CSM SL560 GYRO User manual

CSM

SL560GYRO

Smart Lock Gyro

With their pioneering Heading Lock, Yaw Rate Demand and Gyro Flight

Mode concepts CSM revolutionised the tail rotor gyro. The SL560 uses all

new sensor and processor technology to extend gyro performance still

further.

SL560 key features:-

NNEW! Smart Lock - Enhanced Heading Lock mode that gives even

better lock & stop.

NGyro Flight Modes (as pioneered by CSM)

NSelectable Super Servo support - gives optimum update rate for

Super & Digital servos.

NQuick-setup - makes it simple to set gyro sense, servo type & servo

travel from your transmitter.

NNEW! Quick-trim - accurately corrects linkage set-up.

NBuilt-in Exponential - gives a smooth, progressive stick response.

NYaw Rate Demand - with rudder rates & throws it gives you total

control of stick sensitivity.

NCommand conditioning - removes stick bounce & improves

performance with PPM (FM) receivers.

NAcceleration Gain - gives automatic, dynamically adjusting gain

tracking.

NDual Independent Stop-Tracking - gives separate optimisation of

left and right stop quality.

NHigh Resolution pulse measurement and generation systems.

NPC interface - allows access to over 20 internal gyro parameters for

performance customization.

NTwo stage power supply regulation.

NInternal vibration damping.

NSmall, lightweight, single box design.

NOutstanding customer support & repair service.

2

Like other CSM gyros, your SL560 gyro incorporates advanced

features not found in other makes of gyro. Please read this

manual fully before installing and flying.

Radio System requirements

The wiring of this gyro is compatible with JR, Futaba, Hi-Tec, Graupner,

Robbe and the current style blue plug Sanwa/Airtronics radio systems. To

use this unit with other makes of radio please check with the service centre

gyro requires an auxiliary channel with travel adjustments to control the

gyro mode/gain. It cannot be used with basic RC systems that lack such a

channel. We recommend that you use an RC system that also provides

travel adjustment on the rudder channel. Most current production computer

RC transmitters have these facilities.

Servo choice

Servo speed

Optimum performance from the SL560 is obtained when it is used in

conjunction with a high speed Super Servo or Digital Servo (0.1 seconds/60

degrees or less). Use with slower servos will significantly reduce gyro

performance.

Super Servos

The term super servo is used to describe servos capable of running at high

data frame rates (250 frames/second or more). Examples of this type of

servo are Airtronics 94757, JR 8700G and Futaba S9253. The use of super

servos with the SL560 is highly recommended as they allow the gyro to

fully exploit its fast response. When used with this type of servo the "Super

Servo" support of the SL560 should be activated. This can be done during

the Quick-setup routine (but may also be accessed via the PC interface if

desired).

Warning: Use of the Super Servo facility with servos not designed to

accept the high frame rate will result in damage to the servo and may

cause malfunction in flight.

The Quick-setup routine runs the servo in standard mode so it is always

possible to access this routine with a standard servo even when the gyro has

Super Servo support on.

3

Standard Servos

With "Super Servo" support off the SL560 will work with any servo in the

Futaba, JR and Sanwa ranges (and many other makes) but as with any gyro

system a fast servo with a speed of 0.12 sec/60 deg. or better is to be

preferred.

Batteries, power consumption and wiring

Although the power consumption of the gyro unit itself is very modest, as

with all high performance Solid State gyro systems the speed of the gyro

response will work the tail rotor servo harder than slower mechanical gyro

systems. Especially where a high performance servo is being used the

battery drain from the tail rotor servo can be high. We recommend that

you use a good quality battery state monitor and check it carefully

before each flight.

Your receiver battery is a vital part of your tail rotor system. Remember

that a battery in a low state of charge or an old battery that has developed a

high internal resistance will adversely affect servo performance, especially

its acceleration, and may even cause the tail to wag on an otherwise well set

up helicopter. You may wish to consider maintaining the charge in your

receiver battery between flights by the use of a quality Delta Peak type field

charger. In installing the gyro also bear in mind that voltage losses down

long servo extension leads will also detract from servo performance. Where

the installation requires extensions to be used (either between the receiver

and gyro or between the gyro and the servo) avoid using ones that are

unnecessarily long.

The SL560 philosophy

To get the best from this gyro system it is useful to understand how the

SL560 differs from conventional gyros.

