Bartington CU1 User manual

www.bartington.com

INNOVATION IN MAGNETICS

Telephone: +44 (0)1993 706565 •Fax: +44 (0)1993 774813 •Email: [email protected] •Website: www.bartington.com

Bartington Instruments Ltd

5, 8, 10, 11 & 12 Thorney Leys Business Park

Witney, Oxford, OX28 4GE. England

®The copyright of this document is the property of Bartington Instruments Ltd.

Bartington is a registered trademark of Bartington Instruments Limited in the following countries: Australia, Brazil, Canada, China, European Union, India,

Israel, Japan, Mexico, New Zealand, Norway, Russia, Singapore, South Korea, Switzerland, Turkey, United Kingdom, United States of America and Vietnam.

Operation Manual for

CU1 Helmholtz Coil System

Control Unit

OM3224/4

BARTINGTON INSTRUMENTS

Page 2 of 21 OM3224/4

Table of Contents

1. About this Manual 3

1.1. Symbols Glossary 3

2. Safe Use 4

3. Introduction 4

4. CU1 Features 5

4.1. Front Panel 5

4.1.1. ON/OFF Power Switch with LED Indicator 5

4.1.2. Front Panel Connectors 5

4.2. Rear Panel 6

4.2.1. Rear Panel Connectors 6

5. Compatibility 6

6. CU1 Control Unit Installation 7

6.1. Test Assembly Location and Ventilation Requirements 7

6.2. CU1 Control Unit Connection to the PA1 Power Amplifier 7

6.2.1. Current Control Output 7

6.2.2. Current Monitor Input 7

6.3. Sensor Connection to CU1 Control Unit Device Under Test Input 7

6.4. Sensor Connection to CU1 Control Unit Auxiliary Input 8

6.5. CU1 Control Unit Connection to NI Acquisition Card 8

6.6. CU1 Control Unit Mains Power Supply 8

7. Powering Sequence 9

8. Troubleshooting, Care and Maintenance 9

9. Storage and Transport 9

10. Disposal 10

10.1. Waste Electrical and Electronic Equipment (WEEE) Regulations 10

Appendix A: Connecting the Components of the Helmholtz Coil System 11

Appendix B: Helmholtz Control Unit CU1 DAQ/PXI Connection 12

Appendix C: Guidance for Connection to Mains Supply 20

BARTINGTON INSTRUMENTS

Page 3 of 21 OM3224/4

1. About this Manual

This manual provides the information necessary to help customers install and operate the CU1

Control Unit. It is one component of the Bartington Instruments Helmholtz Coil System. This

manual should therefore be read in conjunction with:

• Compatible Helmholtz Coils Operation Manuals

• PA1 Control Power Amplifier Manual OM3225

• CU2 Closed-Loop Module (if applicable) OM3999

• Helmholtz Coil Control Software OM3596.

All manuals are available from the Helmholtz Coil System Operation Manual page. The relevant

products outline drawings can be found on the Helmholtz Coil System outline drawing page.

This manual should also be read in conjunction with the product brochure DS2613 which can

also be found on the product page.

Photographs of key components are included, labelled with numbers. A number in the text in

square brackets [ ] refers to that label.

Bartington Instruments cannot advise on the integration of this equipment with any third party

products.

1.1. Symbols Glossary

The following symbols used within this manual call your attention to specific types of

information:

WARNING: Indicates a situation in which serious bodily injury or death could result if the

warning is ignored.

Caution: Indicates a situation in which bodily injury or damage to your instrument, or both,

could result if the caution is ignored.

Identifies items that must be disposed of safely to prevent unnecessary damage to the

environment.

Note: A paragraph in this format provides useful supporting information on how to make

better use of your purchase.

BARTINGTON INSTRUMENTS

Page 4 of 21 OM3224/4

2. Safe Use

WARNING: The CU1 Control Unit is powered by mains electricity and contains uninsulated

parts. Ensure that the unit is properly earthed at all times. Ensure all local and national

codes on electrical installation and grounding are observed. Safety protection will be

impaired if the unit is used in a manner not specified in this manual.

