CSN Turbo-Tech CIRC-3 Service manual

www.csnglobal.com.au

Turbo-Tech CIRC-3 Pump & Bridge Control

Installation & Instruction

Manual

IMPORTANT AFETY IN TRUCTION

When installing and using this electrical equipment, basic safety precautions must be

followed.

1. READ AND FOLLOW ALL IN TRUCTION .

2. WARNING - To reduce the risk of injury, do not permit children to use this equipment unless they

are closely supervised at all times. This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities, or lack of experience or knowledge,

unless they have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety. In order to avoid the possibility of hyperthermia (heat stress) occurring, it

is recommended that the average temperature of spa pool water should not exceed 40 degrees C.

3. CAUTION – Connect only to a circuit protected by a Class A Safety Switch. This equipment shall be

located out of reach of a person in the tub.

4. FOR PA & HOT TUB U E ONLY – This equipment was specifically designed for use on spas

and hot tubs only in conjunction with an approved spa control system. For other applications consult

the manufacturer.

5. WARNING: Risk of Electric hock. (For pa & Hot Tub Use)

Ensure this equipment is installed out of reach of persons in the spa or hot tub. For safety, this

equipment is intended to be installed in an enclosure that requires the use of a tool to gain access to

the equipment. Also ensure the equipment is adequately fixed into position. Install in accordance

with these installation instructions and wiring diagram.

6. AVE THE E IN TRUCTION .

CAUTION

To reduce the potential risk of fire, electrical shock, or injury to persons:

1. All electrical wiring (both installation & repair) must be done by a licensed electrician and in

accordance with local, provincial, and national ordinances.

2. No modifications, additions or deletions should be made to this equipment.

3. When servicing, be sure the power is off before accessing this equipment.

4. Do not use cables or connections other than the ones supplied with this equipment. If the supply cord

is damaged, it shall be replaced by the manufacturer or its service agent or similarly qualified person

in order to avoid a hazard.

CIRC-3 VARIABLE PEED PUMP IN TALLATION

GENERAL

Your TURBO-TECH CIRC-3 pump has been quality built and engineered to give maximum energy efficiency under

normal spa water pumping conditions. Consult the manufacturer for any other applications.

LOCATION OF PUMP

For the best pump performance, locate the system as close to the water source as possible, preferably in a dry

position lower than the spa water level. Make sure the pump has adequate ventilation, is well fixed at the base plate

provided and is not accessible to persons whilst in the spa. Provide adequate access around the pump for inspection

and maintenance.

PLUMBING CONNECTION

Fit the pump to your plumbing scheme using the 40mm (1.5”) Quick Connect Unions provided. Ensure Union

O’Rings are clean. Lube with silicon based lubes only (DO NOT USE PETROLEUM BASED LUBRICANTS). Hand

tighten Unions only. Do not over tighten.

TARTING & PRIMING PUMP

Do not run unit dry. Always be certain that the pump casing is filled with water before starting the unit. Allow a

reasonable amount of time for priming. If the pump will not start or will not prime, see troubleshooting section in this

manual.

www.csnglobal.com.au

MAINTENANCE

Keep motor clean. Ensure that louvered openings and cooling fins are free from dust and debris to avoid

overheating. Over a period of time the shaft seals may become damaged or worn and must be replaced.

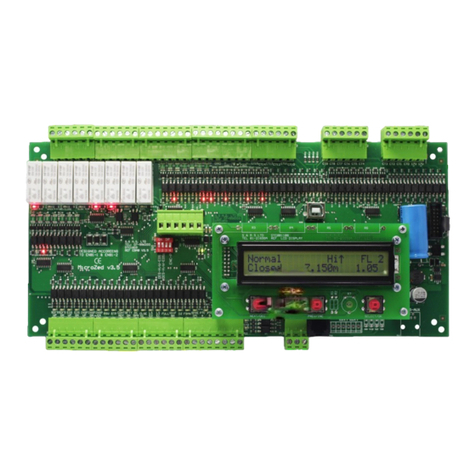

CIRC-3 BRIDGE CONTROL IN TALLATION

GENERAL

Your CIRC-3 Bridge Control is engineered to interface your variable speed pump with your spa control system. The

CIRC-3 Bridge receives signals from the spa control system and from these signals interprets the various modes the

spa control system is in (i.e. filtration, heating, turbo jet action). The bridge Control then sends instructions to the

Circ-3 variable speed motor to select the most appropriate, energy efficient speed for the motor to run at for that

particular mode.

LOCATION OF BRIDGE CONTROL

The CIRC-3 Bridge Control should be located and fixed in a convenient position between the CIRC-3 variable speed

pump and the spa control system. Make sure the Bridge Control is not accessible to persons whilst in the spa.

Provide adequate access around the Bridge Control for inspection and maintenance.

ELECTRICAL CONNECTION

The CIRC-3 Bridge Control is provided with all the cables necessary to connect between the variable speed pump

and the spa control system. The following diagram illustrates the various cables and connections necessary.