Conventional gyro systems

In a conventional gyro the pilot applies a rudder command which is

transmitted through the gyro to the servo. As the helicopter responds to the

command the gyro detects the movement and opposes the pilot's command

and reduces the servo deflection. The yaw rate achieved in such a system

depends on the 'gain' of the gyro. The more gain the gyro has the lower the

yaw rate that can be achieved. It is common with such systems to have to

reduce the gyro gain to achieve the required yaw rate for some manoeuvres

(this being accomplished with the gyro gain switch).

4

The SL560 system

The SL560 employs a 'Yaw Rate Demand' philosophy making it a true yaw

rate gyro. In this system the rudder command from the pilot is interpreted

as a request to the gyro to establish the desired yaw rate. The gyro drives

the tail rotor servo as needed to obtain this yaw rate. This means that the

SL560 makes full yaw rate available even at high gain settings. With this

system you can use the rudder travel adjustments ('Travel Volume', 'ATV')

and rudder rates facilities to set up the desired full-stick yaw rate and the

gyro gain switch now becomes a 'Flight Mode Switch' for the gyro. There is

no need for so called Pilot Authority Mixing - indeed you should not use

pilot authority mixing with this gyro

It is important to realise that with this system the limits to the servo travel

are set by the gyro and not by the transmitter's travel adjustment of the

rudder channel. The servo travel limits imposed by the gyro are set during

the Quick-setup sequence as described later in this manual.

Behaviour on the ground

For those used to conventional gyro systems the behaviour of the SL560 on

the ground may seem unusual.

Unlike conventional systems, it is quite normal for the SL560 in Standard

mode (mode 0) to provide full tail rotor servo movement for rudder

commands that are as little as 30% of the full stick movement. This is a

consequence of the Yaw Rate Demand feature, and is why the SL560 gives

such a crisp response.

With the helicopter on the ground and the SL560 set in Smart Lock mode

(mode 1) you will find that even very small movements of the rudder stick

will set the servo moving slowly and may, over the course of a few

seconds, reach full travel. This apparently strange behaviour is caused by

the stationary helicopter not responding to the heading corrections

requested by the gyro. In the absence of a response from the helicopter the

gyro continues to increase the servo command in an attempt to get the

helicopter to obey. In flight the helicopter will, of course, respond to the tail

servo movements and the system will act normally. In order to minimise

these movements the trim of the rudder stick needs to be very accurately

set. To do this the SL560, during its Quick-setup routine, samples the mid-

stick signal to an accuracy much finer than one click of trim. This feature

also accommodates the variations in servo pulse standards adopted by RC

manufacturers.

5

Flight Modes

The SL560 has two flight modes selectable by the transmitter gyro gain

switch (or Auxiliary channel switch). Note: A rotary knob or slider is not

recommended as it is not possible to accurately and repeatedly set the gain

with these.

Mode 0 (Standard Mode)

This mode gives flying characteristics that are similar to conventional gyro

systems. However, unlike conventional gyros, this mode operates a Yaw

Rate Demand scheme making high yaw rates available at high gain levels.

Mode 1 (Smart Lock Mode)

This mode gives both Yaw Rate Demand and Heading Lock. It provides a

much higher resistance to unwanted yawing movements than can be

obtained with a conventional gyro system. This mode has great advantages

in the following situations:

1) For the beginner, where this mode makes it possible for him/her to

almost ignore the tail rotor control in the initial hovering phase, which is

made even easier as this mode allows the tail trim to be set before the

helicopter leaves the ground.

2) For cross-wind hovering manoeuvres where the natural tendency of the

helicopter to weathercock into wind needs to be resisted.

3) For backwards flight manoeuvres and general "3D" flying.

The Standard mode may be employed for basic forward flight where the

natural tendency of the helicopter to weathercock can be helpful, especially

to the less experienced pilot. The graph (Figure 1) shows the way in which

the gyro gain channel provides both mode switching and independent gain

adjustment of the two modes. If the gyro gain channel pulse is longer than

the centre value the gyro is in Mode 0 while with the gain channel pulse

shorter than the centre value the gyro is in Mode 1. The travel adjustment

(or ATV) settings for the two switch positions of the gain channel provide a

convenient way of adjusting (from the transmitter) the gain for the two

modes. Increasing the ATV of the gyro gain channel increases the gain for

6

that mode. Please note that it is not possible to use the SL560 with basic

radio systems that lack a suitable channel for controlling the gyro gain.