WARNING: There are no customer serviceable components within this unit. The unit

should be opened by Bartington Instruments personnel only.

WARNING: This product is not qualified for use in explosive atmospheres or life support

systems. Consult Bartington Instruments for advice.

3. Introduction

The CU1 Control Unit constitute an interface unit between a Helmholtz Coil System and a

National Instruments-based control system. Signal corresponding to field generation are sent

to the PA1, whilst current monitor signals are return to the CU1. It also provides signal filtering

and power supply to one or two magnetometers connected to the Auxiliary and/or Device Under

Test inputs. Compatible NI cards can be directly connected to the back of the CU1 for ease of

interface.

The full Helmholtz Coil System consists of:

• HC1, HC2, HC9 or HC16 Helmholtz Coils: an assembly of up to three Helmholtz coils. See

related operation manuals. Ferronato Helmholtz Coils can also be operated through this

system.

• PA1 Power Amplifier. See OM3225.

• CU1 Control Unit: the control unit for the system which enables it to interface with a PC-

based test, measurement and control system.

• Optional CU2 Closed-Loop Module: allows active cancellation of external DC and AC

magnetic field disturbances using the CU2 Reference Magnetometer. See OM3999.

A diagram showing the connection of these separate items into one system is given in Appendix

A.

The CU1 can connect directly to a National Instruments acquisition card or PXI system to provide

a PC-based control system for the Helmholtz Coil System. A LabVIEW™-based Helmholtz Coil

Control Software is available from our website, and is designed to operate when the system is

running from a NI card, with the CU1 and PA1.

BARTINGTON INSTRUMENTS

Page 5 of 21 OM3224/4

4. CU1 Features

4.1. Front Panel

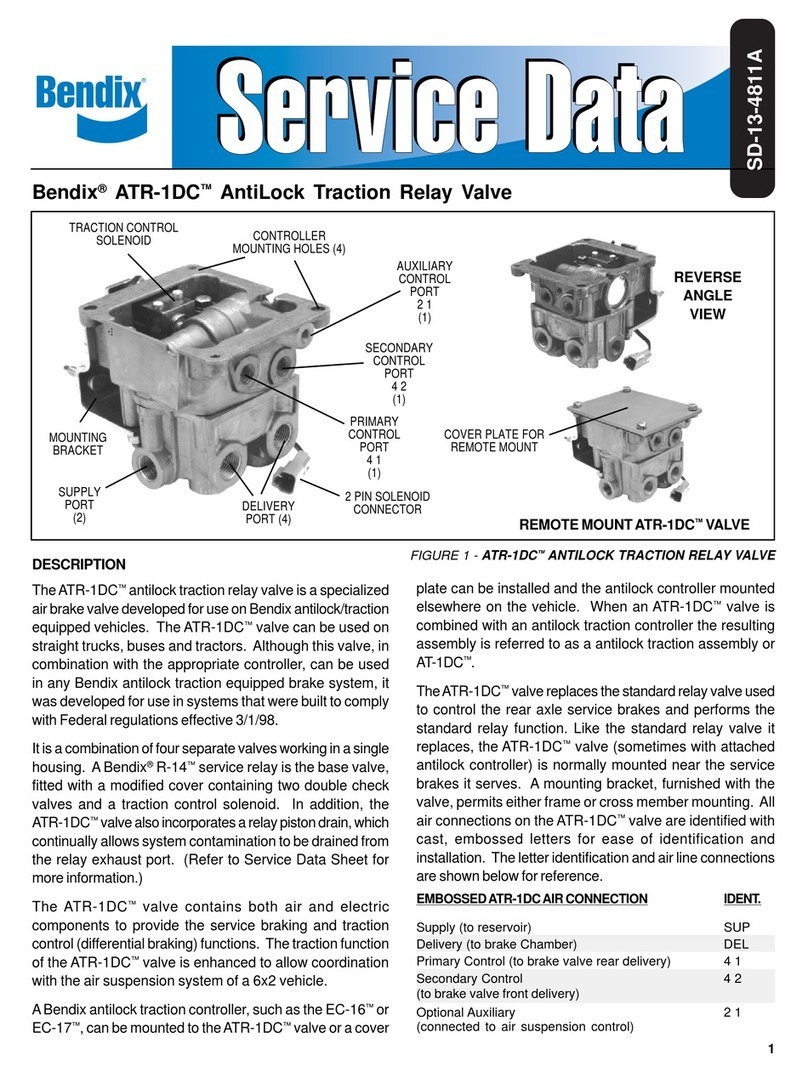

Figure 1. Front view of CU1 Control Unit.

