2

Table of Contents

Section 1 – System overview ............................................................................................................................... 3

1.1 – Major Components..................................................................................................................................... 3

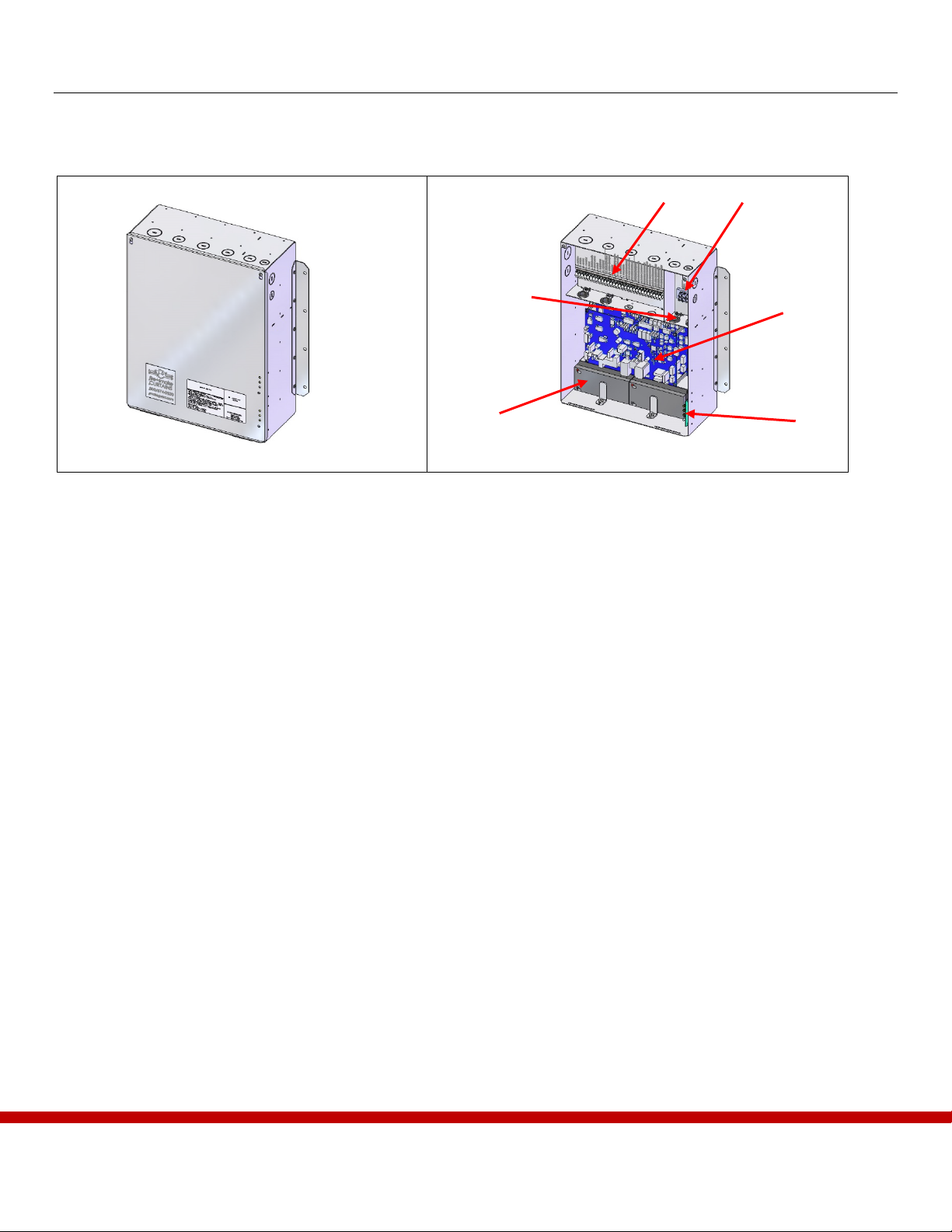

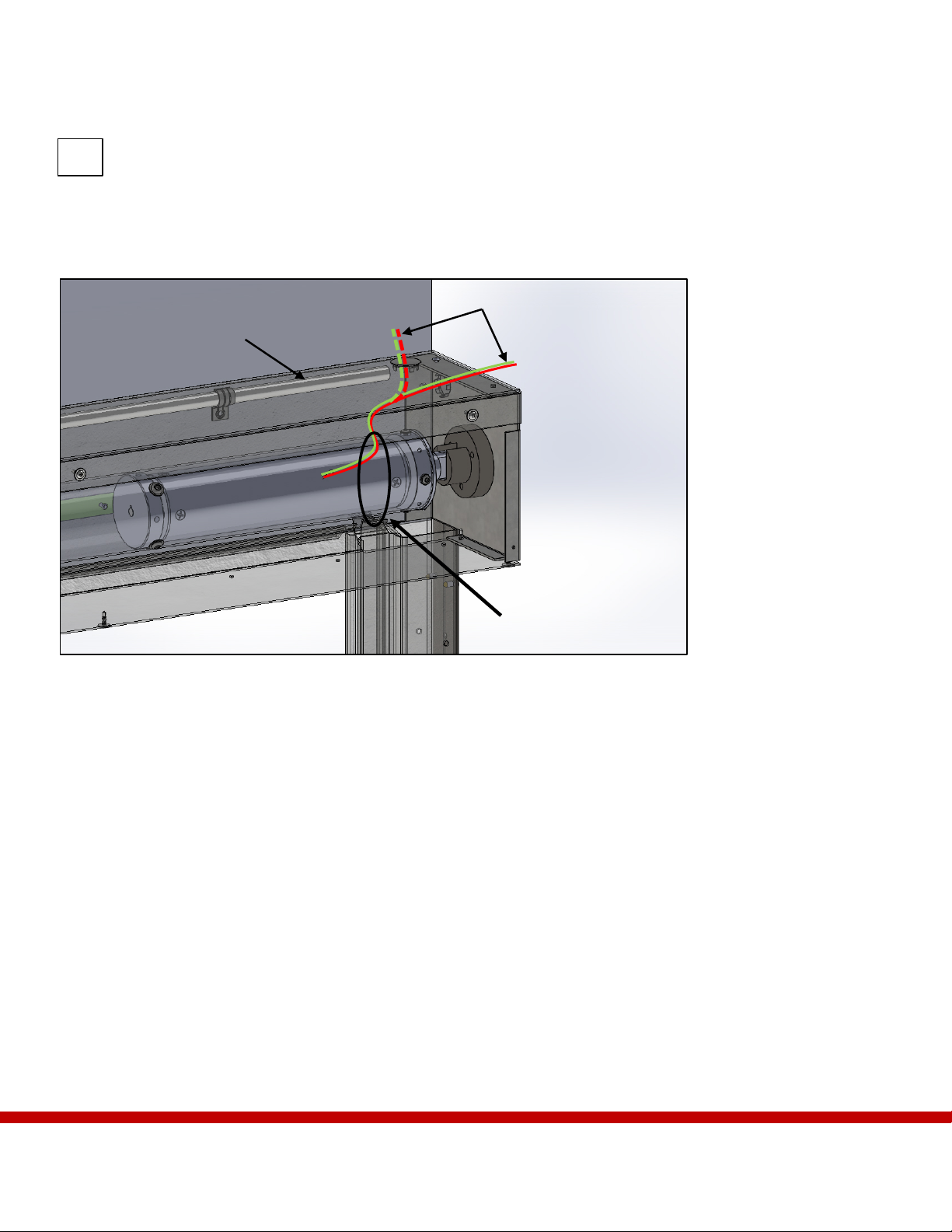

Section 2 – Main Controller and Conduit Routing.............................................................................................. 4

2.1 – Optional Wireless Jogger ........................................................................................................................... 5

2.2 – Checklist..................................................................................................................................................... 5

Section 3 – Main Controller Installation.............................................................................................................. 6

Section 4 – Housing Installation .......................................................................................................................... 7