Gain channel operation

The centre pulse value is set at the factory at 1.51ms. However the Quick-

setup routine will adjust the gyro centre value to accurately match that of

your particular radio system. This accommodates the different pulse length

standards adopted by different radio system manufacturers.

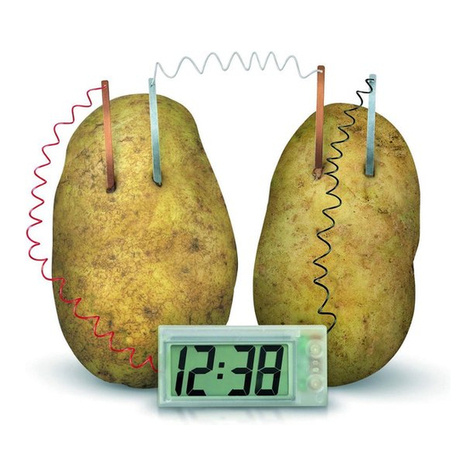

100%

centre value

0% Short pulse Long pulse

Flight Mode 0Flight Mode 1

Gain channel pulse length

Gain

(Standard Mode)(Smart Lock Mode)

Increasing gain Increasing gain

First Switch Position

Increasing gain channel ATV Increasing gain channel ATV

Second Switch Position

Gyro

Figure 1. The Gyro gain channel acts as both gyro mode switch and gain

control

Installation

Preparing the helicopter mechanics

Attention to the tail control linkage is important to getting the best from this

gyro. You should aim for an easy-moving but slop-free linkage between the

tail servo and the tail blades. Inspect the bearings/thrust races in the tail hub

for smoothness of operation. Check the pitch slider and ball links for slop

and replace if needed. Some helicopters that have noticeable 'give' in the

tail linkage may benefit from the addition of a rear-mounted tail servo and

rigid pushrod. You should also fit a long servo arm (between 15 & 20mm)

to the tail servo.

Remember that during aerobatic manoeuvres the combination of a high

performance gyro and a fast tail servo can place very high loads on the tail

rotor drive train. While you have the helicopter on the bench to install the

7

gyro is a good time to check the condition of tail drive gears, belts, pulleys

etc. Inspect them regularly to ensure that they are in good condition.

Mounting the gyro

The gyro may be mounted lengthways (longitudinally) or across

(transversely) within the model however it should have its axis of rotation

(as marked on the back of the gyro case) parallel to the main shaft of the

helicopter. For setting up you will need to see the LEDs so mount the gyro

where these can readily be seen.

Axis of rotation

Make this parallel to the

Attach to helicopter using two of the self-adhesive foam strips provided

SERVO

RUD. IN

GAIN PWR REV

SL

560

GYRO

Power indicator LED

Gyro sense reverse LED

(red) (yellow)

Mount gyro where

these are visible main shaft of the helicopter

Indicator LEDs

For high vibration environment

use four strips as shown.

SUPER

SERVO

Super Servo LED

(green)

PC

Figure 2. Gyro orientation

The gyro sensor (together with the electronics of the gyro) is anti-vibration

mounted inside the gyro case. However, to provide further vibration and

shock resistance it is important that the gyro be mounted to the airframe

using two of the double sided adhesive foam strips provided. Do not use

any other type of mounting foam as this will reduce the performance of

your gyro. Replacement strips are available as a CSM spare. For good

adhesion, ensure that the surface to which the gyro is attached is smooth,

hard and clean. As with all high performance solid state gyro systems, the

SL560 performs best if sited at a point of low vibration in the helicopter

airframe. Where possible avoid siting the gyro at the extreme front of the

radio tray for example as this area is often subject to high levels of main

rotor generated vibration. Also many plastic radio trays are too flexible and

8

better performance can often be gained by mounting the gyro at the rear of

the frames.

Radio and tail linkage adjustment

In our experience most problems with gyro systems arise from incorrect

radio set-up, incorrect servo arm length, or poor adjustment of the tail

control linkage. The following sequence is designed to avoid these snags

and ensure a faultfree installation first time. You may need to consult your

radio control system manual in order to identify the receiver channels for

the rudder and gain inputs to the gyro, however we have included

information for some commonly used systems later in this manual.