Key

1. Current Control Output 4. Current Monitor Input

2. Auxiliary Input 5. ON/OFF power switch with LED indicator

3. Device Test Input

4.1.1. ON/OFF Power Switch with LED Indicator

The ON/OFF power switch [5] controls AC mains power to the CU1 Control Unit.

The LED indicator has two colour states (red or green) and is controlled by the user software.

4.1.2. Front Panel Connectors

Inputs

Auxiliary Input [2]: this is a single ended or differential input, which can be that of a three-axis

magnetic field sensor.

Device Test Input [3]: this is a single ended or differential input for a three-axis magnetic field

sensor to be tested. This sensor is also termed the Device Under Test (DUT).

Current Monitor Input [4]: this is a differential input for monitoring the current in the Helmholtz

Coil. This should be connected to the Current Monitor Output of the PA1 Power Amplifier.

Auxiliary and DUT inputs are provided with a switchable, analogue, anti-aliasing filter which can

be enabled via a National Instruments acquisition card connected to the CU1.

Details of the pin-outs are available in DR3320.

Outputs

Current Control Output [1]: this provides three differential analogue outputs to the PA1 Power

Amplifier which control the power to be applied to the Helmholtz Coil in order to generate and

regulate the required DC or AC magnetic field.

Details of the pin-outs are available on DR3320.

1 2 3 4 5

BARTINGTON INSTRUMENTS

Page 6 of 21 OM3224/4

4.2. Rear Panel

Figure 2. Rear view of CU1 Control Unit

Key

6. Mains input IEC socket 8. Connector 1

7. Earth terminal post 9. Connector 0

4.2.1. Rear Panel Connectors

Mains Input IEC Socket [6]: this is for connection of an IEC lead. See datasheet DS2613 for

supply voltage.

Earth terminal post [7]: if an appropriate earth/ground connection is not provided through the

mains supply lead, connect this terminal post to the National Instruments system chassis earth

terminal, the instrument rack earth, or a permanent earth ground.

Connector 0 [8]: this is a National Instruments system interface socket for connection to the

National Instruments system DAQ module.

Connector 1 [9]: as Connector 0.

5. Compatibility

The CU1 Control Unit is compatible with Bartington Instruments PA1 for use in Bartington

Helmholtz Coil System. The CU1 is also compatible for use with the CU2 Closed-Loop Module.

A range of National Instruments card can directly connect to the CU1. A non-exhaustive list of

compatible card is included here:

• NI-PXI-6289 Card + compatible Chassis and Controller and connection cables

• NI-PCIe-6353 + connection cables

• NI-USB-6363 + connection cables

6789

BARTINGTON INSTRUMENTS

Page 7 of 21 OM3224/4

6. CU1 Control Unit Installation

6.1. Test Assembly Location and Ventilation Requirements

The CU1 has no forced ventilation requirements and can be sited typically on top of the PA1. The

CU1 and PA1 should be located at least 3m from the Helmholtz Coils to avoid interferences.

Note: For optimum results, the ambient temperature should not exceed the maximum

specified in the data sheet.

6.2. CU1 Control Unit Connection to the PA1 Power Amplifier

6.2.1. Current Control Output

Connect the CU1 Current Control Output [1] to the PA1 Current Control Input using the cable

provided. Labels on the cable identify each end of the cable.

6.2.2. Current Monitor Input

Connect the Current Monitor Input [4] to the PA1 Current Monitor Output using the cable

provided. Labels on the cable identify each end of the cable.

The Current Monitor signal is sent to the National Instruments card for digitisation and is

available in the Helmholtz Coil Control Software.

