Table of contents

The information herein is correct at the time of issue but may be subject to change without prior notice

1. EC Declaration of Conformity ....................................................................... 4

2. Safety .................................................................................................... 5

2.1. Important information ............................................................................. 5

2.2. Warning signs ..................................................................................... 5

2.3. Safety precautions ................................................................................ 6

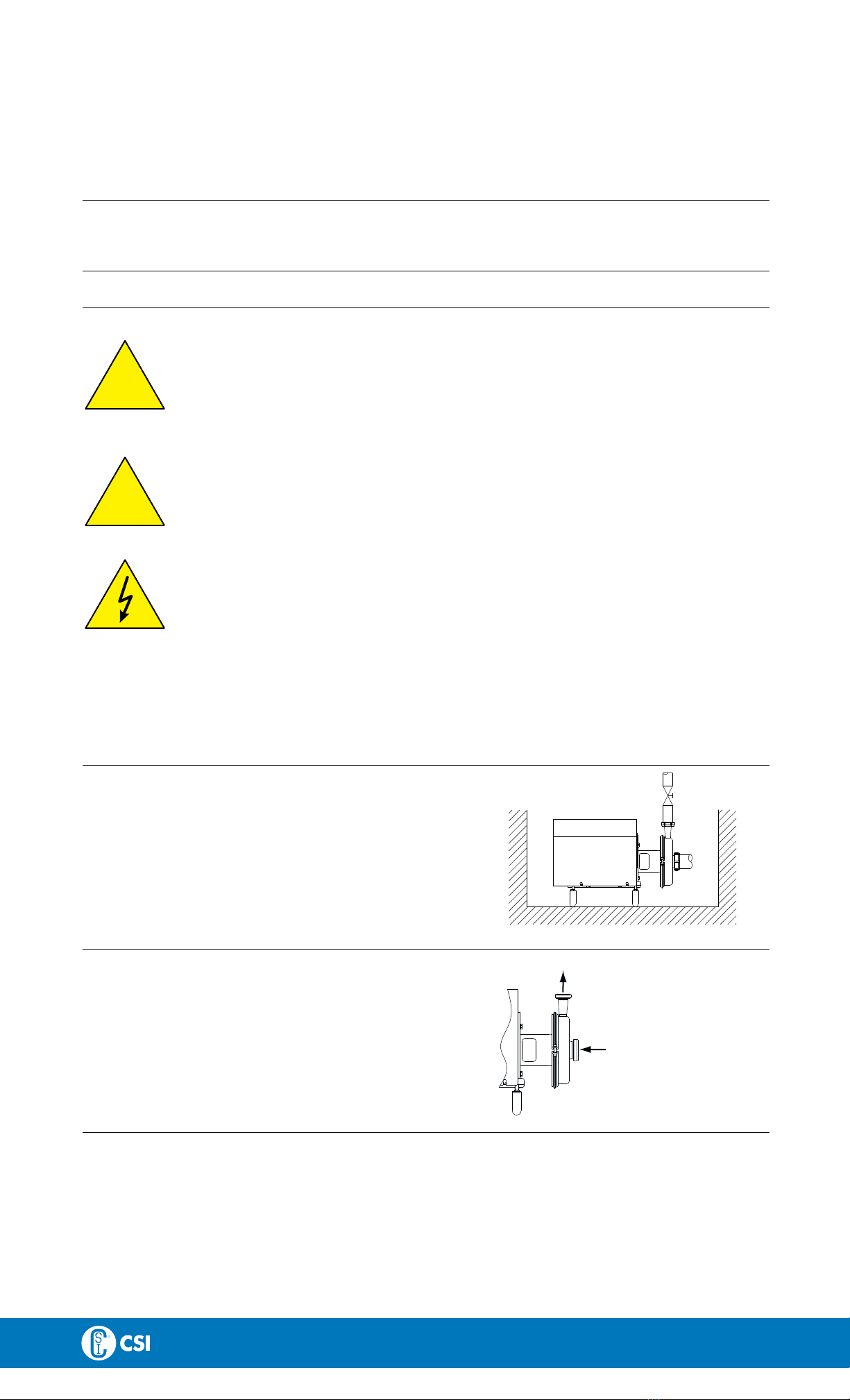

3. Installation .............................................................................................. 8

3.1. Unpacking/delivery ............................................................................... 8

3.2. Installation ......................................................................................... 9

3.3. Pre-use check ..................................................................................... 10

3.4. Recycling information ............................................................................. 10

4. Operation ............................................................................................... 11

4.1. Operation/Control ................................................................................. 11

4.2. Trouble shooting .................................................................................. 13

4.3. Recommended cleaning ......................................................................... 14

5. Maintenance ........................................................................................... 15