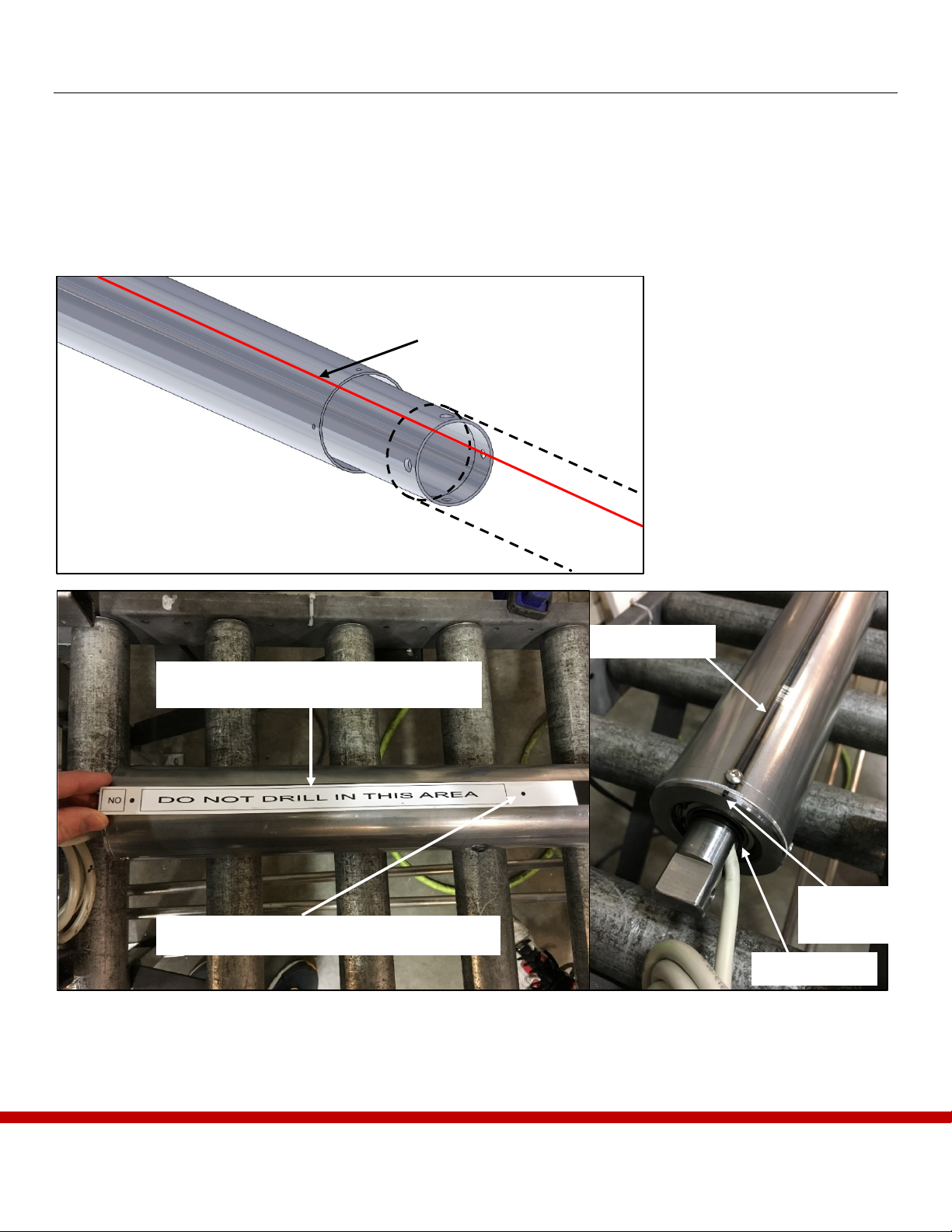

Section 5 – Preparing the Tubing ........................................................................................................................ 9