6.3. Sensor Connection to CU1 Control Unit Device Under Test Input

Both single-ended and differential output sensors can be connected to the Device Under Test

input. The supply voltage to the sensor can be set by the user. Both the selection of the sensor

output type and the supply voltage can be set through the software and is controlled via one of

the digital I/O line on the National Instruments card.

The Device Under Test output is sent to the National Instruments card for digitisation and is

available in the Helmholtz Coil Control Software.

Refer to the datasheet DS2613 for details of the supply voltage limits, and the analogue input

range.

Ensure to not apply a supply voltage exceeding the connected sensor’s rating.

An extension cable to connect to the sensor’s cable to the CU1 Device Under Test port is supplied

with the CU1. This is to be used in case the sensor cable is not long enough.

Note: Bartington Instruments can supply suitable cables for all Bartington Instruments

compatible magnetic field sensors.

BARTINGTON INSTRUMENTS

Page 8 of 21 OM3224/4

6.4. Sensor Connection to CU1 Control Unit Auxiliary Input

Both single-ended and differential output sensors can be connected to the Auxiliary input. The

selection of the sensor output type is set through the software and is controlled via one of the

digital I/O line on the National Instruments card. The supply voltage to the sensor is set to ±15V

and cannot be changed by the user.

The Auxiliary output signal is sent to the National Instruments card for digitisation and is

available in the Helmholtz Coil Control Software.

Refer to the datasheet DS2613 for details of the supply voltage limits, and the analogue input

range.

Ensure to not apply a supply voltage exceeding the connected sensor’s rating.

Self-resetting semiconductor fuses limit the current to each Auxiliary power rail output,

protecting the connected sensor. The fuses can be reset by switching off the unit and allowing it

to cool for a few minutes.

Note: Bartington Instruments can supply suitable cables for all Bartington Instruments

compatible magnetic field sensors.

6.5. CU1 Control Unit Connection to NI Acquisition Card

The CU1 Control Unit can be connected to a National Instruments interface cards using two

shielded cables manufactured by National Instruments (SHC68-68-EPM cables). Details of the

pin-out of the CU1 to the acquisition card can be found in Appendix B.

The CU1 will emit a beep when connection to a National Instruments acquisition card and PC is

not detected. The beep will also sound at powering up until the Helmholtz Coil Control Software

is started.

6.6. CU1 Control Unit Mains Power Supply

Details of suitable power supply for the CU1 Control Unit are provided in the product brochure,

with the supply beeing earthed/grounded. The supply from a standard wall outlet should be

suitable in most countries. A compatible mains cable supplied with a UK 13A plug, an EU plug or

bare ends can be specified at the time of ordering. In the latter case, refer to Appendix C.

A slow blow fuse is fitted internally, to limit the mains supply current to the power supply

modules.

Caution: If the power supply fuse has blown, this indicates a faulty unit. Please contact

Bartington Instruments on +44 1993 776813.

BARTINGTON INSTRUMENTS

Page 9 of 21 OM3224/4

7. Powering Sequence

Before powering the system, you should ensure that all the connections between the Helmholtz

Coil and the PA1, the PA1 and the CU1 and/or CU2 as well as the CU1 to a suitable National

Instruments acquisition card (or PXI-system) are done.

Once all connections are done, the following sequence should be used:

• Power the PC and National Instruments acquisition card or PXI system

• If using a CU2, ensure that the CU2 Reference Magnetometer is connected to the CU2 Module

• Power the CU1

• Power the PA1

To power down the system, the reverse sequence should be followed.

Please note that the equipment should be left to warm up for at least 12 hours before any of the

calibration is undertaken.

8. Troubleshooting, Care and Maintenance

In the event of any apparent malfunction, please email service@bartington.com, or telephone

the Bartington Instruments service team on +44 (0)1993 706565.

Note: Fault finding by customers may invalidate the warranty.

9. Storage and Transport

The CU1 Control Unit should be handled with care.

Bartington Instruments has supplied this product in appropriate packaging for transporting it

safely. This packaging should be used for any future transport.

Refer to datasheet DS2613 for this product’s maximum environmental, electrical and mechanical

ratings.