5.1. General maintenance ............................................................................. 15

5.2. Cleaning Procedure ............................................................................... 16

5.3. Dismantling of pump/shaft seals ................................................................ 17

5.4. Assembly of pump/single shaft seal ............................................................ 19

5.5. Assembly of pump/flushed shaft seal ........................................................... 21

5.6. Adjustment of shaft ............................................................................... 24

6. Technical data ......................................................................................... 25

6.1. Technical data ..................................................................................... 25

6.2. Relubrication intervals ............................................................................ 26

6.3. Torque Specifications ............................................................................. 26

6.4. Weight (kg) ........................................................................................ 26

6.5. Noise emission .................................................................................... 27

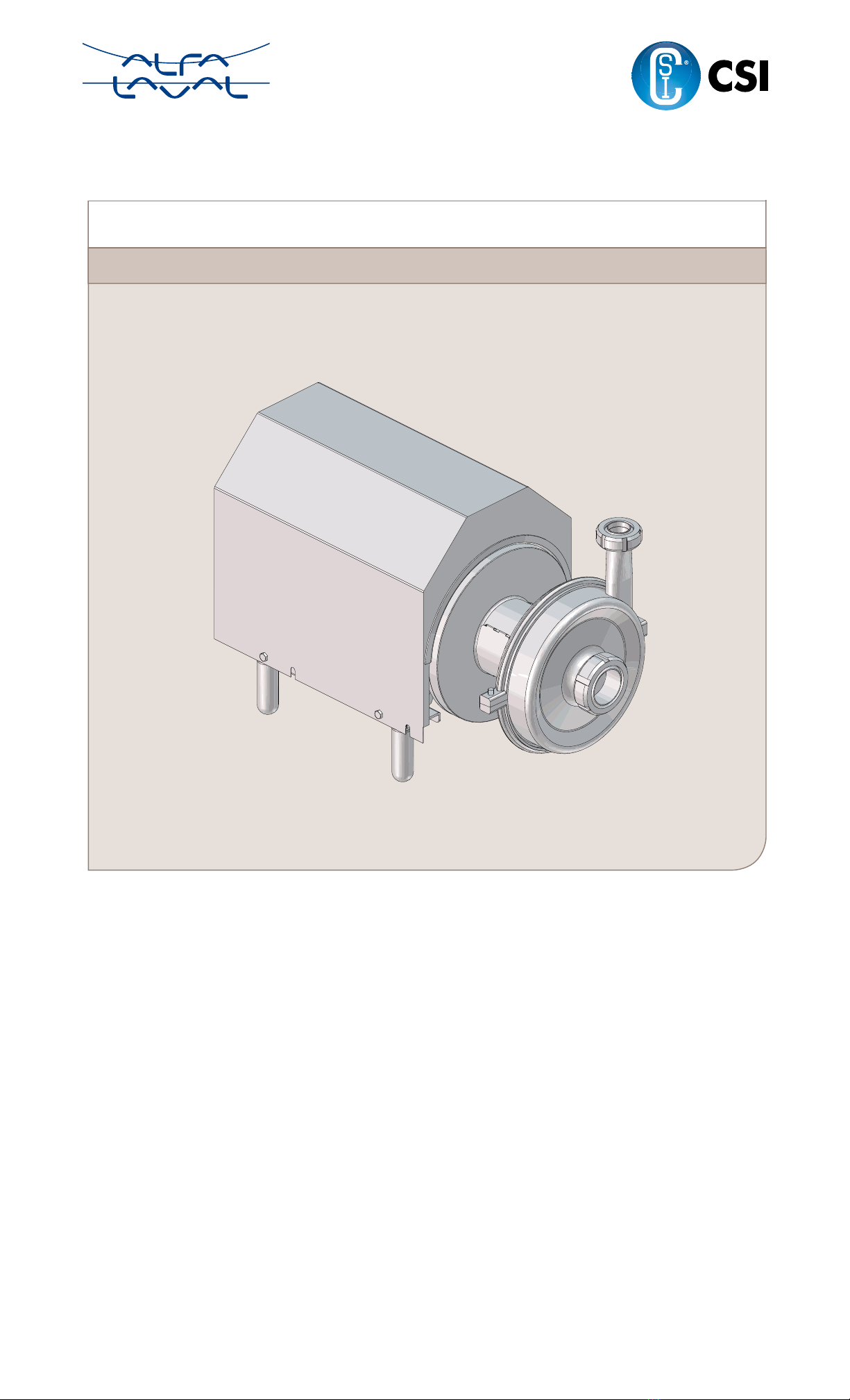

7. Parts list and service kits ............................................................................ 28

7.1. Drawing ............................................................................................ 28

7.2. SolidC - Wet end ................................................................................. 30

7.3. SolidC - Motor-dependent parts ................................................................ 32

7.4. SolidC - Shaft seal ................................................................................ 34

3