TFP802

Page 5 of 6

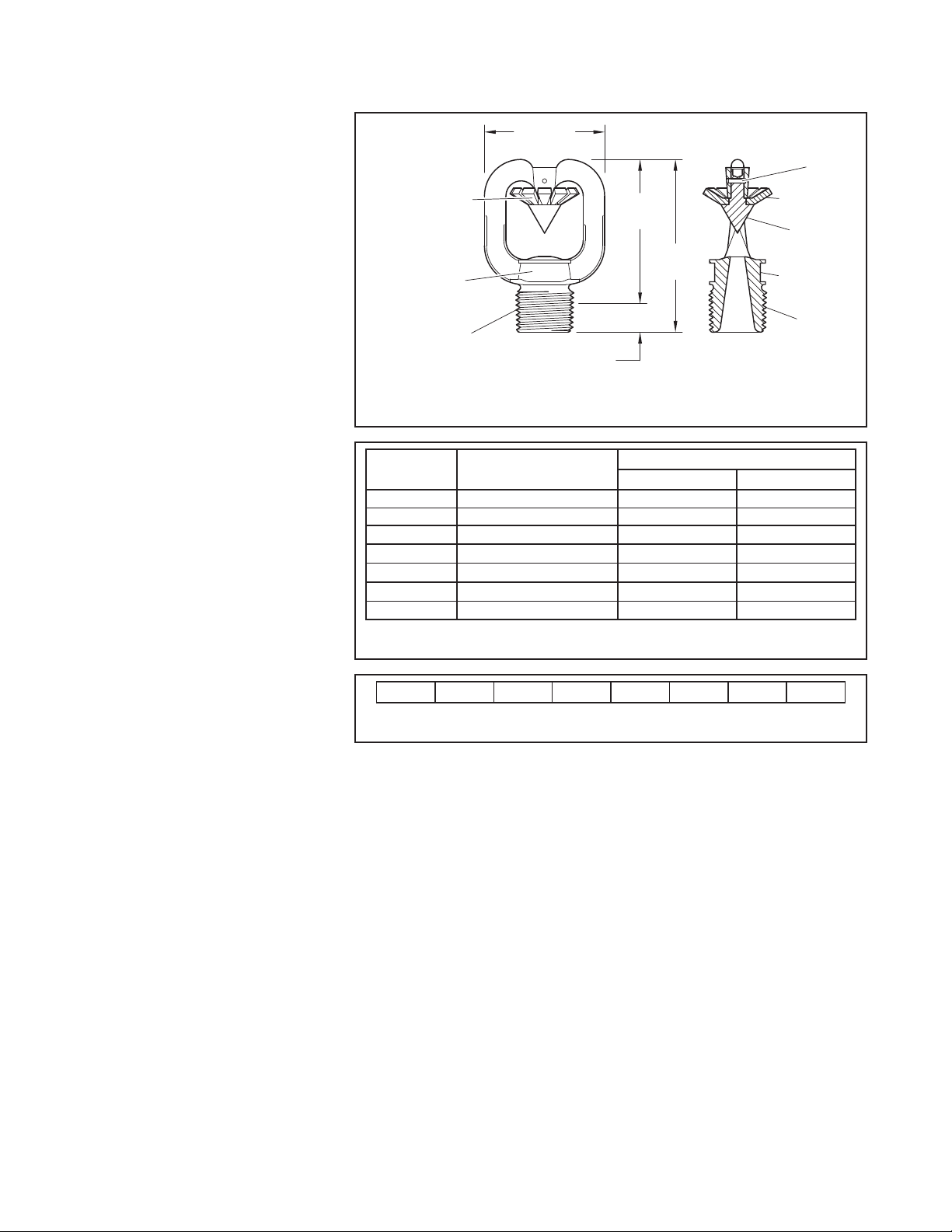

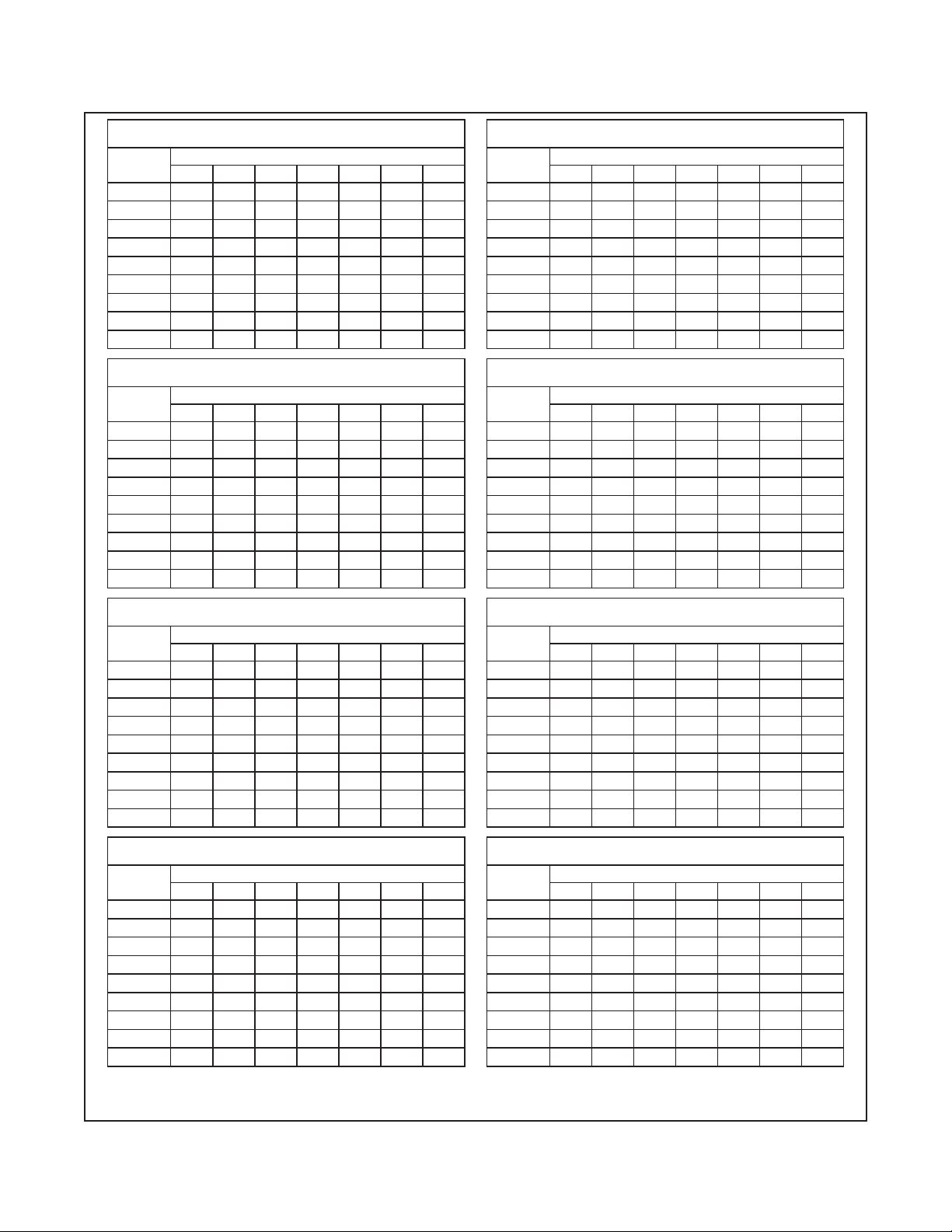

MAXIMUM AXIAL DISTANCE FOR 65° SPRAY ANGLE

IN METERS

FIXED

ANGLE

ORIFICE SIZE

16 18 21 24 28 32 34

0° 3,2 3,8 4,0 4,0 4,4 4,6 4,7

30° 2,5 3,3 3,3 3,6 3,8 4,1 4,2

45° 2,2 3,0 3,0 3,4 3,5 3,8 3,9

60° 2,0 2,8 2,9 3,3 3,4 3,6 3,8

90° 1,8 2,6 2,7 3,1 3,2 3,3 3,5

120° 1,8 2,3 2,3 2,3 2,5 2,7 2,9

135° 1,7 1,8 1,9 2,0 2,1 2,4 2,6

150° 1,6 1,7 1,7 1,9 1,9 2,2 2,3

180° 1,5 1,5 1,5 1,7 1,8 2,0 2,1

MAXIMUM AXIAL DISTANCE FOR 80° SPRAY ANGLE

IN METERS

FIXED

ANGLE

ORIFICE SIZE

16 18 21 24 28 32 34

0° 2,7 3,2 3,4 3,7 4,0 4,3 4,3

30° 2,2 2,5 2,7 3,2 3,5 3,7 3,7

45° 1,9 2,3 2,4 3,1 3,2 3,4 3,4

60° 1,7 2,1 2,3 3,0 3,1 3,3 3,3

90° 1,5 1,8 2,1 2,8 2,9 3,0 3,0

120° 1,4 1,4 1,8 2,0 2,2 2,1 2,4

135° 1,3 1,4 1,5 1,7 1,8 1,9 2,1

150° 1,2 1,2 1,4 1,5 1,7 1,7 1,8