Caution: Exceeding the maximum environmental ratings may cause irreparable damage to

the equipment.

BARTINGTON INSTRUMENTS

Page 10 of 21 OM3224/4

10. Disposal

This product should not be disposed of in domestic or municipal waste. For information about

disposing of this product safely, check local regulations for disposal of electrical / electronic

products.

10.1. Waste Electrical and Electronic Equipment (WEEE) Regulations

This product complies fully with Restriction of the Use of Certain Hazardous Substances in

Electrical and Electronic Equipment (RoHS) and WEEE Regulations current at the time of

writing.

BARTINGTON INSTRUMENTS

Page 11 of 21 OM3224/4

Appendix A: Connecting the Components of the Helmholtz Coil System

PXI CHASSIS

CU1

PA1

DAQ DAQ

Connector 0 Connector 1

Current

Control

Output

Aux

Input

Current

Monitor

Input

Device

Test

Input

Current

Control

Input

Current

Monitor

Output

DUT

Sensor

Optional

aux sensor

if required

HC1

Current

Output to

HC1/HC2

BARTINGTON INSTRUMENTS

Page 12 of 21 OM3224/4

Appendix B: Helmholtz Control Unit CU1 DAQ/PXI Connection

Analogue Outputs

Signal

PXI function Pin (Cn1)

Auxiliary X output AI.16 68

Auxiliary Y output AI.17 33

Auxiliary Z output AI.18 65

Device Under Test X output AI.19 30

Device Under Test Y output AI.20 28

Device Under Test Z output AI.21 60

No Connection AI.22 25

No Connection AI.23 57

No Connection AI.24 34

No Connection AI.25 66

No Connection AI.26 31

No Connection AI.27 63

Current Monitor X output AI.28 61

Current Monitor Y output AI.29 26

Current Monitor Z output AI.30 58

Power Supply Monitor AI.31 23

Analogue Output Reference AI.Gnd 64

Analogue Inputs

Signal

PXI function Pin (Cn1)

Y Channel Drive Signal AO.2 Cn1.22

X Channel Drive Signal AO.3 Cn1.21

Z Channel Drive Signal AO.1 Cn0.21

Power Supply Control Signal AO.0 Cn0.22

Digital Control Inputs

Signal

PXI function Pin (Cn1)

