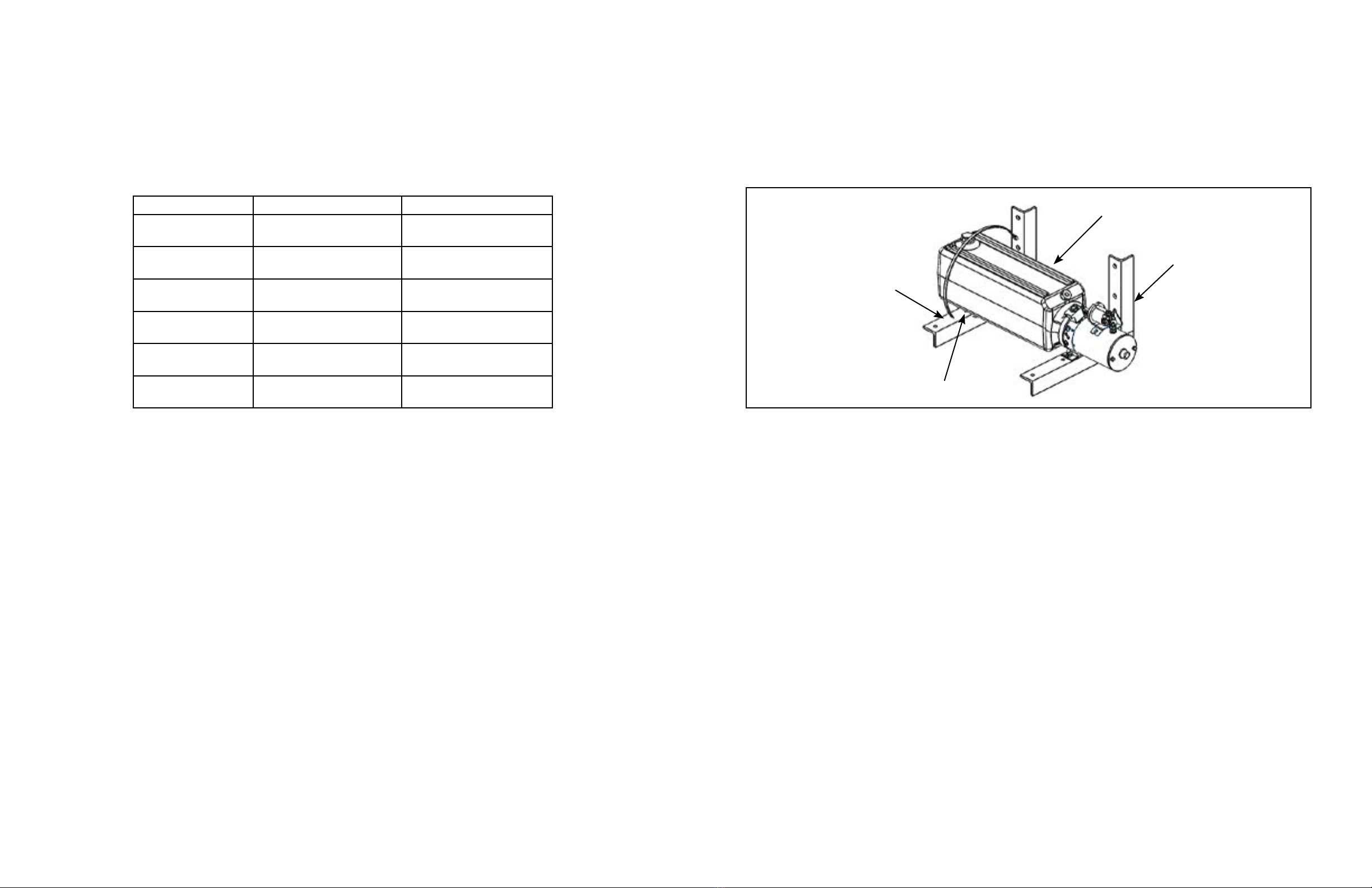

8. Checkallboltsandttingsregularly.Keepthemtight.Seetableonpage4fortorqueval-

ues.

9. Alwaysoperatehoistonarmandlevelsurface.

10. Always make sure area around truck is clear and safe for hoist operation and dumping.