TARTING & OPERATING CIRC-3 Y TEM

Circ-3 incorporates sophisticated electronics to control and deliver the various quiet, energy efficient features

designed into this product. Once all the cable connections have been made and the pump primed, turn on your spa

control system and bridge control via the spa mains isolating switch. Set your spa control system as per the spa

control manufacturer’s recommendations incorporating your personal preferences in regards to time, filtration cycles,

desired water temperature, equipment fitted etc. Please note, for the “Pump 1” outlet, you need to set this in the

“2 Speed Pump” configuration as per the spa control system manufacturer’s instructions.

www.csnglobal.com.au

The CIRC-3 Bridge will now start its boot up process. As part of the boot up process when Turbo-Tech Circ-3 is

started from a power off status, a full systems check automatically occurs. This process may take up to 5 seconds to

complete after the initial power up. The variable speed motor will then start. The CIRC-3 Bridge will determine what

mode the spa control is in and select the appropriate speed for the variable speed motor to run at. A manual input by

the spa user to the “Pump 1” button on the spa control keypad for high speed (Turbo Jet action) will cause the Bridge

Control to tell the motor to run at full speed. A second input will cause it to go back to either a heating or filtration

mode speed.

IMPORTANT NOTE

After the spa control system calls for Pump 1 to turn off completely, the Bridge Control

must be given a chance to reboot after a manual input for the pump to re start is made.

Therefore under these conditions, please allow 5 seconds after pressing

the Pump 1 button for the motor to start. Continuous inputs to the Pump 1

button within the 5 second delay will disrupt the boot up and delay or confuse the start

up process. If this occurs, refrain from any further inputs for one to two minutes, and

then start the process again, this time allowing the system 5 seconds to start.

TROUBLE HOOTING

MOTOR WILL NOT TART:

1. Check circuit breaker.

2. Check cabling is correctly fitted as per wiring instruction.

3. Check for loose connections.

4. Check spa control system is correctly configured with the “Pump 1” outlet set to “2 Speed”.

5. Check for any error symbols on the spa control system and follow manufacturer’s recommendations

for any of those error messages.

MOTOR OVERHEATING AND/OR HUTTING DOWN:

1. Check for incorrect cabling and/or loose connections.

2. Make sure motor gets adequate ventilation and is free from debris.

3. Make sure ambient temperature where motor is located is not exceeding 50 degrees C.

MOTOR MAKING HUMMING NOI E BUT WILL NOT TART:

1. Check for debris causing the pump impeller to jam.

NOI E:

1. Check plumbing vibration.

2. Check for cavitation due to air leaks, obstruction, undersized suction or dirty filter element.

3. Check for debris in the pump wet section.

PUMP WILL NOT PRIME:

1. Make sure pump is installed at the proper level and the plumbing lines have been correctly installed to

allow water to freely enter the pump.

2. Open Air Control valves to release any possible air lock.

3. Loosen off pump discharge union SLIGHTLY whilst motor is running to bleed off any air locked in the

pump wet section. Retighten once water appears.

4. Make sure all suction and discharge lines are clear and unobstructed and all valves are open.

5. Check for air leaks in the suction line.

LOW WATER FLOW AT HIGH PEED:

1. Check for clogged plumbing lines or dirty filter element.

2. Check for worn or damaged impeller.

3. Check to ensure motor is transitioning correctly between its 3 speed options.

WATER LEAK

1. Check for contamination or damage to the shaft rotary seal. Replace if necessary.

2. Check union compression fittings; make sure they are properly aligned and secure. Hand tighten

only. Do not use tools.

3. Make sure O’Rings are properly seated, free from contamination and not damaged.

www.csnglobal.com.au

BRIDGE CONTROL DOE NOT TRAN ITION PEED CORRECTLY OR A REQUIRED:

1. Check that cabling is installed correctly in accordance with the wiring diagram.

2. Check to ensure all connections are not loose.

3. Make sure Spa Control System is configured for a “2 Speed Pump” on the “Pump 1” outlet.

4. Make sure spa control system is correctly programmed and configured for filtration maintenance and

heating cycles.

5. Check for a clean power supply to the Bridge Control.

6. Check circuit breakers.

7. Make sure the pump is given 5 seconds to start from an “OFF” status before making further inputs to

the “Pump 1” button on the spa control keypad. Further inputs made within the 5 second boot up

period WILL disrupt the start up and transitioning process. If this happens, make no further inputs for

1 to 2 minutes to allow the system to stabilise, then press the “Pump 1” button once and wait 5

seconds for motor to start before making any further inputs.

WARRANTY

CSN Global Pty Ltd extends to the original purchaser only, a warranty for a period of 12 months, that the products

they manufacture are free from defects in material and/or workmanship (pump seals 30 days) from the date of

purchase. If within 12 months, any such product shall prove defective, it shall be repaired or replaced at CSN

Global’s sole option and discretion as follows:

•The original retail purchaser shall first contact the installing dealer, as soon as possible after the discovery

of the defect, but in no event later than the expiry date of this warranty.

•The Dealer shall then advise CSN Global of the claim including the model number, serial number and date

of purchase for the defective item.

•The Dealer/retail purchaser shall present evidence to verify the date of purchase.

•CSN will advise the dealer of the address to which the defective item may be returned.

•CSN will repair or replace the defective item, at its sole discretion and return it to the dealer.

•Transport costs are not covered by this warranty and must be paid by the consumer.

•This warranty does not restart in the event of a product defect. The warranty expires 12 months from the

date of purchase, regardless of any corrective action taken by CSN on defects reported to them within the

warranty period.

EXCLU ION

1. The warranty shall not apply to failures resulting from negligence, abuse, misuse, misapplication,

improper installation, alteration or modification, chemical corrosion, or improper maintenance.

2. Any items manufactured by other companies and used by CSN may carry warranties by the original

manufacturers.

3. CSN is not liable for incidental or consequential damages, loss of time, inconvenience, incidental

expenses, labour or material charges in connection with removal or replacement of the equipment.

CSN is not responsible for any implied warranties or representations by others and the foregoing warranty is

exclusive and in lieu of all warranties provided therein.

Some states and territories do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

Table of contents