Radio Set-up

First enter the menus of your transmitter and set up the rudder and gain

channels as follows:-

NCentre rudder trims and (if fitted) rudder sub trim.

NSet rudder travel adjustment (ATV) to 90%. Most transmitters have

separate adjustments for left and right movements and you should

make sure you have set the travel adjustment for both directions. At

this stage (i.e. before the gyro has been installed) we are using this

value to help establish the right servo arm length. Once the gyro has

been installed the rudder ATV is used to set the yaw rate demand.

NEnsure that the rudder rates are set to the default value of 100%.

NSet the gain channel travel adjustment to 60% (both ways).

NEnsure that Automatic Tail Stabilisation (ATS) or 'REVO' mixing is

INHIBITED.

NEnsure that pilot authority mixing is INHIBITED.

NPut the throttle hold switch to the OFF position.

Rudder channel checks

NAt this point you should plug the rudder servo directly into the rudder

output of the receiver.

NTurn on the radio and open and close the throttle. The rudder servo

should not move as the throttle is operated. If it does, then ATS or

REVO mixing is still active. You will need to inhibit it before

proceeding further. Make sure it is inhibited in all your transmitter's

idle-up states.

9

Mid stick trim

NWith the rudder stick and trim centred make sure that servo arm is at

right angles to tail push rod.

NNow adjust push rod length until the pitch of the tail blades is about 8

degrees with the rudder stick centred. This will correspond

approximately to the pitch of the tail in the hover and ensures that the

servo will be close to its mid position in the hover. The diagram below

will help you judge 8 degrees of pitch.

8

8

0

0

Servo arm length

NWatch the tail rotor linkage while moving the rudder stick slowly fully

left and fully right. If the linkage does not approach either extreme of

the pitch linkage travel then increase the servo arm length. Conversely,

if the linkage binds at one extreme or the other then slightly reduce the

servo arm length. Re-check the mid-stick pitch set-up and repeat this

test. You are looking to achieve a servo arm length that gives full pitch

linkage movement but avoids the linkage binding or the servo stalling.

Many helicopters have pitch systems that do not give equal throw

about the hover pitch value. The SL560 has independent servo throw

adjustments for left and right which will accommodate this and fine

tuning of the servo throw is done later (in the Quick-setup routine).

Rudder control sense

NNow we must establish that the sense of the transmitter rudder control

is correct (i.e. that the application of a right rudder command causes a

change in tail pitch that will rotate the model to the right). Failure to

do this will cause an uncontrollable pirouette on take-off.

Beginners who are in any doubt on this aspect of the set-up should

seek advice. To work out which way the tail rotor will go just

remember the leading edge (front) of the tail blades will point in the

direction that the tail rotor will go, so for a left stick command you

want the tail blades to point to the right (tail swings to the right and the

nose goes left). It is vital for this test that you have the tail blades fitted

the right way around!

10

Gain channel checks

NPlug the rudder servo directly into the channel on the receiver you are

going to use for the gyro gain/mode control. (This allows us to check

for correct gain channel operation).

NOperate the gyro gain switch and observe the servo movement. If there

is no movement check that you have correctly identified the gain

channel and its switch.

NNow move the rudder stick over its full range and observe the servo. If

it moves then pilot authority mixing is still active. Disable it and repeat

this test.

Connecting the gyro

NIt is now time to connect the gyro into the system. Power down the

radio and connect the servo to the gyro's output and connect the gyro's

rudder and gain inputs to the correct receiver channels.

NPower up, and wait until the red gyro power LED comes on

(approximately 5 seconds).

NMove the rudder stick and check that the servo swings both ways. If it

swings the same way for left and right stick movements you have the

rudder and gain inputs of the gyro transposed. Connect rudder and gain

inputs correctly and repeat this test .

NWe must now identify which gain switch position gives mode 0 and

which gives mode 1. The flight modes can be identified by the

different way the servo reacts in the two modes. For both gain switch

positions hold the rudder stick at full travel for two seconds and

release to centre. If the servo returns close to mid position the gyro is

in Standard mode (mode 0), while if the servo stays at or near full

travel the gyro is in Smart Lock mode (mode 1). For future reference

note which switch position corresponds to which mode.