AUX self-Test Enable P0.8 52

Device Under Test Self-Test Enable P0.9 17

Device Under Test Input Gain P0.10 49

Reserved P0.11 47

Reserved P0.12 19

LED colour P0.13 51

Reserved P0.14 16

Alarm Buzzer P0.15 48

PSU Monitor Select 0 P0.16 11

PSU Monitor Select 1 P0.17 10

BARTINGTON INSTRUMENTS

Page 13 of 21 OM3224/4

PSU Monitor Select 2 P0.18 43

No Connection P0.19 42

No Connection P0.20 41

PSU Monitor Enable P0.21 6

No Connection P0.22 5

No Connection P0.23 38

Auxiliary Input select P0.24 37

Device Under Test Input Select P0.25 3

Device Under Test Input Polarity P0.26 45

Reserved P0.27 46

Reserved P0.28 2

Filter Enable P0.29 40

Filter Select 0 P0.30 1

Filter select 1 P0.31 39

Input Select

Signal PXI function Pin

Device Under Test Input Select P0.25 3

Auxiliary Input select P0.24 37

0 Single ended / unbalanced input mode

1 Differential / balanced input mode

Device Self-Test

Signal PXI function Pin

AUX Self-Test Enable P0.8 52

Device Under Test Self-Test Enable P0.9 17

0 Device in self-test mode

1 Device in normal operating mode

Device Input Polarity

Signal PXI function Pin

Device Under Test Input Polarity P0.26 45

0 Device input normal polarity

1 Device input signal polarity inverted

BARTINGTON INSTRUMENTS

Page 14 of 21 OM3224/4

Device Input gain

Signal PXI function Pin

Device Under Test Input Gain P0.10 49

0 Device Under Test Input Gain = 100

1 Device Under Test Input Gain = 1

Input Filter

Signal PXI function Pin

Filter Enable P0.29 40

Filter Select 0 P0.30 1

Filter select 1 P0.31 39

Select Inputs Nominal frequency at –3dB

point of Selected filter

0 1 EN

0 0 0 10Hz

1 0 0 100Hz

0 1 0 1KHz

1 1 0 10KHz

X X 0 No Filter

Power Supply Monitor

Signal PXI function Pin

PSU Monitor Enable P0.21 6

PSU Monitor Select 0 P0.16 11

PSU Monitor Select 1 P0.17 10

PSU Monitor Select 2 P0.18 43

0 1 2 EN

X X X 0 Output Disabled (voltage uncertain)

0 0 1 1 ¬Device under test negative supply

voltage

1 0 1 1 Device under test negative supply

current

0 1 1 1 ¬Device under test positive supply

Voltage

1 1 1 1 ¬Device under test positive supply

current

X X 0 1 Invalid input (voltage uncertain)

BARTINGTON INSTRUMENTS

Page 15 of 21 OM3224/4

LED

Signal PXI function Pin

LED colour P0.13 51

0 Led colour = Red

1 Led colour = Green

Alarm

Signal PXI function Pin

Alarm Buzzer P0.15 48

0 Alarm active

1 Alarm silent

Notes

Logic inputs are defined as

0 logic Low (0V)

1 logic High (+5V)

X State has no effect

The National Instruments DAQ analogue outputs are single ended with a common reference

connection whilst its analogue inputs should be operated in NRSE (Non-referenced single-ended

mode), refer to the relevant National instruments DAQ User manual for further information.

The power supply to the DUT has a dual rail output with a range which is twice the level of the

control voltage input from the NI DAQ system. The control voltage range of 0 to +/-10V will

correspond to a voltage output of 0 to +/-20V from the power supply.

The X, Y & Z Channel drive signals are balanced outputs with a range twice that of the control

voltage input from the NI DAQ system. The control voltage range of 0 to +/-10V will correspond to

a voltage output on the drive signals of 0 to +/-20V.

The power supply monitor voltage returns half the actual measured voltage.

The power supply currents return the current measured across a 1 Ohm (1%) resistor.

Reserved lines may be used for later enhancements by Bartington Instruments.

All Reserved lines must be held at logic High (+5V).

Lines marked No Connection Should be left disconnected.