180° 1,1 1,1 1,2 1,4 1,4 1,6 1,7

MAXIMUM AXIAL DISTANCE FOR 95° SPRAY ANGLE

IN METERS

FIXED

ANGLE

ORIFICE SIZE

16 18 21 24 28 32 34

0° 2,1 2,4 2,9 3,2 3,4 3,7 3,8

30° 1,8 2,0 2,4 3,0 3,2 3,3 3,4

45° 1,6 1,9 2,1 2,9 3,0 3 ,1 3,1

60° 1,4 1,8 2,1 2,8 2,9 3,0 3,0

90° 1,2 1,5 2,0 2,5 2,6 2,7 2,7

120° 1,1 1,1 1,5 1,6 1,9 1,8 2,0

135° 1,0 1,1 1,2 1,4 1,6 1,6 1,7

150° 0,9 0,9 1,1 1,2 1,4 1,4 1,4

180° 0,9 0,9 1,1 1,1 1,2 1,3 1,4

MAXIMUM AXIAL DISTANCE FOR 110° SPRAY ANGLE

IN METERS

FIXED

ANGLE

ORIFICE SIZE

16 18 21 24 28 32 34

0° 1,8 2,1 2,7 2,9 3,4 3,4 3,5

30° 1,6 1,9 2,2 2,7 2,9 3,0 3,0

45° 1,4 1,8 2,0 2,6 2,7 2,7 2,8

60° 1,3 1,7 1,9 2,5 2,6 2,6 2,7

90° 1,1 1,4 1,8 2,3 2,3 2,3 2,4

120° 0,8 1,0 1,4 1,4 1,7 1,7 1,7

135° 0,8 0,8 1,1 1,1 1,4 1,4 1,4

150° 0,7 0,8 0,9 1,0 1,1 1,1 1,3

180° 0,7 0,7 0,8 0,9 1,1 1,1 1,1

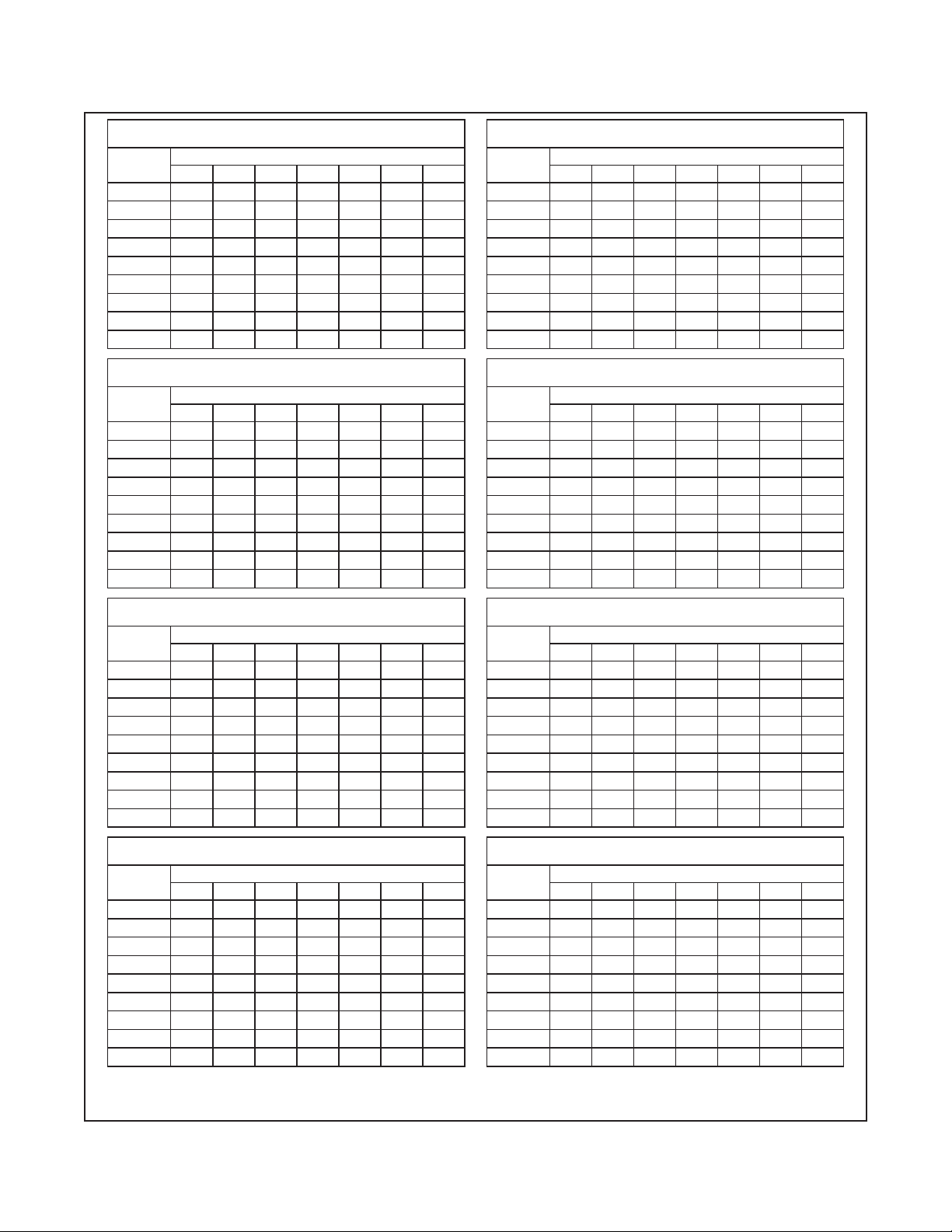