You should now have your gyro installed and have your radio and tail

linkage set up correctly and may now proceed with the Quick-setup routine

as described below.

11

The Quick-setup routine.

The unique Quick-setup facility of the SL560 allows the important

parameters of Rudder stick centre, Gyro sense, Servo type and Travel limits

to be quickly and simply set up from the transmitter. The set-up is stored in

the gyro's non-volatile memory so the routine will only need repeating if

one of these parameters needs to be changed.

Before entering the Quick-setup routine it is important that:-

NAll forms of mixing to the tail rotor channel (i.e. Automatic Tail

Stabilisation, or throttle to tail rotor mixing) are inhibited.

NThe trim and sub trim of the tail rotor channel are centred.

NThe tail rotor servo operating sense has been correctly set in the

transmitter. Failure to do this will cause an uncontrollable pirouette

on take-off. Beginners who are in any doubt on this aspect of the

set-up should seek advice.

NThe correct operating sense can be established by looking at the tail

rotor blades. With a left tail rotor command held on, the leading edge

of the tail blades are pointing to the right (see Figure 3)

For LEFT TAIL COMMAND

the leading edge of the

tail blades point to the

RIGHT (as shown here)

For RIGHT TAIL COMMAND

the leading edge of the

tail blades point to the

LEFT (as shown here)

Figure 3

Getting

tail servo

operating

sense

right.

If the tail blades move in the wrong direction the condition of the servo

reversing of the tail rotor channel should be changed and the movement of

the tail blades re-checked.

12

Performing the Quick-setup

To access the Quick-setup you toggle the gain switch a couple of times

during the gyro boot-up time (this is the first few seconds after the radio

system is switched on). The gyro acknowledges this by zipping the servo

back and forth a couple of times before parking it in the mid position. The

gyro also samples the mid-stick pulse width at this time so you need to

have the rudder trim set to centre before entering the Quick-setup. Make

sure you do not touch the rudder stick at this time. For maximum

accuracy turn on the transmitter and allow a few seconds for it to settle

before turning on the receiver and starting the Quick-setup. If low gain

values (less than 35%) are set the gyro may not enter the Quick-setup.

Gyro sense reversing

The first item to be set is the gyro sense reversing. Check that the yellow

"REV" LED turns on and off as the rudder stick is moved fully left and

right. Now, if the servo operating sense has been set correctly as

described previously, simply push the rudder stick to the left and release

it back to the middle. This will set the gyro sense to match your system.

The servo will travel over to allow the user to check that left tail command

is indeed being given and once this has been checked the gyro sense is

'entered' by toggling the gain switch once (i.e. into mode 0 and back to

mode 1) The gyro will 'zip' the servo back and forth in acknowledgement

and again park the servo in the middle.

Super servo support

Now set the Super Servo support. By pushing the stick left and right you

will observe the green "SUPER SERVO" LED turns on and off. Just select

super servo on or off as required (LED ON = SUPER SERVO ACTIVE).

Having done so, release the stick to the middle and enter the super servo

condition by toggling the gain switch. This will be acknowledged as before

by zipping the servo back and forth.

Servo travel limits

Following the acknowledgement the servo travels over to the first travel

limit and this can now be adjusted. Hold the stick over in the direction of

the servo deflection to increase the limit or hold it over against the

deflection to reduce the limit. The servo will move as you change the limit

and with its slow movement it is possible to set the limit very accurately.

13

When the correct limit has been found enter this value by toggling the gain

switch. Once again an acknowledging 'zip' is given. Now the servo travels

over to the remaining travel limit. Adjustment and entering is the same as

the first limit. Once this limit has been entered the Quick-setup routine is

complete. A double acknowledgement is given to show this and the servo

will centre, and the gyro will halt with no activity until the power is cycled.

Restart checks

For the set-up changes to take effect the gyro must be turned off for about 5

seconds and turned on again. At turn on the gyro takes approximately 5

seconds to re-boot. Having re-started the system check the operation of the

tail servo for rudder inputs and helicopter movements. Do this for both

flight modes. It is important to check the gyro operating sense. To do this

simply set the gyro in mode 1 (Smart Lock mode) and rotate the helicopter

90 degrees to the right (clockwise as viewed from above) then look at the

tail blades. These should have their leading edges pointing to the right.