BARTINGTON INSTRUMENTS

Page 16 of 21 OM3224/4

CN0 Connections pin-out

Pin Control Unit Signal PXI pin Name In/out Range

1 Reserved P2.6 In 0/5V Digital

2 Reserved P2.4 In 0/5V Digital

3 Reserved P2.1 In 0/5V Digital

4 Digital Ground D.Gnd Ground 0V Nominal

5 Reserved P1.6 In 0/5V Digital

6 Reserved P1.5 In 0/5V Digital

7 Digital Ground D.Gnd Ground 0V Nominal

8 No Connection +5V

9 Digital Ground D.Gnd Ground 0V Nominal

10 Reserved P1.1 In 0/5V Digital

11 Reserved P1.0 In 0/5V Digital

12 Digital Ground D.Gnd Ground 0V Nominal

13 Digital Ground D.Gnd Ground 0V Nominal

14 No Connection +5V

15 Digital Ground D.Gnd Ground 0V Nominal

16 Reserved P0.6 In 0/5V Digital

17 Reserved P0.1 In 0/5V Digital

18 Digital Ground D.Gnd Ground 0V Nominal

19 Reserved P0.4 In 0/5V Digital

20 Reserved APFI 0 In 0/5V Digital

21 Z Axis Drive AO.1 In ±10V analogue

22 Power Supply Drive AO.0 In ±10V analogue

23 No Connection AI.15 Out ±10V analogue

24 analogue Output Ground AI.Gnd Ground 0V Nominal

25 No Connection AI.6 Out ±10V analogue

26 No Connection AI.13 Out ±10V analogue

27 analogue Output Ground AI.Gnd Ground 0V Nominal

28 No Connection AI.4 Out ±10V analogue

29 analogue Output Ground AI.Gnd Ground 0V Nominal

30 No Connection AI.3 Out ±10V analogue

31 No Connection AI.10 Out ±10V analogue

32 analogue Output Ground AI.Gnd Ground 0V Nominal

33 No Connection AI.1 Out ±10V analogue

34 No Connection AI.8 Out ±10V analogue

35 Digital Ground D.Gnd Ground 0V Nominal

36 Digital Ground D.Gnd Ground 0V Nominal

37 Reserved P2.0 In 0/5V Digital

38 Reserved P1.7 In 0/5V Digital

39 Reserved P2.7 In 0/5V Digital

40 Reserved P2.5 In 0/5V Digital

BARTINGTON INSTRUMENTS

Page 17 of 21 OM3224/4

41 Reserved P1.4 In 0/5V Digital

42 Reserved P1.3 In 0/5V Digital

43 Reserved P1.2 In 0/5V Digital

44 Digital Ground D.Gnd Ground 0V Nominal

45 Reserved P2.2 In 0/5V Digital

46 Reserved P2.3 In 0/5V Digital

47 Reserved P0.3 In 0/5V Digital

48 Reserved P0.7 In 0/5V Digital

49 Reserved P0.2 In 0/5V Digital

50 Digital Ground D.Gnd Ground 0V Nominal

51 Reserved P0.5 In 0/5V Digital

52 Reserved P0.0 In 0/5V Digital

53 Digital Ground D.Gnd Ground 0V Nominal

54 analogue Input Ground AO.Gnd Ground 0V Nominal

55 analogue Input Ground AO.Gnd Ground 0V Nominal

56 analogue Output Ground AI.Gnd Ground 0V Nominal

57 No Connection AI.7 Out ±10V analogue

58 No Connection AI.14 Out ±10V analogue

59 analogue Output Ground AI.Gnd Ground 0V Nominal

60 No Connection AI.5 Out ±10V analogue

61 No Connection AI.12 Out ±10V analogue

62 No Connection AI. Sense Ground 0V Nominal

63 No Connection AI.11 Out ±10V analogue

64 analogue Output Ground AI.Gnd Ground 0V Nominal

65 No Connection AI.2 Out ±10V analogue

66 No Connection AI.9 Out ±10V analogue

67 analogue Output Ground AI.Gnd Ground 0V Nominal

68 No Connection AI.0 Out ±10V analogue

CN1 Connections pin-out

Pin Control Unit Signal PXI pin Name In/out Range

1 Filter select 0 P0.30 In 0/5V Digital

2 Reserved P0.28 In 0/5V Digital

3 Device Under Test Input

Select

P0.25 In 0/5V Digital

4 Digital Ground D.Gnd Ground 0V Nominal

5 No Connection P0.22 In 0/5V Digital

6 PSU Monitor Enable P0.21 In 0/5V Digital

7 Digital Ground D.Gnd Ground 0V Nominal

8 No Connection +5V

9 Digital Ground D.Gnd Ground 0V Nominal

BARTINGTON INSTRUMENTS

Page 18 of 21 OM3224/4

10 PSU Monitor Select 1 P0.17 In 0/5V Digital

11 PSU Monitor Select 0 P0.16 In 0/5V Digital

12 Digital Ground D.Gnd Ground 0V Nominal

13 Digital Ground D.Gnd Ground 0V Nominal

14 No Connection +5V

15 Digital Ground D.Gnd Ground 0V Nominal

16 Reserved P0.14 In 0/5V Digital

17 Device Under Test Self-Test P0.9 In 0/5V Digital

18 Digital Ground D.Gnd Ground 0V Nominal

19 No Connection P0.12 In 0/5V Digital