MAXIMUM AXIAL DISTANCE FOR 125° SPRAY ANGLE

IN METERS

FIXED

ANGLE

ORIFICE SIZE

16 18 21 24 28 32 34

0° 1,4 1,5 2,0 2,4 3,0 3 ,1 3,2

30° 1,1 1,1 1,9 2,1 2,6 2,6 2,7

45° 0,9 1,1 1,8 1,8 2,4 2,3 2,5

60° 0,8 0,9 1,7 1,8 2,2 2,2 2,4

90° 0,6 0,8 1,4 1,5 1,8 1,8 2,0

120° 0,5 0,7 1,0 1,0 1,1 1,1 1,4

135° 0,5 0,5 0,8 0,8 1,0 1,0 1,1

150° 0,5 0,5 0,6 0,7 0,8 0,8 1,1

180° 0,4 0,4 0,5 0,6 0,7 0,8 1,0

MAXIMUM AXIAL DISTANCE FOR 140° SPRAY ANGLE

IN METERS

FIXED

ANGLE

ORIFICE SIZE

16 18 21 24 28 32 34

0° 1,2 1,4 1,8 2,0 2,4 2,4 2,4

30° 1,0 1,1 1,7 1,7 1,9 2,1 2,1

45° 0,8 0,8 1,5 1,5 1,7 2,0 2,0

60° 0,7 0,8 1,4 1,4 1,6 1,7 1,8

90° 0,5 0,7 1,2 1,2 1,4 1,4 1,5

120° 0,5 0,5 0,7 0,8 0,8 0,9 1,1

135° 0,4 0,5 0,5 0,5 0,6 0,8 0,8

150° 0,4 0,4 0,5 0,5 0,5 0,7 0,8

180° 0,3 0,3 0,4 0,4 0,5 0,6 0,7

MAXIMUM AXIAL DISTANCE FOR 160° SPRAY ANGLE