Quick-trim reset

The Quick-trim value is zeroed when the gyro enters the Quick-setup

routine. This allows you to assess the error in the tail linkage adjustment

during the Quick-trim procedure.

14

Information on popular radio types.

The SL560 is designed to accept a wide range of radio system parameters

(frame rate, servo pulse timings etc.) however it is not possible to provide

information as to channel usage and radio set-up details for all

manufacturers' equipment. The information below covers some popular

systems. If you wish to use this gyro with other types of radio system

please consult your radio manual. In case of difficulty please contact your

radio manufacturer or the CSM technical department (Email: tech@csm-

ltd.co.uk) for advice. Connect the gyro to your receiver as indicated in the

following table:-

Radio

Type

Gyro "RUD IN"

connect to

Gyro "GAIN"

connect to

J R "Rudd" "Gear", "Aux2" or "Aux3"

Futaba Channel 4 Channel 5 or Channel 7

Connect the "SERVO" output to the tail rotor servo.

JR PCM10S/SX

Set-up with 'code 44' disabled

On these radios it is easier to disable the JR 'code 44' (gyro sense adjust)

and control the gyro gain by a switch. In this case the gain for the two gyro

modes is adjusted by the two travel adjustment values for the gyro channel.

Initial values of 60% should be used.

Set-up with 'code 44' enabled

If you wish the gyro to switch automatically between mode 0 and mode 1

as the Flight Mode (Idle Up) switch is operated you will need to enable the

JR 'code 44' gyro sensing facility.

When using 'code 44' you should remember that the SL560 gain control

works from the centre of the channel outwards. As a consequence an LCD

value of 50% (the channel centre) is in reality zero gain (the switchover

point between the two gyro modes). Increasing the value above 50% will

increase the gain in one flight mode while the other mode is adjusted by

decreasing the value below 50%: be aware that this value will be reversed

so that an LCD value of 25% will actually be a higher gain value than a

LCD value of 30%. Note: if the gyro is adjusted through the JR gyro

software, the gyro channel travel adjustments should be set to equal values

15

each way. Initially set them to 100% and only increase them if you run out

of gain adjustment with the code 44 parameters. The starting point should

be with the code 44 parameters set to 10% and 90%.

JR X388S/X3810/X8103

On these radios it is easier to control the gyro gain through the gear channel

as it is not always possible to have control over other channels on a 2

position switch. Note: if so desired it is possible to set the gyro up using the

JR gyro software on the 3810/8103, see the PCM10 instructions above.

Futaba 9ZHP/ZAP

This transmitter gives independent gyro gain values for each of the idle up

states (& throttle hold) and for both gyro modes (i.e. eight gain values in

all). If you use different head speeds in each idle up state you should

optimise the gyro gain separately in each idle up state. However initially all

the flight conditions should have the same gyro configuration. To check all

the flight conditions you will need to go into the various menus mentioned

below and turn throttle hold on and off and then try each of the idle up

positions in order to see the status for all the conditions (see your ZAP/ZHP

manual for more detail). First ensure that in all flight modes the gyro sense

mode is set to INHIBIT. To do this go to the "GYR" entry of the

"helicopter condition" menu and for each flight condition press the INH

key to select the INHIBIT state. Then press END to exit the gyro sense

menu. Now check under the "PMX" entry that no throttle to rudder or

rudder to gyro mixing is active in any of the flight conditions. Then check

in the "P->R" entry that pitch to rudder mixing is inhibited. Now enter the

"ATV" menu. Press "RUD" to select the Rudder channel and for all flight

modes make RATE A and RATE B equal to 90%. Then press "GYR" to

select the Gyro menu and set RATE A and RATE B to 60% for all flight

modes. Press END to exit the ATV menu.

Now press "MDL" to enter the "model menu". Use the "FNC" entry to

allocate the gyro control to a switch of your choice. Finally use the "SRV"

menu to check that the gyro gain behaves as required in all flight modes

and both gyro modes.

Sanwa RD6000

This particular radio demands a slightly different set-up than normal

although it may be used with the CSM SL560. There are no spare

switchable channels on the RD6000 so to change gyro mode you will have

16

to use one of the flight mode switches. There are three flight modes

Normal, Flight Mode 1 and Flight Mode 2. There is no switch either for

throttle hold and this function is usually achieved by using Flight Mode 2

(see the transmitter instruction manual).