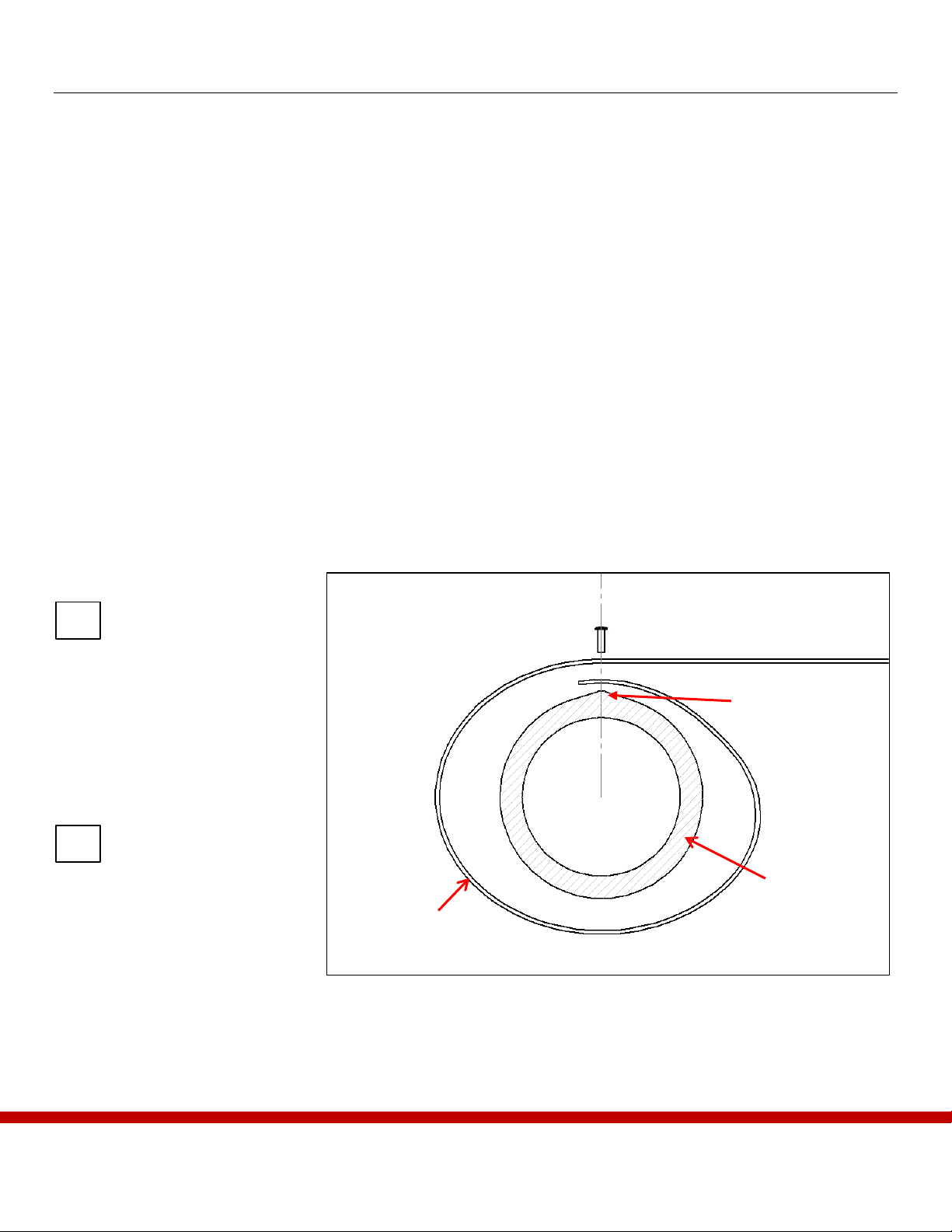

Section 6 – Curtain Attachment ........................................................................................................................10

Section 7 – Install the Curtain............................................................................................................................11

Section 8 – Attach the Bottom Bar....................................................................................................................12

8.1 – Attach the Roller Bracket ......................................................................................................................... 15

Section 9 – Attach the Side Guides ...................................................................................................................16

9.1 – Attach Up-Limit Stops ............................................................................................................................. 17

Section 10 – Cover Attachment.........................................................................................................................18

10.1 – Front Cover Attachment......................................................................................................................... 18

10.2 – Bottom Cover Attachment ..................................................................................................................... 18

Section 11 – Electrical Connections..................................................................................................................19

11.1 – 120VAC Connections ............................................................................................................................ 19

11.2 – Curtain Wiring........................................................................................................................................ 20

11.3 – Initiating Device Circuit......................................................................................................................... 20

11.4 – Optional Keyed Test Deploy Switch...................................................................................................... 20

11.5 – Optional Door Activation Switches ....................................................................................................... 21

11.6 – Optional SRS/Edge Sensor Curtain Switches ........................................................................................ 21

Section 12 – System Testing..............................................................................................................................22

12.1 – Calibration.............................................................................................................................................. 22

12.2 – System Test ............................................................................................................................................ 22

12.3 – Test Optional Keyed Switch .................................................................................................................. 22

12.4 – Test Optional Door Activation/Screen Rewind Switches...................................................................... 23

12.5 – Batteries.................................................................................................................................................. 23

Section 13 – Troubleshooting ............................................................................................................................24

13.1 – Contact Smoke Guard ............................................................................................................................ 25

Section 14 – Glossary .........................................................................................................................................26