IN METERS

FIXED

ANGLE

ORIFICE SIZE

16 18 21 24 28 32 34

0° 1,1 1,1 1,4 1,5 1,8 2,1 2,1

30° 0,8 0,9 1,3 1,4 1,5 1,8 1,9

45° 0,7 0,8 1,1 1,2 1,4 1,6 1,7

60° 0,5 0,7 1,1 1,1 1,1 1,4 1,6

90° 0,4 0,5 0,9 1,0 0,7 1,1 1,3

120° 0,3 0,4 0,5 0,6 0,5 0,7 0,8

135° 0,3 0,3 0,4 0,4 0,5 0,5 0,6

150° 0,2 0,2 0,3 0,3 0,5 0,5 0,5

180° 0,2 0,2 0,2 0,2 0,5 0,5 0,5

MAXIMUM AXIAL DISTANCE FOR 180° SPRAY ANGLE

IN METERS

FIXED

ANGLE

ORIFICE SIZE

16 18 21 24 28 32 34

0° 0,8 0,9 1,1 1,1 1,2 1,8 1,8

30° 0,7 0,7 1,1 1,1 1,1 1,5 1,5

45° 0,5 0,6 1,0 1,0 1,1 1,3 1,3

60° 0,5 0,5 0,8 0,8 1,0 1,1 1,1

90° 0,3 0,5 0,6 0,6 0,8 0,9 0,9

120° 0,2 0,3 0,3 0,3 0,5 0,5 0,5

135° 0,2 0,2 0,2 0,2 0,4 0,4 0,4

150° 0,2 0,2 0,2 0,2 0,3 0,3 0,3

180° 0,2 0,2 0,2 0,2 0,2 0,2 0,2

TABLE D

MAXIMUM AXIAL DISTANCE BETWEEN NOZZLE TIP AND

PLANE-OF-PROTECTION FOR EXPOSURE PROTECTION — METERS