This leaves the flight mode 1 switch available for gyro mode switching, the

gyro channel will also be used. The SL560 gyro is plugged into the rudder

channel and the auxiliary lead from the gyro is plugged into the gyro

channel in the receiver, (Channel 5). The way in which it will operate will

be as follows: the gyro can be set for example to operate in conventional

mode when in Normal Flight Mode with a gain of +70%, and then in Smart

Lock Mode with a gain of -70% when in Flight mode 1. Depending on

whether or not you have a driven tail during autos will determine what

value you will need to use in Flight Mode 2 which will be Throttle Hold

Mode.

You should experiment with settings until you are satisfied. The rotation or

pirouette rate will still be controlled by the use of EPA** on the rudder

channel, and should be set to about 60% initially for both left and right

throws. This can be increased after flight testing if you require a quicker

rotation rate. The SL560 Quick-setup routine can still be utilised by

toggling the Flight Mode 1 switch a couple of times to enter this mode.

** EPA =End Point Adjustment. See the RD6000 instructions for details.

Flying the gyro

When competition levels of heading stability are needed we recommend

that the receiver of the model is turned on for about 3 minutes immediately

before use.

Turn-on sequence

1. Turn on your transmitter.

2. With the model stationary on the ground turn on your receiver.

3. Wait while the gyro goes through its self test/boot up sequence and the

red Power LED comes on.

4. Move the rudder stick fully in both directions and ensure that the tail

rotor servo responds to stick movements. (Do not move the gain

switch until the boot up is complete unless you wish to enter the

Quick-setup routine)

5. Your SL560 is now ready for flight.

17

!! Make sure the model is not moved during the gyro

self test period. !!

Initial flight trials

We suggest that you reduce the rudder travel adjustments in your

transmitter to 80% for the first few flights until you get used to the

response of the gyro system. If you run a very high head speed or your tail

servo is slower than 0.12sec/60 degrees you may wish to reduce the gyro

gains to 50% for these initial tests.

Mode 1 Gain setting

First select Flight mode 1 (Smart Lock mode) and hover the helicopter. Use

short small 'stabs' of rudder control to disturb the helicopter in yaw and

observe. If some tendency to oscillate is seen, slightly reduce the gyro gain.

Conversely if no tendency to oscillate is seen try increasing the gain. You

are looking at this stage for the highest gain that gives no sign of oscillation

when the tail is disturbed by sudden changes in tail command. Once you

have adjusted the mode 1 gain to your liking set your transmitter to give the

same gain value for Flight mode 0. This value may be refined later but first

we need to adjust the mode 0 trim with the Quick-trim procedure.

Quick-trim

Note:- Even if you do not wish to fly in mode 0 it is important for

optimum performance that you go through the Quick-trim procedure.

The Quick -trim facility allows the gyro to correct for imperfections in the

mechanical adjustment of the tail pitch linkage. While hovering in calm

conditions, switch to Flight mode 0 (Standard mode) and you will probably

find that the helicopter will start to rotate because of slight imperfections in

the servo linkage adjustment. Do not try to correct this with the

transmitter trim. While hovering or in slow forward flight simply switch

the gyro mode/gain switch on your transmitter back and forth five times

between the two modes. Hold each mode for about 1 second. The right

timing for this is easily obtained by counting the clicks of the switch out

aloud to yourself as you do it. If the adjustment of the tail linkage is within

a reasonable range of the correct setting the Quick-trim will now

compensate for the residual trim error and the trim state of mode 0 should

match that of mode 1. Repeat the Quick-trim sequence several times to

allow the gyro to home in on the perfect trim. If, having repeated the

18

Quick-trim several times, you still observe a trim difference between the

modes this means that the adjustment of the tail linkage is outside the limits

of the Quick-trim system. Do not move the trim on the transmitter but

observe the direction of the trim error in mode 0 and adjust the tail pushrod

length to correct it. If the trim error in mode 0 causes the helicopter to

rotate anticlockwise (a leftward trim error) adjust the linkage length to put

more right tail pitch on and vice versa. Once the pushrod length has been

changed you will need to repeat the Quick-trim routine for the gyro to

adjust to the new mechanical set-up.

If you make changes (e.g. to the hovering head speed) that may affect the

tail trim you should repeat the Quick-trim procedure. The Quick-trim is

zeroed by the Quick-setup routine.