20 No Connection AFPI 1 In 0/5V Digital

21 Y Channel Drive Signal AO.3 In ±10V analogue

22 X Channel Drive Signal AO.2 In ±10V analogue

23 PSU Monitor Out AI.31 Out ±10V analogue

24 Analogue Output Ground AI.Gnd Ground 0V Nominal

25 No Connection AI.22 Out ±10V analogue

26 Current Monitor Y output AI.29 Out ±10V analogue

27 Analogue Output Ground AI.Gnd Ground 0V Nominal

28 Device Under Test, Y output AI.20 Out ±10V analogue

29 Analogue Output Ground AI.Gnd Ground 0V Nominal

30 Device Under Test X output AI.19 Out ±10V analogue

31 No Connection AI.26 Out ±10V analogue

32 Analogue Output Ground AI.Gnd Ground 0V Nominal

33 Auxiliary Y output AI.17 Out ±10V analogue

34 No Connection AI.24 Out ±10V analogue

35 Digital Ground D.Gnd Ground 0V Nominal

36 Digital Ground D.Gnd Ground ±10V analogue

37 Auxiliary Input select P0.24 In 0/5V Digital

38 No Connection P0.23 In 0/5V Digital

39 Filter Select 1 P0.31 In 0/5V Digital

40 Filter enable P0.29 In 0/5V Digital

41 No Connection P0.20 In 0/5V Digital

42 No Connection P0.19 In 0/5V Digital

43 PSU Monitor Select 2 P0.18 In 0/5V Digital

44 Digital Ground D.Gnd Ground 0V Nominal

45 Device Under Test Input

Polarity

P0.26 In 0/5V Digital

46 Reserved P0.27 In 0/5V Digital

47 Reserved P0.11 In 0/5V Digital

48 Alarm Buzzer P0.15 In 0/5V Digital

49 Device Under Test Input Gain P0.10 In 0/5V Digital

50 Digital Ground D.Gnd

BARTINGTON INSTRUMENTS

Page 19 of 21 OM3224/4

51 LED P0.13 In 0/5V Digital

52 AUX Test Enable P0.8 In 0/5V Digital

53 Digital Ground D.Gnd Ground 0V Nominal

54 Analogue Input Ground AO.Gnd Ground 0V Nominal

55 Analogue Input Ground AO.Gnd Ground 0V Nominal

56 Analogue Output Ground AI.Gnd Ground 0V Nominal

57 No Connection AI.23 Out ±10V analogue

58 Current Monitor Z output AI.30 Out ±10V analogue

59 Analogue Output Ground AI.Gnd Ground 0V Nominal

60 Device Under Test Z output AI.21 Out ±10V analogue

61 Current Monitor X output AI.28 Out ±10V analogue

62 Analogue Output Reference AI. Sense 2 Ground 0V Nominal

63 No Connection AI.27 Out ±10V analogue

64 Analogue Output reference AI.Gnd Ground 0V Nominal

65 Auxiliary Z output AI.18 Out ±10V analogue

66 No Connection AI.25 Out ±10V analogue

67 Analogue Output Ground AI.Gnd Ground 0V Nominal

68 Auxiliary X output AI.16 Out ±10V analogue

BARTINGTON INSTRUMENTS

Page 20 of 21 OM3224/4

Appendix C: Guidance for Connection to Mains Supply

1. Ensure that the mains feed is from a clean AC supply with the following characteristics:-

Voltage Range 100V to 240V AC

Frequency 50/60Hz

It is highly recommended that this mains feed is via an appropriate Residual Current Circuit

Breaker, rated at 30mA trip current. This must comply with local regulations.

2. The mains input connectors are as follows:-

Device Input Connector Mating Cable Connector

Power Amplifier PA1 IEC C20 IEC C19

Control Unit CU1 IEC C14 IEC C13

These cables are available in specific versions for most countries.

3. If an un-terminated IEC connector lead is supplied with the equipment, the wires must be

wired accordingly:-

BROWN LIVE

BLUE NEUTRAL

GREEN/YELLOW EARTH

4. It is essential that the control unit CU1 and the Power Amplifier PA1 are properly earthed at all

times.

5. It is recommended that the mains to each unit is supplied via an appropriate mains fuse:-

Power Amplifier PA1 13A

Control Unit CU1 13A

This is appropriate for the use over the whole supply voltage range.

6. This installation MUST be carried out by a trained, competent person.

7. Before initial switch-on, an appropriate earth bonding test should be performed to ensure a

robust earth connection.

8. To disconnect mains power, the mains supply cord must be removed from the rear panel

mains input connector.

Table of contents