Mode 0 Gain setting

You may now adjust the mode 0 gain in the same way as described for

mode 1 above.

You should now check both modes for tail wagging in fast forward flight.

Should this be observed, you should lower the gyro gain slightly.

Stop Optimisation

Further improvement to the pirouette stop quality can often be gained by

adjustment of the linkage geometry and the gyro's Stop-Tracking controls

and acceleration gain. These are accessed by the PC interface. Please refer

to the PC interface manual for more detail.

Adjusting the stick response

After initial setting use the rudder ATV, Rates, and Exponential facilities of

the transmitter to tailor the control response as required. Beware that the

SL560 makes high rates of yaw available (at all gain settings). If an

increase in available yaw rate is required increase the rudder travel on your

transmitter gradually until the desired response is obtained. Remember that

increasing the rudder travel adjustment will not increase the overall tail

servo throw as this is set by the gyro's own travel limiters.

The SL560 has built-in exponential. This reduces control sensitivity around

the mid-stick position. Remember that the ATV and rates facilities work

together so that setting the rudder ATV to 80% in both directions and also

setting a rudder rate of 60% will give a total rudder throw of 0.8 x 0.6 =

0.48 = 48%

19

Automatic Tail Stabilisation (ATS)

This should not be used with the SL560 gyro

Pilot Authority Mixing

This should not be used with the SL560 gyro.

Tail rotor dynamics

To realise the full benefit of the SL560 it is important to have a basic

understanding of the dynamics of the tail rotor system. It is a common

misconception that the higher the electronic gyro gain is, the better the

system will work. Whilst this is generally true, the electronic gain is only

one part of the tail rotor system and of equal importance is the amount of

tail pitch range available, and the tail rotor disk size. The disk size is also

related to the tail rotor speed. Of course there are other influences on the

tail system but these are the most important and can be grouped together as

mechanical gain.

If the mechanical gain is not correct, then the gyro will not be able to

function to its best ability. For this reason it is important to select the

correct size servo arm that will give maximum tail pitch movement without

stalling the servo. In most helicopters this will be an arm of between 15 and

20 mm radius. Note: As the servo travel limits are set during the Quick-

setup routine, increasing the rudder travel adjustment will not increase the

servo throw as this is limited electronically in the gyro. The rudder travel

adjustment is used instead to adjust the rotation rate.

Tail blade size

The correct length of tail blade can only be selected by flight testing. There

are 2 types of test to ascertain the correct size:

1) With the model in the hover at its normal flight rpm, making sure the

gyro is in Smart Lock mode, make a rapid vertical climb for 50 to 60 feet:

there should be no discernible rotation of the model. If the tail does not

maintain its position this is a good indication that the diameter is too small.

Note: if the model is over pitched and there is a noticeable drop in rotor

rpm during the climbout, then this will invalidate the test as the tail would

probably not be able to cope with this situation regardless of the set-up.

2) This test is only really necessary for those who wish to do advanced

aerobatics/3D flying and should only be carried out those who are confident

20

to do so. With the model at a safe height fly the model sideways, starting

slowly and building up speed until it reaches its maximum possible speed:

a)If the tail manages to hold its position then the blade length is OK.

b)If the tail starts to lag behind, then either more pitch is needed (if the

mechanical limits haven't already been reached) or longer tail blades.

c) If the tail swings round suddenly and cannot return to the correct position

then the tail rotor is stalling and longer tail blades are needed.

Boom supports

Tests have shown that the use of boom supports significantly increase the

rigidity of the tail boom and so allow a higher gyro gain to be used.

Generally the longer the boom supports the better they will work. Note: A

loose/cracked boom support or a loose/cracked boom support clamp can

have a significant effect on the gyro gain. Even a slightly loose boom

clamp or support will have a dramatic effect on the amount of gain that can

be used. Stand on the skids of the model and try to flex the end of the boom

from side to side while holding a finger against the joint to feel any

movement.

Humidity

Under conditions of extremely high humidity it is possible for condensation

to form on the sensor. This can adversely affect gyro performance. Where it

is not possible to avoid subjecting the gyro to such humidity levels it is

advisable to leave the model standing for a few minutes with the radio

switched on so that the internal heating of the gyro helps disperse the

condensation. Always protect the gyro from ingress of water (e.g. rain).

Table of contents